Here is the second part on the topic "Capacitor upgrade in crossover - Is it audible?

This time it is exclusively about the measurable differences of electrolytic capacitors with film capacitors in crossovers of loudspeakers.

The first part about film capacitors can be found here and who likes can read about the measurable differences between sand-cast and low-inductance resistors here.

The third and final part on this topic: Capacitor upgrade in crossover - You Can't Handle the Truth - part-3

The full mini series:

Capacitor upgrade in crossover - Is it audible?

Capacitor upgrade - part two

Capacitor upgrade - part three

Replace resistor by low-inductance resistor - Is it audible?

Different Binding Posts - is it audible?

Audible difference in high-end capacitors? - ABX samples

The test method and test setup were described in detail in the first part. If you're not familiar with what a capacitor (in series with the driver) does, you can read this in part one either - I'm too lazy to repeat all this.

As in part 1, the capacitor is connected in series to the chassis and then measured in the near field.

With almost the same capacitance of the capacitors, the deviations then measured are solely due to the different design/type of the capacitors or of minimal deviation in capacity - there is also a section on this in Part 1.

Electrolytic capacitor versus film capacitor

To obtain more certainty about the accuracy of the measurements, comparisons were made with three different capacitance values - 8.2µF, 47µF and 100µF.

High capacities in series to the driver are mostly used in the mid-range crossover. Therefore the measurement for 100µF was carried out with a mid-range driver.

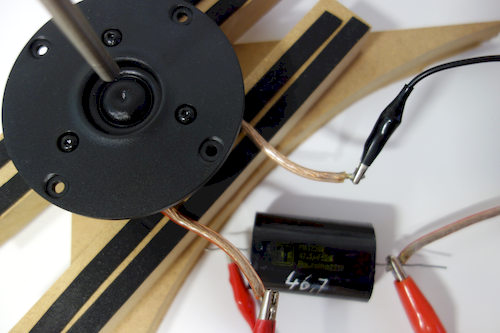

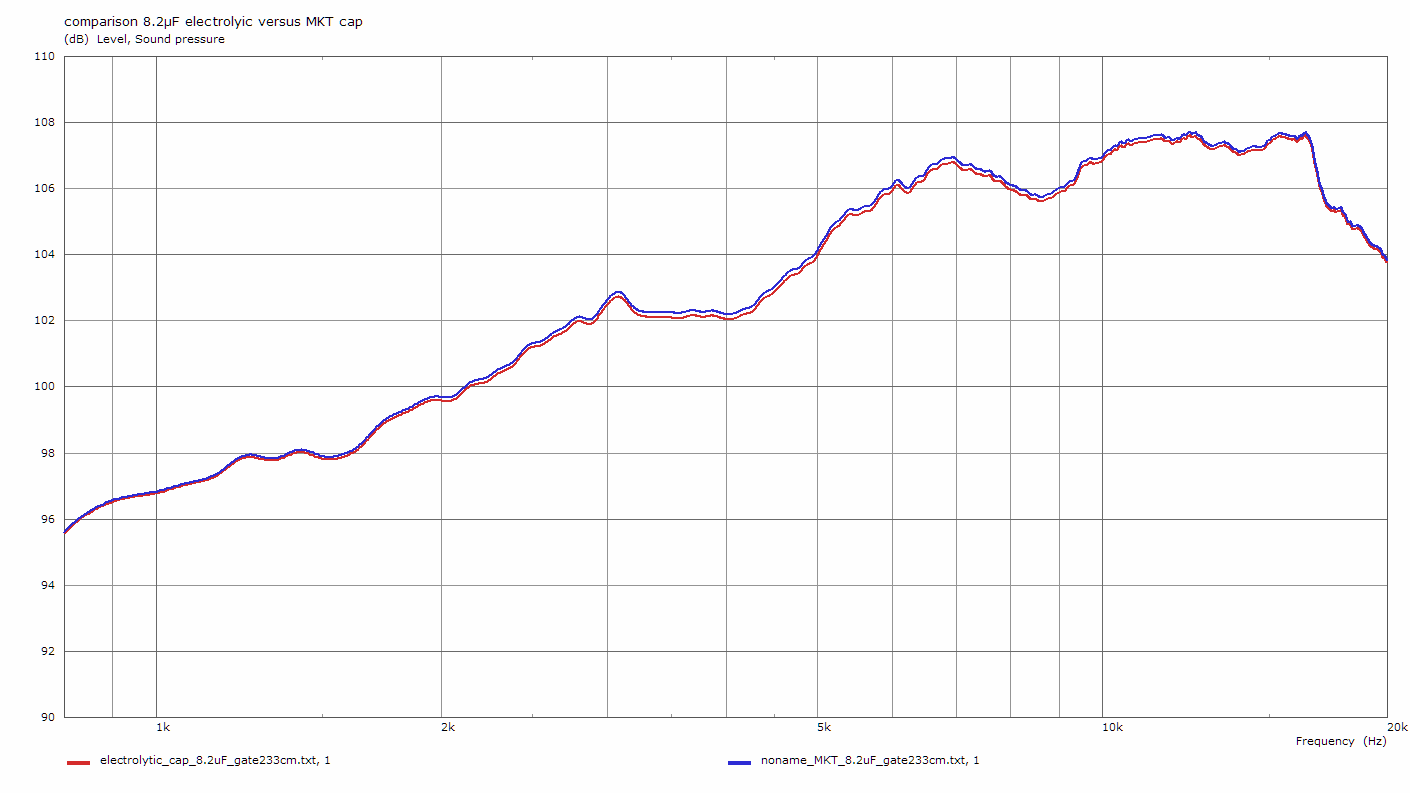

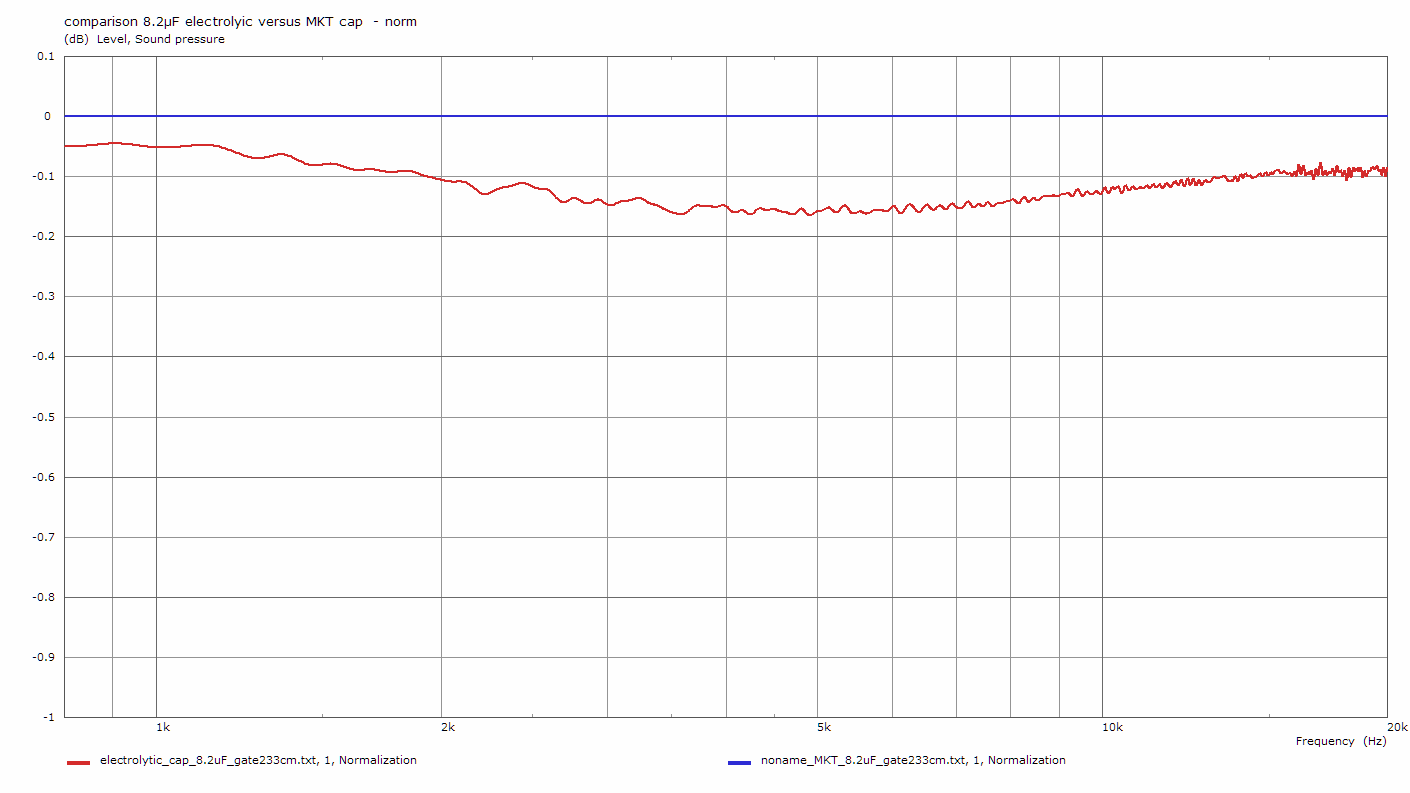

a) Comparison with 8.2µF capacity

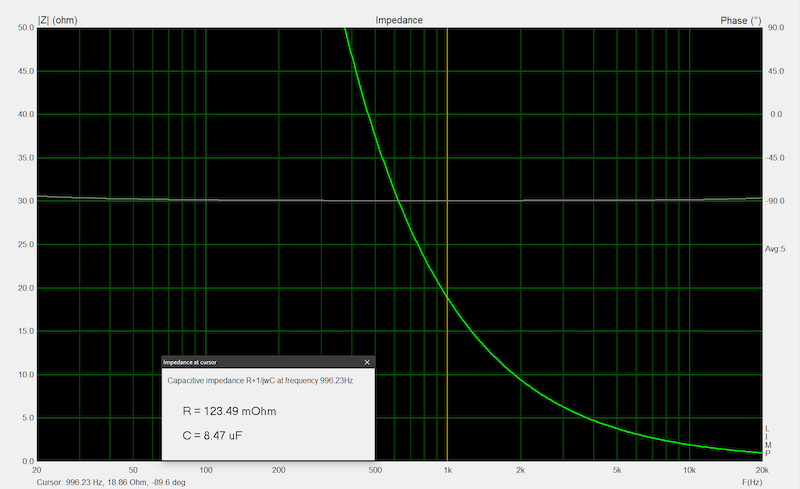

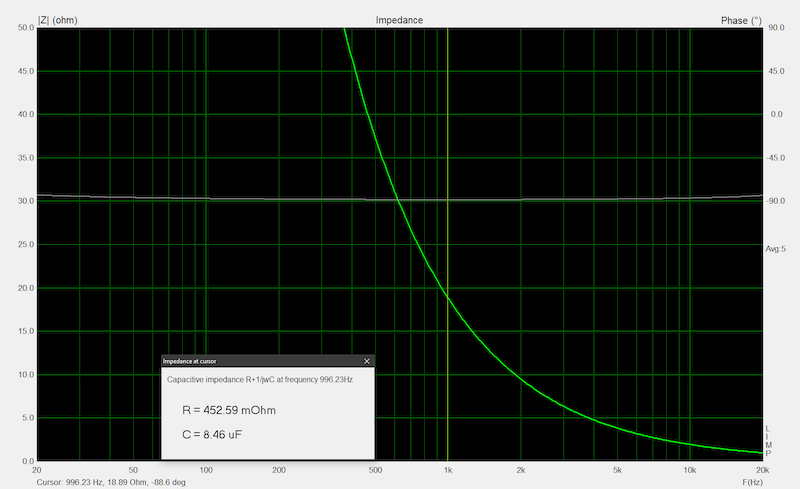

The film capacitor has a capacitance of 8.47µF, the electrolytic capacitor one of 8.46µF. The deviation of the capacitors from each other is therefore only 0.1%. According to the investigations of capacitors with low capacitance deviations made in part 1, the measured deviation should be only minimal.

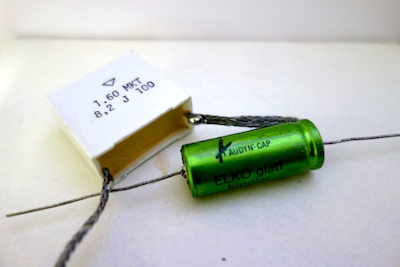

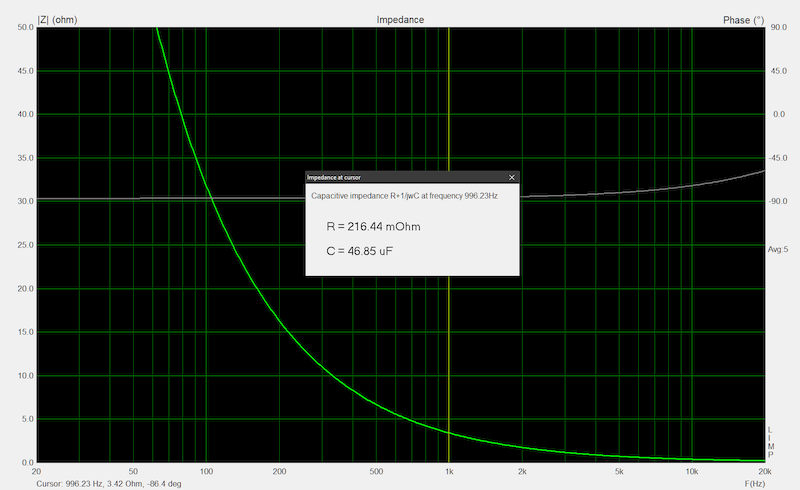

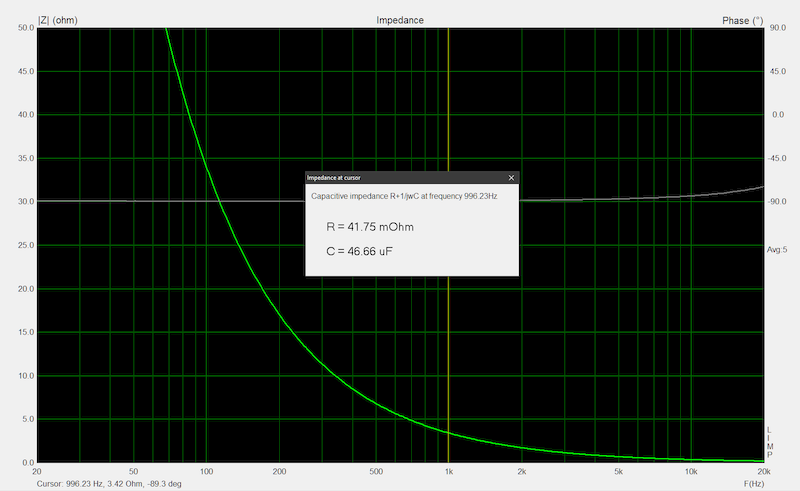

noname MKT

Audyn-Cap electrolytic capacitor

It is easy to see that the resistive part of the electrolytic capacitor is four times as high as that of the film capacitor.

Let's take a look at the frequency response measurements.

A very small difference can be seen. To be able to see the difference better, the diagram is normalized to the frequency response of the MKT capacitor and displayed with a scaling of 0.1dB.

The deviation of the electrolytic capacitor is greater than we would expect due to the small difference in capacitance - for the effects of minimal capacitance deviations see part 1.

Even at high frequencies the deviation is still almost 0.1dB. Between 3 - 6kHz the deviation isalmost about 0.15dB.

Here, the high ESR of the electrolytic capacitor has a clear effect on the frequency response of the tweeter.

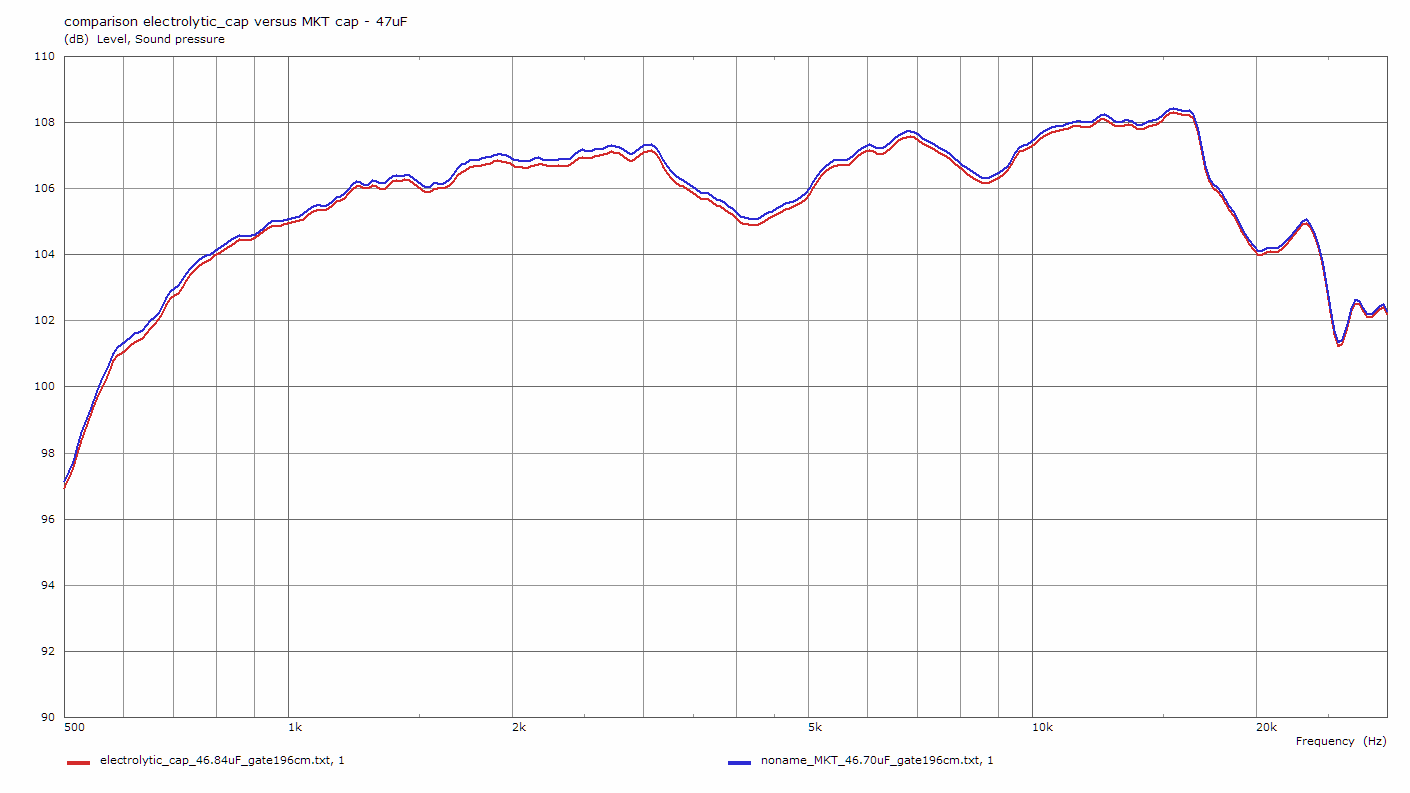

b) Comparison with 47µF capacity

The MKT 250V film capacitor has a capacity of 46.7µF, the electrolytic capacitor with 100V dielectric strength has a capacity of 46.9µF.

The capacitance deviation is therefore about 0.4%.

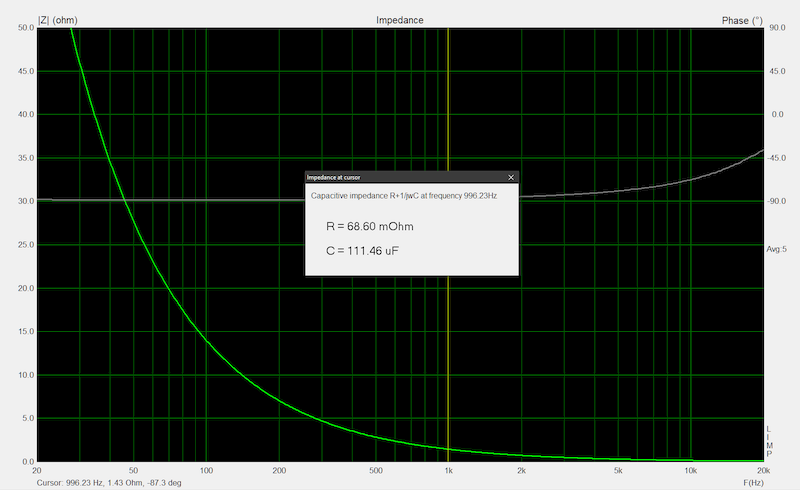

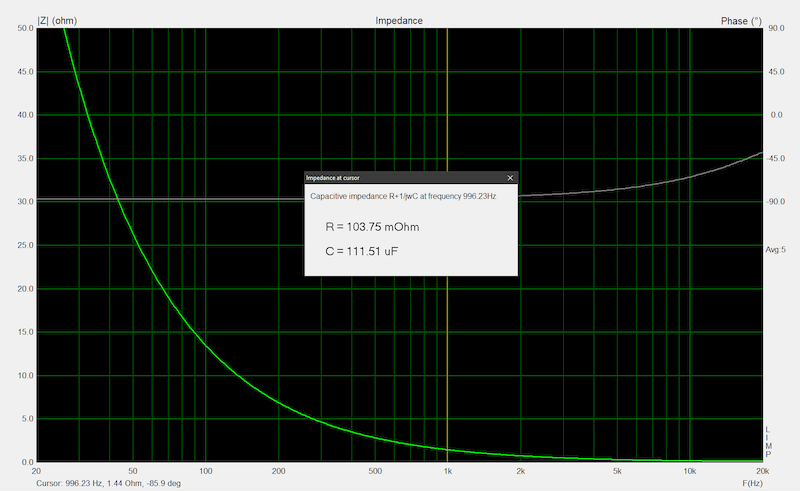

electrolytic capacitor

noname MKT film capacitor

The resistive part of the electrolytic capacitor is five times as high as that of the film capacitor.

Due to the differences in capacitance, one would expect that measured frequency response of the electrolytic capacitor would be slightly above that of the film capacitor. However, due to the high ESR of the electrolytic capacitor, this is not the case here either.

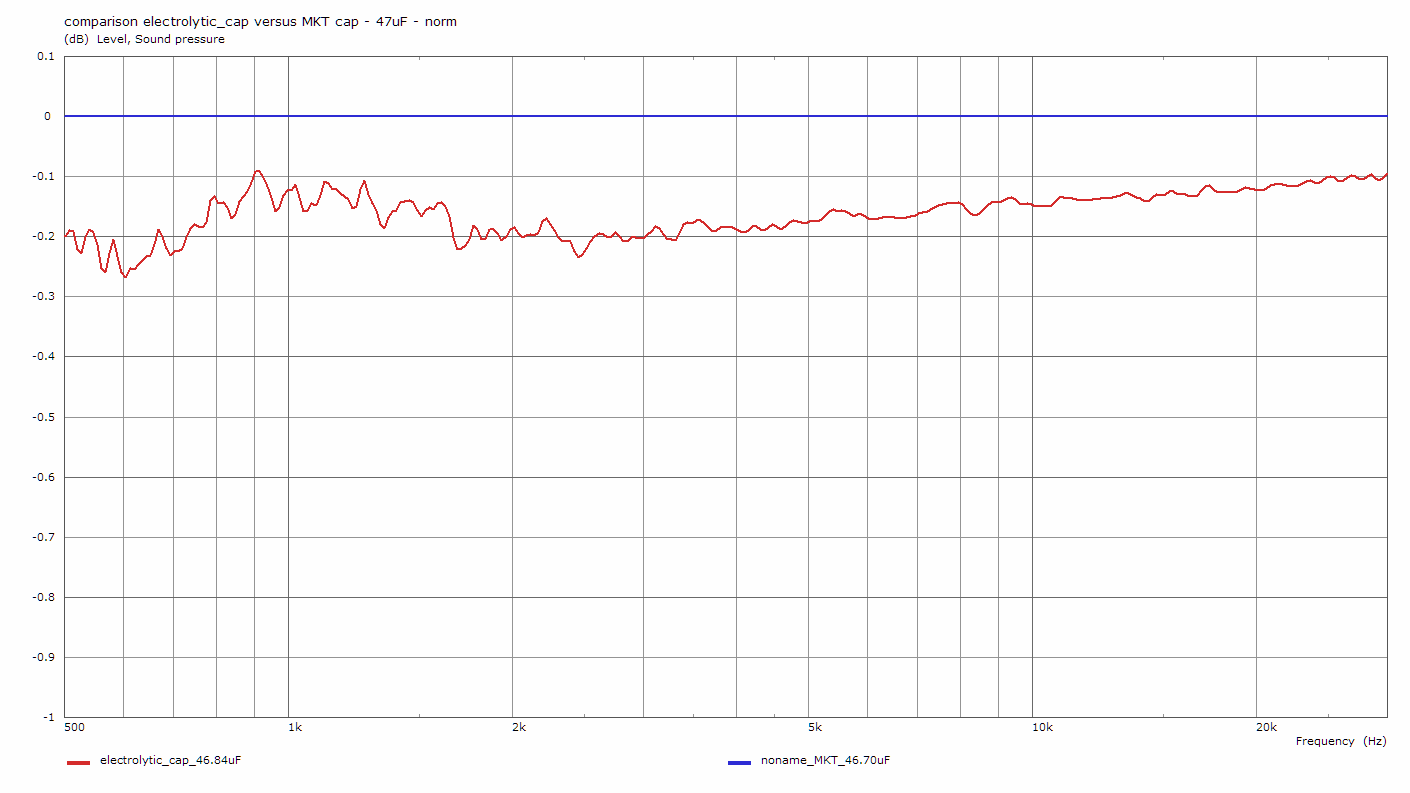

To be able to see the difference better, the diagram is normalized to the frequency response of the MKT capacitor and displayed with a scaling of 0.1dB.

Film capacitor and electrolytic capacitor behave as in the example above.

The maximum sound pressure difference in this case is 0.2dB.

c) Comparison with 100µF capacity

Here, an additional comparison of an old and a new electrolytic capacitor is to be carried out.

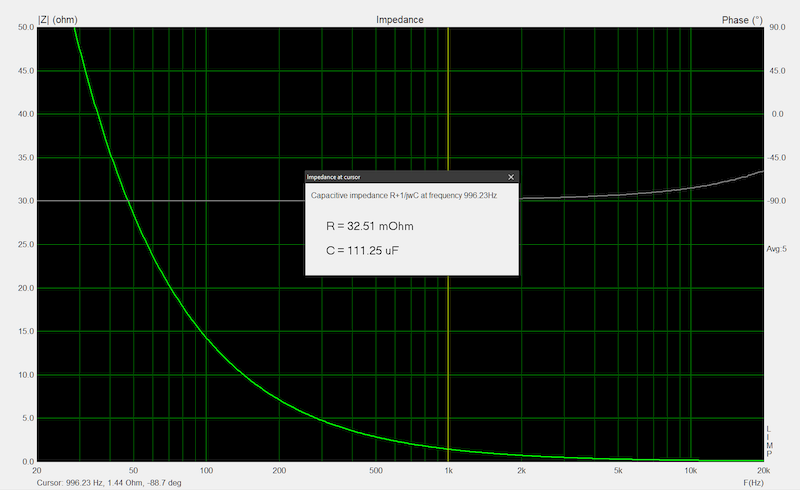

Starting point is a Visaton electrolytic capacitor from 1985 (+-3 years) with 100µF nominal capacity and +-10% tolerance. The measured capacitance of the Visaton electrolytic capacitor is about 111.5µF.

Next are two new electrolytic capacitors (100µF + 8.2µF, +-10% tolerance capacitors) which together have a capacity of 111.5µF.

Finally a combination of film capacitors (100µF + 10µF + 0.82µF, +-5% tolerance capacitors) with a total of 111.3µF.

The deviation of the capacitors compared to the film capacitor is only 0.2%.

The resistive part of the 35 year old Visaton electrolytic capacitor is only two times as high as that of the film capacitor.

The resistive part of the new electrolytic capacitor is three times as high as that of the film capacitor.

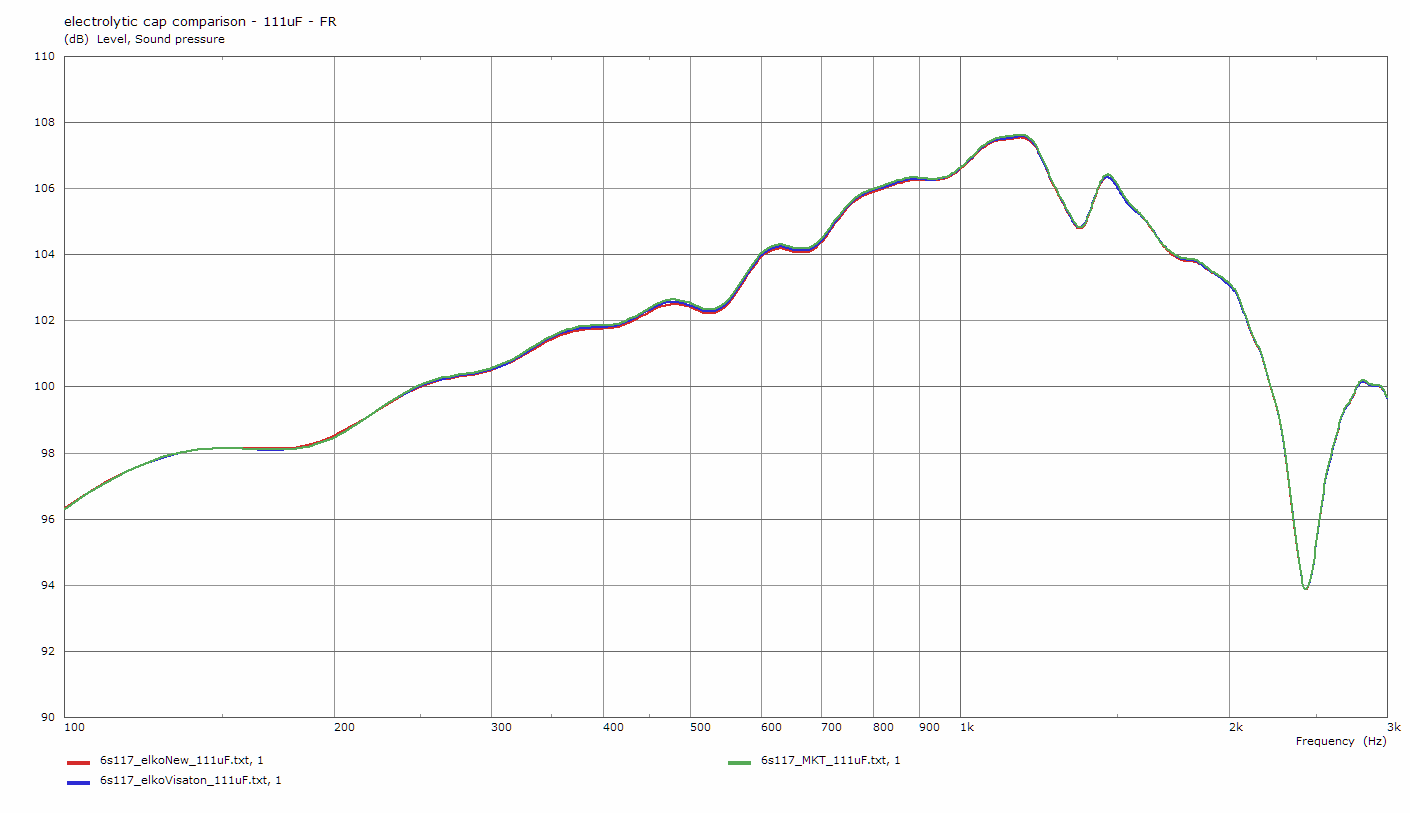

As already mentioned above, such high capacitance values in series to a chassis actually only occur with bass/midrange drivers.

For this reason, this test setup uses a midrange driver instead of a tweeter - the BMS 6S117 midrange driver. The driver was chosen because it has triple aluminum demodulating rings and therefore low distortion. This should make it easier to detect possible distortion caused by capacitors.

The rest of the test setup remains unchanged.

For the evaluation we consider the reasonable frequency range of the chassis (before cone-breakup). Therefore all frequency response diagrams consider the range 100Hz to 3kHz.

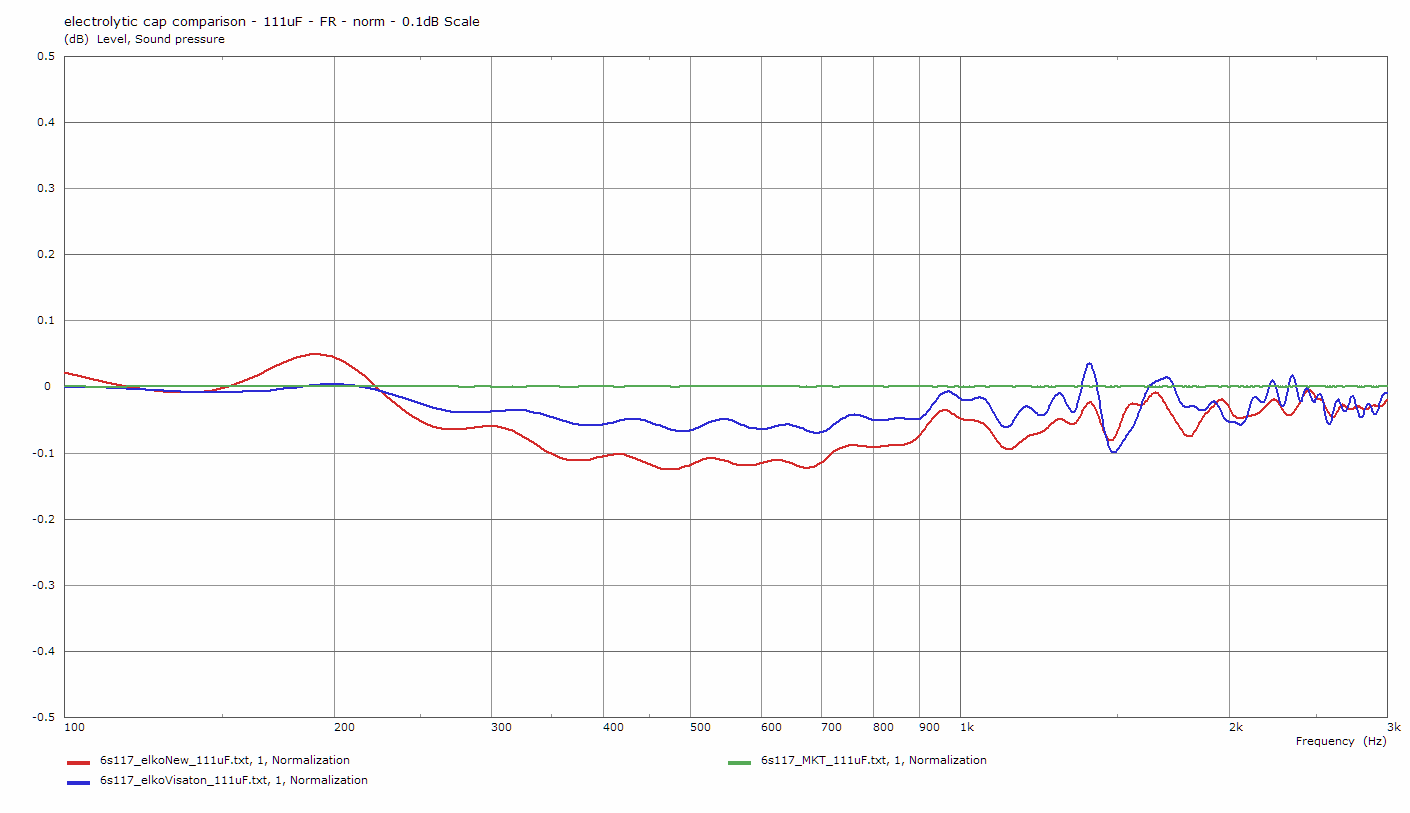

You know the drill... To be able to see the difference better, the diagram is normalized to the frequency response of the MKT capacitor and displayed with a scaling of 0.1dB.

The result is interesting because it shows that the quality of the electrolytic capacitor is also very important.

The 35 year old Visaton electrolytic capacitor has a lower ESR than the combination of two newly purchased electrolytic capacitors. Accordingly, the Visaton cap performs better than the newly purchased electrolytic capacitors compared to the film capacitor.

Nevertheless, the deviations in the frequency response with a maximum of 0.1dB are so small that this should be practically inaudible when replacing the capacitor in the crossover in e.g. a 3-way loudspeaker.

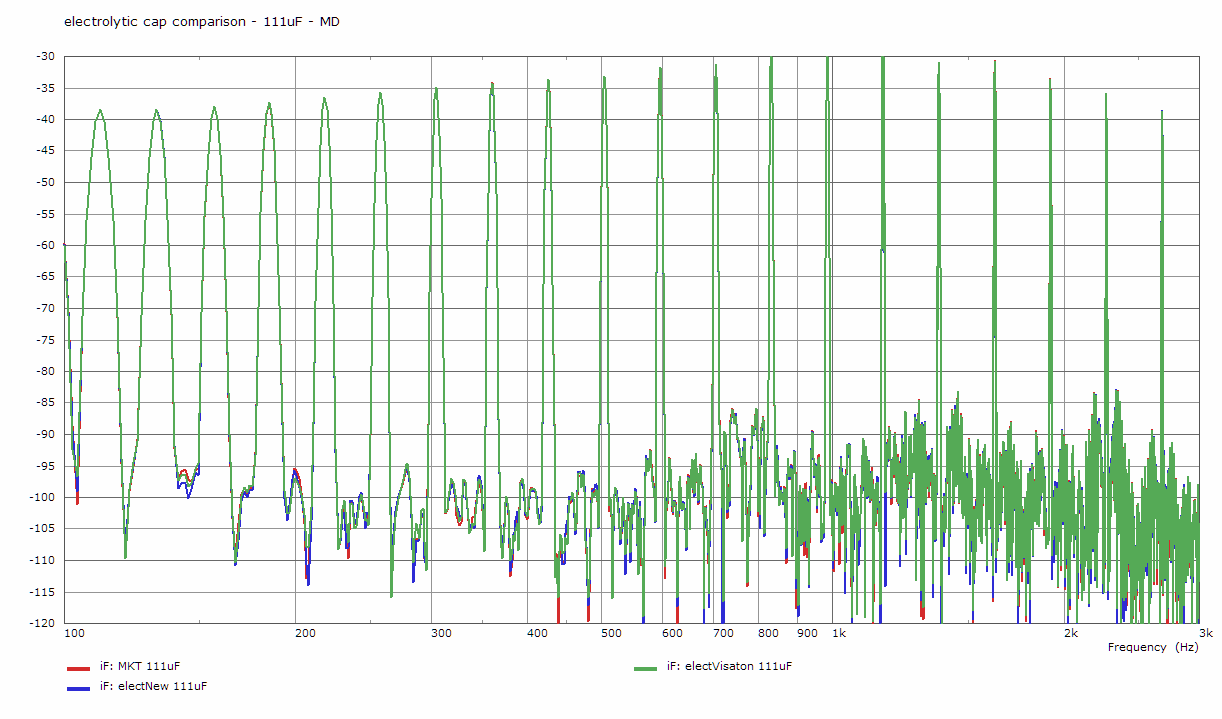

d) Multiton Distortion - Film versus Electrolytic capacitor

Because people keep asking for it, here is the multitone distortion, which contain the harmonic distortion and IMD, of all three 111µF capacitor combinations from section c) in series to the mid range driver.

The distortion attenuation is sometimes more than -60dB (which corresponds to a distortion factor of less than 0.1%), and yet no different contribution of the capacitors can be seen in the multitone distortion.

Conclusion

For the same capacitance, there are measurable differences when comparing electrolytic capacitors against film capacitors (in series with the chassis), which depend strongly on the quality, especially the ESR, of the electrolytic capacitor.

However, the difference in sound pressure in the measurements shown is only 0.2dB in the worst case.

This is higher than in the first part when comparing normal film capacitors against a high-end capacitor, but in the end still insignificant (in most cases).

If the electrolytic capacitor is of good quality, durability does not play a decisive role either.

Only the high tolerance values of electrolytic capacitors and the possible change of the capacitance value over time could pose a problem. Especially when used in the tweeter crossover - this should be avoided.

Very important: according to these measurements a film capacitor does not make a better sound when used in the crossover compared to an electrolytic capacitor.

If you replace capacitors, especially electrolytic capacitors, with film capacitors in the crossover, without checking with an LCR meter, you will most likely notice a change in sound. However, 99% of the change in sound is only due to the different capacitances caused by the capacitor tolerances and not because the film or high-end capacitor "sounds better".

UPDATE:

e) Aged electrolytic capacitors

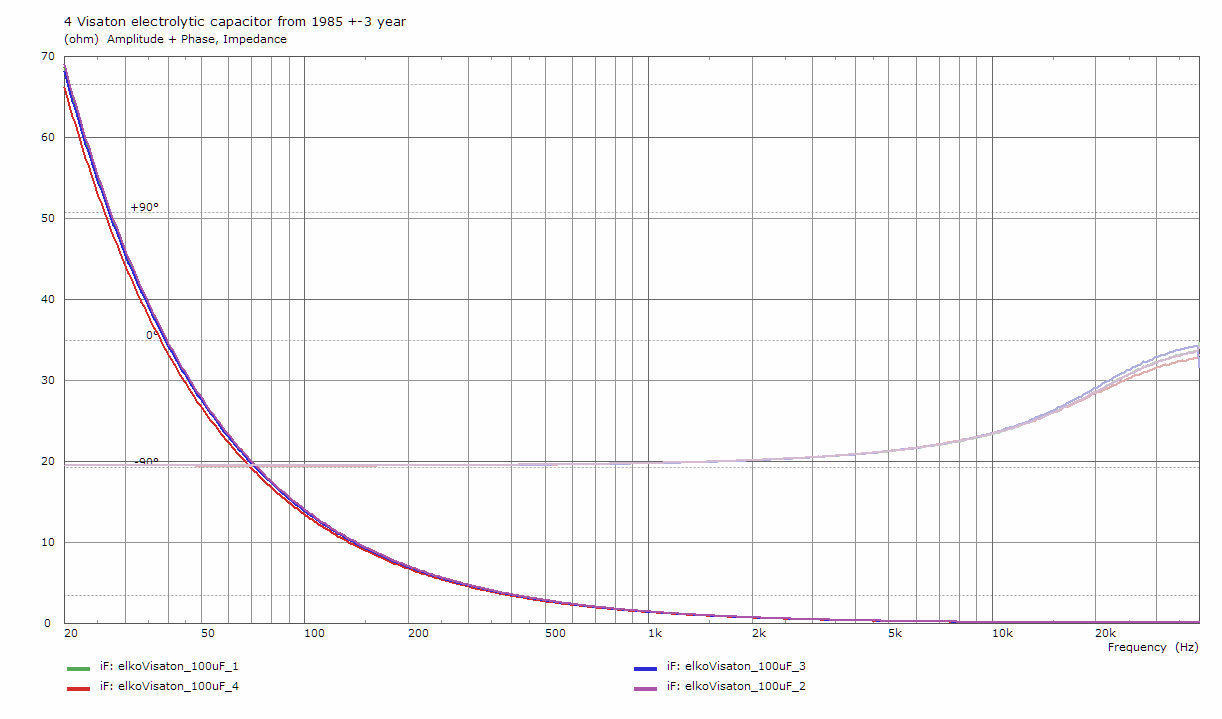

In my stock are four 100µF (+-10% tolerance, 35 VAC) Visaton electrolytic capacitors from 1985 (+-3 years). These were installed in a crossover for over twenty years and were in regular use. The last ten years they were stored in my stock and only used sporadically.

One of these capacitors was already measured in part c). Out of curiosity I measured all four capacitors. I am a bit surprised that at first sight all four are still working.

The measured capacitances@1kHz were between 111µF and 116µF. Thus all electrolytic capacitors slightly exceeded the permissible upper tolerance range. This is most likely due to ageing effects.

I can't say if the full dielectric strength of the capacitors is still given, but I haven't noticed any disadvantages even at high sound pressure levels when they were used in a crossover.

The third and final part on this topic: Capacitor upgrade in crossover - You Can't Handle the Truth - part-3

Update 2022-03-23: Fixed diagrams with corrupted scaling.

This time it is exclusively about the measurable differences of electrolytic capacitors with film capacitors in crossovers of loudspeakers.

The first part about film capacitors can be found here and who likes can read about the measurable differences between sand-cast and low-inductance resistors here.

The third and final part on this topic: Capacitor upgrade in crossover - You Can't Handle the Truth - part-3

The full mini series:

Capacitor upgrade in crossover - Is it audible?

Capacitor upgrade - part two

Capacitor upgrade - part three

Replace resistor by low-inductance resistor - Is it audible?

Different Binding Posts - is it audible?

Audible difference in high-end capacitors? - ABX samples

The test method and test setup were described in detail in the first part. If you're not familiar with what a capacitor (in series with the driver) does, you can read this in part one either - I'm too lazy to repeat all this.

As in part 1, the capacitor is connected in series to the chassis and then measured in the near field.

With almost the same capacitance of the capacitors, the deviations then measured are solely due to the different design/type of the capacitors or of minimal deviation in capacity - there is also a section on this in Part 1.

Electrolytic capacitor versus film capacitor

To obtain more certainty about the accuracy of the measurements, comparisons were made with three different capacitance values - 8.2µF, 47µF and 100µF.

High capacities in series to the driver are mostly used in the mid-range crossover. Therefore the measurement for 100µF was carried out with a mid-range driver.

a) Comparison with 8.2µF capacity

The film capacitor has a capacitance of 8.47µF, the electrolytic capacitor one of 8.46µF. The deviation of the capacitors from each other is therefore only 0.1%. According to the investigations of capacitors with low capacitance deviations made in part 1, the measured deviation should be only minimal.

noname MKT

Audyn-Cap electrolytic capacitor

It is easy to see that the resistive part of the electrolytic capacitor is four times as high as that of the film capacitor.

Let's take a look at the frequency response measurements.

A very small difference can be seen. To be able to see the difference better, the diagram is normalized to the frequency response of the MKT capacitor and displayed with a scaling of 0.1dB.

The deviation of the electrolytic capacitor is greater than we would expect due to the small difference in capacitance - for the effects of minimal capacitance deviations see part 1.

Even at high frequencies the deviation is still almost 0.1dB. Between 3 - 6kHz the deviation is

Here, the high ESR of the electrolytic capacitor has a clear effect on the frequency response of the tweeter.

b) Comparison with 47µF capacity

The MKT 250V film capacitor has a capacity of 46.7µF, the electrolytic capacitor with 100V dielectric strength has a capacity of 46.9µF.

The capacitance deviation is therefore about 0.4%.

electrolytic capacitor

noname MKT film capacitor

The resistive part of the electrolytic capacitor is five times as high as that of the film capacitor.

Due to the differences in capacitance, one would expect that measured frequency response of the electrolytic capacitor would be slightly above that of the film capacitor. However, due to the high ESR of the electrolytic capacitor, this is not the case here either.

To be able to see the difference better, the diagram is normalized to the frequency response of the MKT capacitor and displayed with a scaling of 0.1dB.

Film capacitor and electrolytic capacitor behave as in the example above.

The maximum sound pressure difference in this case is 0.2dB.

c) Comparison with 100µF capacity

Here, an additional comparison of an old and a new electrolytic capacitor is to be carried out.

Starting point is a Visaton electrolytic capacitor from 1985 (+-3 years) with 100µF nominal capacity and +-10% tolerance. The measured capacitance of the Visaton electrolytic capacitor is about 111.5µF.

Next are two new electrolytic capacitors (100µF + 8.2µF, +-10% tolerance capacitors) which together have a capacity of 111.5µF.

Finally a combination of film capacitors (100µF + 10µF + 0.82µF, +-5% tolerance capacitors) with a total of 111.3µF.

The deviation of the capacitors compared to the film capacitor is only 0.2%.

The resistive part of the 35 year old Visaton electrolytic capacitor is only two times as high as that of the film capacitor.

The resistive part of the new electrolytic capacitor is three times as high as that of the film capacitor.

As already mentioned above, such high capacitance values in series to a chassis actually only occur with bass/midrange drivers.

For this reason, this test setup uses a midrange driver instead of a tweeter - the BMS 6S117 midrange driver. The driver was chosen because it has triple aluminum demodulating rings and therefore low distortion. This should make it easier to detect possible distortion caused by capacitors.

The rest of the test setup remains unchanged.

For the evaluation we consider the reasonable frequency range of the chassis (before cone-breakup). Therefore all frequency response diagrams consider the range 100Hz to 3kHz.

You know the drill... To be able to see the difference better, the diagram is normalized to the frequency response of the MKT capacitor and displayed with a scaling of 0.1dB.

The result is interesting because it shows that the quality of the electrolytic capacitor is also very important.

The 35 year old Visaton electrolytic capacitor has a lower ESR than the combination of two newly purchased electrolytic capacitors. Accordingly, the Visaton cap performs better than the newly purchased electrolytic capacitors compared to the film capacitor.

Nevertheless, the deviations in the frequency response with a maximum of 0.1dB are so small that this should be practically inaudible when replacing the capacitor in the crossover in e.g. a 3-way loudspeaker.

d) Multiton Distortion - Film versus Electrolytic capacitor

Because people keep asking for it, here is the multitone distortion, which contain the harmonic distortion and IMD, of all three 111µF capacitor combinations from section c) in series to the mid range driver.

The distortion attenuation is sometimes more than -60dB (which corresponds to a distortion factor of less than 0.1%), and yet no different contribution of the capacitors can be seen in the multitone distortion.

Conclusion

For the same capacitance, there are measurable differences when comparing electrolytic capacitors against film capacitors (in series with the chassis), which depend strongly on the quality, especially the ESR, of the electrolytic capacitor.

However, the difference in sound pressure in the measurements shown is only 0.2dB in the worst case.

This is higher than in the first part when comparing normal film capacitors against a high-end capacitor, but in the end still insignificant (in most cases).

If the electrolytic capacitor is of good quality, durability does not play a decisive role either.

Only the high tolerance values of electrolytic capacitors and the possible change of the capacitance value over time could pose a problem. Especially when used in the tweeter crossover - this should be avoided.

Very important: according to these measurements a film capacitor does not make a better sound when used in the crossover compared to an electrolytic capacitor.

If you replace capacitors, especially electrolytic capacitors, with film capacitors in the crossover, without checking with an LCR meter, you will most likely notice a change in sound. However, 99% of the change in sound is only due to the different capacitances caused by the capacitor tolerances and not because the film or high-end capacitor "sounds better".

UPDATE:

e) Aged electrolytic capacitors

In my stock are four 100µF (+-10% tolerance, 35 VAC) Visaton electrolytic capacitors from 1985 (+-3 years). These were installed in a crossover for over twenty years and were in regular use. The last ten years they were stored in my stock and only used sporadically.

One of these capacitors was already measured in part c). Out of curiosity I measured all four capacitors. I am a bit surprised that at first sight all four are still working.

The measured capacitances@1kHz were between 111µF and 116µF. Thus all electrolytic capacitors slightly exceeded the permissible upper tolerance range. This is most likely due to ageing effects.

I can't say if the full dielectric strength of the capacitors is still given, but I haven't noticed any disadvantages even at high sound pressure levels when they were used in a crossover.

The third and final part on this topic: Capacitor upgrade in crossover - You Can't Handle the Truth - part-3

Update 2022-03-23: Fixed diagrams with corrupted scaling.

Last edited: