- Thread Starter

- #61

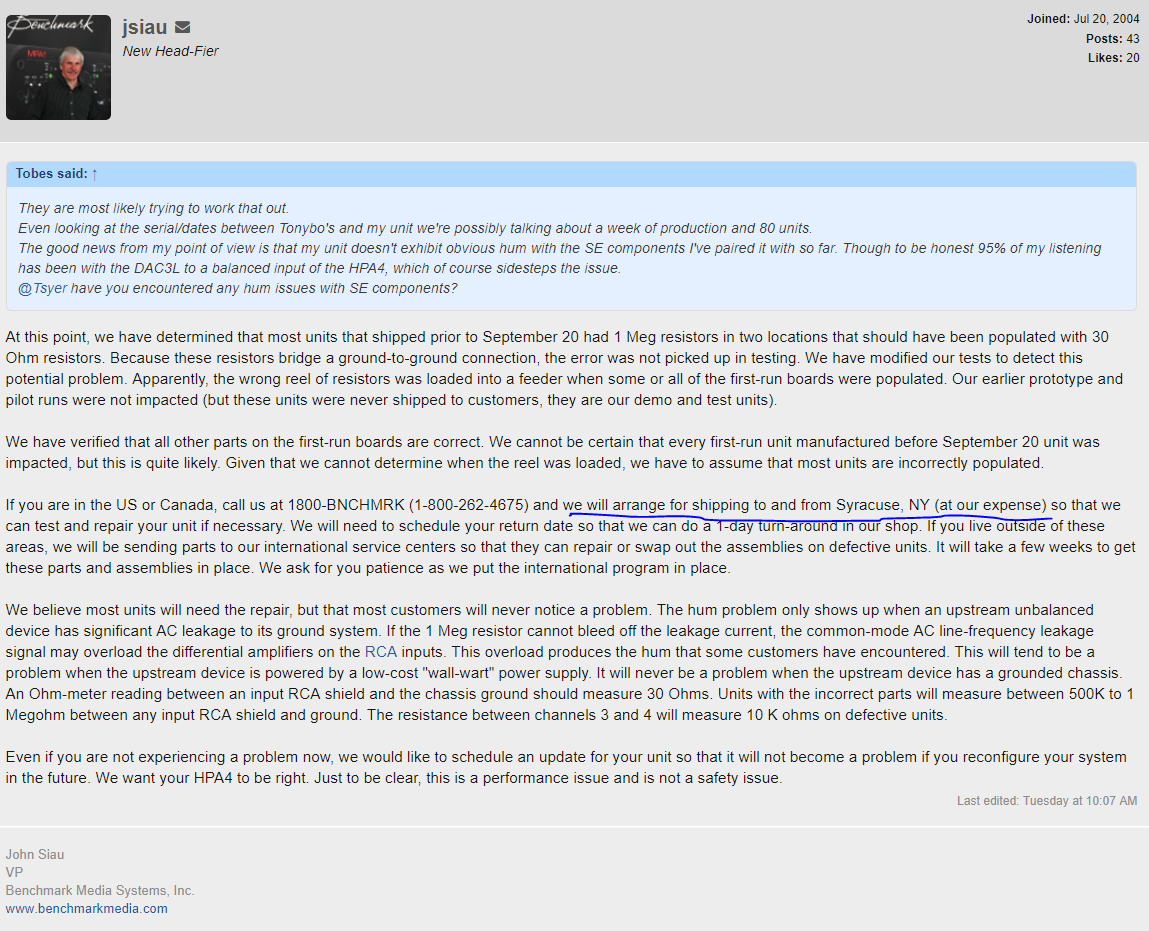

Look at how Benchmark handles this sort of thing:

Most likely because it has a double-insulated external power supply or maybe a double-insulated enclosure. For low power consumption hi-fi products, it costs much less to buy a certified external power supply than to have a product tested.

Demming / Kaizen models of continuous improvement are only worth investing in if the product is going to be made for a fairly long time.

The audio industry seems to be following the "fast fashion" model of clothing companies like H&M / Zara -- make something trendy and cheap, knowing it will quickly fall apart.

As long as the low end of the audio market is dominated by cheap, flavor-of-the-month products, driven by online hype, don't expect the quality to get better.

Heaven help me, but I’m partially defending Schiit. I’m not defending their manufacturing or design and the safety issue discussed here. But on most products Schiit and Benchmark are in different market segments.

In the Jotunheim that I examined, the screws that attach to these standoffs do NOT make a connection to the enclosure. The paint/anodization is not allowing the screw to make connection to the enclosure. The owner of the Saga is reporting the same. That there is no electrical connection between the earth pin and the enclosure.2ndly looking at some of the pics of other Schiit pcb shows that they are mounted with what looks like metal extensions, and it looks like where the extensions are mounted are in contact with a main pad! Earthing pad maybe? “Assumptions at this stage” Then they are bolted to the frame via screws.

In the Jotunheim that I examined, the screws that attach to these standoffs do NOT make a connection to the enclosure. The paint/anodization is not allowing the screw to make connection to the enclosure. The owner of the Saga is reporting the same. That there is no electrical connection between the earth pin and the enclosure.

So yes, there is a bolt and mechanical connection. But not electrical.

Rubbing off the coating was a super pain in the unit I repaired. Sandpaper did nothing. I had to use a sharp implement and spend good 10 to 15 minutes to rub off the coating as to allow the screws to make connection.

What kind of machine is this?You’d expect a lot more....

Like I said in my previous post, I don’t know how I could sleep at night letting products go without basic earthing requirements.... It’s just waiting for a disaster to strike!

I’ve been out in the field where the roof gave way and water leaked into building in multiple times. Clients stupidly places calls to say that a service condition exist and cannot use there machine. When you get there the carpet is saturated in water and as you approached the equipment it’s still connected to the mains with the panel showing a fault code. The 1st thing you do is rip the power out of the mains and cut the plug off so they can’t use it. You can see water all over and inside the product even though most are plastic covers there are metal screw heads protruding out that mount those plastic covers to the frame!

I went to one were the operator was still trying to operate the product even though there’s water all over the top cover! This thing was still plugged in live and wondered why a fault code is displayed on the LCD panel.

What kind of machine is this?

Forgive me, I was curious as to what kind of machine is so important to run that people would run it with water everywhere without thinking twice. I mean I can't even imagine what such a machine would be. I'm imagining some sort of wood cutting machine. It's okay if you don't want to say. Just curious.It doesn’t matter what type of machine it is, it’s not the point. The main point here is anything connected to mains whether it be 110 60hz or 230V 10A 50hz. Whether it be at place of employment or at home and if there is a flood or water or moisture effected make sure the mains to the building or the effected appliances in the area are physically disconnected from power.

In Australia every new residential building in the past 10-15yrs has been mandatory and regulation to have a RCD fitted. Unfortunately, that’s not the same for some commercial or industrial sites. To show how serious safety is on the brand I work on, they now introduce all main switches with RCD that’s distrubuted globally. The RCD has a test switch that must be checked on installation. Form this thread it’s obviously some manufacturers are relying on powder coated paint to guard against electrocution!

Forgive me, I was curious as to what kind of machine is so important to run that people would run it with water everywhere without thinking twice. I mean I can't even imagine what such a machine would be. I'm imagining some sort of wood cutting machine. It's okay if you don't want to say. Just curious.

Rubbing off the coating was a super pain in the unit I repaired. Sandpaper did nothing. I had to use a sharp implement and spend good 10 to 15 minutes to rub off the coating as to allow the screws to make connection.

Forgive me, I was curious as to what kind of machine is so important to run that people would run it with water everywhere without thinking twice. I mean I can't even imagine what such a machine would be. I'm imagining some sort of wood cutting machine. It's okay if you don't want to say. Just curious.

I was working in my home office and last thing I wanted was the dust from Dremel getting everywhere. But yes, if you can do it outside your home, that would be tool of the choice.This is why God invented the Dremel.

I was working in my home office and last thing I wanted was the dust from Dremel getting everywhere.

That’s 2 things at once , amir will end up in the ER doing that.Turn on the vacuum cleaner and Dremel in front of the pipe- works everytime.

The old "I was fixing my Schiit naked and the vacuum cleaner slipped" excuse, they hear that one all the time in the ER.That’s 2 things at once , amir will end up in the ER doing that.