Jopldangla

Member

- Joined

- Aug 27, 2023

- Messages

- 21

- Likes

- 10

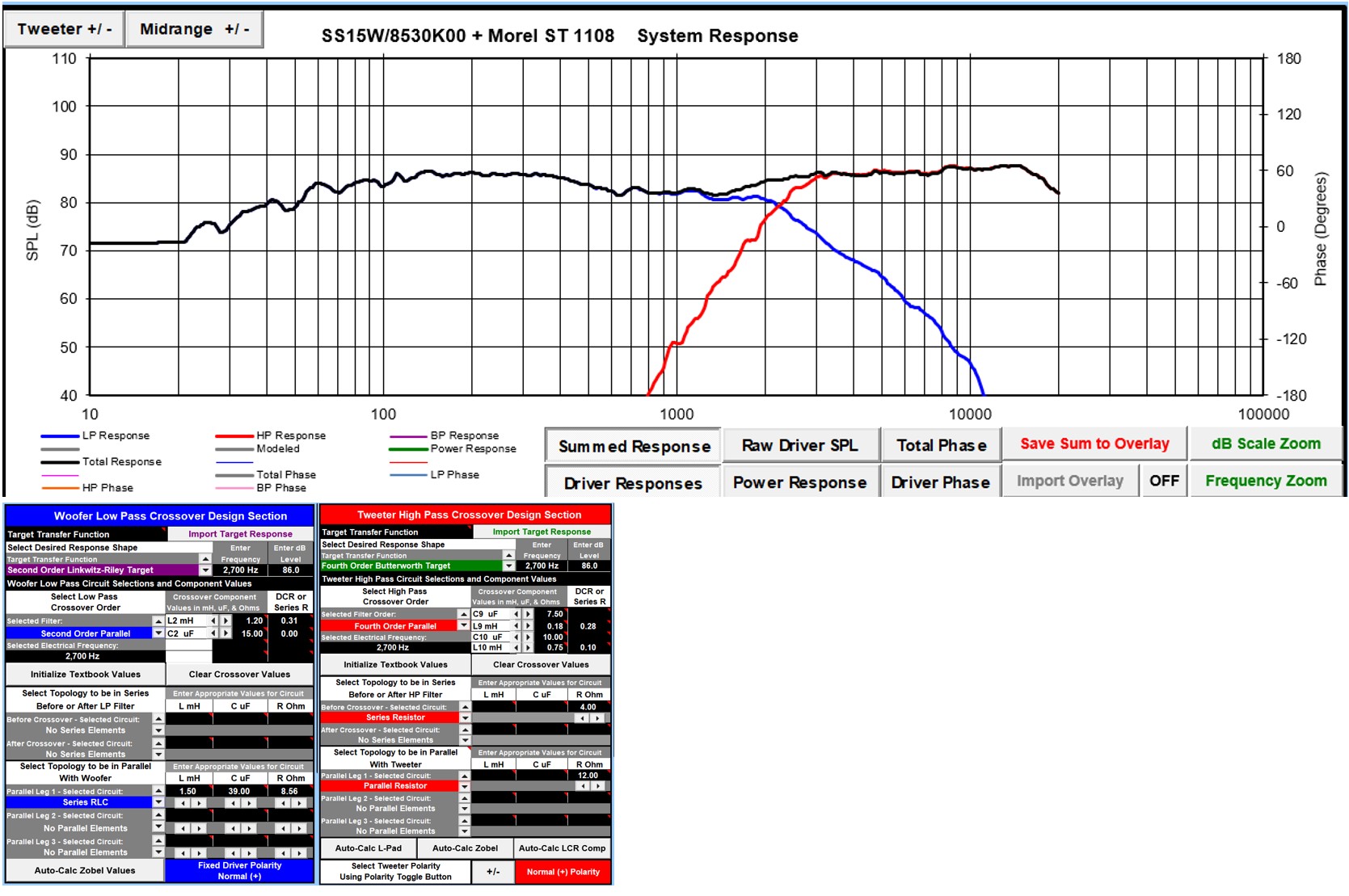

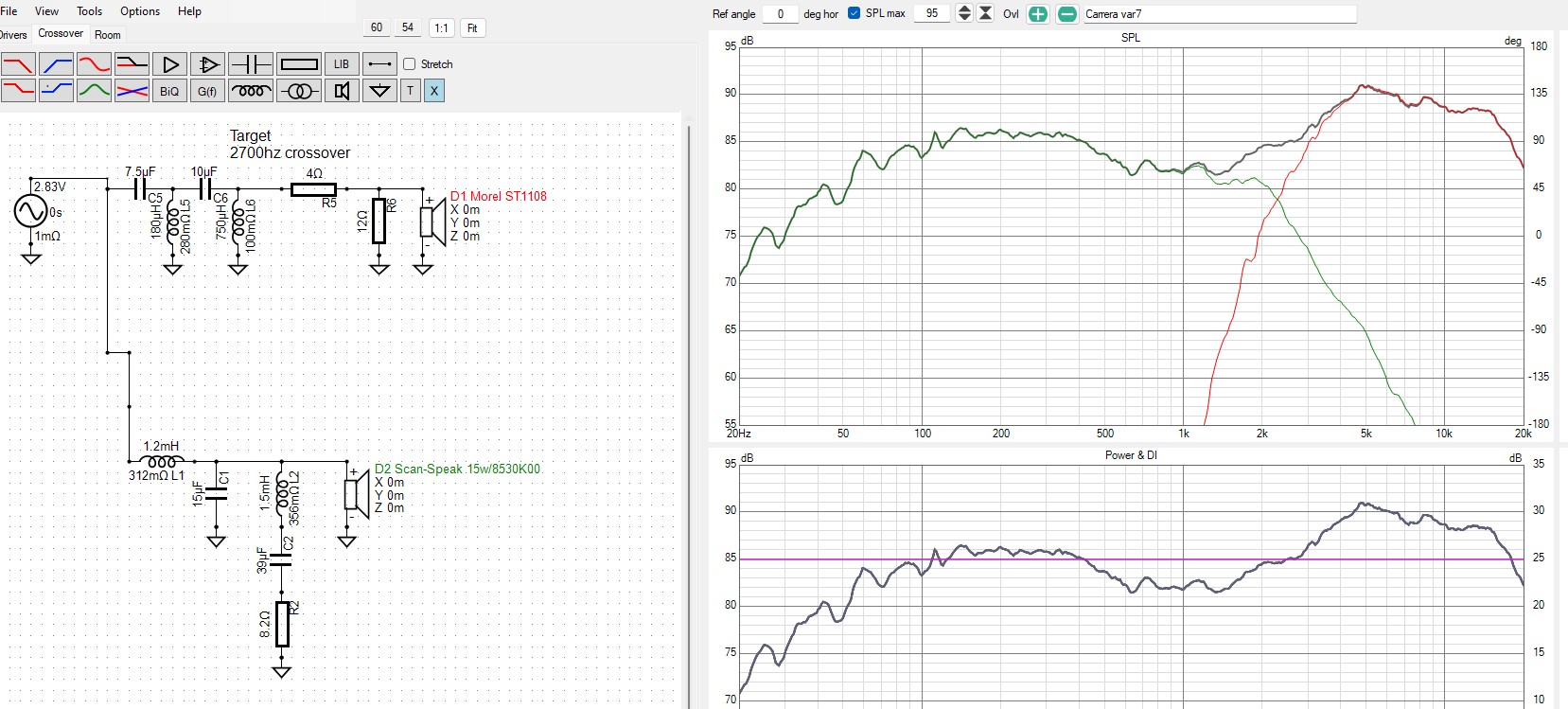

I am working on a x-over design for the Revel105 copy, however I am using the Scanspeak 15W/8530K00 and Morel ST1108 supreme tweeters. I am going to mount the Morels in a waveguide as well, by using some of the guidelines from the huge waveguide thread I found on the internet somewhere

Supreme ST1108 datasheet

15W/8530K00 datasheet

I used tracing tools to create ZMA and FRD files from the datasheets, these files were imported both into the VituixCAD software and Passive Crossover Designer 8.0

I will use roughly the same cabinet design and port sizing.

Here are my results from both tools....I am having trouble figuring out why they don't match. I used the same crossover values from the Revel105 copy build for the scanspeak and matched the crossover frequency for the tweeter but used a higher order filter. I also needed to add an L-Pad to drop the sensitivity of the Morel to match closer to the Scanspeak.

I really appreciate any tips from more experienced folks. I haven't been able to find much information on the Morel ST1108 tweeter online (maybe nobody is using it).

Passive designer followed by VituixCAD

Supreme ST1108 datasheet

15W/8530K00 datasheet

I used tracing tools to create ZMA and FRD files from the datasheets, these files were imported both into the VituixCAD software and Passive Crossover Designer 8.0

I will use roughly the same cabinet design and port sizing.

Here are my results from both tools....I am having trouble figuring out why they don't match. I used the same crossover values from the Revel105 copy build for the scanspeak and matched the crossover frequency for the tweeter but used a higher order filter. I also needed to add an L-Pad to drop the sensitivity of the Morel to match closer to the Scanspeak.

I really appreciate any tips from more experienced folks. I haven't been able to find much information on the Morel ST1108 tweeter online (maybe nobody is using it).

Passive designer followed by VituixCAD