-

Welcome to ASR. There are many reviews of audio hardware and expert members to help answer your questions. Click here to have your audio equipment measured for free!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Replace OP amps. Completely pointless, or not?

- Thread starter DanielT

- Start date

D

Deleted member 46664

Guest

The "Cheapaudioman" YT channel ... The video linked above, in fact.Booted from where?

I took up the challenge of chip flipping from Randy's video... and against all common sense it did make a sonic difference. But the $80.00 discrete opamps he was touting were just ridiculously expensive and i said so. The result was a mass of commentary trying to cool out people wanting to "opamp roll" everything from their A07 all the way to their washing machine... it was crazy how quickly people jumped all over it ... like a bunch of little kids when the icecream truck pulls into the school yard... gees. In the end I had so badly polluted that video's comments that Randy warned me and I just walked away. Some things just aren't worth the trouble...

D

Deleted member 46664

Guest

15 Hz is exceptionally high, it should be 1.6 Hz or so, and indicates something was in need of repair from the get-go. It's possible the the opamp was bad, but it's even more possible (IME) that the fiddling around to change things, especially if you soldered or desoldered, may have inadvertently fixed things. The f3 is not a function of opamp type.

Rule 1 of modification is to verify proper operation BEFORE trying the mod.

Also, separation is not a worry. At very high frequencies it might degrade from waaaaaaaaay past anything audible to waaaaay past anything audible. The practice you see is very common.

As a service tech I would 100% agree with you ... BEFORE you fix it, know what you are fixing. But I was playing "audiophile" at the moment and just wanted to be able to honestly say "Nope... no difference here"... but of course that's not what happened.

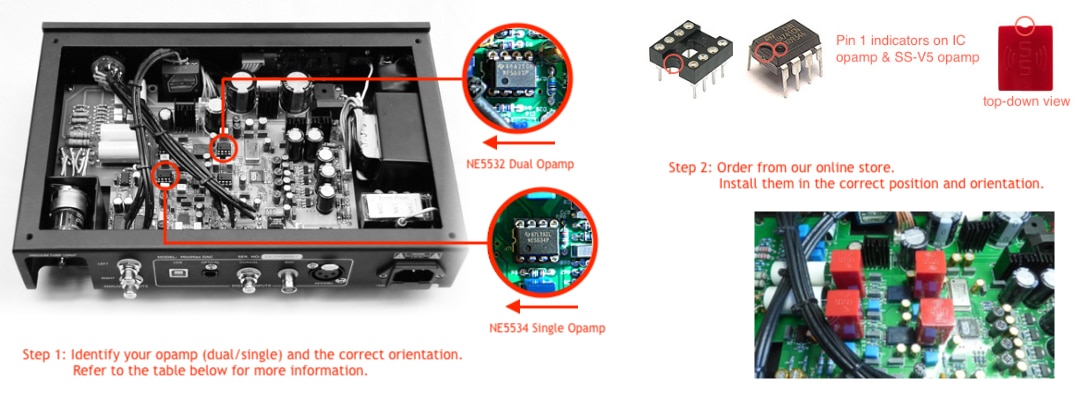

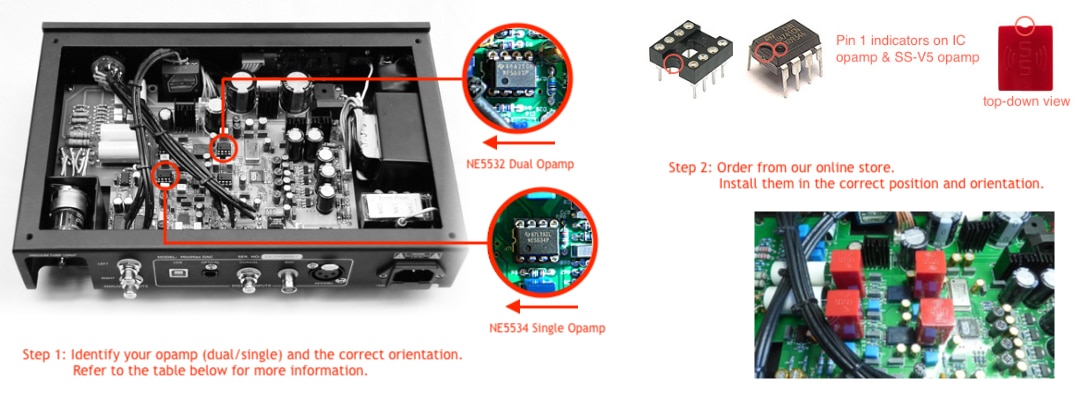

The chips are in sockets, designed to be flipped by the manufacturer... so it wasn't like I cleared a solder bridge or fixed a cold joint, it was designed to be a zero skill swap ... (And yes I have a history of accidental repairs, as does any tech.)

I did test the 5532s I pulled out... They seem to be okay. But that doesn't mean they were okay in that circuit, as you point out.

D

Deleted member 46664

Guest

But every generic audio opamp shuld work in this application without making the changes you describe.

Exactly ... that should have been the case.

Cote Dazur

Addicted to Fun and Learning

Your opinion is only valuable for you if not backed up with clear technical data and properly conducted subjective testing.So my advice might be useless for you, but not for others.

"Sound clearer", you might as well have written, the veil was lifted.Aiyima a04 with LM4562 is more dynamic, goes deeper in the bass and sound clearer.

JSmith

Master Contributor

An interesting few video's on the subject of potentially fake opamps;

JSmith

JSmith

- Thread Starter

- #168

OT:

Nop, I forgot. I can not replace OP amps in my AIYIMA A07 TPA3255 because I replaced it with my neighbor's electric guitar. So now, on the contrary, I want a LOT of distortion.Really audible . He he.

. He he.

The best distortion.

Guitar amplifier was not included in the change so I have to fix some nice, cool, guitar tube amp.

Nop, I forgot. I can not replace OP amps in my AIYIMA A07 TPA3255 because I replaced it with my neighbor's electric guitar. So now, on the contrary, I want a LOT of distortion.Really audible

The best distortion.

Guitar amplifier was not included in the change so I have to fix some nice, cool, guitar tube amp.

I would get in there and start resoldering connections and examine traces under magnification. The mechanics of flexing can temporarily fix a poor solder joint or hairline crack but it won't stay that way. Your starting point was a literally broken unit, so don't try drawing any conclusions from the opamp change.As a service tech I would 100% agree with you ... BEFORE you fix it, know what you are fixing. But I was playing "audiophile" at the moment and just wanted to be able to honestly say "Nope... no difference here"... but of course that's not what happened.

The chips are in sockets, designed to be flipped by the manufacturer... so it wasn't like I cleared a solder bridge or fixed a cold joint, it was designed to be a zero skill swap ... (And yes I have a history of accidental repairs, as does any tech.)

I did test the 5532s I pulled out... They seem to be okay. But that doesn't mean they were okay in that circuit, as you point out.

Bow_Wazoo

Major Contributor

- Joined

- Jan 3, 2021

- Messages

- 1,038

- Likes

- 875

Is there a schematic of this op amp? What components are used here?

www.bursonaudio.com

www.bursonaudio.com

Supreme Sound Opamp V6 - Burson Audio

The Burson V6 is a Class-A discrete opamp, epitomizing Burson Audio's engineering excellence. Offering unmatched clarity and detail, it's a top choice for audiophiles upgrading their equipment.

www.bursonaudio.com

www.bursonaudio.com

D

Deleted member 46664

Guest

I would get in there and start resoldering connections and examine traces under magnification. The mechanics of flexing can temporarily fix a poor solder joint or hairline crack but it won't stay that way. Your starting point was a literally broken unit, so don't try drawing any conclusions from the opamp change.

I just did that ... And yes you are correct, my starting point was a defective amp. My test turned out to be a repair!

It took a while but I finally did figure it out. It was the #$%@ crappy sockets! I used the old trick of probing the sockets with a needle to ensure the pins were connecting properly and there were a couple of spots where even the slightest touch would change the behaviour... so I replaced them with the high quality sockets I use with my other projects .... so far so good... with both NE5532s and RC4558s from my stock... not the originals from the amp (I've now trashed them).

I never really thought that chip flipping was a thing ... I know better than that ... but I did need an explanation.

Thanks guys... your help and advice is appreciated.

Opamp rolling is entirely real, but depends on the circuit its in. Used as a unity gain buffer, as long as the chosen part is suitable all you'll notice as different is the relative noise levels, which with any decent part will be way down there.

We're you to swap between bipolar and jfet input types in a MC phonostage front end youd notice a hell of a difference, as one type is suitable and other simply isnt. Even swapping between jfet input types in certain MC stages, say opa1611 vs a maxim427 is clearly audible as about a 7db noise penalty.

Likewise if you selected a part that wasn't unity gain stable in the buffer you'd notice it.

As ever generalisations obscure the truth. You have to know the parts, their specs and the circuit conditions they'll be used in

We're you to swap between bipolar and jfet input types in a MC phonostage front end youd notice a hell of a difference, as one type is suitable and other simply isnt. Even swapping between jfet input types in certain MC stages, say opa1611 vs a maxim427 is clearly audible as about a 7db noise penalty.

Likewise if you selected a part that wasn't unity gain stable in the buffer you'd notice it.

As ever generalisations obscure the truth. You have to know the parts, their specs and the circuit conditions they'll be used in

D

Deleted member 46664

Guest

Opamp rolling is entirely real, but depends on the circuit its in. Used as a unity gain buffer, as long as the chosen part is suitable all you'll notice as different is the relative noise levels, which with any decent part will be way down there.

I agree, there are situations where it does matter ... but this should not have been one of them!

So far so good...

Be careful about op amp rolling, as some types may not be stable in the test circuit. Check with a 'scope to be sure there's no misbehavior like oscillations or overshoot. These behaviors can cause a misguided perception of sound quality in a jellybean (op amp). My suspicion is that once proper behavior is verified, you will likely not be able to tell the difference between op amps so long as the devices are operated within their specified limits.

antcollinet

Grand Contributor

So basically what you are saying is if you break the design by swapping the manufacturers carefully selected opamp for one that doesn't work in that design, then you can hear it.Opamp rolling is entirely real, but depends on the circuit its in. Used as a unity gain buffer, as long as the chosen part is suitable all you'll notice as different is the relative noise levels, which with any decent part will be way down there.

We're you to swap between bipolar and jfet input types in a MC phonostage front end youd notice a hell of a difference, as one type is suitable and other simply isnt. Even swapping between jfet input types in certain MC stages, say opa1611 vs a maxim427 is clearly audible as about a 7db noise penalty.

Likewise if you selected a part that wasn't unity gain stable in the buffer you'd notice it.

As ever generalisations obscure the truth. You have to know the parts, their specs and the circuit conditions they'll be used in

This is not a big surprise.

Ricardus

Addicted to Fun and Learning

Yeah, I love these counter examples that talk about breaking the design, and then you hear the difference.So basically what you are saying is if you break the design by swapping the manufacturers carefully selected opamp for one that doesn't work in that design, then you can hear it.

This is not a big surprise.

Like I said to someone on Mastodon a few weeks ago... comparing a broken piece of gear to a properly functioning piece of gear will almost always yield a difference.

DVDdoug

Major Contributor

- Joined

- May 27, 2021

- Messages

- 4,463

- Likes

- 6,149

Those still exist?Likewise if you selected a part that wasn't unity gain stable in the buffer you'd notice it.

Back in the 1970s I was building a preamp that turned-out to be an RF oscillator and it burned-up one channel in my power amplifier. That's how I learned about op-amp instability! I thought I was smart using variable feedback for volume control. I didn't have an oscilloscope so I had to deduce the problem. Before I heard a little pop (as the power amp died) I was very impressed with myself because I wasn't hearing any preamp noise! (I hadn't run a signal through it yet.)

Yup usually older opamps. NWAGuys old primer is a great intro.

nwavguy.blogspot.com

nwavguy.blogspot.com

Op Amp Measurements

INTRO: In last week’s Op Amps: Myths & Facts article I covered the background for op amps, why they’re important, and some common audiophi...

This opens up the brand new hype of socket rolling.I just did that ... And yes you are correct, my starting point was a defective amp. My test turned out to be a repair!

It took a while but I finally did figure it out. It was the #$%@ crappy sockets! I used the old trick of probing the sockets with a needle to ensure the pins were connecting properly and there were a couple of spots where even the slightest touch would change the behaviour... so I replaced them with the high quality sockets I use with my other projects .... so far so good... with both NE5532s and RC4558s from my stock... not the originals from the amp (I've now trashed them).

Similar threads

- Replies

- 35

- Views

- 2K

- Replies

- 102

- Views

- 15K

- Replies

- 33

- Views

- 4K

- Poll

- Replies

- 336

- Views

- 47K

- Replies

- 14

- Views

- 1K