As the topics "capacitor upgrade" and therefore "capacitor sound" is very controversial, the test method and its results are explained in detail. This cannot be dealt with in one minute. Sorry for this and I hope your attention span is still sufficient to read through a long text - whereby the pictures clearly predominate

What is considered in the review? Only the effect of replacing a capacitor in series with a chassis and only the audible part of the frequency spectrum is considered. In this setup, replacing a capacitor should theoretically have the greatest effect on the sound of the loudspeaker.

The typical case for which a "capacitor upgrade" is recommended is e.g. replacing a standard film capacitor with a high-end capacitor in the crossover of the tweeter.

A high-end capacitor can cost hundreds of times more than a standard film capacitor, so it makes sense to take a closer look.

Electrolytic capacitors are a special case, as they age faster and change their capacitance value in the process - These will be discussed in the second part here.

The full mini series:

Capacitor upgrade in crossover - Is it audible?

Capacitor upgrade - part two

Capacitor upgrade - part three

Replace resistor by low-inductance resistor - Is it audible?

Different Binding Posts - is it audible?

Audible difference in high-end capacitors? - ABX samples

0) What does a capacitor in the crossover of the driver do?

To put it simply, the capacitor lets the high frequencies pass and suppresses the low frequencies and in our case creates a high pass.

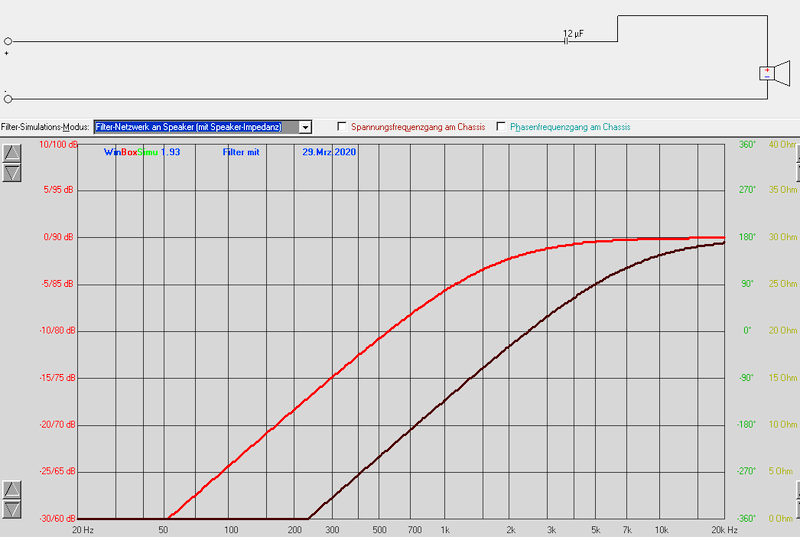

The example below shows an ideal driver (frequency response would be dead straight at 90dB sound power level, also ideal constant 8 Ohm impedance).

The brown curve shows the frequency response of the ideal driver with a 2.7µF capacitor in the crossover section of the driver, the red curve shows a capacitance of 12µF.

You don't need to know more to understand the review.

1) Test setup and method

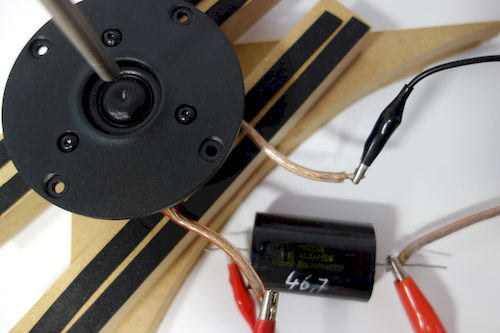

The capacitor is connected in series with a tweeter and is measured with a microphone. Extremely simple construction, which is identical to the typical construction in a crossover.

The tweeter is measured in the near field. Every capacitor is connected in series to the tweeter.

We use the SB21RDC tweeter from SBAcoustics and a calibrated iSEMcon EMX-7150 as measuring microphone. The measurements were performed with the measurement software Arta in dual-channel mode with pink noise.

A test measurement consists of the average of three consecutive measurements to minimize influences like voice coil heating of the tweeter, environmental influences (etc.).

Why were the measurements made in this way?

The argumentation when it comes to the sonic effects of components or equipment (such as loudspeaker cables) always boils down to "previously undiscovered/unmeasurable electrical phenomena".

To my knowledge there is nobody who would seriously claim that there are undiscovered possibilities of sound transmission (from tweeter to microphone). Or that an exchange of a capacitor changes the radiation of the tweeter.

The test setup therefore corresponds one-to-one to listening via loudspeakers, except that the near-field measurement captures even the smallest details and eliminates the influence of the baffle.

So the problem is reduced to the question

"When do the measured effects become audible".

To get a rough idea of when a change in sound pressure level becomes audible, here is a quote from Floyd Toole's book "Sound Reproduction"

Cut the crap. When's the test gonna start?

A little more patience. First of all we have to see what happens with slight changes in capacity in relation to the measured sound pressure.

2) Capacitors - low capacitance deviations

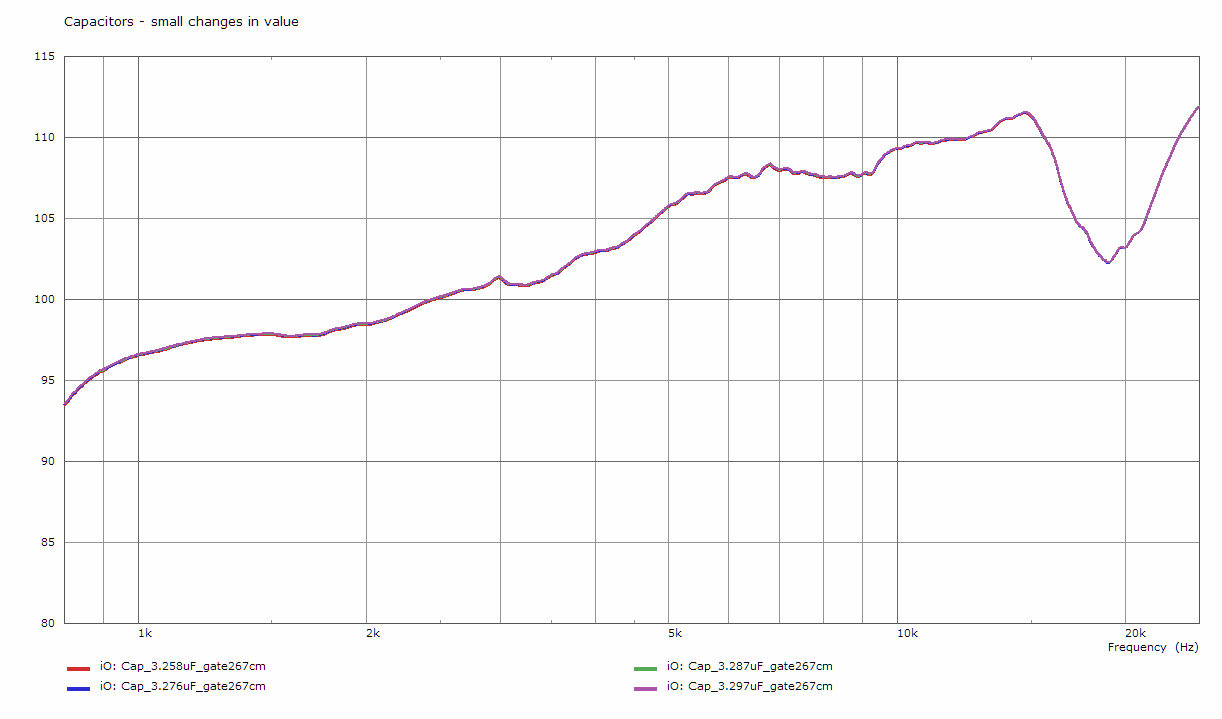

To see what small deviations in the capacitance values of a capacitor ultimately cause acoustically and to verify that the chosen test setup is "fine" enough to detect even the smallest changes, a series of capacitors from the same manufacturer's series but with slightly different capacitance values are measured.

The capacities of the capacitors are

These are deviations that are far below the tolerances of non-selected capacitors, which usually have tolerances of +-2%, +-5% or even +-10%.

For good production series, the tolerance can sometimes be +-1%.

Let's be generous and assume that capacitors have an average deviation of only 2-5% between each other when replacing a capacitor in a crossover with a high-end capacitor.

So if a capacitor upgrade is carried out, we can assume that the capacities will (at least) deviate on average by 2-5% from the originally installed capacitor.

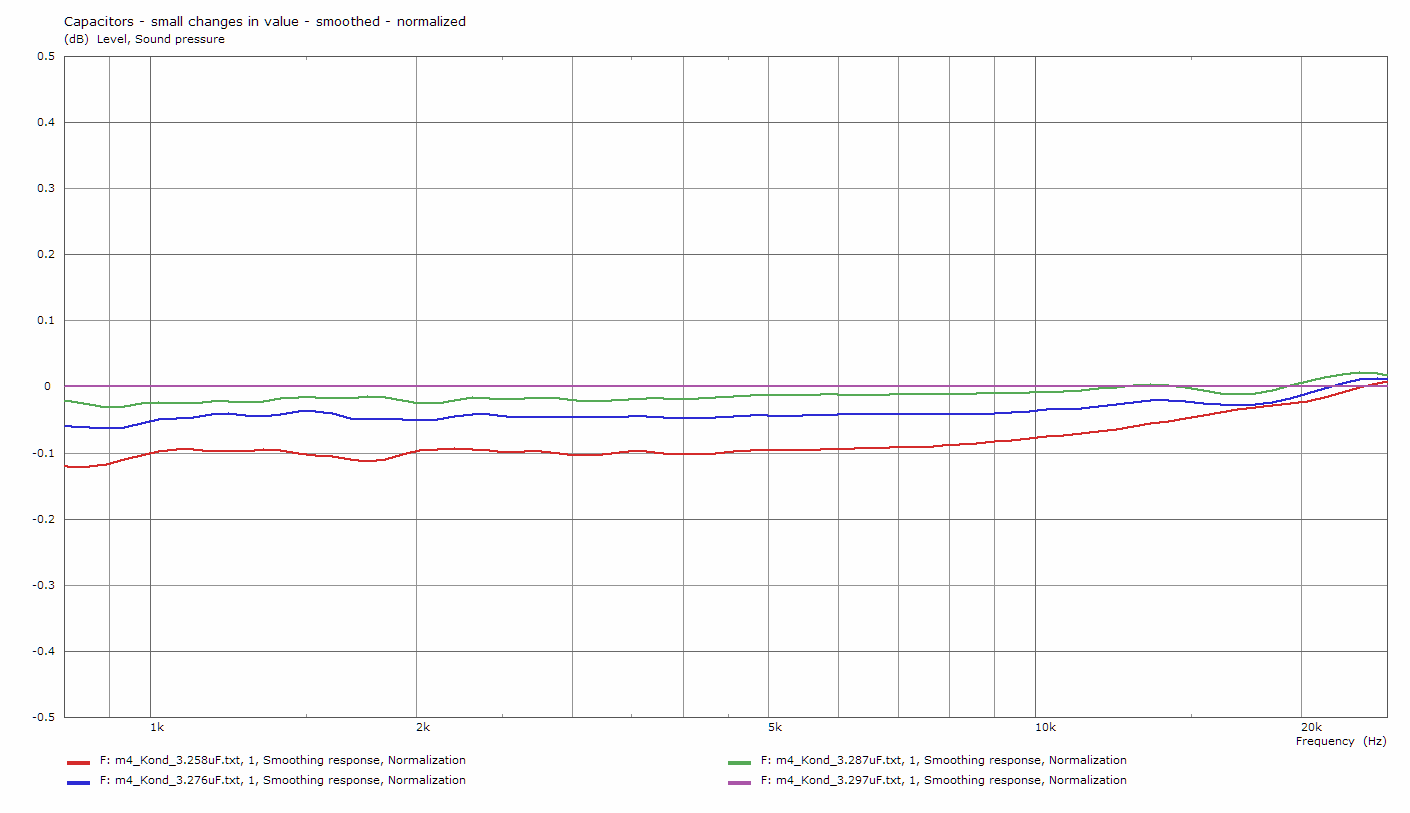

So let's take a look at what happens when the capacitance at 3.3µF of our tweeter varies by a maximum of 1.2%.

The measurements were not smoothed. Okay, that doesn't look like too much sound pressure deviation.

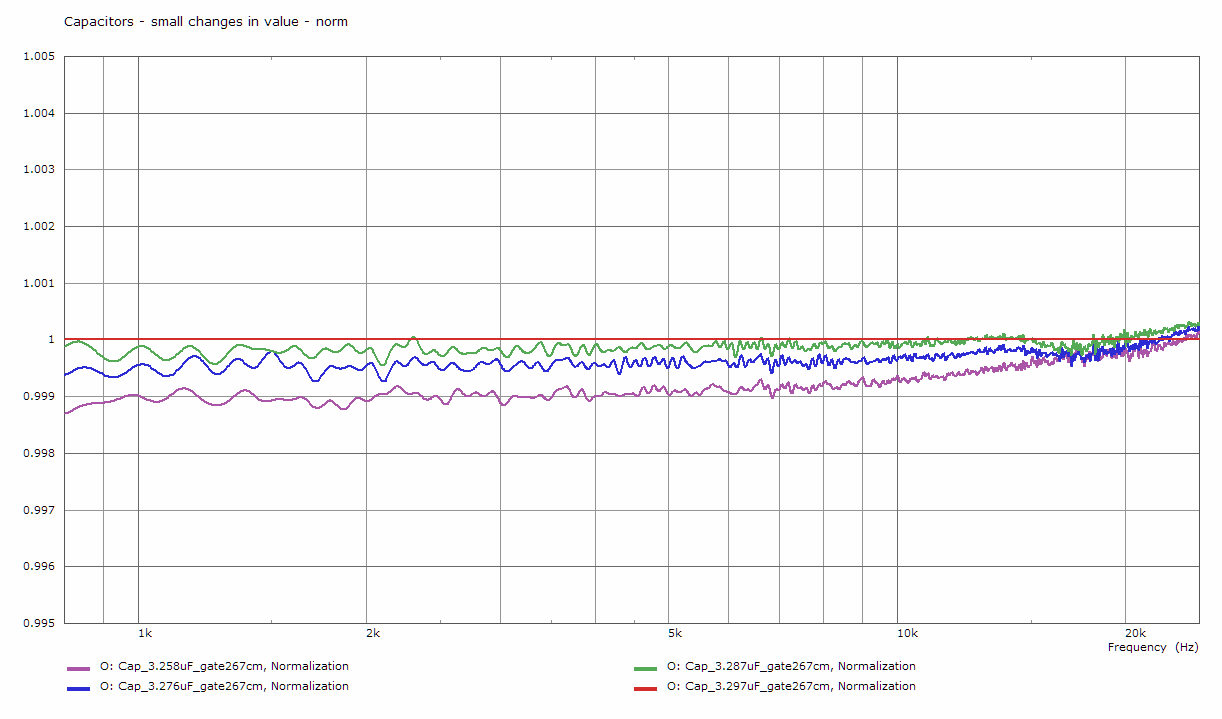

To see the differences better we normalize the curves to the highest capacitance value of 3.297µF and look at the deviation on a 0.1dB scale.

With 1/3-octave smoothing you can see how sensitive the resolution of the test setup is - again 0.1dB scale (now with fixed y-axis labels). Even 0.3% capacity deviation is clearly detected. It is nice to see (within the measurement accuracy of the test setup) how at very high frequencies the capacitors let the signal pass completely.

As quoted above, at least a slope of 0.1dB per octave is probably required to have an audible effect.

The 1.3% maximum deviation provides just under 0.1dB of sound pressure change, but this will not yet provide the minimum 0.1dB slope per octave required in a complete crossover.

But 2% or more deviation could already be audible. This provides a first argument for the audible impression after a capacitor exchange, since as mentioned above, an average deviation of 2-5% must be expected - if the capacitors are not selected during the exchange to fit as closely as possible.

Thus, the foundations have been laid for the correct classification of the following measurement results.

3) ordinary film capacitors versus high-end (film) capacitor

There are several websites on the Internet that deal with the sound of capacitors, describe the sonic properties of each capacitor in detail and even distribute sound notes.

On such sound descriptions, so-called "upgrade kits" draw their raison d'être and promise that the loudspeaker will sound much better after replacing capacitors with high-end capacitors.

So let's take a look at the measurable tonal differences of a high-end capacitor compared to ancient simple film capacitors:

The capacitors were selected to have (nearly) identical capacitance values. The maximum capacitance deviation from the silver z-cap capacitor is only 0.2% (since my measuring systems do not actually provide this measuring accuracy, a certain error tolerance should be added).

Silver Z-cap

Ero MKC

MD-MKP

But if there are large sound pressure changes, these can be completely attributed to the high-end quality of the silver-z-cap.

The Jantzen capacitor is not absurdly expensive, but it comes off very well in terms of tonal evaluation.

http://www.humblehomemadehifi.com/Cap.html

http://www.sup-audio.com/html/high-standard.html

(quote translated)

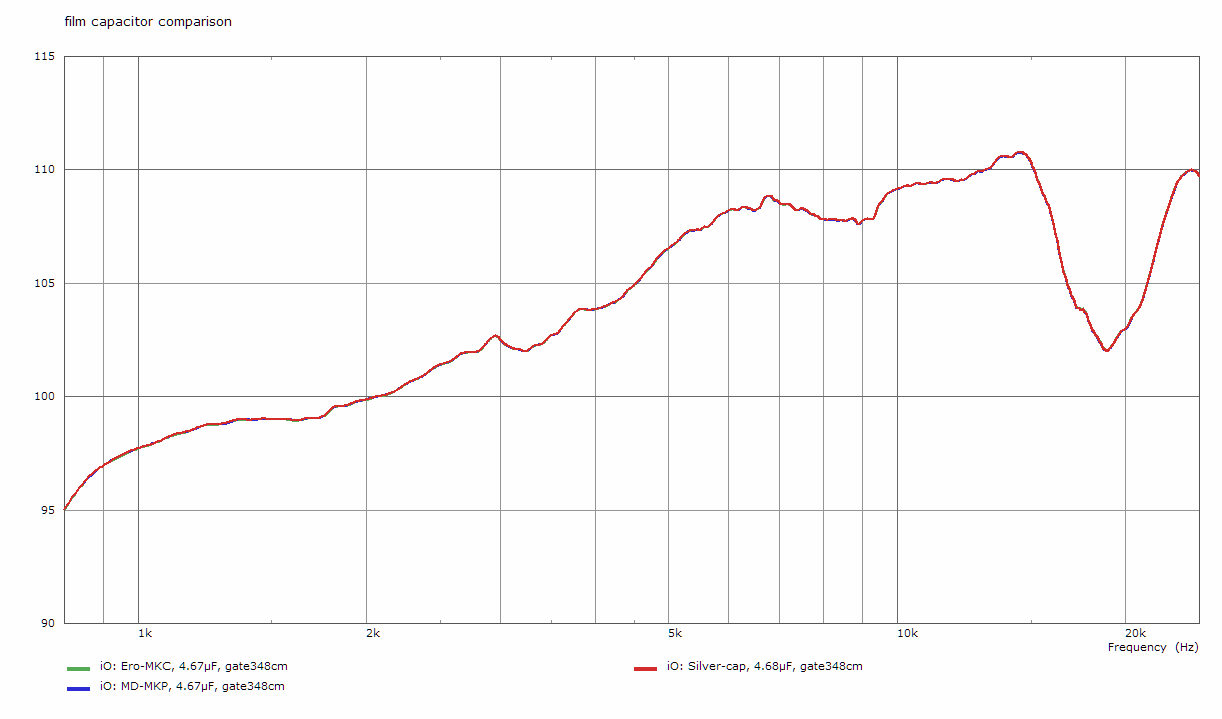

So the expectations are extremely high, let's see how spectacular the actual measurements turn out in the battle of the up to 23 years old capacitors against the high-end capacitor

What the f... are you trying to do, f... us over!

What the f... are you trying to do, f... us over!

That's just the same measurement with three different colors displayed - isn't it?

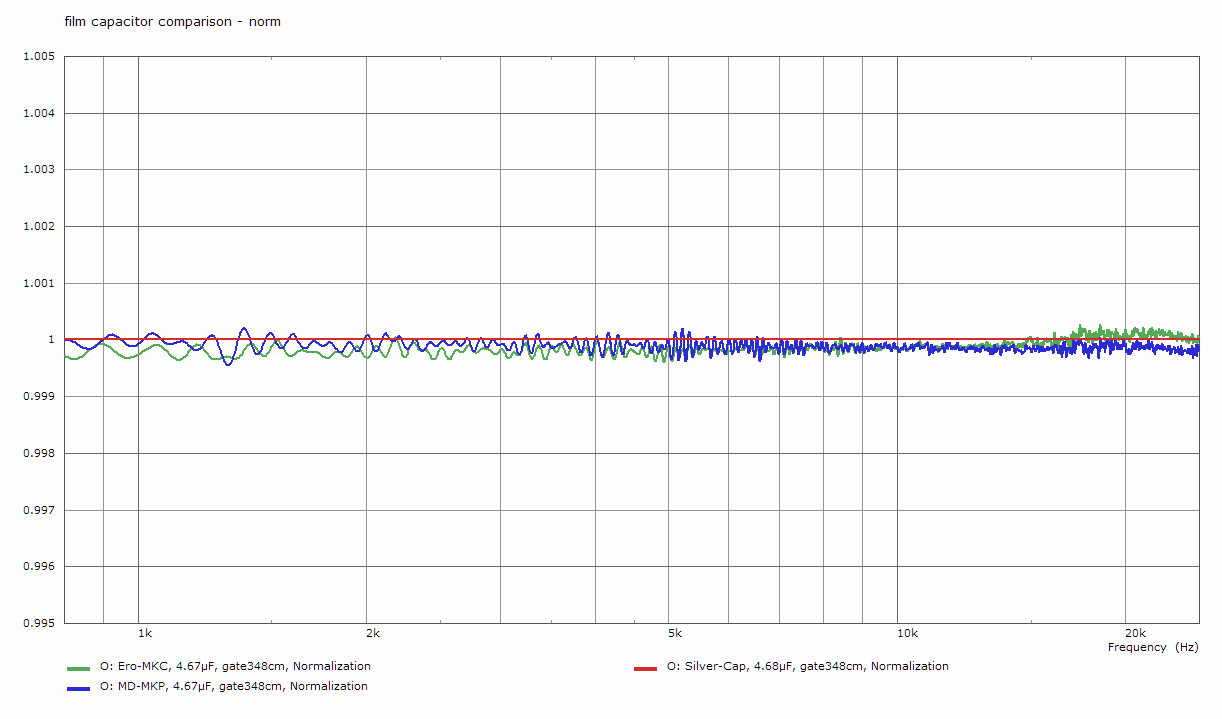

It's not! We should take a closer look, so we normalize to the frequency response of the silver-cap capacitor. The diagram shows a 0.1dB scaling:

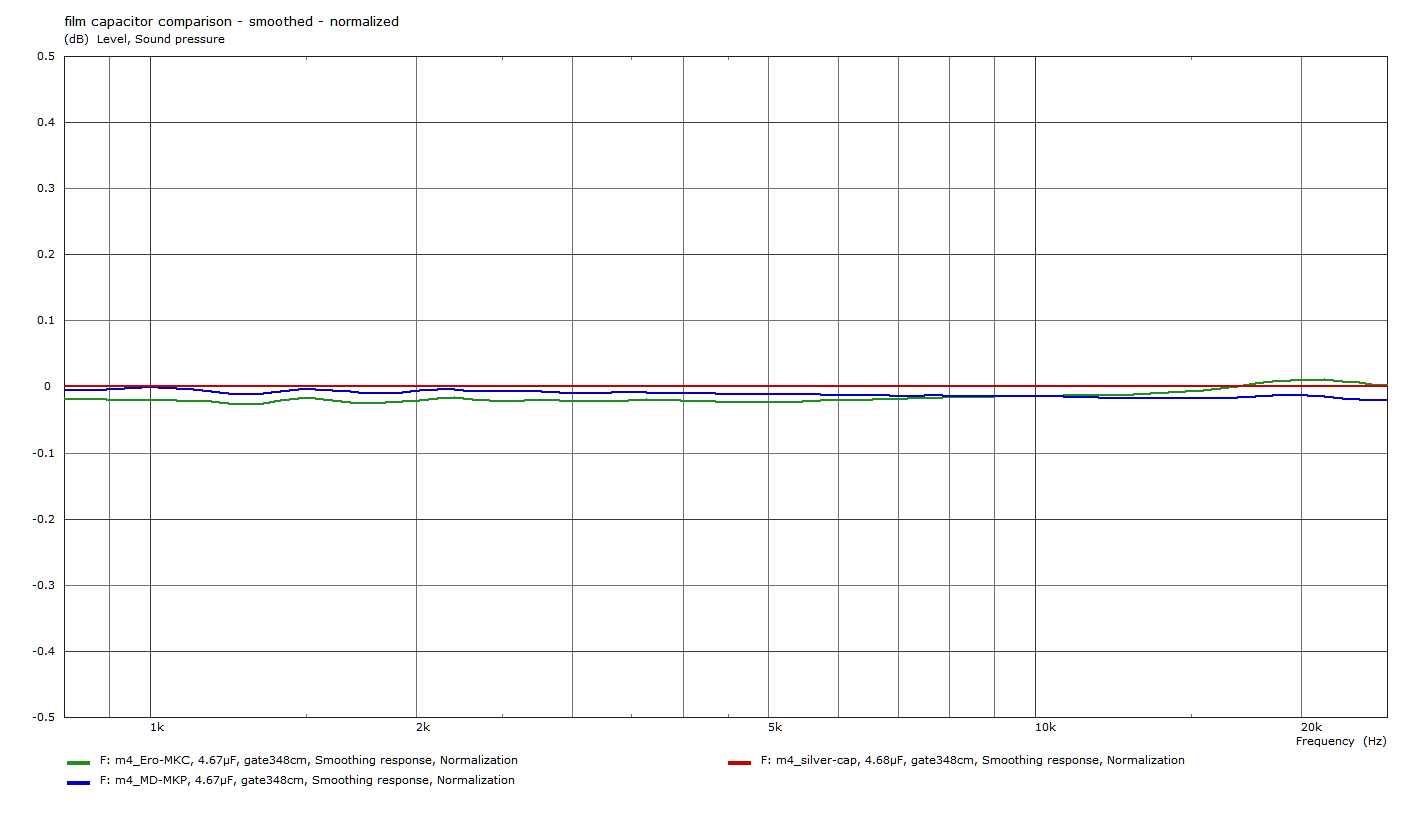

As no smoothing is used, the noise of the test setup disturbs us a bit, hence the display with 1/3-octave smoothing (with fixed y-axis labels):

There are minimal deviations between the curves, but with a maximum of 0.03dB these are so small that it is hardly worth mentioning.

Result: There is practically no measurable acoustic difference between the simple, ancient film capacitors and the current high-end capacitor. Welcome to reality!

This clearly shows that the characteristics of the high-end capacitor cited above, such as "very transparent" or "very detailed" compared to other film capacitors, are pure fantasies of ambitious authors.

To anticipate a few possible questions and criticisms:

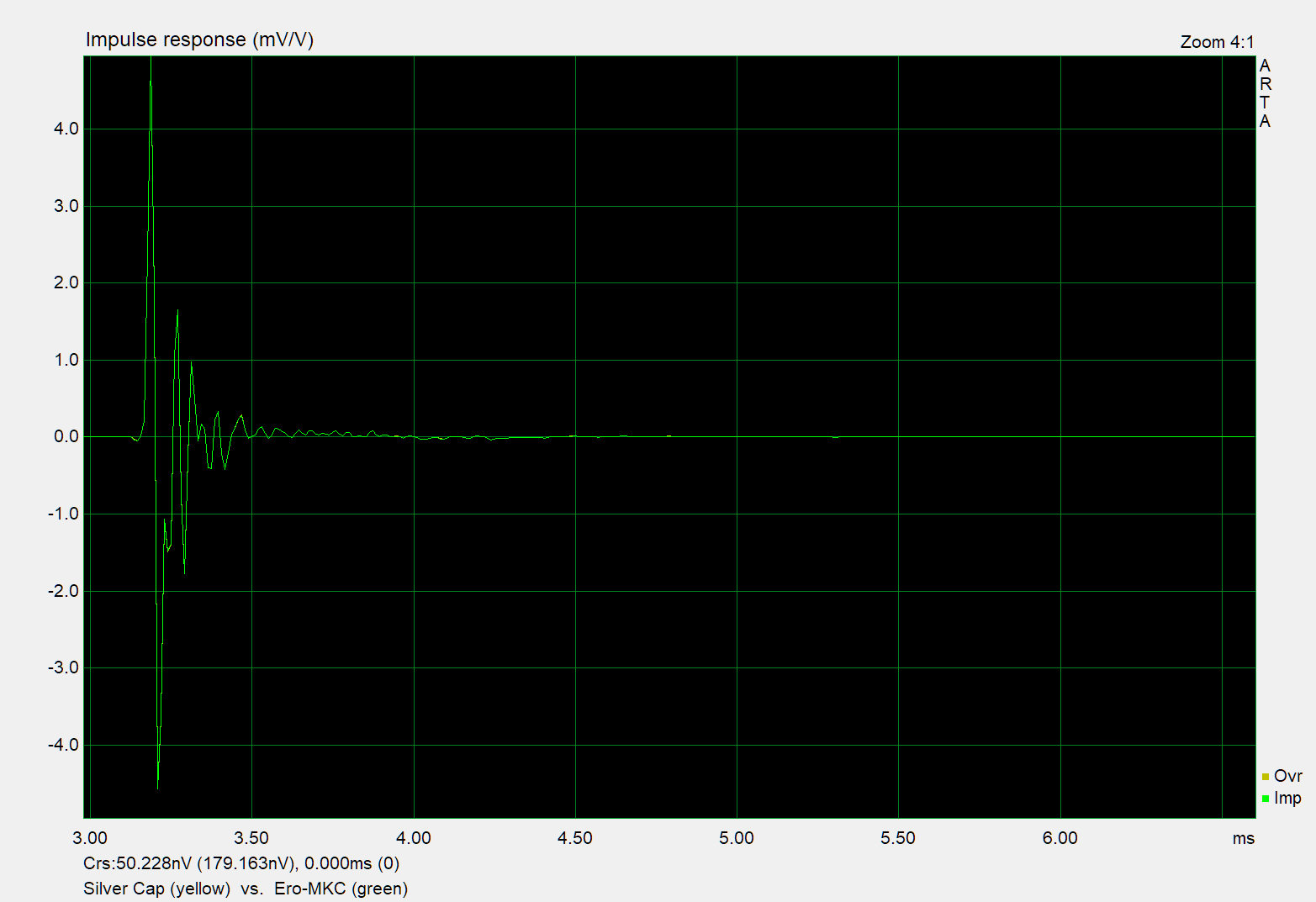

1) Only the frequency responses of the capacitors on the tweeter were compared, the actual differences are certainly in the time-domain!

The measurement of a single driver can be considered a minimum phase system. In this case, the phase corresponds to the minimum phase and can therefore be derived directly from the frequency response. Both together contain all the information necessary to calculate the impulse response, for example.

(Please correct me if there is something wrong with the statement)

Therefore for all doubters the measured comparison of the impulse response of Silver z-cap and the Ero-MKC

2) The difference will certainly be reflected in the decay behavior of the tweeter!

Let's have a look at the transient response of the tweeter with the Silver Z-cap, Ero MKC and the MD-MKP

Within the scope of our measuring accuracy these are completely identical.

3) The difference in quality can be seen in the distortion behavior of complex signals!

For this purpose we look at the measured multi-tone distortions of the individual capacitors in the signal path of the tweeter. The multitone distortions include the harmonic distortions and the intermodulation distortions.

There too, no difference at all can be detected.

Update 2022-03-23: Added full mini series links

Update 2023-10-19: Fixed some y-axis labels

What is considered in the review? Only the effect of replacing a capacitor in series with a chassis and only the audible part of the frequency spectrum is considered. In this setup, replacing a capacitor should theoretically have the greatest effect on the sound of the loudspeaker.

The typical case for which a "capacitor upgrade" is recommended is e.g. replacing a standard film capacitor with a high-end capacitor in the crossover of the tweeter.

A high-end capacitor can cost hundreds of times more than a standard film capacitor, so it makes sense to take a closer look.

Electrolytic capacitors are a special case, as they age faster and change their capacitance value in the process - These will be discussed in the second part here.

The full mini series:

Capacitor upgrade in crossover - Is it audible?

Capacitor upgrade - part two

Capacitor upgrade - part three

Replace resistor by low-inductance resistor - Is it audible?

Different Binding Posts - is it audible?

Audible difference in high-end capacitors? - ABX samples

0) What does a capacitor in the crossover of the driver do?

To put it simply, the capacitor lets the high frequencies pass and suppresses the low frequencies and in our case creates a high pass.

The example below shows an ideal driver (frequency response would be dead straight at 90dB sound power level, also ideal constant 8 Ohm impedance).

The brown curve shows the frequency response of the ideal driver with a 2.7µF capacitor in the crossover section of the driver, the red curve shows a capacitance of 12µF.

You don't need to know more to understand the review.

1) Test setup and method

The capacitor is connected in series with a tweeter and is measured with a microphone. Extremely simple construction, which is identical to the typical construction in a crossover.

The tweeter is measured in the near field. Every capacitor is connected in series to the tweeter.

We use the SB21RDC tweeter from SBAcoustics and a calibrated iSEMcon EMX-7150 as measuring microphone. The measurements were performed with the measurement software Arta in dual-channel mode with pink noise.

A test measurement consists of the average of three consecutive measurements to minimize influences like voice coil heating of the tweeter, environmental influences (etc.).

Why were the measurements made in this way?

The argumentation when it comes to the sonic effects of components or equipment (such as loudspeaker cables) always boils down to "previously undiscovered/unmeasurable electrical phenomena".

To my knowledge there is nobody who would seriously claim that there are undiscovered possibilities of sound transmission (from tweeter to microphone). Or that an exchange of a capacitor changes the radiation of the tweeter.

The test setup therefore corresponds one-to-one to listening via loudspeakers, except that the near-field measurement captures even the smallest details and eliminates the influence of the baffle.

So the problem is reduced to the question

"When do the measured effects become audible".

To get a rough idea of when a change in sound pressure level becomes audible, here is a quote from Floyd Toole's book "Sound Reproduction"

The simplest deviation from flat is probably a spectral tilt. There is some

evidence that we can detect slopes of about 0.1 dB/octave...

Cut the crap. When's the test gonna start?

A little more patience. First of all we have to see what happens with slight changes in capacity in relation to the measured sound pressure.

2) Capacitors - low capacitance deviations

To see what small deviations in the capacitance values of a capacitor ultimately cause acoustically and to verify that the chosen test setup is "fine" enough to detect even the smallest changes, a series of capacitors from the same manufacturer's series but with slightly different capacitance values are measured.

The capacities of the capacitors are

- 3,258µF

- 3,276µF

- 3,287µF

- 3,297µF

These are deviations that are far below the tolerances of non-selected capacitors, which usually have tolerances of +-2%, +-5% or even +-10%.

For good production series, the tolerance can sometimes be +-1%.

Let's be generous and assume that capacitors have an average deviation of only 2-5% between each other when replacing a capacitor in a crossover with a high-end capacitor.

So if a capacitor upgrade is carried out, we can assume that the capacities will (at least) deviate on average by 2-5% from the originally installed capacitor.

So let's take a look at what happens when the capacitance at 3.3µF of our tweeter varies by a maximum of 1.2%.

The measurements were not smoothed. Okay, that doesn't look like too much sound pressure deviation.

To see the differences better we normalize the curves to the highest capacitance value of 3.297µF and look at the deviation on a 0.1dB scale.

With 1/3-octave smoothing you can see how sensitive the resolution of the test setup is - again 0.1dB scale (now with fixed y-axis labels). Even 0.3% capacity deviation is clearly detected. It is nice to see (within the measurement accuracy of the test setup) how at very high frequencies the capacitors let the signal pass completely.

As quoted above, at least a slope of 0.1dB per octave is probably required to have an audible effect.

The 1.3% maximum deviation provides just under 0.1dB of sound pressure change, but this will not yet provide the minimum 0.1dB slope per octave required in a complete crossover.

But 2% or more deviation could already be audible. This provides a first argument for the audible impression after a capacitor exchange, since as mentioned above, an average deviation of 2-5% must be expected - if the capacitors are not selected during the exchange to fit as closely as possible.

Thus, the foundations have been laid for the correct classification of the following measurement results.

3) ordinary film capacitors versus high-end (film) capacitor

There are several websites on the Internet that deal with the sound of capacitors, describe the sonic properties of each capacitor in detail and even distribute sound notes.

On such sound descriptions, so-called "upgrade kits" draw their raison d'être and promise that the loudspeaker will sound much better after replacing capacitors with high-end capacitors.

So let's take a look at the measurable tonal differences of a high-end capacitor compared to ancient simple film capacitors:

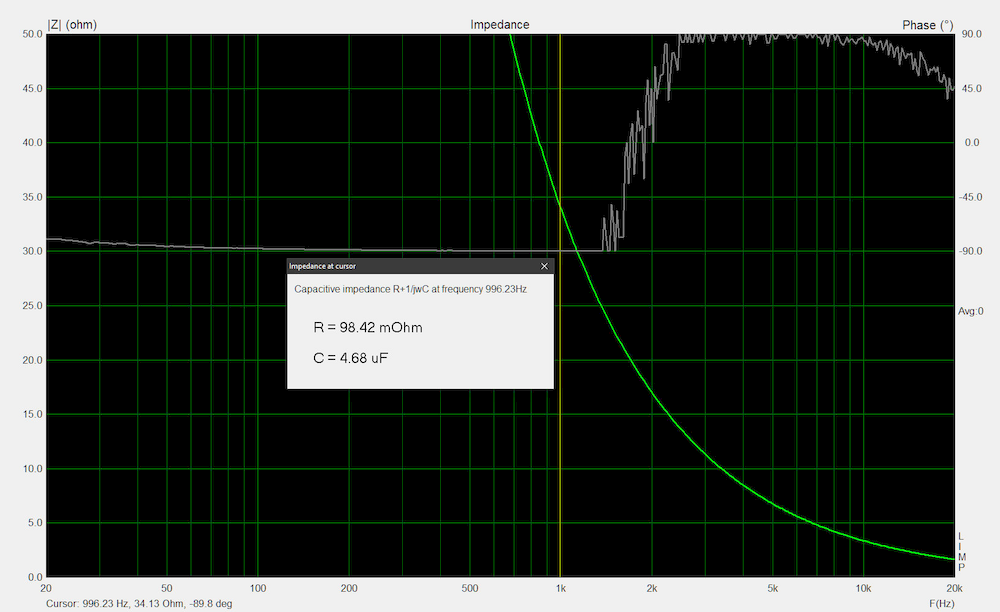

- Jantzen Audio Silver Z-cap 800V (as good as new, polypropylene film, see below for detailed description) - The capacity is 4.68µF

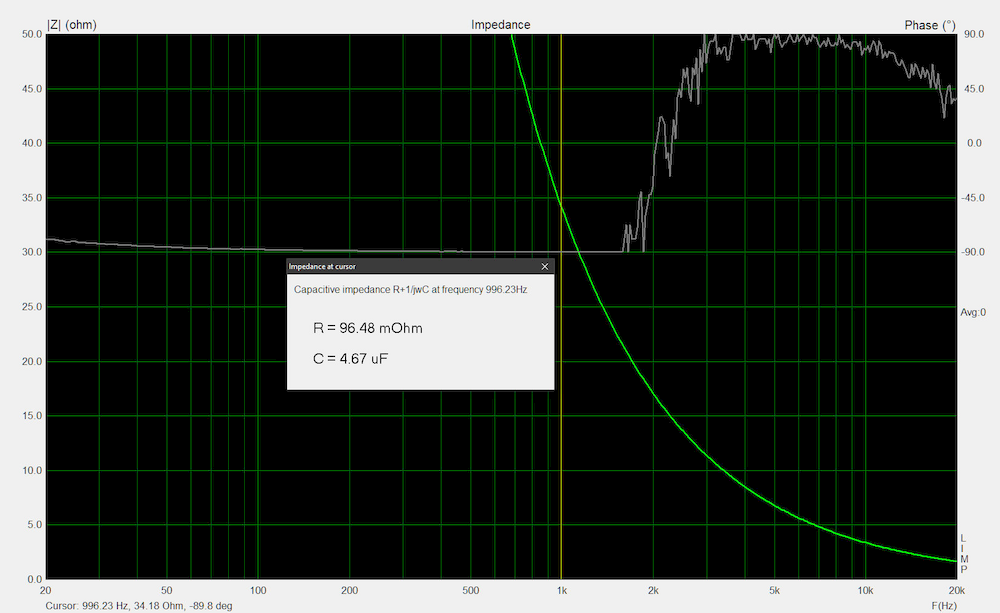

- Ero MKC 160V (polycarbonate capacitor film, high age) - The capacity is 4.67µF

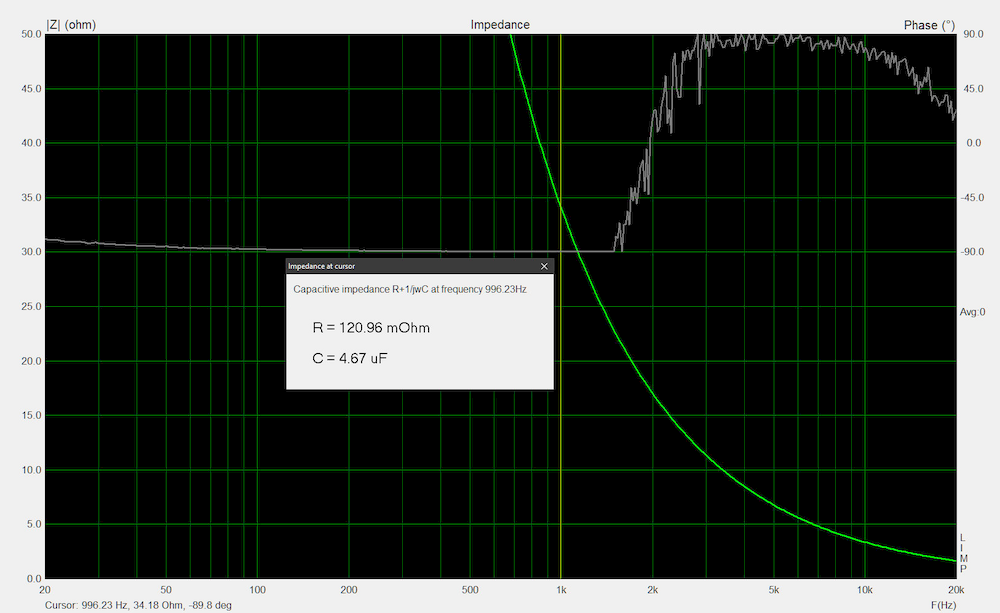

- MD-MKP 400V (Date of manufacture 05.97, manufacturer is unknown to me) - The capacity is 4.67µF (with parallel 0.56µF Jantzen Audio MKP to reach the target capacity)

The capacitors were selected to have (nearly) identical capacitance values. The maximum capacitance deviation from the silver z-cap capacitor is only 0.2% (since my measuring systems do not actually provide this measuring accuracy, a certain error tolerance should be added).

Silver Z-cap

Ero MKC

MD-MKP

But if there are large sound pressure changes, these can be completely attributed to the high-end quality of the silver-z-cap.

The Jantzen capacitor is not absurdly expensive, but it comes off very well in terms of tonal evaluation.

http://www.humblehomemadehifi.com/Cap.html

...the Janzten Silver Gold Z-cap is very detailed and sometimes too detailed for my liking, ...They do well in upgrading existing crossovers of speakers that are a bit on the laid-back side of neutral, they will pump some life and energy into such a system...

Verdict: 11-

http://www.sup-audio.com/html/high-standard.html

(quote translated)

Jantzen Silber Z-Cap: Very transparent and detailed, with emphasis on the heights with great clarity. A condenser, which conveys a high-end flair...

So the expectations are extremely high, let's see how spectacular the actual measurements turn out in the battle of the up to 23 years old capacitors against the high-end capacitor

That's just the same measurement with three different colors displayed - isn't it?

It's not! We should take a closer look, so we normalize to the frequency response of the silver-cap capacitor. The diagram shows a 0.1dB scaling:

As no smoothing is used, the noise of the test setup disturbs us a bit, hence the display with 1/3-octave smoothing (with fixed y-axis labels):

There are minimal deviations between the curves, but with a maximum of 0.03dB these are so small that it is hardly worth mentioning.

Result: There is practically no measurable acoustic difference between the simple, ancient film capacitors and the current high-end capacitor. Welcome to reality!

This clearly shows that the characteristics of the high-end capacitor cited above, such as "very transparent" or "very detailed" compared to other film capacitors, are pure fantasies of ambitious authors.

To anticipate a few possible questions and criticisms:

1) Only the frequency responses of the capacitors on the tweeter were compared, the actual differences are certainly in the time-domain!

The measurement of a single driver can be considered a minimum phase system. In this case, the phase corresponds to the minimum phase and can therefore be derived directly from the frequency response. Both together contain all the information necessary to calculate the impulse response, for example.

(Please correct me if there is something wrong with the statement)

Therefore for all doubters the measured comparison of the impulse response of Silver z-cap and the Ero-MKC

2) The difference will certainly be reflected in the decay behavior of the tweeter!

Let's have a look at the transient response of the tweeter with the Silver Z-cap, Ero MKC and the MD-MKP

Within the scope of our measuring accuracy these are completely identical.

3) The difference in quality can be seen in the distortion behavior of complex signals!

For this purpose we look at the measured multi-tone distortions of the individual capacitors in the signal path of the tweeter. The multitone distortions include the harmonic distortions and the intermodulation distortions.

There too, no difference at all can be detected.

Update 2022-03-23: Added full mini series links

Update 2023-10-19: Fixed some y-axis labels

Last edited: