More likely, it would anneal the steel, making wheels that don't stay in true.I just tap them with a hammer to set them when new.

Stainless steel usually has to get pretty hot to change its hardness. Getting there with a torch would be pretty imprecise. I doubt this treatment was actually beneficial or worthwhile.

I actually enjoy assembling and trueing wheels, but I have had some frustrations getting the right spoke lengths. I have more NIB spokes than I care to admit.

I am always smashing up wheels because I am 6'4", fat, and ride hard.

I have smashed a few wheels, too. But it was the rim that failed, not the spokes, and in every case, I was able to reuse the spokes if I could find a rim with the right spoke-bed diameter. Rims are loaded in bending and compression.

The loads on bicycle wheels are interesting. The tension of the spoke exceeds the compressive loading, and allows the spoke to support a compressive load. The notion that hubs hang from spokes is false--they stand on the spokes near the contact patch. They can do so only if the tension of the spoke is high enough not to give it all up under compressive loading. Pursuant to ASR, tension in spokes serves just about the same purpose as biasing a transistor. The rim itself deflects (changes shape elastically) under loading, but only near the contact patch.

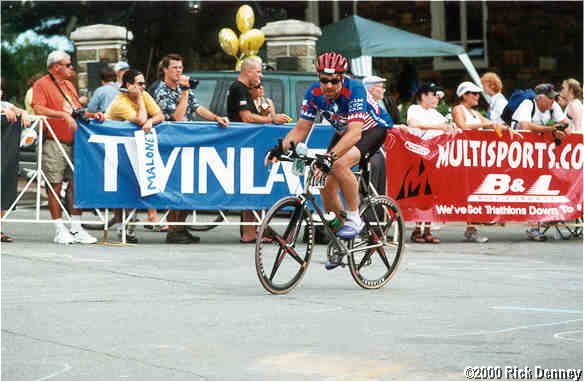

Rick "a good friend of Jobst Brandt back in the day and a former contributor to the Hardcore Bicycle Science group (RIP)" Denney