- Joined

- Nov 16, 2021

- Messages

- 163

- Likes

- 788

I certainly respect what genelec is doing and there is a lot to admire about their approach and implementation but, as you mentioned, the high end hifi market is a bit different than the studio/pro/home theater market and a compact, highly integrated active speaker (even if we could pull all that off well) isn't the solution that most of our customers are looking for in a main system (maybe in secondary rooms/homes etc.).Apologies for mischaracterizing your design process. I think it is fair to say you have a different design approach than say, Genelec, which reflects the market you are trying to break into.

Did you ever consider loading the planar mid in an open back transmission line?

As far as transmission lines go, that's not a big area of expertise for me. In particular, planar drivers don't adhere to the T/S parameter model and I don't know of a transmission line model software that could accommodate them (though maybe Akabak and something of that nature). Our planars are primarily damped around resonance via acoustically resistive cloth sheets very close to the diaphragm. In general, they are very sensitive to the type and proximity of damping materials and reflections/changes in loading.

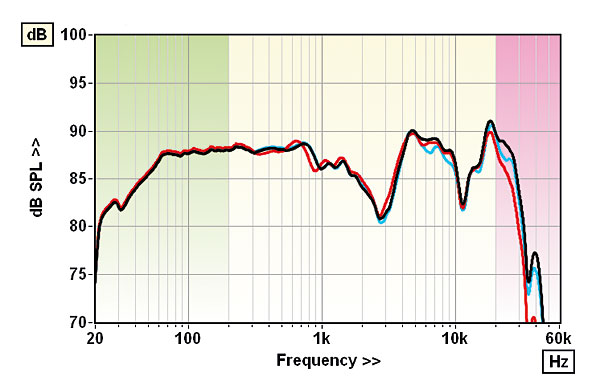

As they stand, there is a gradual, overdamped roll-off and rising in the upper midrange (from the low inductance and narrowing directivity raising the axial response) and we are using sealed chambers behind the driver for loading and boosting them in the lower midrange to flatten them out and extend the usable range/efficiency where it matters.

On our new, smaller planar mid, we ended up with a 90 mm deep tapered back chamber with a combination of wool/polyester felt and a dupont twaron fiber damping to get flat response down to about 400 Hz.