MAB

Major Contributor

The subject of speaker break-in comes up often. It's also called run-in. It's different than aging, or wear-out.

us.kef.com

us.kef.com

Since the subject came up again, I thought it a good time to revisit this topic with some unused drivers I have lying around.

I have two Peerless 831724 10" woofers and two Audax HP210GO 8" woofers, with synthetic cones. I also have four HiVi B3N metal cone micro-woofers.

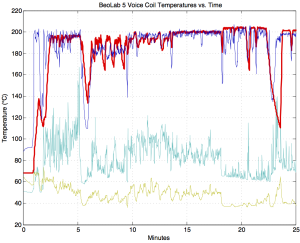

I am presenting the measurements of these drivers before and after break-in. Each set of drivers was broken-in at ambient room conditions for 6 hours, with a signal I thought was sufficient. I don't quantify 'sufficient', except to say I drove them moderately hard with bass for 3 hours, and 3 more hours with pink noise. I specifically kept them well within their power limits, my goal was not to wear them out. I also explore the impact of moderate temperature changes both due to the break-in stress and due to external heating and cooling.

The heating and cooling is primitive. 10 mins in the refrigerator for cooling. I used a space-heater to elevate the temperatures, measurements were made with the heater off since the airflow has significant impact on the results.

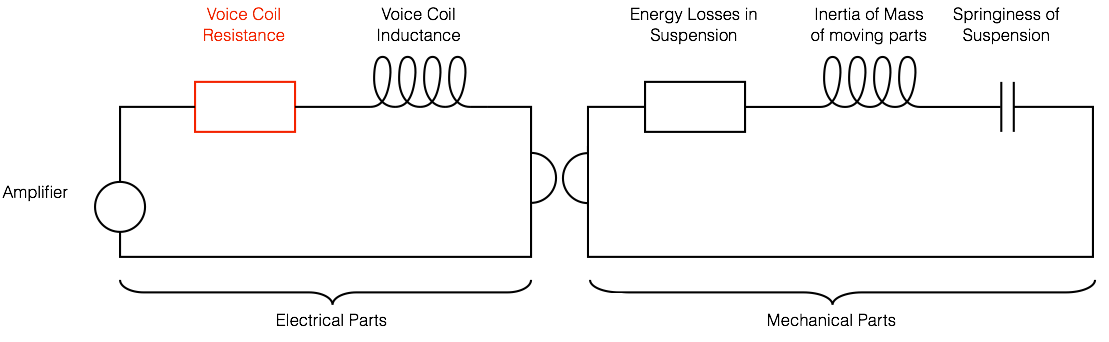

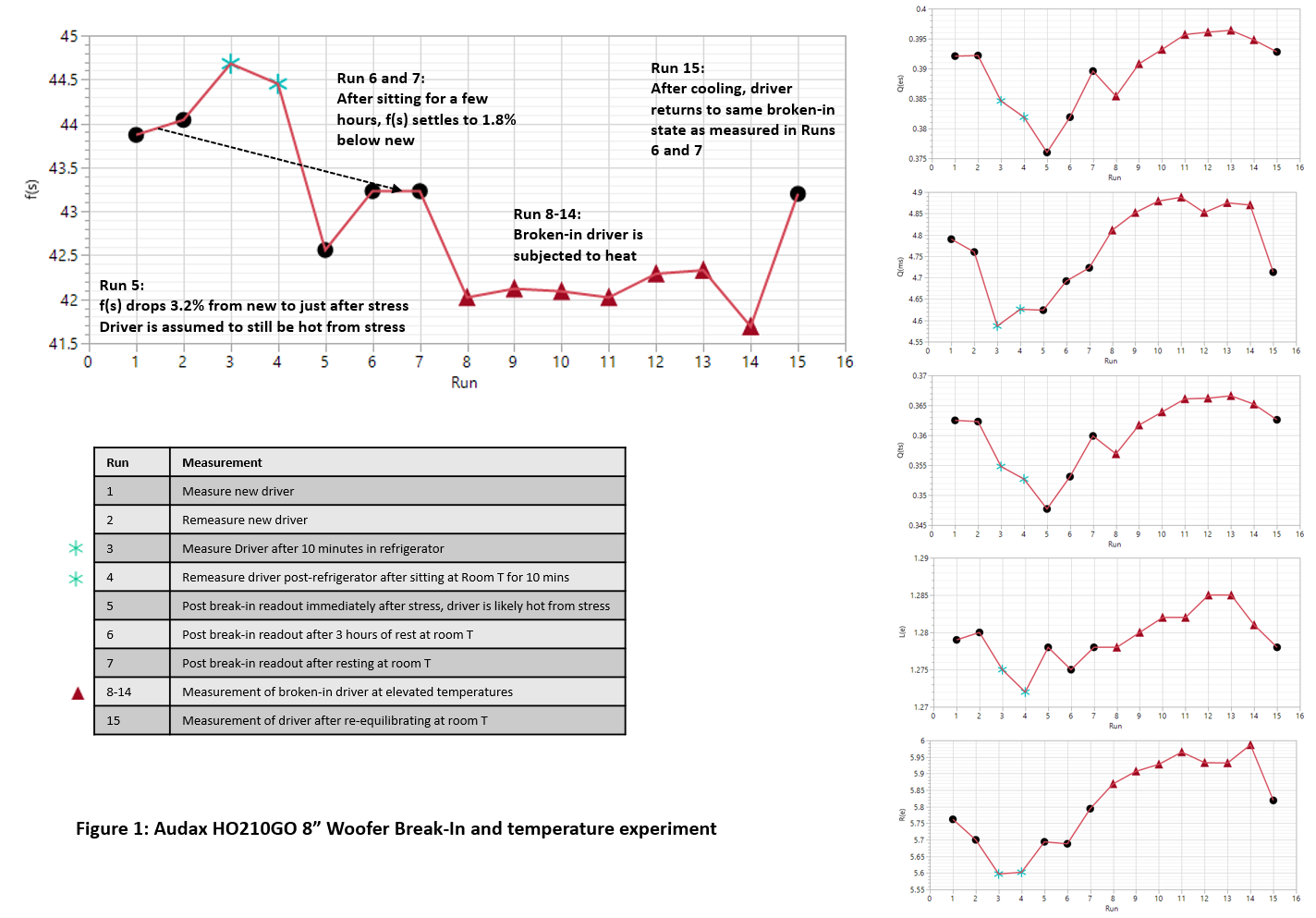

Figure 1 shows the results of a break-in and temperature experiment on an Audax woofer. The raw driver was first measured (runs 1 and 2), then put in a refrigerator for 10 mins, then measured again (Runs 3 and 4). The speaker was then broken-in for 6 hours as described above, and measured immediately after while still hot from stress (Run 5). Then I allowed the driver to cool off to get the post-break-in measurements (Runs 6 and 7). The driver was then subjected to heat from a small space-heater (Runs 8-14). The space heater was moved to attempt to increase the heat, which most notably impacted measurement 14. Finally, after cooling off, the driver was remeasured (Run 15).

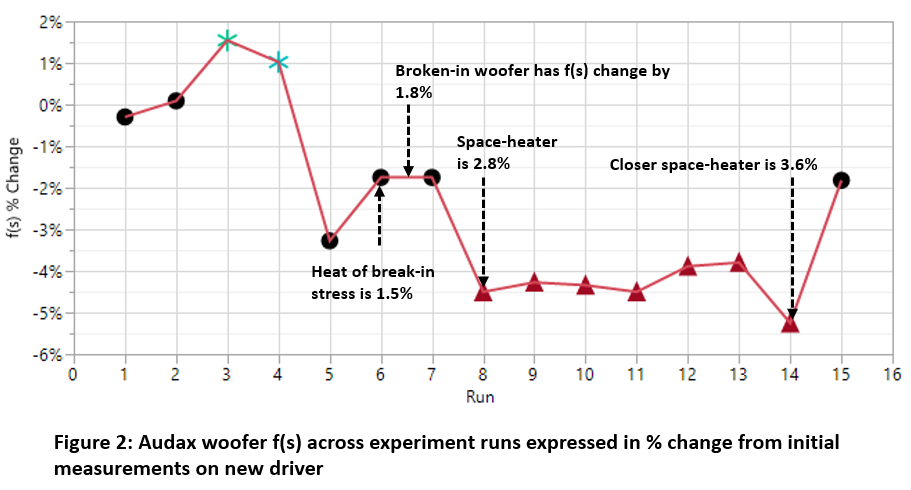

To better summarize the data, the changes in f(s) are normalized to the average of the measurements made right out of the box, which is 44.0 Hz.

Break-in changed f(s) changed by 1.8%, this is small. Not much bigger compared to putting the driver in the refrigerator for 10 mins (1.2%). Not much bigger than the heat from the application of stress (1.5%). And smaller than the impact of the space heater. Perhaps I could have measured the speaker in the refrigerator while cooling it to get better temperature granularity. And longer cool-down to explore larger fluctuations. And applied more heat, perhaps heat to the motor with a hot plate. And correlated it to actual temperatures of the driver components. But despite this rough approach, I think this is a good approximation of some of the changes that will occur in a home.

In summary, this Audax woofer break-in data shows modest changes in f(s) and other parameters. These changes are smaller than environmental effects. It's hard to imagine the measured break-in changes are audible even under ideal conditions.

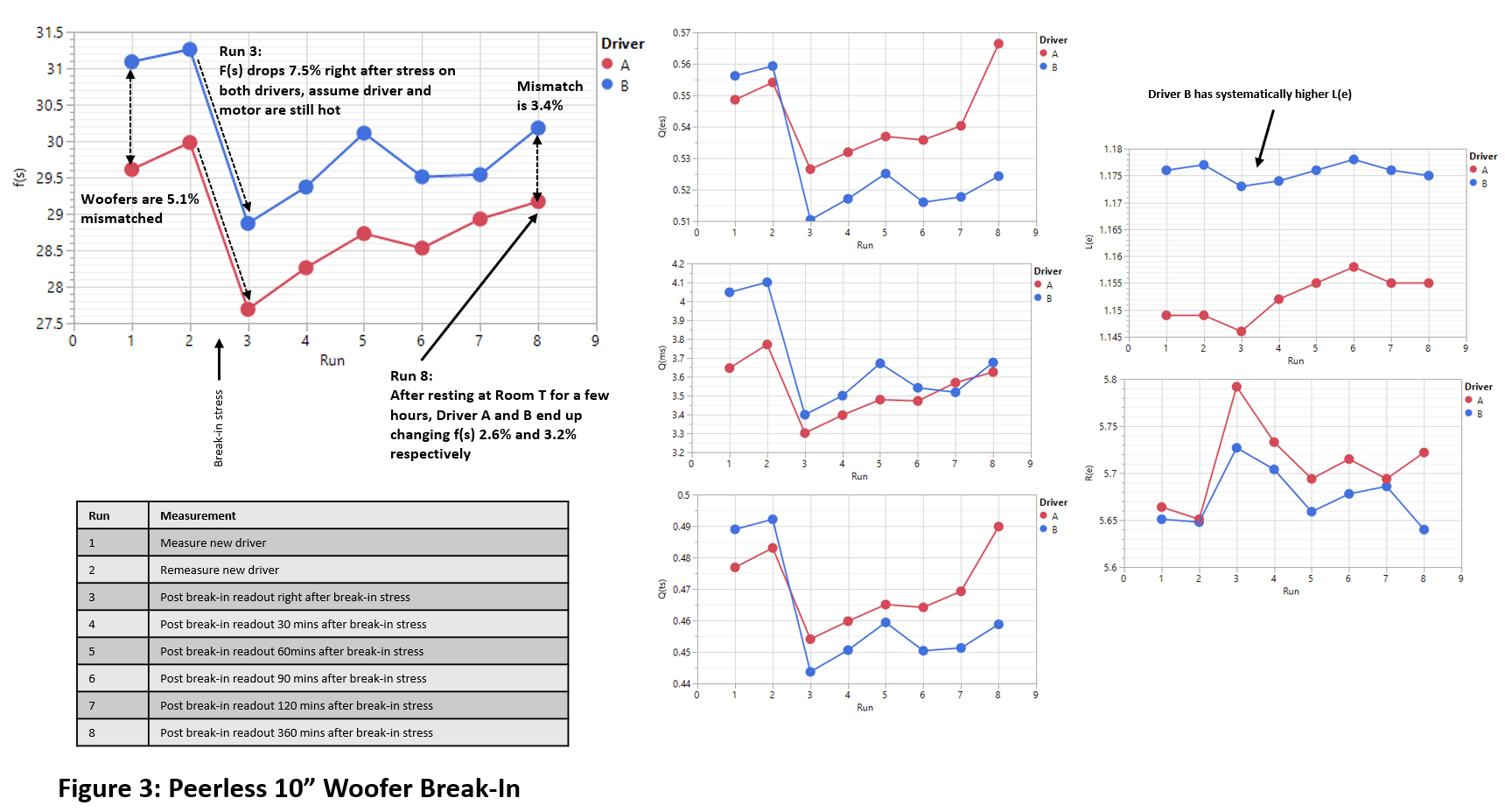

Figure 3 shows a simple break-in experiment on a pair of Peerless 10" drivers.

The Peerless drivers show large mismatch in parameters between the two. They show individually 2.6% and 3.2% change in f(s) post break-in. Run 3 suggests that the impact of the heat due to the break-in stress is larger than the changes due to break-in. And the trends from Run 3 to Run 8 suggest that it took hours for the driver to dissipate the heat from the stress and come back to equilibrium with the room.

The Peerless 10" woofers are more sensitive to the temperature effects of break-in than the actual physical changes due to break-in, the evidence is the f(s) trend from run 3 to run 8 as the driver cools back down to room T. Speaker to speaker matching is also larger than break-in effect. Unclear if the mismatch is due to defect or normal run to run variation. It's difficult to believe these small differences are audible.

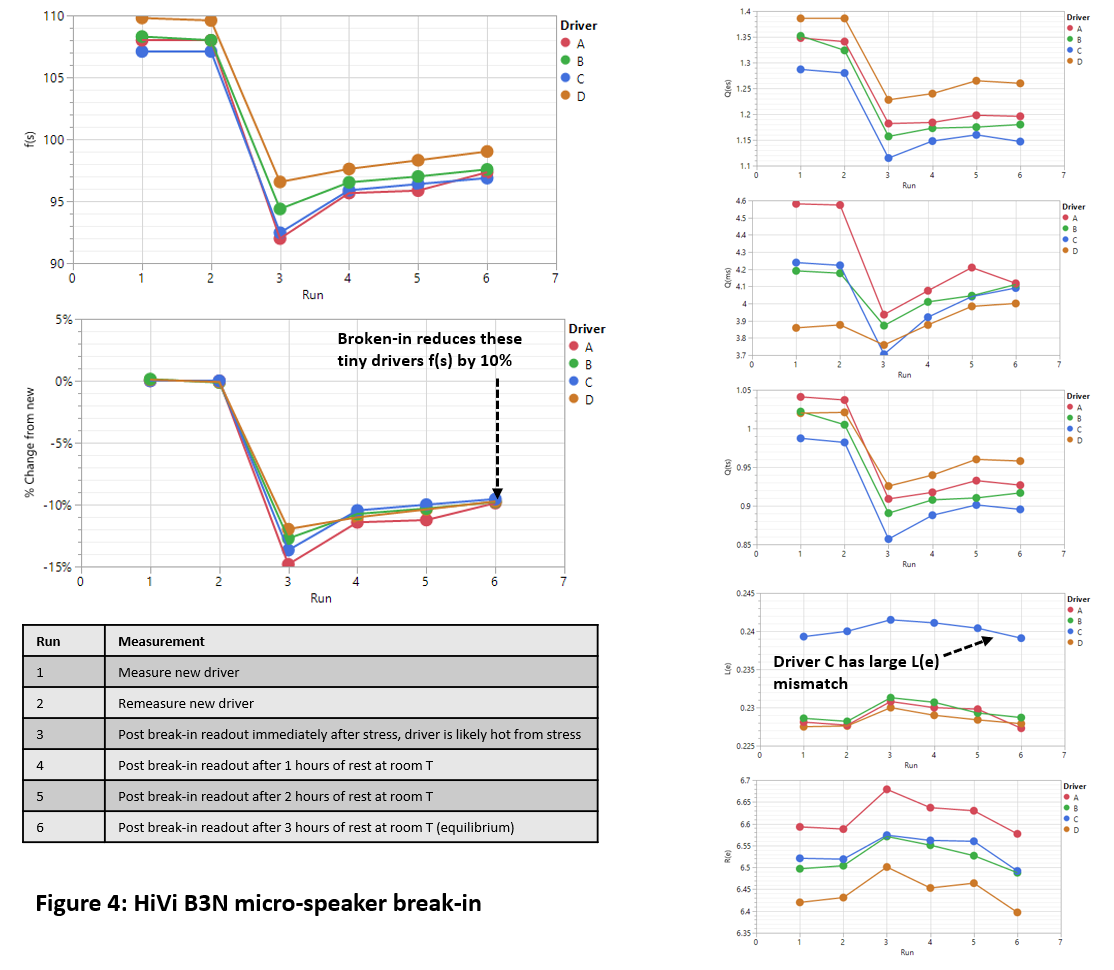

Figure 4 shows the results of break-in on four HiVi B3N micro-speakers:

These drivers' f(s) changes 10% from new. This is quite large compared to all previous drivers I have measured.

I don't know how long it took for the drivers to change. I did confirm that further stress causes no additional change.

This small HiVi speaker does change appreciably with stress. All four units behave the same with stress, despite the fact one driver has outlier L(e). This is the lone observation of a significant break-in effect. Perhaps the size of the driver can allow large changes to occur compared to a larger driver. Perhaps these HiVi drivers are an outlier for break-in.

This is the first time I have seen dramatic changes with stress like this. That being said, I have only made ad-hoc observations and half-dozen concerted measurement attempts to see how big the break-in effect is. But this is the only driver I have ever found to have significant change. Do metal cone drivers break in more? The JBL 15" paper cone woofer I refenced above changed from new only 1-2% over 6 months of heavy use.

My data is confounded by driver sizes, and challenged by sample size and variety. I do wonder if smaller drivers show more changes with break-in, but since the HiVi is the only small driver I have measured it's hard to say that it represents a trend. I certainly haven't seen dramatic changes in tweeter response after break-in or use. I have some data, would be willing to post that as well, it's boring. Additional data and observations are welcome!

- I see people posting YouTube videos of woofers being deformed into the shape of a potato-chip, while the 'tuber yells at me to make sure and break in my drivers before ever listening to them.

- I hear on various forums that you can facilitate the break-in of your speakers by placing them face to face and wiring one out of phase. Turn the volume up. Walk away. Come back later.

- Stores sell things to facilitate break-in. I suggest bank accounts are the only thing that's suffering break-in.

- I've been flamed on the usual forums for suggesting that a person should enjoy their new speakers and ignore any audible effects of break-in. I think most of the changes in the first few hours or days of getting new gear is the listener, not the gear. Despite that some people won't listen to their new HiFi until it has been subjected to various break-in procedures, seemingly out of some compulsion.

- And of course major manufacturers from time to time make a big deal about break-in. According to some, you should expect pretty large differences after break-in. And break-in will take some time. And things will always sound better.

Some Facts About Speaker Break-In

We break down the science behind speaker break-in. Yes, speaker break-in is a thing, and yes, you will hear a difference in your new speakers after playing them for a while.

I belong firmly to a school that isn't quite listed in Kef's marketing statement. I know that drivers do change under break-in; I have measured it. The measurements I have taken and seen tell me break-in is tiny, and smaller than a change in room temperature or voice-coil temperature that a speaker will see under normal operation. I have shown this with a few drivers, I did some fairly careful measurements with a Seas W18 metal cone woofer and a JBL 2216Nd paper 15" cone woofer. Both of those drivers showed very small changes with break-in, even after 6 months of use on the JBL. The JBL in particular changed so little, hard to imagine hearing or even being able to measure with a microphone a significant change in system output in a carefully controlled aging experiment. Certainly way below environmental effects like what the thermostat is set at or how hard have the drivers been playing over the past few minutes or hours.Speaker break-in and cables. If you want to ignite a war in an internet forum, bring up one of these two topics. We're not going to touch cables in this piece, but you speaker break-in non-believers, prepare for it – speaker break-in is most definitely a thing.

There are two radically opposing schools of thought regarding the need to burn-in, or break-in, new speakers.

First Radical School of Thought: Speaker run-in is an utterly ridiculous idea.

This school of thought basically states that our ears become accustomed to the sound of our new speakers (making them seem to sound better) and that the overall performance of a speaker doesn't change perceptively with use.

Second Radical School of Thought: Speakers are only worthwhile to listen to after several hundred hours of burn-in with a white noise generator and increasing amounts of bass-driven music.

This school of thought believes that speakers must be broken in sufficiently and properly in order for the performance of the speaker to be enjoyable to even the average listener.

As usual, the truth lies somewhere in the middle.

Since the subject came up again, I thought it a good time to revisit this topic with some unused drivers I have lying around.

I have two Peerless 831724 10" woofers and two Audax HP210GO 8" woofers, with synthetic cones. I also have four HiVi B3N metal cone micro-woofers.

I am presenting the measurements of these drivers before and after break-in. Each set of drivers was broken-in at ambient room conditions for 6 hours, with a signal I thought was sufficient. I don't quantify 'sufficient', except to say I drove them moderately hard with bass for 3 hours, and 3 more hours with pink noise. I specifically kept them well within their power limits, my goal was not to wear them out. I also explore the impact of moderate temperature changes both due to the break-in stress and due to external heating and cooling.

The heating and cooling is primitive. 10 mins in the refrigerator for cooling. I used a space-heater to elevate the temperatures, measurements were made with the heater off since the airflow has significant impact on the results.

Figure 1 shows the results of a break-in and temperature experiment on an Audax woofer. The raw driver was first measured (runs 1 and 2), then put in a refrigerator for 10 mins, then measured again (Runs 3 and 4). The speaker was then broken-in for 6 hours as described above, and measured immediately after while still hot from stress (Run 5). Then I allowed the driver to cool off to get the post-break-in measurements (Runs 6 and 7). The driver was then subjected to heat from a small space-heater (Runs 8-14). The space heater was moved to attempt to increase the heat, which most notably impacted measurement 14. Finally, after cooling off, the driver was remeasured (Run 15).

To better summarize the data, the changes in f(s) are normalized to the average of the measurements made right out of the box, which is 44.0 Hz.

Break-in changed f(s) changed by 1.8%, this is small. Not much bigger compared to putting the driver in the refrigerator for 10 mins (1.2%). Not much bigger than the heat from the application of stress (1.5%). And smaller than the impact of the space heater. Perhaps I could have measured the speaker in the refrigerator while cooling it to get better temperature granularity. And longer cool-down to explore larger fluctuations. And applied more heat, perhaps heat to the motor with a hot plate. And correlated it to actual temperatures of the driver components. But despite this rough approach, I think this is a good approximation of some of the changes that will occur in a home.

In summary, this Audax woofer break-in data shows modest changes in f(s) and other parameters. These changes are smaller than environmental effects. It's hard to imagine the measured break-in changes are audible even under ideal conditions.

Figure 3 shows a simple break-in experiment on a pair of Peerless 10" drivers.

The Peerless drivers show large mismatch in parameters between the two. They show individually 2.6% and 3.2% change in f(s) post break-in. Run 3 suggests that the impact of the heat due to the break-in stress is larger than the changes due to break-in. And the trends from Run 3 to Run 8 suggest that it took hours for the driver to dissipate the heat from the stress and come back to equilibrium with the room.

The Peerless 10" woofers are more sensitive to the temperature effects of break-in than the actual physical changes due to break-in, the evidence is the f(s) trend from run 3 to run 8 as the driver cools back down to room T. Speaker to speaker matching is also larger than break-in effect. Unclear if the mismatch is due to defect or normal run to run variation. It's difficult to believe these small differences are audible.

Figure 4 shows the results of break-in on four HiVi B3N micro-speakers:

These drivers' f(s) changes 10% from new. This is quite large compared to all previous drivers I have measured.

I don't know how long it took for the drivers to change. I did confirm that further stress causes no additional change.

This small HiVi speaker does change appreciably with stress. All four units behave the same with stress, despite the fact one driver has outlier L(e). This is the lone observation of a significant break-in effect. Perhaps the size of the driver can allow large changes to occur compared to a larger driver. Perhaps these HiVi drivers are an outlier for break-in.

This is the first time I have seen dramatic changes with stress like this. That being said, I have only made ad-hoc observations and half-dozen concerted measurement attempts to see how big the break-in effect is. But this is the only driver I have ever found to have significant change. Do metal cone drivers break in more? The JBL 15" paper cone woofer I refenced above changed from new only 1-2% over 6 months of heavy use.

My data is confounded by driver sizes, and challenged by sample size and variety. I do wonder if smaller drivers show more changes with break-in, but since the HiVi is the only small driver I have measured it's hard to say that it represents a trend. I certainly haven't seen dramatic changes in tweeter response after break-in or use. I have some data, would be willing to post that as well, it's boring. Additional data and observations are welcome!

Last edited: