There is probably not much you can do here WRT noise. I would bridge it with a small piggy back PCB with an Opamp based phono stage using NE5532. Beware that you need to reduce the PS voltage, +/- 23V is too high.The one thing I'm not happy with yet is the Phono stage, as it seems particularly noisy. It's based on BC549, BC559, BC556 and BC546.

View attachment 132709

-

Welcome to ASR. There are many reviews of audio hardware and expert members to help answer your questions. Click here to have your audio equipment measured for free!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

What is on your workbench right now?

- Joined

- Feb 23, 2021

- Messages

- 52

- Likes

- 111

@LTig Thats a good call as it would be easy to design replacement phono boards as the current pair are vertically mounted daughter boards. I'll have a listen to see how it sounds before deciding if it's worth the effort as I don't intend to keep it.There is probably not much you can do here WRT noise. I would bridge it with a small piggy back PCB with an Opamp based phono stage using NE5532. Beware that you need to reduce the PS voltage, +/- 23V is too high.

- Joined

- Feb 23, 2021

- Messages

- 52

- Likes

- 111

What setup do you use to measure speaker response?Refurbished Tannoy Devon (HPD315 drive refoamed). Frequency response at ca. 1m (not bad for almost half century old loudspeakers)

View attachment 128477

Vuki

Senior Member

It was measured in-room at ca 1m. Loudspeaker drive unit center at ca. 1m height. Controls set to rolloff 0, energy -1. Audiomatica Clio microphone, terratec dmx 6fire usb soundcard, rew sw. Mic level was uncalibrated, level was probably around 80db.What setup do you use to measure speaker response?

It would probably look nicer if I used mmm technique...

- Joined

- Feb 23, 2021

- Messages

- 52

- Likes

- 111

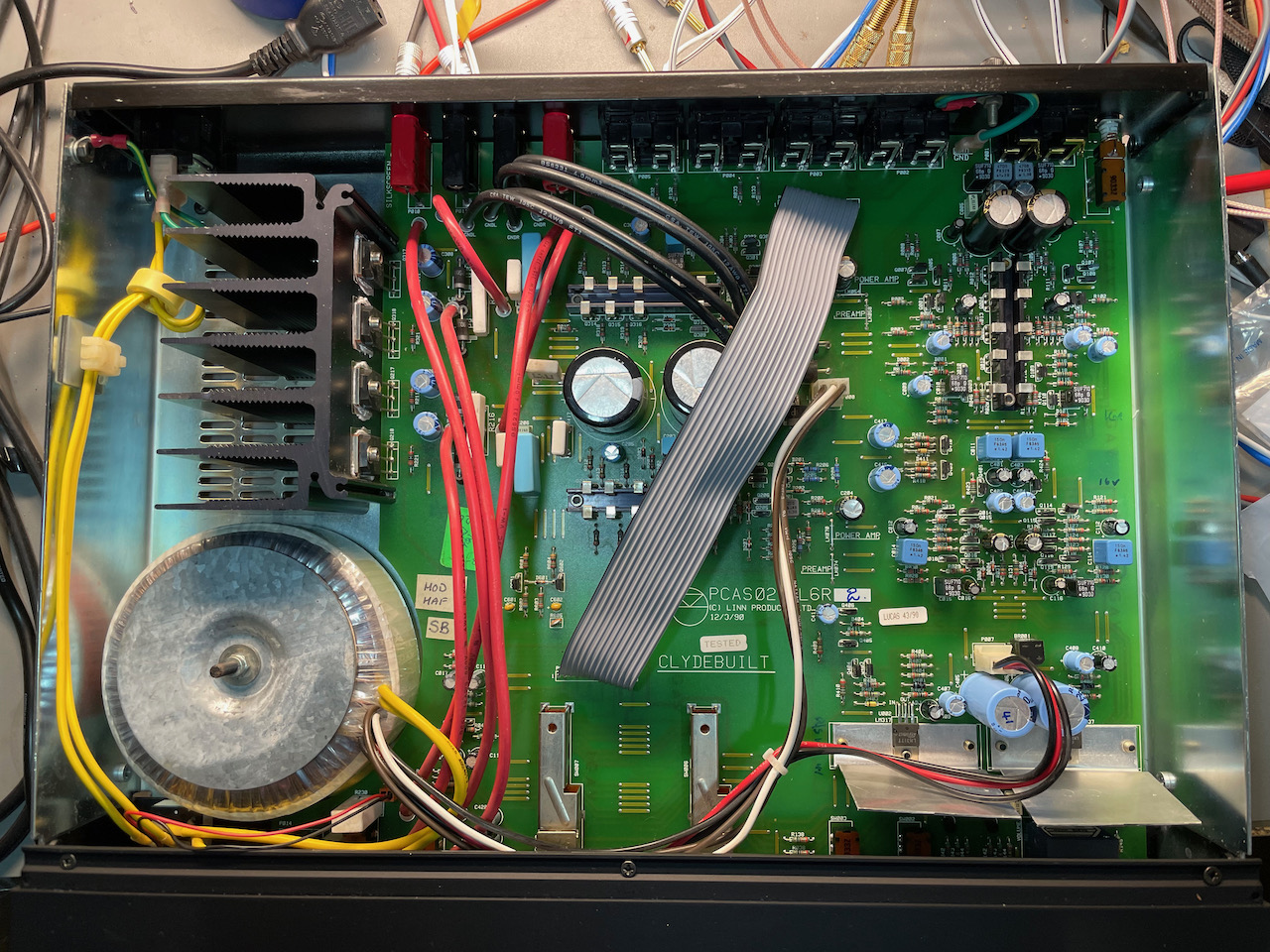

Next project... service this Linn Intek amp that I've owned from new since ~1990. Nicely made kit. All Rubycon caps. It has a slight power on thump on the left channel and higher measured DC offset on that channel (15.4mV vs. 1.9mV).

Last edited:

restorer-john

Grand Contributor

Taking a break between soldering Dolby cat 109 meter frequency filter card, feeding Magic a meaty stick.

Magic is a cutey. He looks a bit like our cat Julio.

restorer-john

Grand Contributor

Next project... service this Linn Intek amp that I've owned from new since ~1990. Nicely made kit.

You know it's UK built when the heatsink is either the casework, or way, way too small. Run that thing in Australia in summer and it would self destruct in one afternoon. @50wpc (rated) that heatsink is a joke. And the flag heatsinks on the regulators? They riveted them to the PCB and riveted the TO-220? Tell me they are captive nuts. Please.

But yes, the overall component quality seems decent.

- Joined

- Feb 23, 2021

- Messages

- 52

- Likes

- 111

You know it's UK built when the heatsink is either the casework, or way, way too small. Run that thing in Australia in summer and it would self destruct in one afternoon. @50wpc (rated) that heatsink is a joke. And the flag heatsinks on the regulators? They riveted them to the PCB and riveted the TO-220? Tell me they are captive nuts. Please.

But yes, the overall component quality seems decent.

You're right @restorer-john piddly arsed heatsink. However on closer inspection it looks the aluminium flag heatsinks are actually screwed in with some sort of self-tapper / captive nut arrangement - I'll have a better look once I've got the pcb out.

On a positive note, they have segregated the differential and VAS supplies from the output, used decent constant current and current mirrors. Interesting arrangement with the drivers using 3x ZTX653 / ZTX753. What do you think @pma?

- Thread Starter

- #311

What do you think @pma?

Well - I am not sure. I suppose that three 653/753 parts would be limited in power dissipation. But, the output stage is connected as a CFP. Frankly, I do not like too much this variant of the output stage. How do they manage thermal stability? Where are those 653/753 packages, on the heatsink?

restorer-john

Grand Contributor

Frankly, I do not like too much this variant of the output stage. How do they manage thermal stability? Where are those 653/753 packages, on the heatsink?

On their own heatsink, not the main heatsink. See the pic above.

I do not like it either. No DC offset adjustment, no boas adjustment and TO92s driving a1306/c2519s? 1W per device.

Am I missing something, there's not enough V to drive those drivers it'll be limited by the fornt end swing.

- Joined

- Feb 23, 2021

- Messages

- 52

- Likes

- 111

No, the ZTX653/753 are clipped on separate strips of heatsink - can be seen in the pic above and below the main reservoir caps. There are 9 transistors mounted so I presume in addition to the drivers, one is the bias spreader and the other the VAS. From what I can see there doesn't appear to be any form of thermal feedback from that inadequate main heatsink :-(Well - I am not sure. I suppose that three 653/753 parts would be limited in power dissipation. But, the output stage is connected as a CFP. Frankly, I do not like too much this variant of the output stage. How do they manage thermal stability? Where are those 653/753 packages, on the heatsink?

- Thread Starter

- #314

No, the ZTX653/753 are clipped on separate strips of heatsink - can be seen in the pic above and below the main reservoir caps. There are 9 transistors mounted so I presume in addition to the drivers, one is the bias spreader and the other the VAS. From what I can see there doesn't appear to be any form of thermal feedback from that inadequate main heatsink :-(

Not exactly. Q287 and 218 are VAS. Q211, 212, 213 and their PNP mirrors are a part of the output stage. Output stage here is CFP (not 2EF). Thermal stability of such output stage depends on Q211 etc Vbe.

- Joined

- Feb 23, 2021

- Messages

- 52

- Likes

- 111

Phew not a pop-rivet, it's some sort of Allen headed self tapper.....You know it's UK built when the heatsink is either the casework, or way, way too small. Run that thing in Australia in summer and it would self destruct in one afternoon. @50wpc (rated) that heatsink is a joke. And the flag heatsinks on the regulators? They riveted them to the PCB and riveted the TO-220? Tell me they are captive nuts. Please.

But yes, the overall component quality seems decent.

Pretty tight, it twisted the legs of the regulator.

MakeMineVinyl

Major Contributor

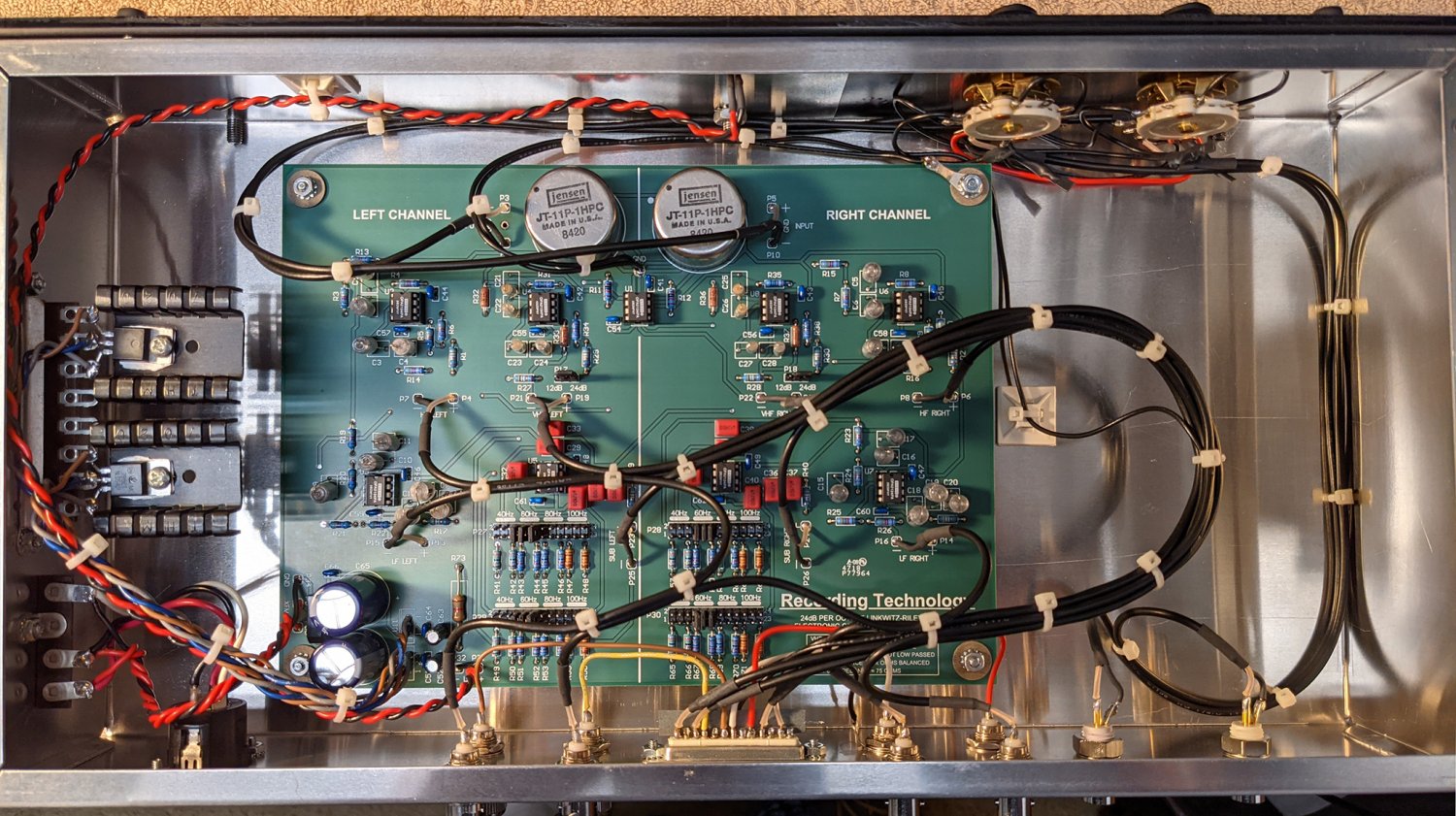

I did some modification work on my crossover today so I thought I'd post a pix. This is a pretty stock-circuit 4th order LR 4 way crossover, nothing unusual except for the selectable subwoofer crossover frequencies and the transformer input coupling, in addition to loops for external EQs for the LF and HF and the usual channel switching. The signal capacitors are NOS polystryene except for the subwoofer channel which uses Wima. I designed it to work specifically with the requirements of my system. I laid out the PCB, chassis etc - 'Recording Technology' is the name of a company I had a long time ago to make mixing consoles - Neve never got worried about competition from me  . The XLR in the lower left hand corner is for the external PSU, and you can see the rail regulators on the left. The outputs are on the DB-25 connector on the back of the chassis. Hopefully the workmanship is a bit better than a certain 'truthful preamp'....

. The XLR in the lower left hand corner is for the external PSU, and you can see the rail regulators on the left. The outputs are on the DB-25 connector on the back of the chassis. Hopefully the workmanship is a bit better than a certain 'truthful preamp'....

restorer-john

Grand Contributor

I did some modification work on my crossover today so I thought I'd post a pix. This is a pretty stock-circuit 4th order LR 4 way crossover, nothing unusual except for the selectable subwoofer crossover frequencies and the transformer input coupling, in addition to loops for external EQs for the LF and HF and the usual channel switching. The signal capacitors are NOS polystryene except for the subwoofer channel which uses Wima. I designed it to work specifically with the requirements of my system. I laid out the PCB, chassis etc - 'Recording Technology' is the name of a company I had a long time ago to make mixing consoles - Neve never got worried about competition from me. The XLR in the lower left hand corner is for the external PSU, and you can see the rail regulators on the left. The outputs are on the DB-25 connector on the back of the chassis. Hopefully the workmanship is a bit better than a certain 'truthful preamp'....

View attachment 135433

Really lovely. Love the BNCs.

One question. Are the two regulators/fins supported by their mounting screws to the chassis or are they floating in mid air as it appears?

Last edited:

MakeMineVinyl

Major Contributor

They are floating from the terminal strips - there wasn't really enough space on the PCB size I wanted to keep. The power supply is a bit overkill, but the parts are what I had in my bins.Really lovely. Love the BNCs.

One question. Are the two regulators/fins supported by their mounting screws to the chassis or are they floating in mid air as it appears?

It looks good.I did some modification work on my crossover today so I thought I'd post a pix. This is a pretty stock-circuit 4th order LR 4 way crossover, nothing unusual except for the selectable subwoofer crossover frequencies and the transformer input coupling, in addition to loops for external EQs for the LF and HF and the usual channel switching. The signal capacitors are NOS polystryene except for the subwoofer channel which uses Wima. I designed it to work specifically with the requirements of my system. I laid out the PCB, chassis etc - 'Recording Technology' is the name of a company I had a long time ago to make mixing consoles - Neve never got worried about competition from me. The XLR in the lower left hand corner is for the external PSU, and you can see the rail regulators on the left. The outputs are on the DB-25 connector on the back of the chassis. Hopefully the workmanship is a bit better than a certain 'truthful preamp'....

View attachment 135433

- Thread Starter

- #320

Last edited:

Similar threads

- Replies

- 81

- Views

- 4K

- Replies

- 0

- Views

- 692

- Replies

- 13

- Views

- 1K

- Replies

- 10

- Views

- 2K