The influence of BP on the sound of loudspeakers has often been controversially discussed. It even goes so far that individual voices describe the influence of binding posts as immense and recommend only very high-quality BPs - That made me curious.

The full mini series:

Capacitor upgrade in crossover - Is it audible?

Capacitor upgrade - part two

Capacitor upgrade - part three

Replace resistor by low-inductance resistor - Is it audible?

Different Binding Posts - is it audible?

Audible difference in high-end capacitors? - ABX samples

Of course it is not possible for me to test "all" binding posts (BP). Therefore I compare binding posts that are generally considered the "worst" ones (on planet earth) and evaluate their possible influence on the sound of loudspeakers.

This way, everyone can decide for himself whether it is worth spending ten or hundert times the price for high-end binding posts, the effect of which is then at best between the results of the worst binding posts and the measurements without binding post - apart from aesthetic differences.

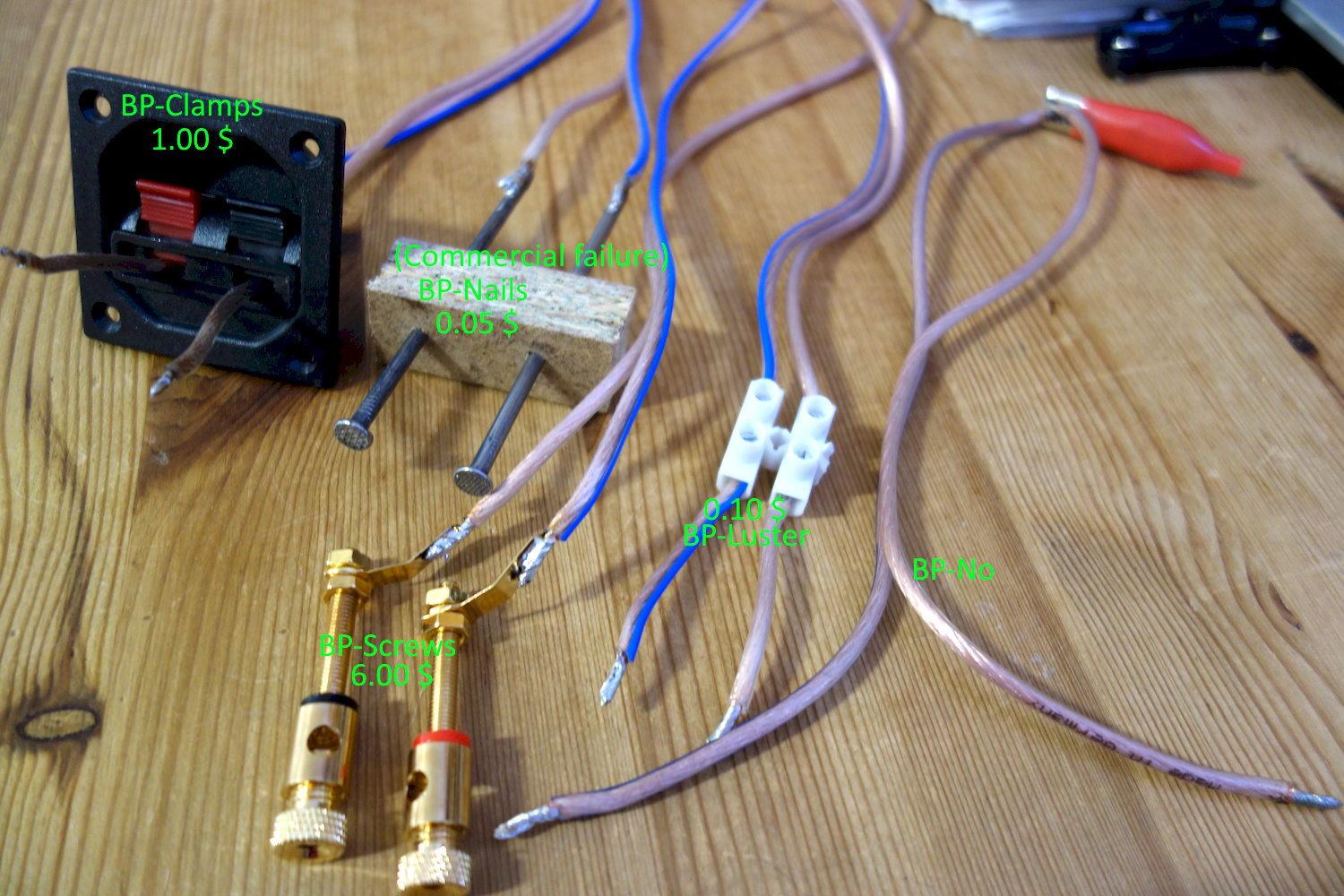

The compared binding posts (BP) are shown here:

BP-No: Without bindig post, serves as baseline. Here only the influence of 0.3m, OFC, 2.5mm² speaker cable is measured.

The measurements of the other BP also use 0.3m of the same speaker cable. The resistance value of the loudspeaker cable can then be subtracted from the BP measurements.

BP-Clamps: Probably the cheapest commonly used type of BP. Great care must be taken to ensure that the clamps are used correctly. The speaker cables must be inserted deep enough to touch the rear panel of the terminal - this is how at least the BP I use works. Personally, I would not use this binding post, as my tests often required several attempts to fix the speaker cable ends correctly.

BP-Luster: I often use luster terminals because I regularly make changes to loudspeakers.

Disadvantage, the screws of the luster terminals must be, after some time, tightened at least once to guarantee a faultless connection.

BP-Screws: These BPs are likely to be used very frequently. The nuts on the screw were adjusted to correspond to a cabinet wall thickness of approximately 21mm (0.83''). If banana plugs are not used, the speaker cable ends must be checked for tightness after some time.

BP-Nails: The secret formula for this BP was found during renovation works of our house, whose foundation walls date back to the 14-15th century.

As you can see on the photo, other adventurers had to pay with their lives to get the secret formula. Before the "Copernican Revolution", people knew just how to make a good binding post.

Why were the cable ends soldered?

With bare speaker cable ends the measured resistances are slightly worse and not as consistent. Therefore all cable ends were soldered.

1. LCR-Meter Comparison

In the first comparison the resistance values of the individual binding posts are simply measured with 0.3m loudspeaker cable.

After deducting the value for 0.3m loudspeaker cable we get a first indication of the influence of the BP on the overall performance of the loudspeaker.

Please note that the given absolute resistance values still have error tolerances which are not given here.

BP-No: 0.005 Ohm (0.3m speaker cable)

BP-Clamps: 0.012-0.005 = 0.007 Ohm

Since further cable transitions were necessary for this measurement (see picture above), the comparison is not quite fair - for the further measurements this disadvantage will no longer exist.

BP-Luster: 0.012-0.005 = 0.007 Ohm

Since further cable transitions were necessary for this measurement (see picture above), the comparison is not quite fair - for the further measurements this disadvantage will no longer exist.

BP-Screws: 0.009-0.005 = 0.004 Ohm

BP-Nails: 0.01-0.005 = 0.005 Ohm

But this is only half the truth, since the LCR meter only measures at a fixed frequency (in this case it was 1kHz), we do not yet know how the resistance values change over the entire audible range.

Cheap BP are supposed to have a negative influence on the high frequency reproduction, that has to be clarified.

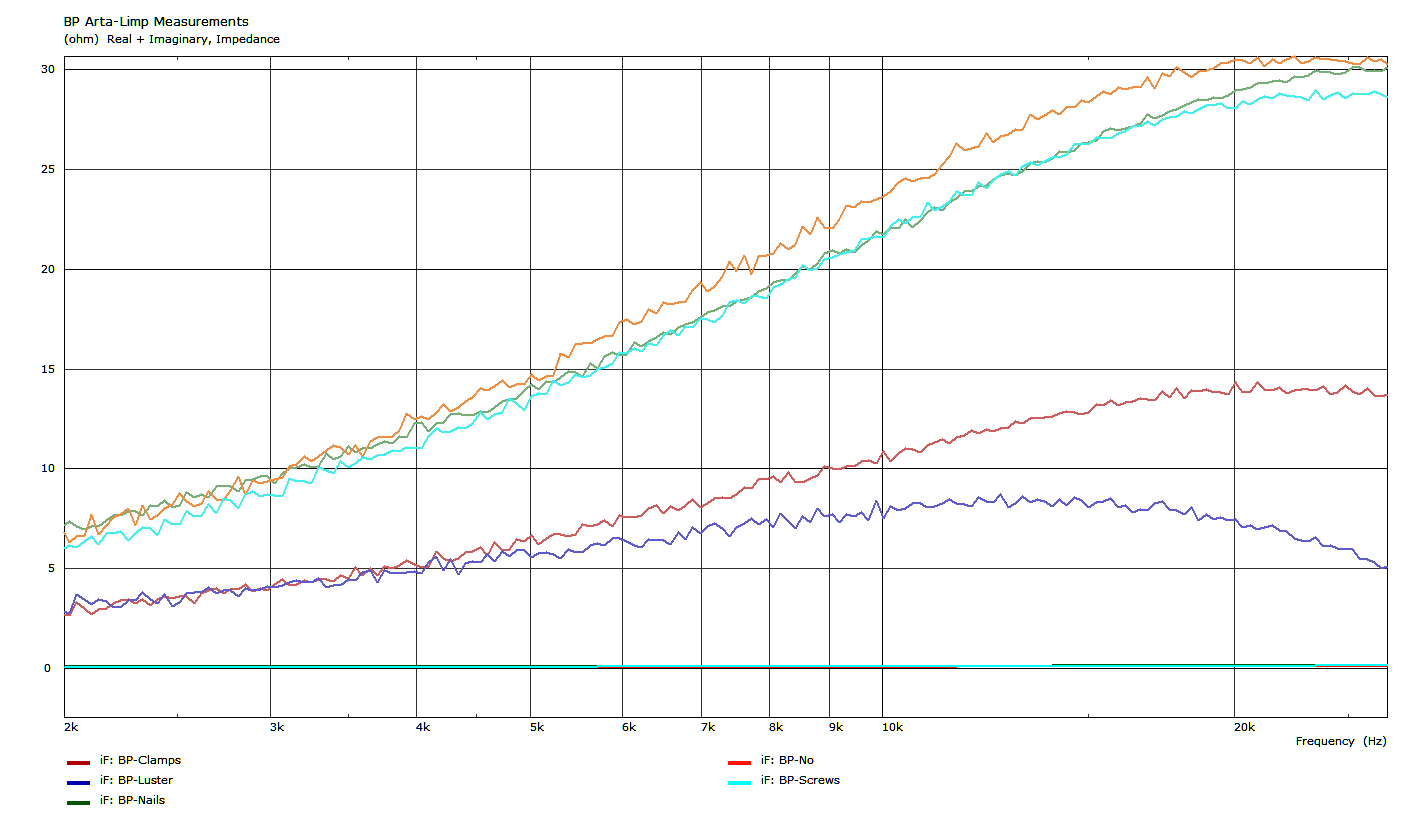

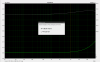

2. Impedance measurement with Arta-Limp

The Arta-Limp software can also function as an LCR meter. For this purpose, the impedance of the component against the frequency is measured.

When measuring the impedance of a resistor, which corresponds to our BP, Arta-Limp calculates the resistive and inductive part (at a given frequency).

The inductive part is shown in a phase >0° in the measurement diagram (less than 0° phase would indicate a capacitive behavior or a bad calibration in this case).

In the diagrams (except BP-No) the impedance of the BP-No is shown as an additional yellow curve.

BP-No: 0.06 Ohm

BP-Clamps: 0.09 - 0.06 = 0.03 Ohm

BP-Luster: 0.07 - 0.06 = 0.01 Ohm

BP-Screws: 0.07 - 0.06 = 0.01 Ohm

BP-Nails: 0.09 - 0.06 = 0.03 Ohm

If all impedance measurements are ploted in one diagram, it can be seen that the resistive part of all binding post is, as expected, close to zero ohms, the inductive part shown as phase angle differs more clearly.

The two different measurement methods clearly show that binding posts have an influence, albeit small, on the overall impedance of the loudspeaker.

Does this lead to an audible influence on the sound of the loudspeaker? This will be clarified in the next section.

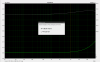

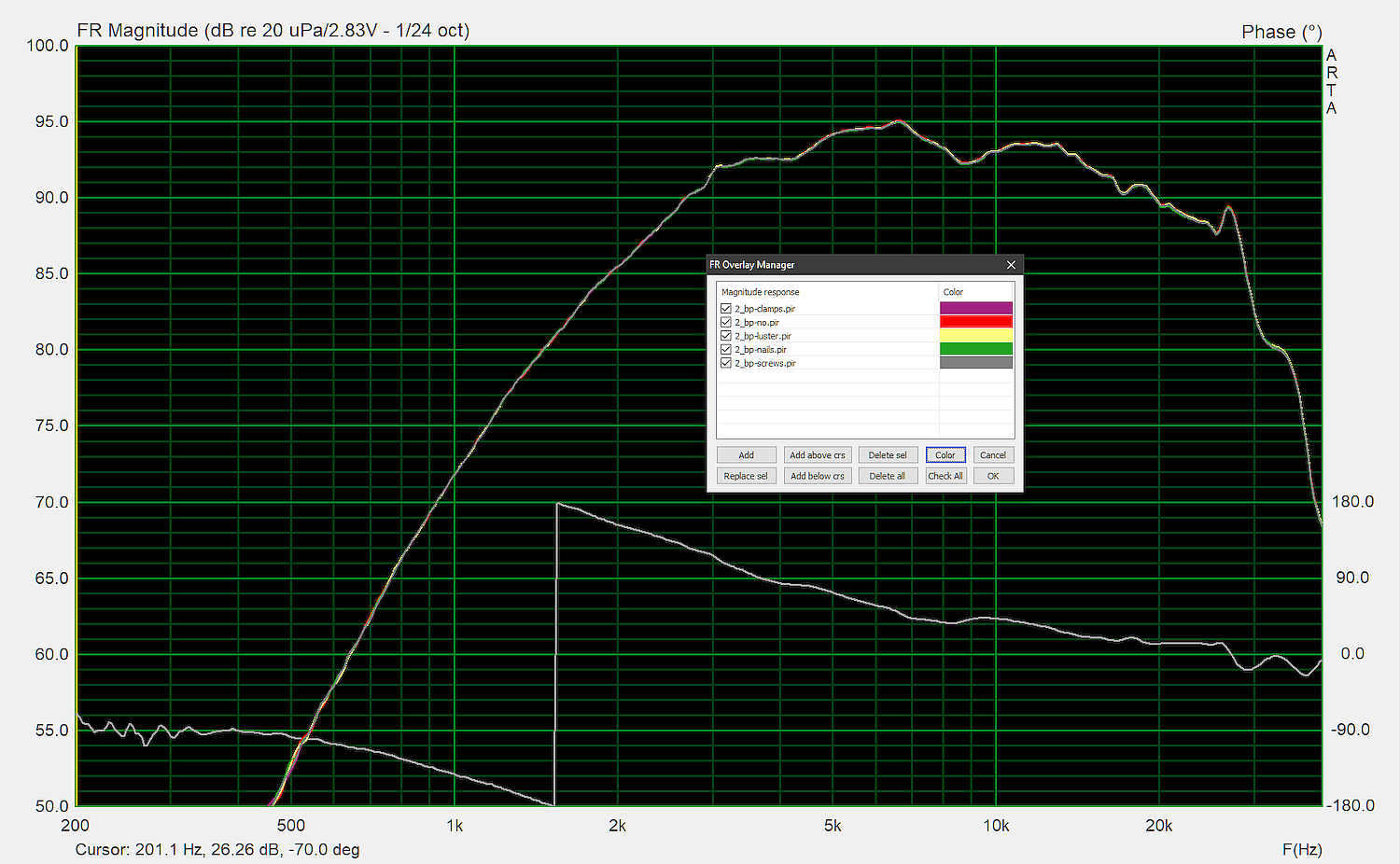

3. Impact on frequency response

In the last part we will look at the effects of BP on the frequency response. For this the same test setup is used as in my posts on "Capacitor upgrade in crossover - Is it audible?" and "Replace resistor by low-inductance resistor - Is it audible?".

The test signal is fed to the tweeter via 5m loudspeaker cable. A simple crossover circuit protects the tweeter from damage and serves to create a realistic test environment.

The binding post to be tested is then placed between the crossover and the connecting cable, just like you do with a real loudspeaker.

The result should not surprise anyone. The effect of the different BP on the frequency response is negligible.

Who is familiar with my other posts, knows what will follow.

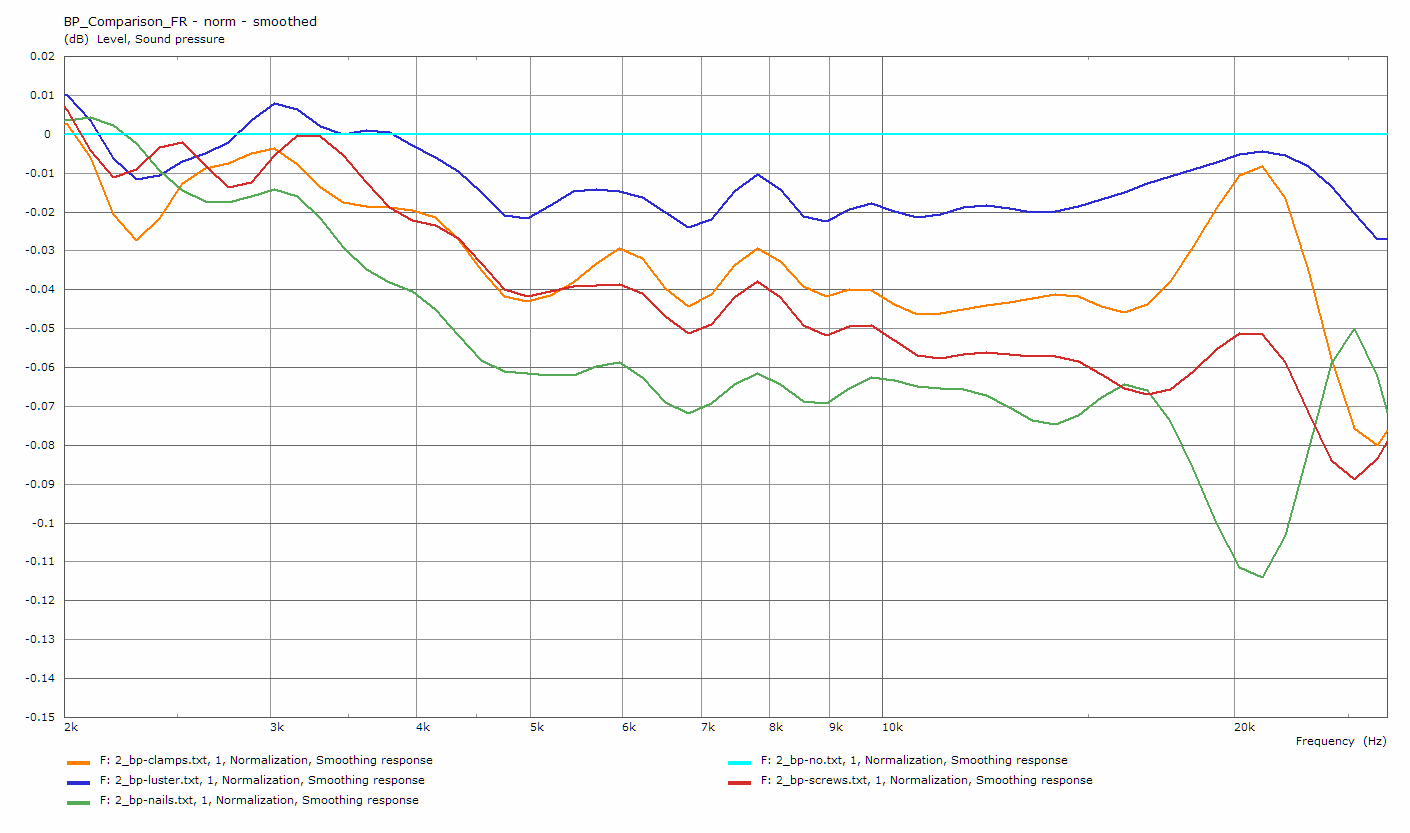

To make sure I'm not bullshitting you, the measurements are normalized to the frequency response of the BP-No, smoothed with 1/3 dB/oct and displayed with a 0.01 dB scale:

(only the frequency range down to -10dB of maximum sound pressure is displayed, 2-30kHz, to exclude possible noise interference):

Please do not regard the results presented here as absolute. I have had series of measurements where, for example, the BP-Screws were closer to our baseline BP-No (the measurement without a binding post) than shown above.

But the tendency was always similar, best results were always achieved by the luster terminal and the highest sound pressure reduction (greatest resistance effect) was caused by using fu... nails as binding post.

When using reasonable binding posts (therefore no nails), their effect on the frequency response is still well below 0.1dB according to my measurements and thus inaudible.

(If the loudspeaker cables were soldered to the nails instead of attaching them with crocodile clips as here in the test, their use as BP should also cause frequency response changes well below 0.1dB)

Before this is mentioned, also other measurements like distortions, decay,... no effect can be determined.

4. Conclusion

Had long considered whether I should write anything at all to binding posts, since common sense tells you that the impact should be minimal.

But after reading in forums over and over again and being told in YouTube videos how dramatic the effects of high-end BP are on the sound of loudspeakers, I had no choice.

When using quite "normal, reasonable" binding posts, the effects on the sound of the speaker is inaudible. Important are of course cleanly processed solder joints and firmly seated contacts when using banana plugs.

Then the resistance of the binding post should be below/around 0.01 Ohm. If you extend your loudspeaker cable by one meter, you will cause a greater effect than using normal binding posts.

Here is another comparison. In almost all crossovers a resistor in series to the tweeter is used (as part of a voltage divider) - usually with values around 1-3 Ohm.

Their tolerances are often around 2% for MOX resistors, but for other resistors it can be 5-10%.

Even if only a 1 Ohm resistor is used, the tolerances are in absolute terms with +- 0.02 Ohm to +-0.1 Ohm significantly higher than the resistance caused by binding posts.

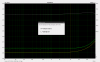

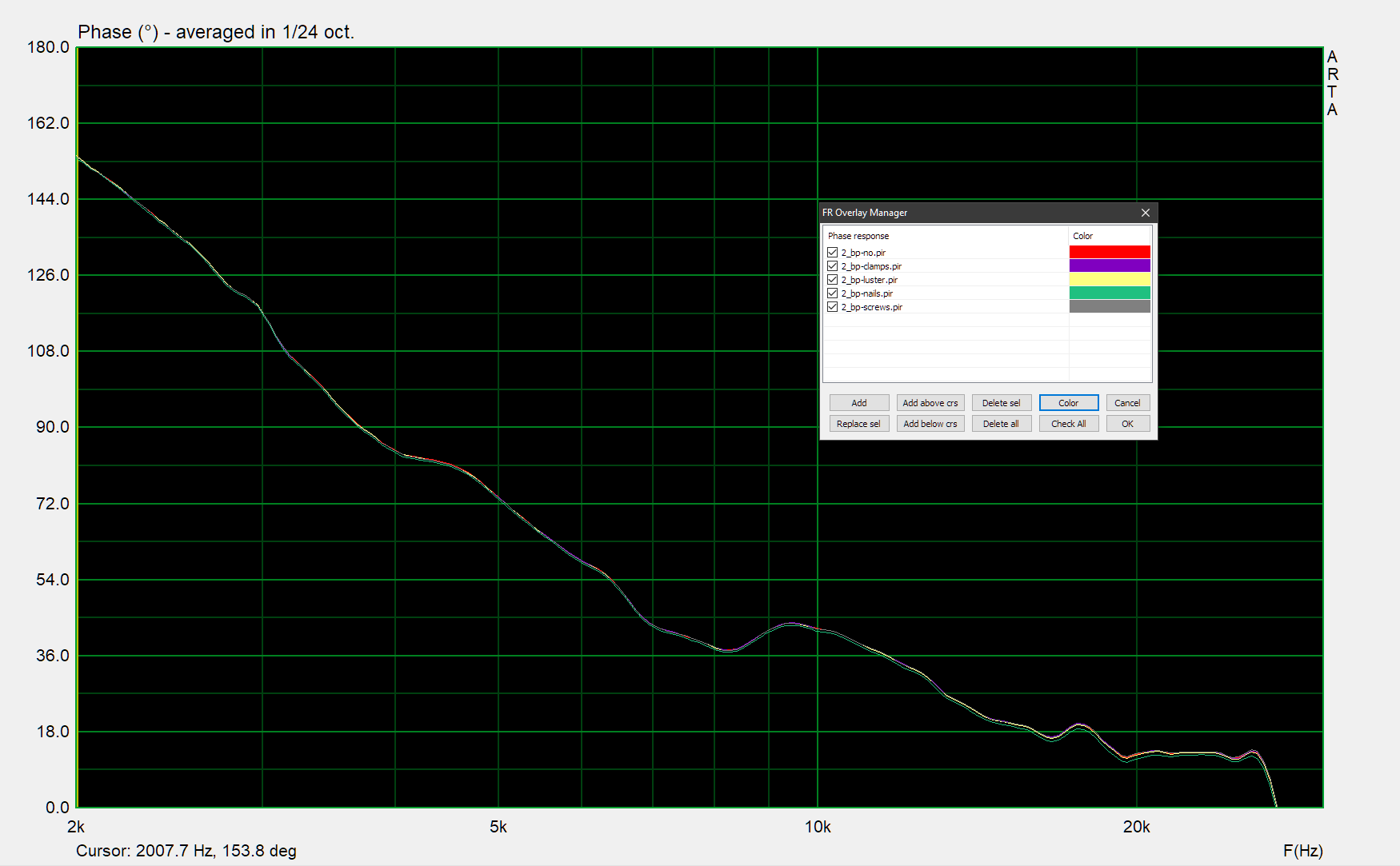

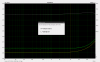

Update: Phase frequency response

To complete the analysis, here is a comparison of the phase frequency response for the different BPs.

With the sound pressure frequency response (which is shown above) and the phase frequency response, "sound waves are completely defined", all other representations such as impulse response or step response can be directly transformed into each other via (inverse) Fourier transformation.

This means that there is also no difference on the temporal level.

Here, too, there is no difference between the different BPs. Only the iron nails show a minimally deviating phase curve above 3kHz, but even in the range of the largest deviation between 10-30kHz, this is just 1° - which is not perceptible.

Highly magnified phase frequency response in the range 10-30kHz:

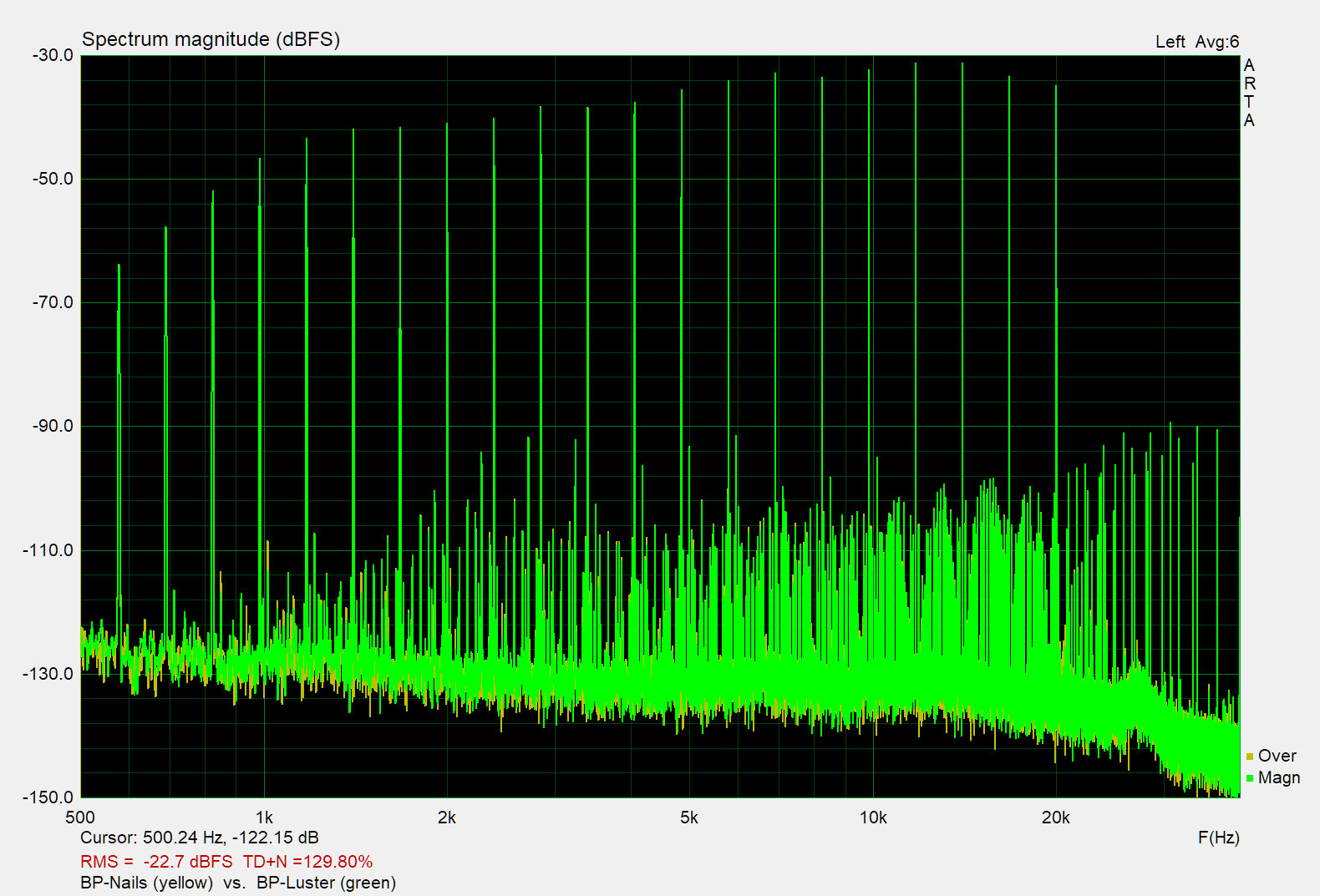

Update: Multitone distortion (including IMD)

After no differences on frequency response or temporal level are detectable, the argument usually comes that the distortion behavior could change audibly with different BP.

Therefore, here is the multitone comparison of the best BP (BP-Luster, green curves) with the worst BP (BP-Nails, yellow curves):

When excited with a multitone signal, you get intermodulation distortion (IMD) and harmonic distortion (HD). Here, too, there is no difference between the BPs (except for the usual small fluctuations).

Update: When steel is used in BP, there is measurably increased distortion at extremely low levels at high amp powers - see here for more details. As things stand, the differences are so small that they do not play a role in speaker distortion.

Update 2022-03-23: Added full mini series links

Update 2022-04-05: Added phase response and IMD section

Update 2023-02-13: Added remark about steel in BP

The full mini series:

Capacitor upgrade in crossover - Is it audible?

Capacitor upgrade - part two

Capacitor upgrade - part three

Replace resistor by low-inductance resistor - Is it audible?

Different Binding Posts - is it audible?

Audible difference in high-end capacitors? - ABX samples

Of course it is not possible for me to test "all" binding posts (BP). Therefore I compare binding posts that are generally considered the "worst" ones (on planet earth) and evaluate their possible influence on the sound of loudspeakers.

This way, everyone can decide for himself whether it is worth spending ten or hundert times the price for high-end binding posts, the effect of which is then at best between the results of the worst binding posts and the measurements without binding post - apart from aesthetic differences.

The compared binding posts (BP) are shown here:

BP-No: Without bindig post, serves as baseline. Here only the influence of 0.3m, OFC, 2.5mm² speaker cable is measured.

The measurements of the other BP also use 0.3m of the same speaker cable. The resistance value of the loudspeaker cable can then be subtracted from the BP measurements.

BP-Clamps: Probably the cheapest commonly used type of BP. Great care must be taken to ensure that the clamps are used correctly. The speaker cables must be inserted deep enough to touch the rear panel of the terminal - this is how at least the BP I use works. Personally, I would not use this binding post, as my tests often required several attempts to fix the speaker cable ends correctly.

BP-Luster: I often use luster terminals because I regularly make changes to loudspeakers.

Disadvantage, the screws of the luster terminals must be, after some time, tightened at least once to guarantee a faultless connection.

BP-Screws: These BPs are likely to be used very frequently. The nuts on the screw were adjusted to correspond to a cabinet wall thickness of approximately 21mm (0.83''). If banana plugs are not used, the speaker cable ends must be checked for tightness after some time.

BP-Nails: The secret formula for this BP was found during renovation works of our house, whose foundation walls date back to the 14-15th century.

As you can see on the photo, other adventurers had to pay with their lives to get the secret formula. Before the "Copernican Revolution", people knew just how to make a good binding post.

Why were the cable ends soldered?

With bare speaker cable ends the measured resistances are slightly worse and not as consistent. Therefore all cable ends were soldered.

1. LCR-Meter Comparison

In the first comparison the resistance values of the individual binding posts are simply measured with 0.3m loudspeaker cable.

After deducting the value for 0.3m loudspeaker cable we get a first indication of the influence of the BP on the overall performance of the loudspeaker.

Please note that the given absolute resistance values still have error tolerances which are not given here.

BP-No: 0.005 Ohm (0.3m speaker cable)

BP-Clamps: 0.012-0.005 = 0.007 Ohm

Since further cable transitions were necessary for this measurement (see picture above), the comparison is not quite fair - for the further measurements this disadvantage will no longer exist.

BP-Luster: 0.012-0.005 = 0.007 Ohm

Since further cable transitions were necessary for this measurement (see picture above), the comparison is not quite fair - for the further measurements this disadvantage will no longer exist.

BP-Screws: 0.009-0.005 = 0.004 Ohm

BP-Nails: 0.01-0.005 = 0.005 Ohm

But this is only half the truth, since the LCR meter only measures at a fixed frequency (in this case it was 1kHz), we do not yet know how the resistance values change over the entire audible range.

Cheap BP are supposed to have a negative influence on the high frequency reproduction, that has to be clarified.

2. Impedance measurement with Arta-Limp

The Arta-Limp software can also function as an LCR meter. For this purpose, the impedance of the component against the frequency is measured.

When measuring the impedance of a resistor, which corresponds to our BP, Arta-Limp calculates the resistive and inductive part (at a given frequency).

The inductive part is shown in a phase >0° in the measurement diagram (less than 0° phase would indicate a capacitive behavior or a bad calibration in this case).

In the diagrams (except BP-No) the impedance of the BP-No is shown as an additional yellow curve.

BP-No: 0.06 Ohm

BP-Clamps: 0.09 - 0.06 = 0.03 Ohm

BP-Luster: 0.07 - 0.06 = 0.01 Ohm

BP-Screws: 0.07 - 0.06 = 0.01 Ohm

BP-Nails: 0.09 - 0.06 = 0.03 Ohm

If all impedance measurements are ploted in one diagram, it can be seen that the resistive part of all binding post is, as expected, close to zero ohms, the inductive part shown as phase angle differs more clearly.

The two different measurement methods clearly show that binding posts have an influence, albeit small, on the overall impedance of the loudspeaker.

Does this lead to an audible influence on the sound of the loudspeaker? This will be clarified in the next section.

3. Impact on frequency response

In the last part we will look at the effects of BP on the frequency response. For this the same test setup is used as in my posts on "Capacitor upgrade in crossover - Is it audible?" and "Replace resistor by low-inductance resistor - Is it audible?".

The test signal is fed to the tweeter via 5m loudspeaker cable. A simple crossover circuit protects the tweeter from damage and serves to create a realistic test environment.

The binding post to be tested is then placed between the crossover and the connecting cable, just like you do with a real loudspeaker.

The result should not surprise anyone. The effect of the different BP on the frequency response is negligible.

Who is familiar with my other posts, knows what will follow.

To make sure I'm not bullshitting you, the measurements are normalized to the frequency response of the BP-No, smoothed with 1/3 dB/oct and displayed with a 0.01 dB scale:

(only the frequency range down to -10dB of maximum sound pressure is displayed, 2-30kHz, to exclude possible noise interference):

Please do not regard the results presented here as absolute. I have had series of measurements where, for example, the BP-Screws were closer to our baseline BP-No (the measurement without a binding post) than shown above.

But the tendency was always similar, best results were always achieved by the luster terminal and the highest sound pressure reduction (greatest resistance effect) was caused by using fu... nails as binding post.

When using reasonable binding posts (therefore no nails), their effect on the frequency response is still well below 0.1dB according to my measurements and thus inaudible.

(If the loudspeaker cables were soldered to the nails instead of attaching them with crocodile clips as here in the test, their use as BP should also cause frequency response changes well below 0.1dB)

Before this is mentioned, also other measurements like distortions, decay,... no effect can be determined.

4. Conclusion

Had long considered whether I should write anything at all to binding posts, since common sense tells you that the impact should be minimal.

But after reading in forums over and over again and being told in YouTube videos how dramatic the effects of high-end BP are on the sound of loudspeakers, I had no choice.

When using quite "normal, reasonable" binding posts, the effects on the sound of the speaker is inaudible. Important are of course cleanly processed solder joints and firmly seated contacts when using banana plugs.

Then the resistance of the binding post should be below/around 0.01 Ohm. If you extend your loudspeaker cable by one meter, you will cause a greater effect than using normal binding posts.

Here is another comparison. In almost all crossovers a resistor in series to the tweeter is used (as part of a voltage divider) - usually with values around 1-3 Ohm.

Their tolerances are often around 2% for MOX resistors, but for other resistors it can be 5-10%.

Even if only a 1 Ohm resistor is used, the tolerances are in absolute terms with +- 0.02 Ohm to +-0.1 Ohm significantly higher than the resistance caused by binding posts.

Update: Phase frequency response

To complete the analysis, here is a comparison of the phase frequency response for the different BPs.

With the sound pressure frequency response (which is shown above) and the phase frequency response, "sound waves are completely defined", all other representations such as impulse response or step response can be directly transformed into each other via (inverse) Fourier transformation.

This means that there is also no difference on the temporal level.

Here, too, there is no difference between the different BPs. Only the iron nails show a minimally deviating phase curve above 3kHz, but even in the range of the largest deviation between 10-30kHz, this is just 1° - which is not perceptible.

Highly magnified phase frequency response in the range 10-30kHz:

Update: Multitone distortion (including IMD)

After no differences on frequency response or temporal level are detectable, the argument usually comes that the distortion behavior could change audibly with different BP.

Therefore, here is the multitone comparison of the best BP (BP-Luster, green curves) with the worst BP (BP-Nails, yellow curves):

When excited with a multitone signal, you get intermodulation distortion (IMD) and harmonic distortion (HD). Here, too, there is no difference between the BPs (except for the usual small fluctuations).

Update: When steel is used in BP, there is measurably increased distortion at extremely low levels at high amp powers - see here for more details. As things stand, the differences are so small that they do not play a role in speaker distortion.

Update 2022-03-23: Added full mini series links

Update 2022-04-05: Added phase response and IMD section

Update 2023-02-13: Added remark about steel in BP

Last edited: