I think the surface area is nice but it is not a lot of mass. I use a lot of GPUs for computation/mining and I almost bought these for some of mine. I don't think they are that much better than a regular GPU backplate when used alone, most people were buying these mainly because they also have convenient holes for attaching fans which is what is dissipating most of the heat. So I think for an amp it is better to mount the PCB it directly to chassis (or with a cheap aluminium plate in between) with some TIM (pad or paste) in between. I think NC252MP already comes with an alu plate, does it not?Hi. I am planning on building a 6 Ch AMP (I already have 3 module nc252mp but I will probably only use 2 + something else because the nc252mp is overkill for tweeters). Regarding thermal dissipation do you think this kind of copper plate (for GPU) could be useful or its a waste of money (30 euros each with 5mm thickness) ?

-

WANTED: Happy members who like to discuss audio and other topics related to our interest. Desire to learn and share knowledge of science required. There are many reviews of audio hardware and expert members to help answer your questions. Click here to have your audio equipment measured for free!

- Forums

- Audio, Audio, Audio!

- Amplifiers, Phono preamp, and Analog Audio Review

- Stereo and Multichannel Amplifier Reviews

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

PMA-NC252MP power amplifier

- Thread starter pma

- Start date

Thx for your experience. Yes the module already have an alu plate. I was thinking on the 3 solutions:

1) mount nc252mp directly to chassis (like everybody)

2) mount nc252mp alu plate with the GPU plate with a very thin layer of paste and cut a square on the bottom of chassis (passive ventilation of the copper plate)

3) buy a chassis with dissipation side and mount the module on it (like this thread) buy you need a thick chassis

Maybe I am overthinking but I want to maximum the lifetime of my future system and 60 euros is ok for me for a 10 years mini system

1) mount nc252mp directly to chassis (like everybody)

2) mount nc252mp alu plate with the GPU plate with a very thin layer of paste and cut a square on the bottom of chassis (passive ventilation of the copper plate)

3) buy a chassis with dissipation side and mount the module on it (like this thread) buy you need a thick chassis

Maybe I am overthinking but I want to maximum the lifetime of my future system and 60 euros is ok for me for a 10 years mini system

DSJR

Major Contributor

Nah - you're over-thinking it sirI do not like the 8ohm resistive test at all because no real speaker makes such light load, because of its complex impedance. And if we go to EPDR, equivalent peak dissipation resistance, then even the speakers that seem to have reasonable magnitude curve fall below 3 ohm. The 8 ohm resistor test is IMO good only to make nice plots, and this is really not my intention. The DUT has to be pushed to the limits.

My vibe going back to the late 60's when I bought HiFi mags with my pocket money, is that the main power rating to take notice of in the company of its peers is the 8 ohm one. Yes today, I do agree that most speakers are more like 4 - 6 ohms nominal and some with nasty dips below that, but when I'm looking at specs of say, these Hypex moards, or the latest whiz-bang desktop miniature with excellent general performance, I myself anyway, like to see the 8 ohm rating followed by how much extra is available into a 4 ohm load (I remember being shocked how some of the now vintage US high end behemoths doubled their power from 8 to 4 to 2 ohms and some even managed not to melt into 1 ohm as presented by certain panel speakers back then. Next to see how the distortion changes into evermore cruel loads and out put levels.

That's my excuse and I'm sticking to it

Anyway, please keep doing what you're doing, 'cos I and others find it fascinating

- Thread Starter

- #64

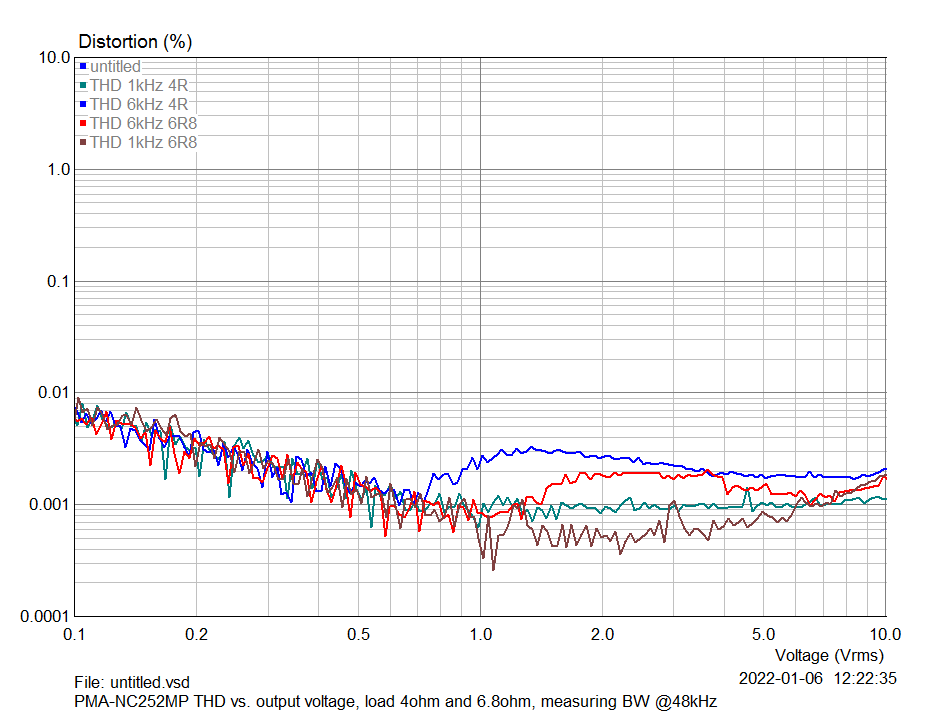

I think this measurement might be quite interesting. It is a THD plot vs. amplifier output voltage, at 1kHz and 6kHz, into 4ohm and 6.8ohm load resistors. It shows how the THD distortion (not THD+N) evolves with amplitude, frequency and load. Especially the 6kHz plots are interesting. Measuring bandwidth is 48kHz. BTW, 10V makes 25W/4ohm and 14.7W/6.8ohm. P = V^2/R.

I think this measurement might be quite interesting. It is a THD plot vs. amplifier output voltage, at 1kHz and 6kHz, into 4ohm and 6.8ohm load resistors. It shows how the THD distortion (not THD+N) evolves with amplitude, frequency and load. Especially the 6kHz plots are interesting. Measuring bandwidth is 48kHz. BTW, 10V makes 25W/4ohm and 14.7W/6.8ohm. P = V^2/R.

View attachment 177253

Yes it is interesting but nothing bad.

Amen! and Amen! Brings to mind the first automotive Class D, the diminutive WOW SO SMALL chassis...which got really hot...and I heard from my coworker who had taken a job there generated a lot of warranty returns.a temptation for most assemblers to use quite small amplifier case with not much heatsinking capability. This make a benefit of smaller size and weight, however the power capabilities of the Hypex modules are not completely utilized and reliability and life span may suffer.

- Thread Starter

- #67

Measuring this amp has been a challenge to me. Unfortunately, my soundcards are not good enough to do the job and they deteriorate the amp's distortion parameters. This amp has really very low distortion.

Last edited:

I see no use reason for a smaller unit that makes enough heat to be detrimental to the amp & my A/C bill. If a smaller (fan-less) case can be made that runs at the same temp as a normal large case (which would likely be an in-between case), then I can see the appeal of a smaller case. But, IMHO, never if internal heat goes up.Thank you, I think if you read this thread you would understand why the case is "big" with big heatsinks. I want to run it at lowest temperature under any possible conditions like long-term full power. I do not want the module to be limited at 1/5 maximum power in a longer run. The module itself has idle power consumption of 15.5W (you may check in the datasheet, 8.5W SMPS, and 3.5W per amp channel). If I use the heatsink with thermal resistance of 0.4°C/W, the temperature increase at idle is +6.2°C. If you use a conventional implementation with the module mounted on sheet metal, the thermal resistance can be estimated from (and is likely several °C/W).

Flat Plate Heat Sink Calculator

The free flat plate heat sink calculator is a tool for calculating the perfomance a heat sink formed from a flat sheet of metal cool via natural convection and radiationwww.heatsinkcalculator.com

and the temperature will be increased much much more. The second reason is that the the 19" wide case fits to my audio components. A small box does not. I have no need to use small boxes and to reduce life span and product reliability. However I know - who cares.

So this is my design philosophy, I do not care about miniaturization at expense of reliability.

I know you're not selling commercially yet, but my man if you do, please ground that case.

Otherwise, nice work

You can have power but the expense is reliability (and perhaps some other things). Or you can have power & reliability at the added expense of heat sinks & weight. You may not always get what you pay for but you definitely will not get what you don't pay for. If you are unwilling to pay for the heat sinks and their weight, then your reliability will be suspect. That is something that I see in many things these days. A short time & off to the land fill it goes to be replaced by something else cheap that will do the same thing, pass through one's house hold on it's way to the land fill. Costing one time & money repetitively.Wow with all this heatsinks the cost is going to quite high, both product + shipping.

How long does it last running full power?

- Thread Starter

- #72

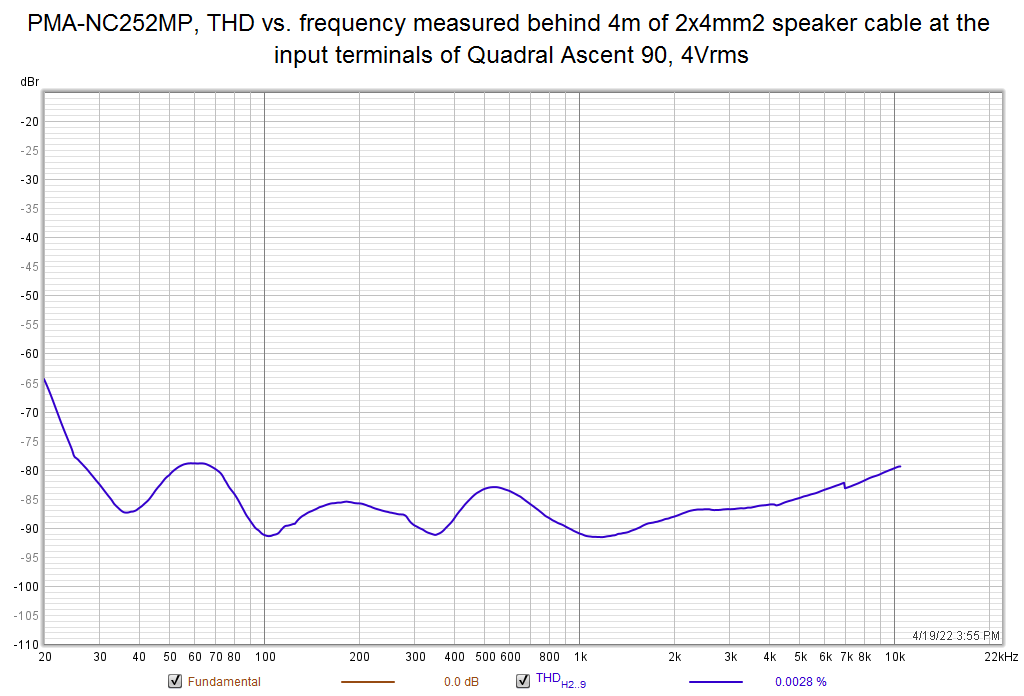

A real REAL WORLD measurement, THD vs. frequency measured behind the 4m of 2x4mm^2 speaker cable, at the Quadral Ascent 90 speaker input terminals. Voltage level is 4Vrms. It covers the whole chain, the DAC, preamp, power amp, cable and speaker. See the modulation due to finite cable impedance. It is not a sterile single component lab measurement with a resistor load.

maty

Major Contributor

Maybe same measurements with a good class AB amplifier to compare...

- Thread Starter

- #74

Yes I have them in my archive. This is as good as my best class AB amps, and maybe better at very low frequencies. It is all the cable impedance divider effect + speaker nonlinearity resulting in nonlinear speaker current.Maybe same measurements with a good class AB amplifier to compare...

There is also extremely low modulation of frequency response by the speaker impedance, again just because of the cable impedance. Cables do make a measurable difference, according to their length and cross section area.

May I ask what is that copper colored thing on the bigger smps transformer?I shorten the cable to the XLR inputs ) BTW, these cables are shielded.

I did not measure it but compared it to the Audiophonics model, and this one is absolutely dead silence, even with your ears glued to the speakers.

I did not want to hurt you, your amp is fantastic too ) Thanks for your explanation !

here my NC252MP version

Vuki

Senior Member

Measures better with Cosmos ADC

- Thread Starter

- #78

Yes, I could not measure below 0.001% reliably enough before. Topping D10s/Cosmos combo has harmonic distortion components at or below -130dBr.Measures better with Cosmos ADC

- Thread Starter

- #79

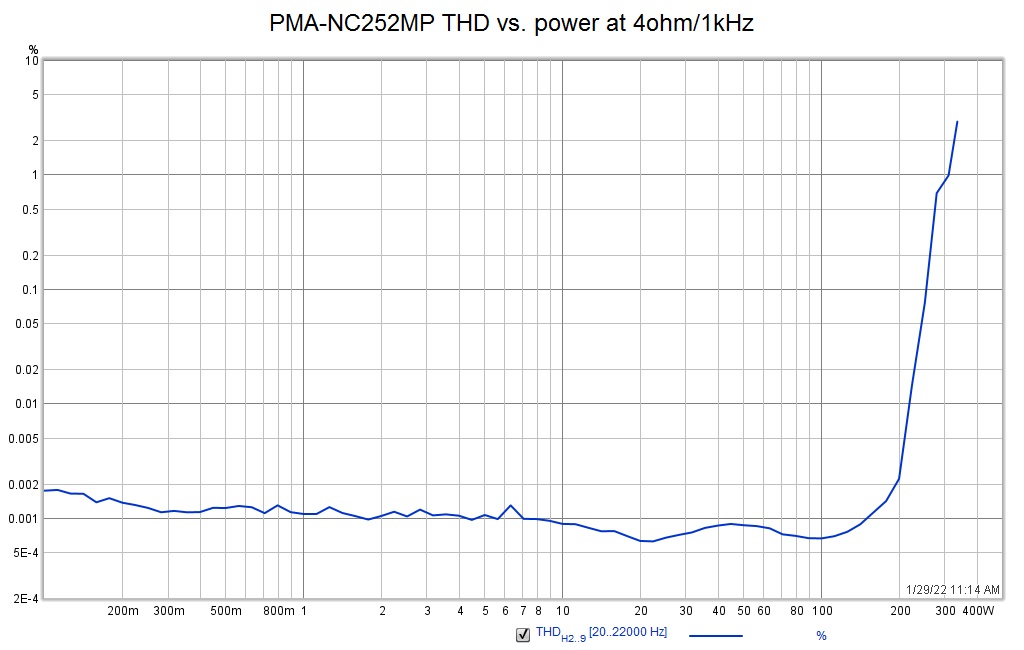

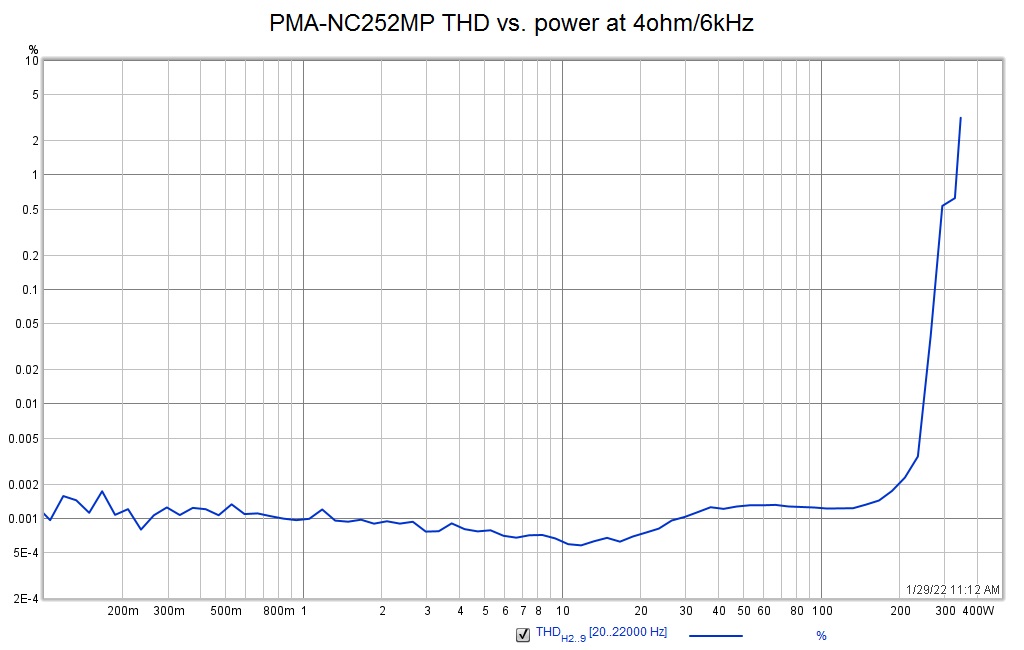

Now, a few measurements that are "not so nice"

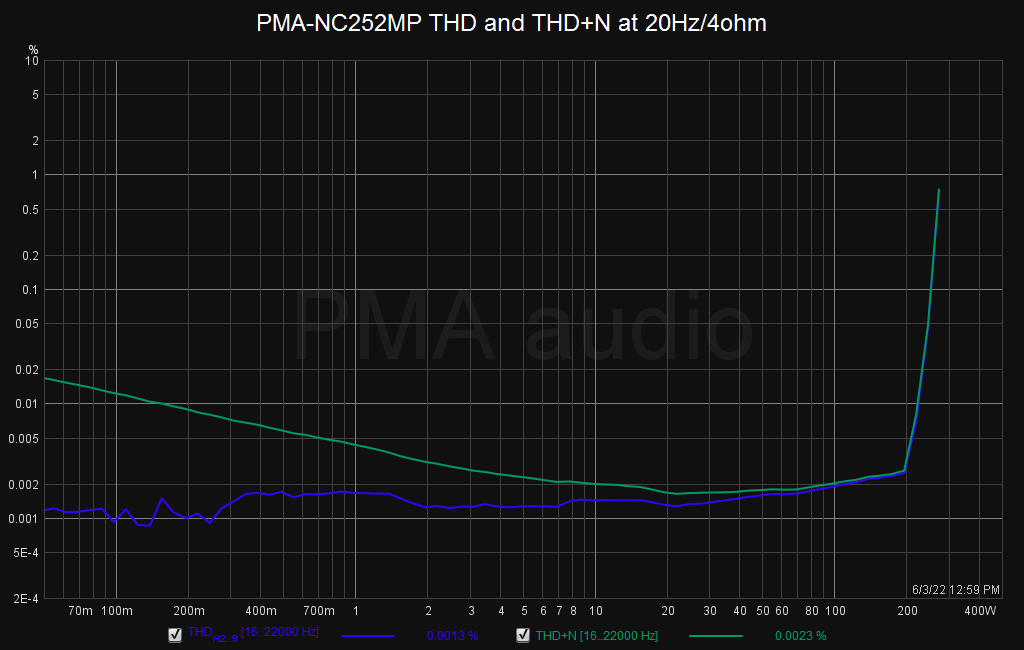

First, THD and THD+N vs. power at 20Hz/4ohm. We can see that clean power is reduced to 200W/4ohm and this remains up to 100Hyz.

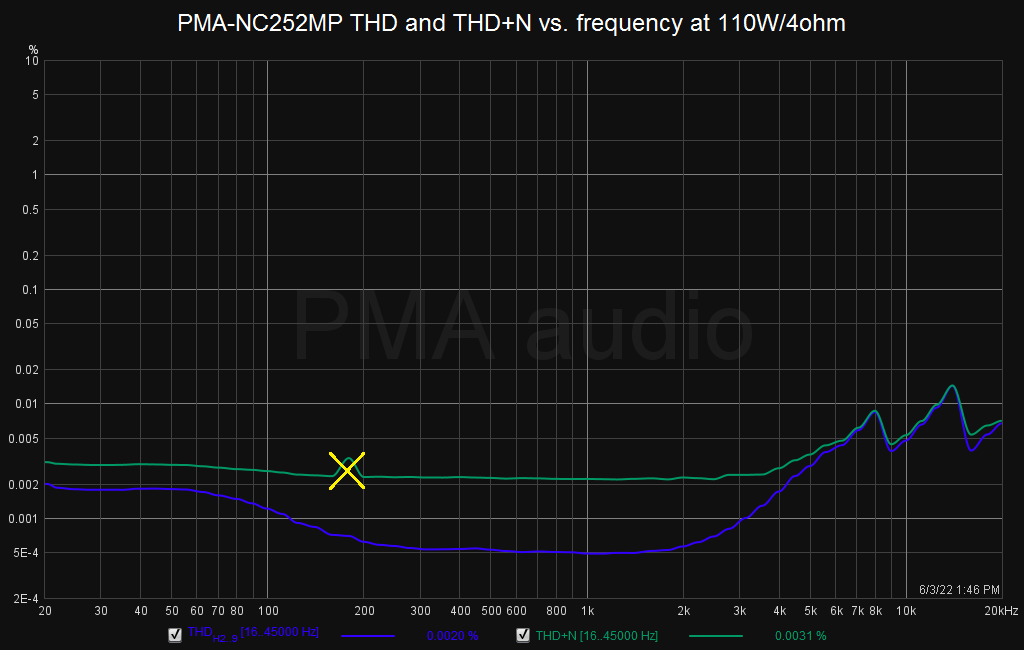

2nd, something that the class D designers and reviewers "forgot" to tell you. We can see it from the THD and THD+N measurement below, taken at 110W/4ohm.

The mere and usual THD+N does not tell the story, but THD does. This amplifier is optimized between 200Hz - 2kHz, in other words, to measure nicely at 1kHz. Below 200Hz we can see THD rising, because of the SMPS residuals and worse function at low frequency load currents. Above 2kHz the measurement with @45kHz BW shows rise of THD and later THD+N, this is because the ultrasound noise components above 22kHz play their game in THD and THD+N calculations. Observing the spectrum during measurements it reminds to a DSD spectrum, which is no surprise. (yellow cross is a measuring error, I did not want to repeat the measurement and wait another 5 minutes or so)

So, still not as a good as a very good linear amplifier.

First, THD and THD+N vs. power at 20Hz/4ohm. We can see that clean power is reduced to 200W/4ohm and this remains up to 100Hyz.

2nd, something that the class D designers and reviewers "forgot" to tell you. We can see it from the THD and THD+N measurement below, taken at 110W/4ohm.

The mere and usual THD+N does not tell the story, but THD does. This amplifier is optimized between 200Hz - 2kHz, in other words, to measure nicely at 1kHz. Below 200Hz we can see THD rising, because of the SMPS residuals and worse function at low frequency load currents. Above 2kHz the measurement with @45kHz BW shows rise of THD and later THD+N, this is because the ultrasound noise components above 22kHz play their game in THD and THD+N calculations. Observing the spectrum during measurements it reminds to a DSD spectrum, which is no surprise. (yellow cross is a measuring error, I did not want to repeat the measurement and wait another 5 minutes or so)

So, still not as a good as a very good linear amplifier.

- Thread Starter

- #80

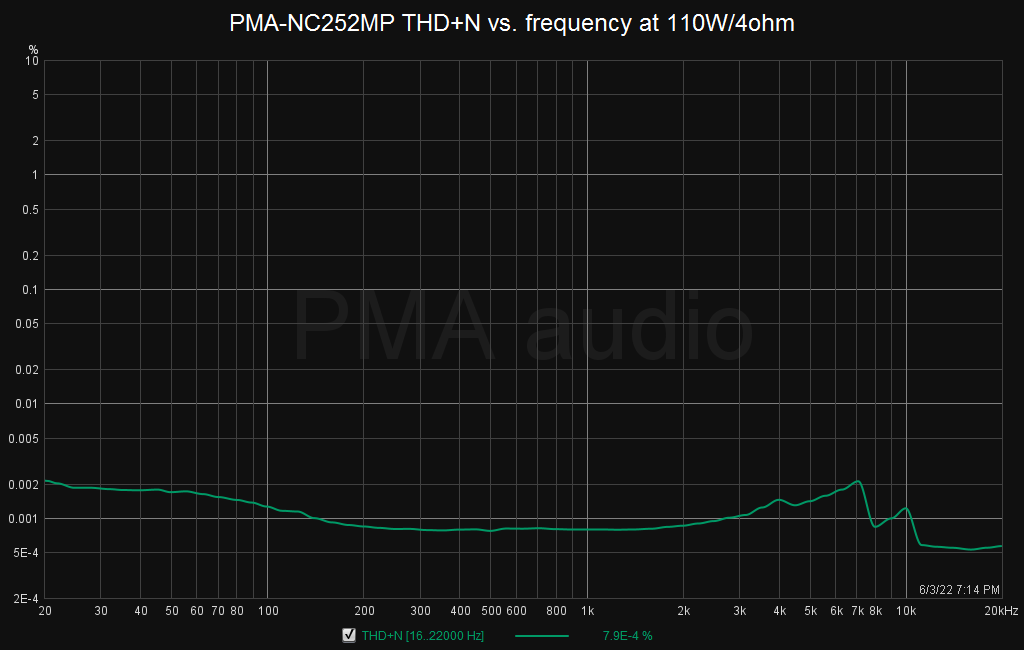

And this is the way to do the marketing "trick" to get the nice datasheet plot. You will limit the measuring bandwidth to 22kHz - which is absolutely pointless, as now we can see 3rd harmonic of no more than 7kHz base frequency. And you show only THD+N (or SINAD, as you like it) extended to 20kHz. No problem that it shows no distortion above 10kHz, only and only noise. And, the noise with 22kHz BW as a miracle falls 3-4 x lower, of about 10-12dB. The goal was achieved, usual parameters were changed and tailored to the new technology, that was somehow unable to compete under usual standard test conditions. Datasheets will have nice plots and the marketing dept. will be satisfied, as well as the common customers. Now find a platform to support it and you are done.

Similar threads

- Poll

- Replies

- 482

- Views

- 81K

- Replies

- 12

- Views

- 2K

- Poll

- Replies

- 389

- Views

- 78K

- Poll

- Replies

- 649

- Views

- 143K

- Replies

- 354

- Views

- 72K