Based on discussions in various threads on multiple audio forums, the lifetime in wear hours of a phonograph stylus remains an open and frequently intensely debated question. Manufacturer’s claims for example range from a few hundred hours for conical styli, up to 500 hours for elliptical styli, and into the thousands of hours for more advanced shapes. We have even read claims for certain stylus shapes lasting up to 20,000 hours. The problem is that manufacturers don’t provide contemporary research or data to support these longer life claims. To add to consumer confusion, a review of select manufacturer’s owners’ manuals from the early 1980s onward reveal a dramatic change in much longer stated wear hours along with less specificity and greater ambiguity in their statements. That period of wear hour creep so to speak coincided with compact discs (CD) displacing vinyl records, a trend that has only recently reversed, with vinyl in 2022 eclipsing CD sales. In one pertinent yet recent example, Ortofon moved from stating “up to 2,000 hours” in stylus wear to “Ortofon recommends replacing your stylus after no more than 1,000 hours to preserve the life of your records” in the June 2023 issue of Stereophile. This recognition of more believable stylus wear lifetimes is welcomed, but without technical support these claims are assumed to be marketing numbers, even if well intended.

What is needed to support any claim on stylus life is an experimental framework used to gather data across a range of stylus shapes and VTF conditions. Ideally this work would come from the industry, updated to include a full range of stylus shapes, including newer advanced stylus shapes that simulate the cutting head used in making record stampers. Unfortunately this work is not available to consumers and that fact has created significant confusion. Determining how long a diamond stylus lasts regardless of its shape is like asking how long is a piece of string with multiple answers offered for the same stylus shape.

A first attempt to address this question was made by Steve Hoffman Forum member @Ray Parkhurst (Note, aka Vinyl Engine [VE] member @ray_parkhurst and ASR member @ray_parkhurst) in his Stylus Wear Study recorded on the Vinyl Engine website (Stylus Wear Study (1)). Unfortunately, his results were not widely accepted due to the nature of test conditions. That experiment used a linear-tracking turntable, a low VTF cartridge, and repeated play of a single side of a vinyl record for the duration of the test, 1,000 hours. This procedure was deemed too different from normal use by a majority of observers.

A proposed more mainstream set of conditions would be as follows:

- Standard but good quality turntable with dust cover

- Alignment and anti-skating per manufacturer

- Standard mount cartridge

- Elliptical stylus

- Typical / moderate VTF

- Play multiple LPs in VG+ or better used condition

- Records cleaned with widely accepted methods

- Stylus cleaned and alignment checked periodically

- Typical household environmental conditions, monitored for temperature and humidity.

The cartridge will be secured very tightly to the headshell to prevent any movement. Additionally, one of the unique features of Audio-Technica MM cartridges is that their styli are inserted upward into the belly of the cartridge and lock securely in place with an audible "click." This eliminates any possibility of forward/backward or side-to-side movement of the stylus. To be absolutely sure, @BMRR will check the alignment at each read point to verify nothing has changed.

To make the test practical, each record side will be played for ~12hrs with the TT on automatic repeat. The room and TT will be monitored for temperature and humidity, including under the dust cover. Then the record will be flipped, the stylus cleaned, and the other side played for ~12hrs. This routine will be repeated with a fresh record each day until the conclusion of the test. The stylus will be removed at pre-determined playing time intervals and sent to @ray_parkhurst for photomacrographic imaging. This analytical process will be conducted at 0hrs (i.e., the new stylus), 48hrs, 96hrs, 240hrs, 360hrs, and 480hrs, with timing adjusted based on observations. A further test point after 480hrs would be added if necessary. In my opinion, Ray is an expert in styli imaging and through considerable experience has learned how to evaluate stylus wear, as seen in this Vinyl Engine entitled Stylus Evaluation Imaging.

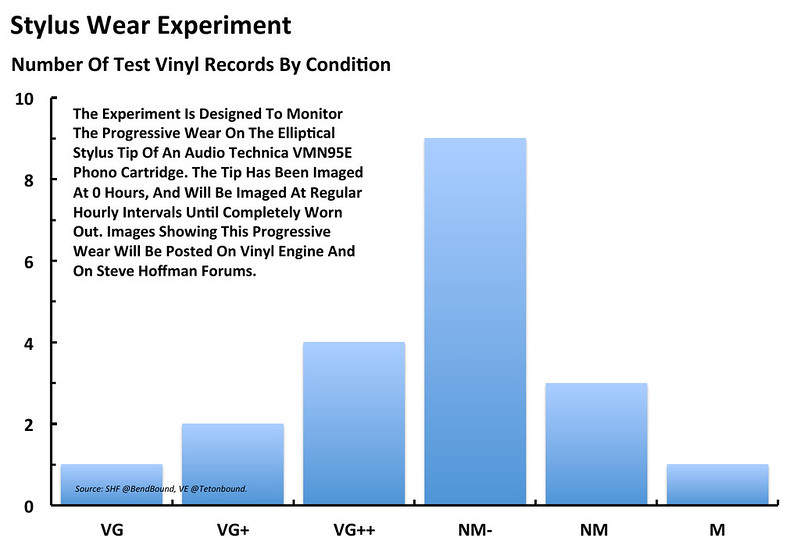

VE member @Tetonbound (SHF and ASR @BendBound) will supply records for this experiment. Twenty (20) records at least will be employed in VG++ to NM condition. These records were cleaned in an 80 kHz ultrasonic (US) tank (made by Vibrato) for 20 minutes, rotating on a Vinyl Stack spindle assembly. The set up will include circulating cleaning solution through a Neo•Pure PH-27097-S35 water filter, to 0.35 microns. To ensure good US cleaning, only two records at a time were processed. The solution was a laboratory grade triple distilled water, Ilfotol surfactant (wetting agent) and isopropyl alcohol (~99%) in a process and chemical proportions adapted from Neil Antin (PRECISION AQUEOUS CLEANING OF: VINYL RECORDS, 3rd Edition, January 2022). Then after the US cleaning, all records were vacuumed on a VPI17 using AIVS Formula No.6 record cleaning solution, rinsed using ultra-pure water, and revacuumed until visibly dry. All records were further dried in warm air from a SIMCO Ionizing Aerostat machine to eliminate static charge on the vinyl. All cleaned records were re-sleeved in Diskeeper™ sleeves, made by Sleeve City.

To provide additional data on the sonic impact of record wear, two records will be recorded by @Tetonbound before the experiment using a Tascam DA-3000 pro-level recorder at 96kHz and 24 bit. These recordings will be done on near mint records to establish a baseline of sonic quality of selected records. At the end of the experiment the same two records will be re-recorded at the exact same recording levels to evaluate sonic degradation and high frequency loss, if any. One record will be the first played in the experiment, and the second the last played, so that data will be available for examine record wear from the stylus in both it’s new and worn conditions. We are still working through how to get to vinyl wear and change in sonic qualities from the wearing stylus and we do note experience here as seen in this Audio Science Review "Test" thread.

This experiment is designed to establish an acceptable baseline for stylus wear for one stylus shape at a specific VTF. We envision follow-up experiments to gather data on other stylus types and/or under different VTF conditions. Our goal is to provide guidance on stylus wear supported by a rigorous process with photomacrographic images, and on expected degradation of the sonic qualities of the vinyl, if any.

Since @ray_parkhurst and VE@BMRR live on extreme opposite sides of the U.S., the VMN95E stylus will rack up quite a few frequent flyer miles for this experiment, pushing the expected total elapsed time for this experiment to be ~3 months, but images taken at each read point will be published so the community can follow along with the experiment. A final report is planned once the test and analysis is completed.

If there are any others who would be willing to volunteer to do a similar experiment with a different stylus type, or to contribute financial support to this and follow-on experiments, please reply to this thread or by PM to either @BMRR on VE, on ASR @ray_parkhurst, or @BendBound.

What is needed to support any claim on stylus life is an experimental framework used to gather data across a range of stylus shapes and VTF conditions. Ideally this work would come from the industry, updated to include a full range of stylus shapes, including newer advanced stylus shapes that simulate the cutting head used in making record stampers. Unfortunately this work is not available to consumers and that fact has created significant confusion. Determining how long a diamond stylus lasts regardless of its shape is like asking how long is a piece of string with multiple answers offered for the same stylus shape.

A first attempt to address this question was made by Steve Hoffman Forum member @Ray Parkhurst (Note, aka Vinyl Engine [VE] member @ray_parkhurst and ASR member @ray_parkhurst) in his Stylus Wear Study recorded on the Vinyl Engine website (Stylus Wear Study (1)). Unfortunately, his results were not widely accepted due to the nature of test conditions. That experiment used a linear-tracking turntable, a low VTF cartridge, and repeated play of a single side of a vinyl record for the duration of the test, 1,000 hours. This procedure was deemed too different from normal use by a majority of observers.

A proposed more mainstream set of conditions would be as follows:

- Standard but good quality turntable with dust cover

- Alignment and anti-skating per manufacturer

- Standard mount cartridge

- Elliptical stylus

- Typical / moderate VTF

- Play multiple LPs in VG+ or better used condition

- Records cleaned with widely accepted methods

- Stylus cleaned and alignment checked periodically

- Typical household environmental conditions, monitored for temperature and humidity.

The cartridge will be secured very tightly to the headshell to prevent any movement. Additionally, one of the unique features of Audio-Technica MM cartridges is that their styli are inserted upward into the belly of the cartridge and lock securely in place with an audible "click." This eliminates any possibility of forward/backward or side-to-side movement of the stylus. To be absolutely sure, @BMRR will check the alignment at each read point to verify nothing has changed.

To make the test practical, each record side will be played for ~12hrs with the TT on automatic repeat. The room and TT will be monitored for temperature and humidity, including under the dust cover. Then the record will be flipped, the stylus cleaned, and the other side played for ~12hrs. This routine will be repeated with a fresh record each day until the conclusion of the test. The stylus will be removed at pre-determined playing time intervals and sent to @ray_parkhurst for photomacrographic imaging. This analytical process will be conducted at 0hrs (i.e., the new stylus), 48hrs, 96hrs, 240hrs, 360hrs, and 480hrs, with timing adjusted based on observations. A further test point after 480hrs would be added if necessary. In my opinion, Ray is an expert in styli imaging and through considerable experience has learned how to evaluate stylus wear, as seen in this Vinyl Engine entitled Stylus Evaluation Imaging.

VE member @Tetonbound (SHF and ASR @BendBound) will supply records for this experiment. Twenty (20) records at least will be employed in VG++ to NM condition. These records were cleaned in an 80 kHz ultrasonic (US) tank (made by Vibrato) for 20 minutes, rotating on a Vinyl Stack spindle assembly. The set up will include circulating cleaning solution through a Neo•Pure PH-27097-S35 water filter, to 0.35 microns. To ensure good US cleaning, only two records at a time were processed. The solution was a laboratory grade triple distilled water, Ilfotol surfactant (wetting agent) and isopropyl alcohol (~99%) in a process and chemical proportions adapted from Neil Antin (PRECISION AQUEOUS CLEANING OF: VINYL RECORDS, 3rd Edition, January 2022). Then after the US cleaning, all records were vacuumed on a VPI17 using AIVS Formula No.6 record cleaning solution, rinsed using ultra-pure water, and revacuumed until visibly dry. All records were further dried in warm air from a SIMCO Ionizing Aerostat machine to eliminate static charge on the vinyl. All cleaned records were re-sleeved in Diskeeper™ sleeves, made by Sleeve City.

To provide additional data on the sonic impact of record wear, two records will be recorded by @Tetonbound before the experiment using a Tascam DA-3000 pro-level recorder at 96kHz and 24 bit. These recordings will be done on near mint records to establish a baseline of sonic quality of selected records. At the end of the experiment the same two records will be re-recorded at the exact same recording levels to evaluate sonic degradation and high frequency loss, if any. One record will be the first played in the experiment, and the second the last played, so that data will be available for examine record wear from the stylus in both it’s new and worn conditions. We are still working through how to get to vinyl wear and change in sonic qualities from the wearing stylus and we do note experience here as seen in this Audio Science Review "Test" thread.

This experiment is designed to establish an acceptable baseline for stylus wear for one stylus shape at a specific VTF. We envision follow-up experiments to gather data on other stylus types and/or under different VTF conditions. Our goal is to provide guidance on stylus wear supported by a rigorous process with photomacrographic images, and on expected degradation of the sonic qualities of the vinyl, if any.

Since @ray_parkhurst and VE@BMRR live on extreme opposite sides of the U.S., the VMN95E stylus will rack up quite a few frequent flyer miles for this experiment, pushing the expected total elapsed time for this experiment to be ~3 months, but images taken at each read point will be published so the community can follow along with the experiment. A final report is planned once the test and analysis is completed.

If there are any others who would be willing to volunteer to do a similar experiment with a different stylus type, or to contribute financial support to this and follow-on experiments, please reply to this thread or by PM to either @BMRR on VE, on ASR @ray_parkhurst, or @BendBound.

![[IMG] [IMG]](https://live.staticflickr.com/65535/52889931749_5d6b50ae5d_h.jpg)

![[IMG] [IMG]](https://live.staticflickr.com/65535/52889188127_a34ef3a3f8_k.jpg)