Pearljam5000

Master Contributor

- Joined

- Oct 12, 2020

- Messages

- 6,703

- Likes

- 8,056

I wonder what amp they're using in the 8361Looks like they use the same amplifier and charge substantially more money!

I wonder what amp they're using in the 8361Looks like they use the same amplifier and charge substantially more money!

May the same!I wonder what amp they're using in the 8361

Is there really a consensus? Google is about the worst way to investigate pros and cons of something like this, Google struggles to generate answers to simple technical problems, just a mish mash of opinions raked by popularity and monetizability. Google can't even align a woofer in a sealed box, it's not designed to give the answer you suggest.The general consensus is beryllium is a better material. I'm sure you could google all the pros and cons.

Can you show the data, including the magnitude of the breakup? Yes, all other things being equal, the high specific stiffness/weight of Be pushes the dome's resonances and artifacts higher.I'm not sure if that's true, first breakup for aluminium or titanium is around 10khz. Don't forget the speaker is active with correction. Where beryllium it's around 16khz.

Uh, are you asking OP to destroy one of their speakers due to your fantasy about Beryllium? I hope you understand how naïve this is.Do you think you could use some heat and remove the tweeter from the glue?

Test the tweeter independently.

Find a matching tweeter, something that would work as a good replacement.

3d print a small part if needed.

And put a new tweeter in?

I want beryllium

Let’s do the same test with cloth, guess what you’ll want to have after seeing thatInteresting comparison of titanium , beryllium and aluminum

Skip to 2:40

Similar discrete class D, just with more power.I wonder what amp they're using in the 8361

Commonly for dynamic range improvement over aluminium and also some times because people preffer the tonality over aluminium.If they used titanium instead of aluminum

That would also be a an upgrade ,no?

I think Amirm has his revels not just because they play louder then the 8361a but also because of the tonality that beryllium brings.None of that implies there would be any audible improvement.. There really isn't any evidence that the 8351/8361 tweeter has any kind of significantly audible issues.

I personally think Be tweeters are more about bling and "uniqueness" than the material properties. They don't seem to make much difference in measurements usually and having heard Be Revels and non-Be I didn't think there was a huge treble difference. I mean does this look like a speaker that has significantly better treble than this? Sure doesn't to me.

Personally if I was wanting to upgrade the Ones I'd be looking to improve the bass, it could use some form of cardioid or other directivity improvement without the huge/expensive W371A. But that would necessitate redesigning the entire cabinet so it would end up an entirely new product in terms of development and manufacturing.

audiosciencereview.com

audiosciencereview.com

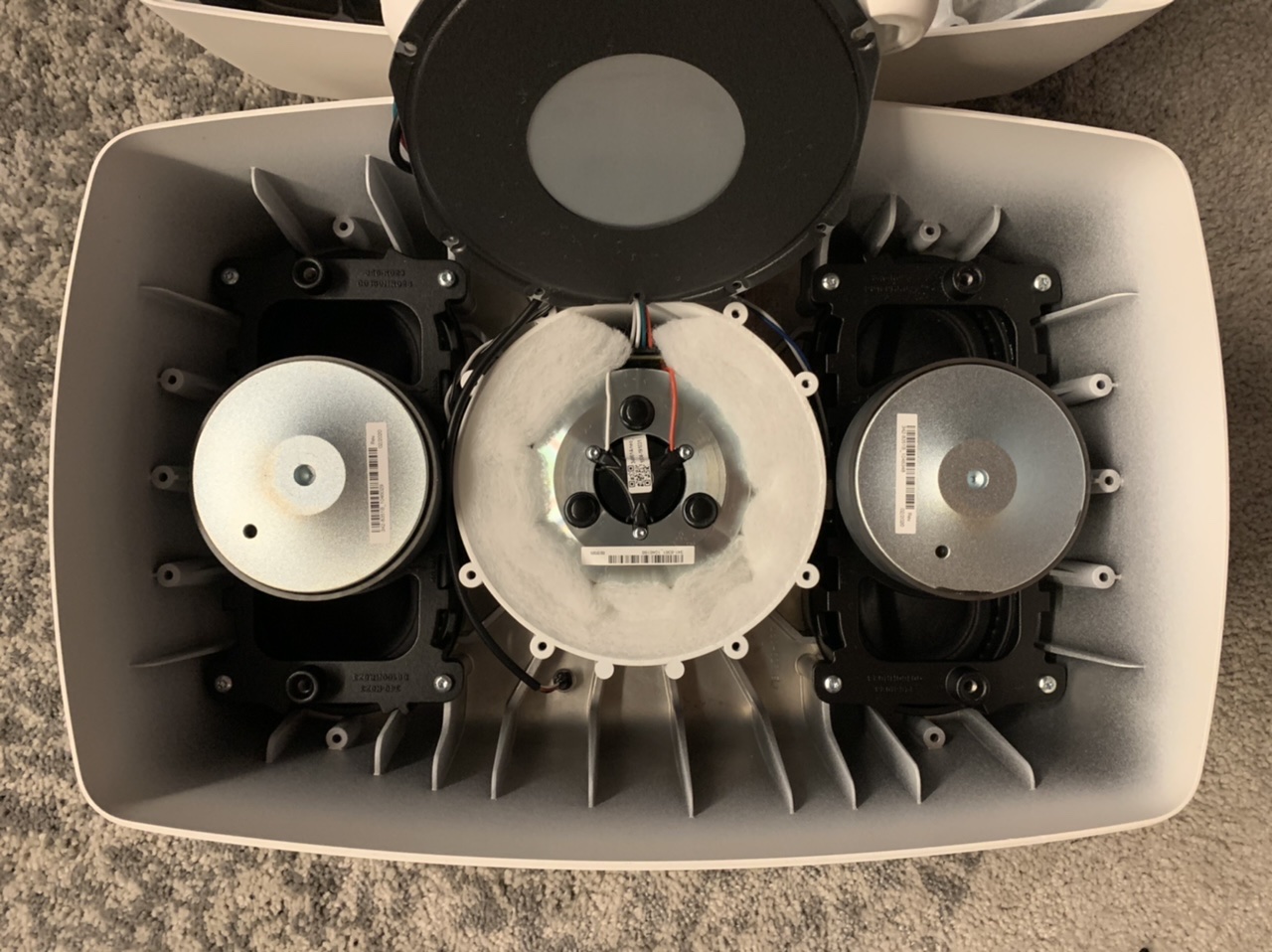

What do you mean? The mid + HF combo is completely filled with damping material and closed from the back, the photo is in the original post.Has anybody an explanation why they use a relatively low amount of damping material for the midrange driver?

I have built some loudspeaker and did some experimentsWhat do you mean? The mid + HF combo is completely filled with damping material and closed from the back, the photo is in the original post.

I really like this thread, people who never heard them trying to fix imaginary problems, suggesting that genelec engineers don't know how to test something. I just wait for someone to want to change the resistors for "audiophile grade" ones. No wonder Genelec doesn't really aim at hifi market other than a few small models

I have built some loudspeaker and did some experiments.

I am sure that the Genelec engineers are good engineers. But you have to optimize the whole speaker for a production. E.g. It is much harder to stuff a cabinet consistently with material. So the midrange might improve but in the end you get more deviations from speaker to speaker. So there is much more to it.

The amount of damping material is relatively low and you need very dense material or stuffed material to effect any waves below about 1kHz significantly.

The coax is a sealed unit, it doesn't care about the cabinet's stuffing. If it weren't they'd have to have a separate sub-chamber.I have built some loudspeaker and did some experiments.

I am sure that the Genelec engineers are good engineers. But you have to optimize the whole speaker for a production. E.g. It is much harder to stuff a cabinet consistently with material. So the midrange might improve but in the end you get more deviations from speaker to speaker. So there is much more to it.

The amount of damping material is relatively low and you need very dense material or stuffed material to effect any waves below about 1kHz significantly.

You keep asserting this. Look at the picture, the mid enclosure is the small cylinder and it is 100% filled. It's not 'packed', but that is not typical.Has anybody an explanation why they use a relatively low amount of damping material for the midrange driver?

The waves from inside the midrange cabinet will be transmitted outside through the cone of the midrange driver, which is very thin compared to the cabinet.The coax is a sealed unit, it doesn't care about the cabinet's stuffing. If it weren't they'd have to have a separate sub-chamber.

Yes you have to be sure that the material doesn't get contact with the cone. Such polyester wool has almost no effect in the lower midrange. You either have to stuff it or use much denser material. It is effective in the higher mids though.You keep asserting this. Look at the picture, the mid enclosure is the small cylinder and it is 100% filled. It's not 'packed', but that is not typical.

Hard to get more damping in the mid enclosure without packing it tight.

Damping material isn't a game changer, so trying to stuff more damping material into the enclosure isn't of much utility and risks contacting the cone.

There are a lot of differences between these speakers other than the tweeter, like SO MANY differences. The Salon 2s are not coaxial and they have much wider dispersion for starters. Also, one person's sighted comparison in non-ideal conditions doesn't even consistently translate to any other person in the first place.I think Amirm has his revels not just because they play louder then the 8361a but also because of the tonality that beryllium brings.

Maybe (I'm no expert) is it you don't see the measured difference because of smoothing especially clouding anything over 10khz where the difference is mostly expected. I would really like to know. Just a guess.

mid+tweeter combo is the same as 8351B, the rest is just bigger and more powerfulThere's no 8361 teardown anywhere

So what the…. Are you trying to “improve” suggesting other stuffings should be used? When distortion or linearity isn’t a problem at the midrange anyway?????The waves from inside the midrange cabinet will be transmitted outside through the cone of the midrange driver, which is very thin compared to the cabinet.

Yes you have to be sure that the material doesn't get contact with the cone. Such polyester wool has almost no effect in the lower midrange. You either have to stuff it or use much denser material. It is effective in the higher mids though.