-

WANTED: Happy members who like to discuss audio and other topics related to our interest. Desire to learn and share knowledge of science required. There are many reviews of audio hardware and expert members to help answer your questions. Click here to have your audio equipment measured for free!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Recoton RCA Cable Review (Ultra Cheap Cable)

- Thread starter amirm

- Start date

Why? In my opinion they are the funniest, they convey the concept of how stupid some audiophile paranoia areSurprisingly, this marvellous site is getting a little boring with it’s review of outdated and irrelavent gear.

rebbiputzmaker

Major Contributor

- Joined

- Jan 28, 2018

- Messages

- 1,099

- Likes

- 463

One thing that nobody has mentioning are the contacts. It’s important to make sure that your connections are clean. Dirty contacts can affect your sound.

RoadHustler

New Member

- Joined

- May 22, 2021

- Messages

- 4

- Likes

- 1

I love this...

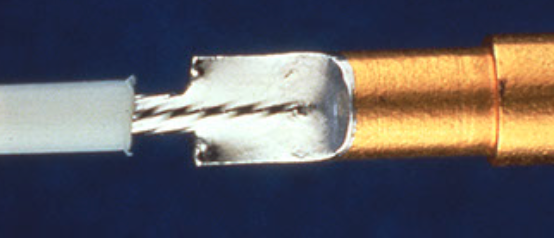

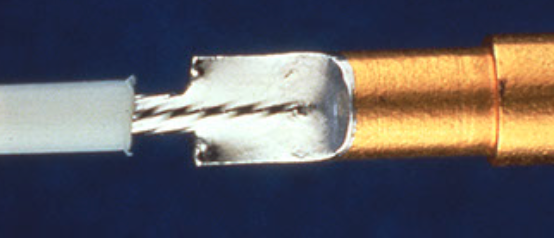

What a properly soldered connection should look like for comparison.

But not the best that is possible:

*Unless the price of solder is skyrocketing, and

*Unless shaky hands caused too much stripped insulation (unnecessarily exposed conductor).

sam_adams

Major Contributor

- Joined

- Dec 24, 2019

- Messages

- 1,006

- Likes

- 2,476

But not the best that is possible:

*Unless the price of solder is skyrocketing, and

*Unless shaky hands caused too much stripped insulation (unnecessarily exposed conductor).

NASA has a differing opinion.

High use like Amir's prevents connection corrosion but promotes various stress issues which makes total sense. In my systems the connectors often stay for years, BUT when I have removed them, or grabbed some from the wire drawer YEARS later I have seen massive corrosion inside the connectors which has led me to slice the wire open and found corrosion many inches up the wire.

But not the best that is possible:

*Unless the price of solder is skyrocketing, and

*Unless shaky hands caused too much stripped insulation (unnecessarily exposed conductor).

Are there any of the Mogami or others that have best sealing around the wire/insulation or do we just throw them away every few years? Fun building wires but never really looked for best corrossion proofing.

Thoughts on that?

With the small cups on male female connectors like a Canon connector or better the cup fill point is critical to enable the pin to fit the mating connector assembly. Too much solder and the pin will not fit into the precision assembly of the connector package. They apparently prefer crimping but myself I have found solder to be much more reliable and predictable. This is a textbook solder joint for a precision pin assembly. I've done up to several hundred per day, day after day and this is perfectO.

But not the best that is possible:

*Unless the price of solder is skyrocketing, and

*Unless shaky hands caused too much stripped insulation (unnecessarily exposed conductor).

Robin L

Master Contributor

Look, just about everybody into this hobby has redundant interconnects, and just about everybody has this type of interconnect. Nobody's hyping a non-product like this. That, in fact, is the point. If the interconnect is in one's collection and one has the possibility of using that interconnect, it's relevant. Somebody might be considering upgrading interconnects to something much more expensive. But this test indicates that sound quality and expense are non-correlate. Knowing the limits of measurement and audibility is always relevant, no matter how "irrelevent" [sic] one might consider the gear. Because if there is no audible or measurable difference between a $20,000 AQ interconnect and a throwaway that came packed with your DVD player ten years ago, that is very relevant. That $20,000 interconnect lives on the corner of snake oil and rip-off. Arim shining a light on that can do nothing but good.Surprisingly, this marvellous site is getting a little boring with it’s evaluations of outdated and irrelevent gear. A waste of Amir’s expensive test equipment and his own deep wealth of experience.

sam_adams

Major Contributor

- Joined

- Dec 24, 2019

- Messages

- 1,006

- Likes

- 2,476

I have seen massive corrosion inside the connectors which has led me to slice the wire open and found corrosion many inches up the wire.

That's caused by outgassing of chlorides from PVC insulation—usually very low-grade PVC. Phthalates are used to make the PVC soft and flexible but once it starts to degrade, it gets all gooey and sticky—think about clear PVC covered speaker wire. Most of the good cables, Mogami, Canare, Belden, Gotham, all use XLPE (Cross-Linked Polyethylene) on the main conductors and better grade PVC that lasts for years without breakdown.

Thank you for the info. I did pitch 50ft of clear Monster wire too. It was really bad as you described.That's caused by outgassing of chlorides from PVC insulation—usually very low-grade PVC. Phthalates are used to make the PVC soft and flexible but once it starts to degrade, it gets all gooey and sticky—think about clear PVC covered speaker wire. Most of the good cables, Mogami, Canare, Belden, Gotham, all use XLPE (Cross-Linked Polyethylene) on the main conductors and better grade PVC that lasts for years without breakdown.

LOL, I never did like them myself... textbooks; I mean; not the joint!This is a textbook solder joint for a precision pin assembly.

But not the best that is possible:

*Unless the price of solder is skyrocketing.

Looks like the malnourished Biafra child's ribcage.

We used to instruct our lab techs to fill it a bit more but not as fluffy as a beer-belly American.

(old-skool style)

Does look a bit cheapo on the leadLooks like the malnourished Biafra child's ribcage.

Hey, I resemble that remark!but not as fluffy as a beer-belly American

KSTR

Major Contributor

This is a quite good article.Blue Jeans Cables did an article on hum rejection in unbalanced RCA cables. Seems legit even if a bit less rigorous than some tests. My notion is that shielding designs can matter, but not as much for audio applications.

Note the important point, though:

"Our conclusion is that for rejection of low-frequency, high-energy noise, just as electrical theory would suggest, a coaxial cable with a highly-conductive double braid shield will outperform similar braid/foil and single braid cables". (Bold mine).

In other words, they compared the best possible cable design with already excellent ones, wrt to audio.

Those cheapo cables have a way different shield construction, the simple spiralled shield.

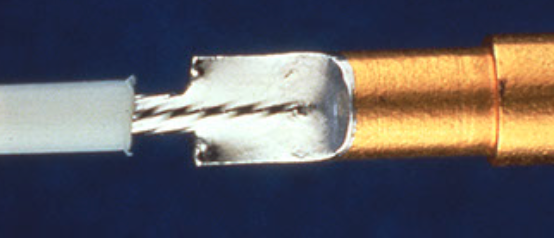

Below is a example, and mind you, that's from a rather good specimen from my junk cable drawer:

(I broke a few wires while dismantling, please ignore).

The cheaper stuff looks much worse, smaller inner diameter which means way less strands for the shield spiral. They hardly come close to 70% coverage and, more importantly, the resistance of the screen is often on the order of 1 Ohm (!!!) for a 1.5m or 2m cable. That allows the smallest balancing currents along the "shield" to build up large noise voltage (1mA --> 1mV) and this will cause buzz/hum in any but the most benign small setups.

Back in the day, a HiFi stack consisted of an integrated amp, a turntable, a cassette deck, a CD player, all class-II mains supplies with traditional transformers. For those setups, even the worst cables in terms of shield resistance are good enough as that are conditions close to what was the environment used for measurment here: (almost) now balancing currents.

However, once you have any significant balancing currents, hell breaks loose with those high shield resistance cables.

The only thing "wrong" with these is the possible corrosion of the tin plating causing problems some time in the future, and the loose fit they likely have.

Not quite. The test conditions are such that the real-world problems of these cables did not appear. It basically tested what is clear anyway: copper is a good enough conductor to prevent any harm of the signal from the conductive processes itself.lol. this is the masterpiece of your slap_in_your_face reviews series. you can drop the mic now

But signal integrity in an real-life use case was not tested for (and that's fine with me, but we have to be aware of that limitation).

Once again, and for all to sing along, over and over again until it finally sinks in:

The most important property of an unbalanced signal cable is lowest possible shield resistance.

The most important property of an unbalanced signal cable is lowest possible shield resistance.

The most important property of an unbalanced signal cable is lowest possible shield resistance.

The most important property of an unbalanced signal cable is lowest possible shield resistance.

The most important property of an unbalanced signal cable is lowest possible shield resistance.

....

- Thread Starter

- #176

The real world scenario is that millions of people have no problem with these cables. To wit, this is what was supplied with every device and still is for many. To avoid the rare issues, it is best to adopt balanced interconnects. Not try to put lipstick on chicken with respect to RCA connection.The test conditions are such that the real-world problems of these cables did not appear.

KSTR

Major Contributor

@amirm,

I was called for help by many dozens of users with (small to medium) hum/buzz problems and in almost all cases switching from long el-cheapo RCAs to the shortest possible ones with low shield resistance (like single braided shield video cable) solved the issues.

Millions of people may have no problems, but ten thousands of people do. It's the percentage that matters, not the absolute numbers.

I was called for help by many dozens of users with (small to medium) hum/buzz problems and in almost all cases switching from long el-cheapo RCAs to the shortest possible ones with low shield resistance (like single braided shield video cable) solved the issues.

Millions of people may have no problems, but ten thousands of people do. It's the percentage that matters, not the absolute numbers.

KSTR

Major Contributor

As for you test conditions: Even though it is simple to inject known amounts of shield current with the AP you don't do that, and you don't measure DC shield resistance directly either.

As I said, this is fine with me, you are entitled to choose whatever test conditions you want.

But then don't tell us (and notably the fraction of electronic design engineers with decades of hands-on experience and profound theoretical background) that these cables are absolutely fine for signal integrity. They are not. Period.

As I said, this is fine with me, you are entitled to choose whatever test conditions you want.

But then don't tell us (and notably the fraction of electronic design engineers with decades of hands-on experience and profound theoretical background) that these cables are absolutely fine for signal integrity. They are not. Period.

The issue is almost entirely with transparent PVC. I have never, ever seen this with normal pigmented wire insulation. XLPE is fine, but there's nothing wrong with pigmented PVC; I just stripped some 10 year old Home Depot electrical cord (my preferred speaker cable) and the copper was bright and shiny.That's caused by outgassing of chlorides from PVC insulation—usually very low-grade PVC. Phthalates are used to make the PVC soft and flexible but once it starts to degrade, it gets all gooey and sticky—think about clear PVC covered speaker wire. Most of the good cables, Mogami, Canare, Belden, Gotham, all use XLPE (Cross-Linked Polyethylene) on the main conductors and better grade PVC that lasts for years without breakdown.

- Thread Starter

- #180

"Long el-cheapo" is not at all common. The type of cable I tested are the throw-in ones which are almost always 1 meter or less. The solution to a long one is to go balanced, not hope and pray a thicker shield reduces the voltage differential to fix your problem.@amirm,

I was called for help by many dozens of users with (small to medium) hum/buzz problems and in almost all cases switching from long el-cheapo RCAs to the shortest possible ones with low shield resistance (like single braided shield video cable) solved the issues.

Millions of people may have no problems, but ten thousands of people do. It's the percentage that matters, not the absolute numbers.

Similar threads

- Poll

- Replies

- 52

- Views

- 11K

- Replies

- 8

- Views

- 647

- Poll

- Replies

- 88

- Views

- 19K

- Poll

- Replies

- 180

- Views

- 26K

- Poll

- Replies

- 138

- Views

- 20K

G