Hi all,

I created a topic for the power-on issue that I have with my Yamaha A-S700.

In short, sometimes it would power on, sometimes wouldn't. The problem is rectified sometimes by physically disconnecting and removing the power cord. Gradually becoming more stubborn over time. Yesterday could not switch on at all, today switched on once - i.e. eventually became totally unmanageable until fixed.

Not to flood this thread, the link is here

www.audiosciencereview.com

www.audiosciencereview.com

Experts, can you have a look please?

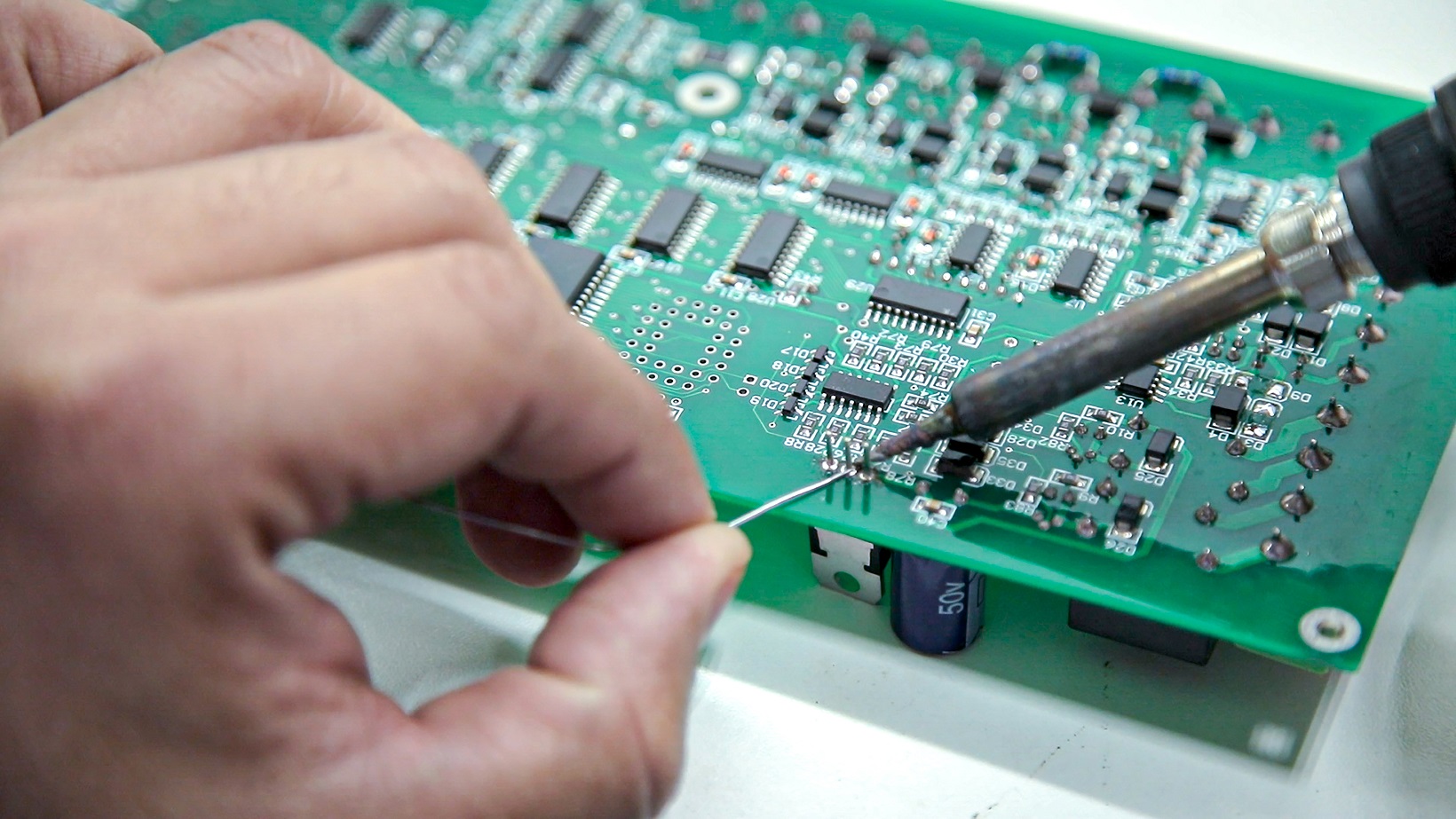

A couple of pictures of inside Yamaha A-S700 to stay on topic

I created a topic for the power-on issue that I have with my Yamaha A-S700.

In short, sometimes it would power on, sometimes wouldn't. The problem is rectified sometimes by physically disconnecting and removing the power cord. Gradually becoming more stubborn over time. Yesterday could not switch on at all, today switched on once - i.e. eventually became totally unmanageable until fixed.

Not to flood this thread, the link is here

[FIXED] Yamaha A-S700 intermittent power-on failure (and eventually full failure)

[ SOLVED ] Yamaha A-S700 intermittent power-on failure. Updated as of 16 March 2024 Please help in repairing my Yamaha A-S700 Over recent time my A-S700 has developed an intermittent fault (and today eventually failed completely). It started a week ago, it would not switch on. I tried on/off...

www.audiosciencereview.com

www.audiosciencereview.com

Experts, can you have a look please?

A couple of pictures of inside Yamaha A-S700 to stay on topic

Attachments

Last edited: