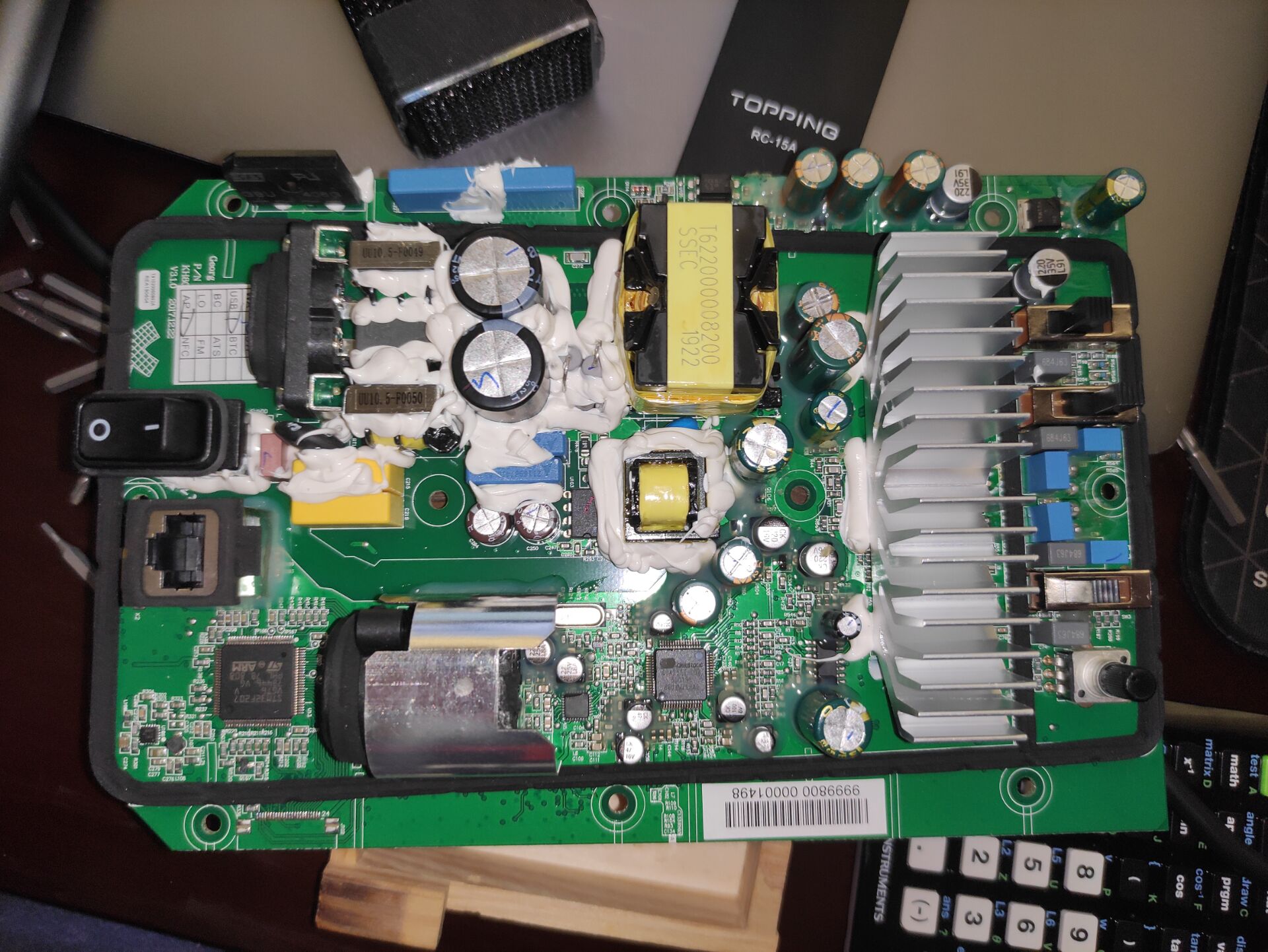

A friend of mine decided to look at the inside of the KH80DSP because he found the Neumanns run hotter than his JBL LSR305P MkII. Seems like there hasn't been any teardown picture of the KH80DSP on the internet. My friend kindly allowed me to share these disassembly pictures on this forum, so there they are!

-

Welcome to ASR. There are many reviews of audio hardware and expert members to help answer your questions. Click here to have your audio equipment measured for free!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Neumann KH80DSP Teardown

- Thread starter Χ Ξ Σ

- Start date

- Thread Starter

- #3

"Nope. The amp chip is covered by a heatsink, and the screws holding the heatsink to the board are glued down. Not sure if I can take that apart without breaking anything."

Says the man.

Mario Sanchez

Active Member

- Joined

- Jan 11, 2021

- Messages

- 161

- Likes

- 288

I'm that friend who did the teardown. The chip amps' heatsinks have their screws glued down against the board. I'm not sure if I could take them off without breaking the whole thing so I left it as is.

- Joined

- May 21, 2019

- Messages

- 4,036

- Likes

- 6,880

Thanks for going as far as you didI'm that friend who did the teardown. The chip amps' heatsinks have their screws glued down against the board. I'm not sure if I could take them off without breaking the whole thing so I left it as is.

Mario Sanchez

Active Member

- Joined

- Jan 11, 2021

- Messages

- 161

- Likes

- 288

I could try using a hot air gun or something similar to melt the glue at a later time. It would prove to be a risky endeavour though.

Mario Sanchez

Active Member

- Joined

- Jan 11, 2021

- Messages

- 161

- Likes

- 288

I plan to do another disassembly to clean up the curious soot-like substance inside the speaker cabinet (these are pretty new - been in my hands for less than a month, maybe they slept too long in the warehouse?), I'll use that chance to see if I could investigate a little deeper into the speaker itself.Thanks for going as far as you did

Mario Sanchez

Active Member

- Joined

- Jan 11, 2021

- Messages

- 161

- Likes

- 288

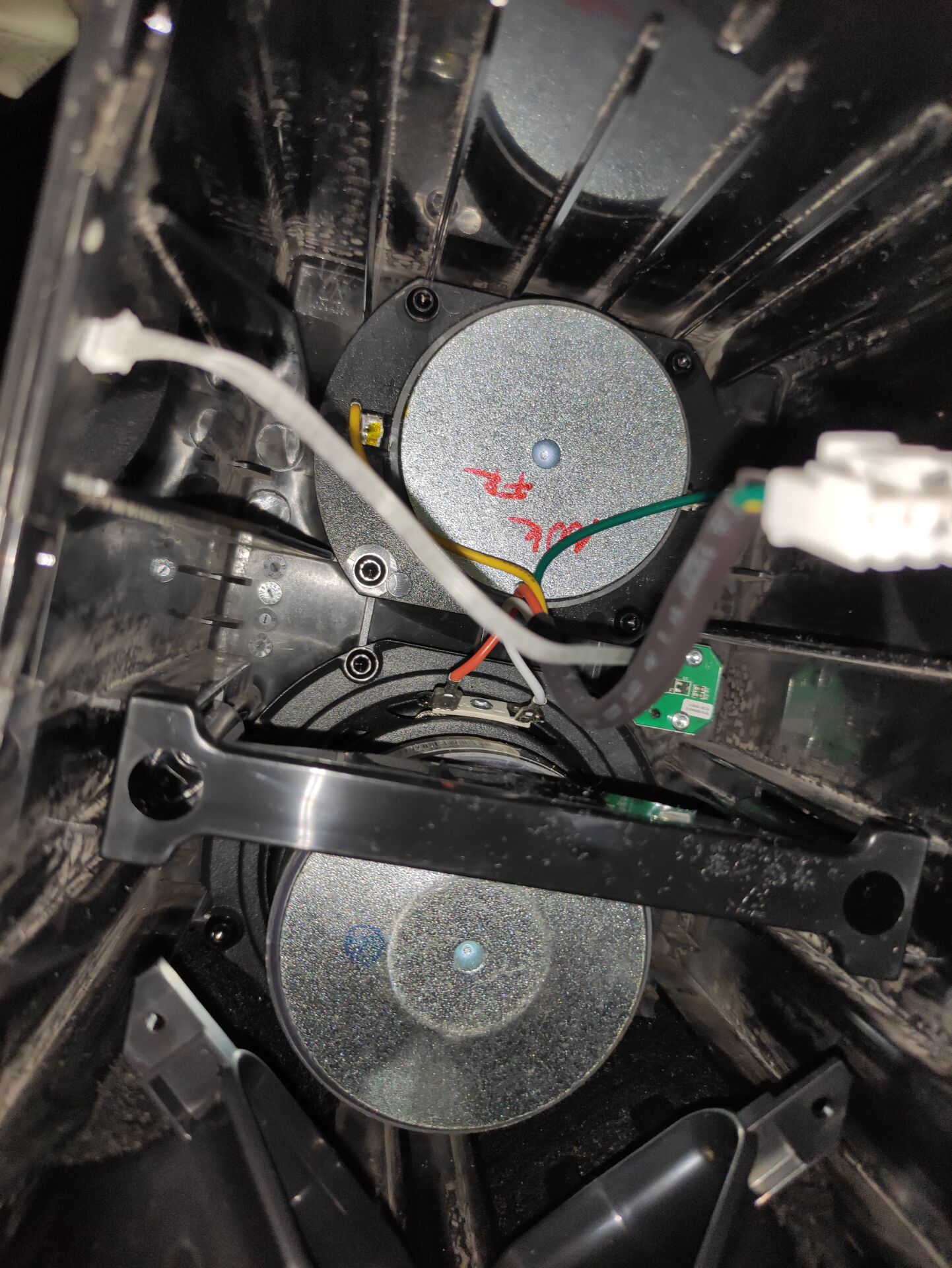

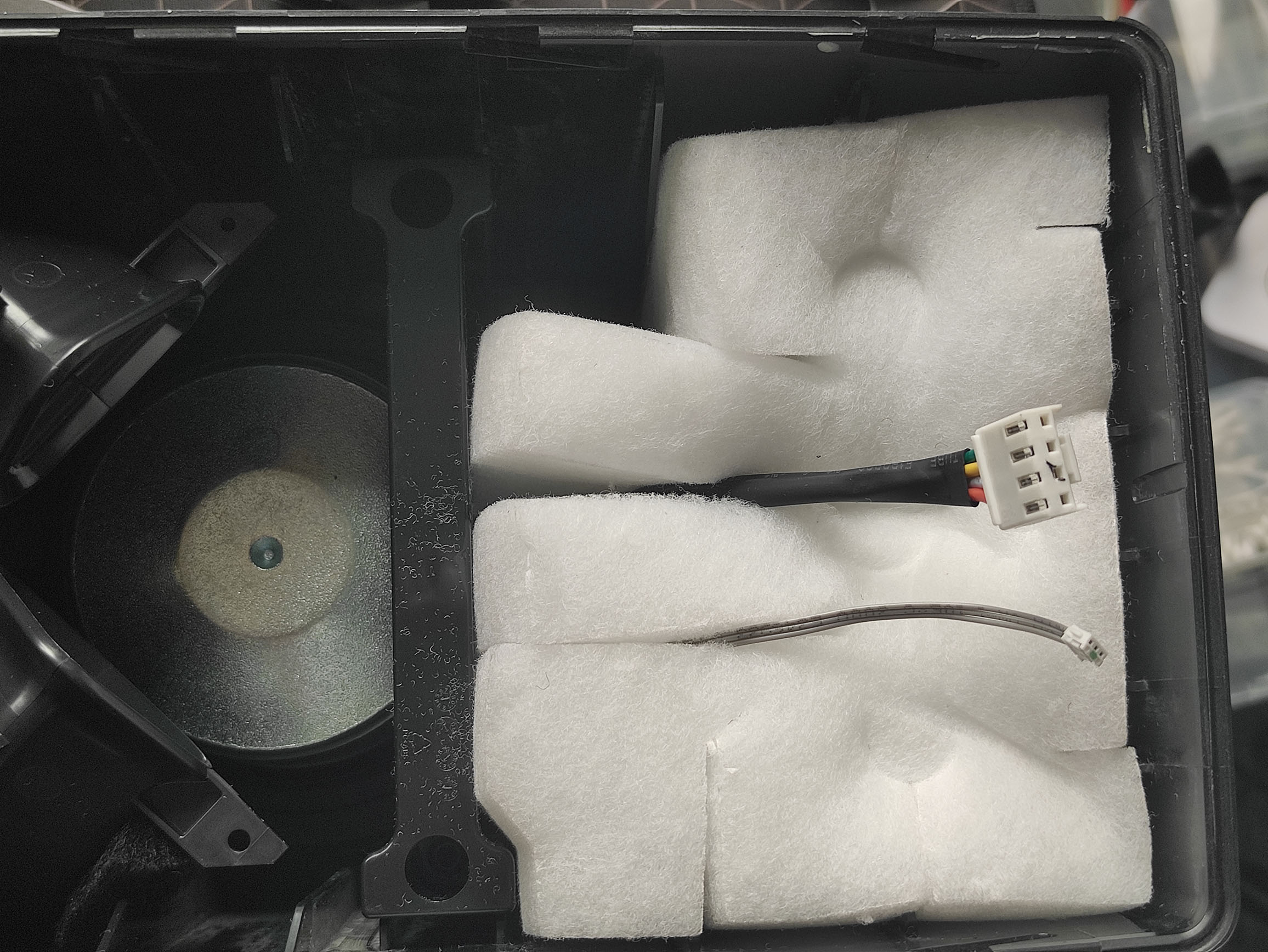

A quick look at the drivers:

I must say, they look rather unsuspecting!

More details to follow.

I must say, they look rather unsuspecting!

More details to follow.

restorer-john

Grand Contributor

My goodness.

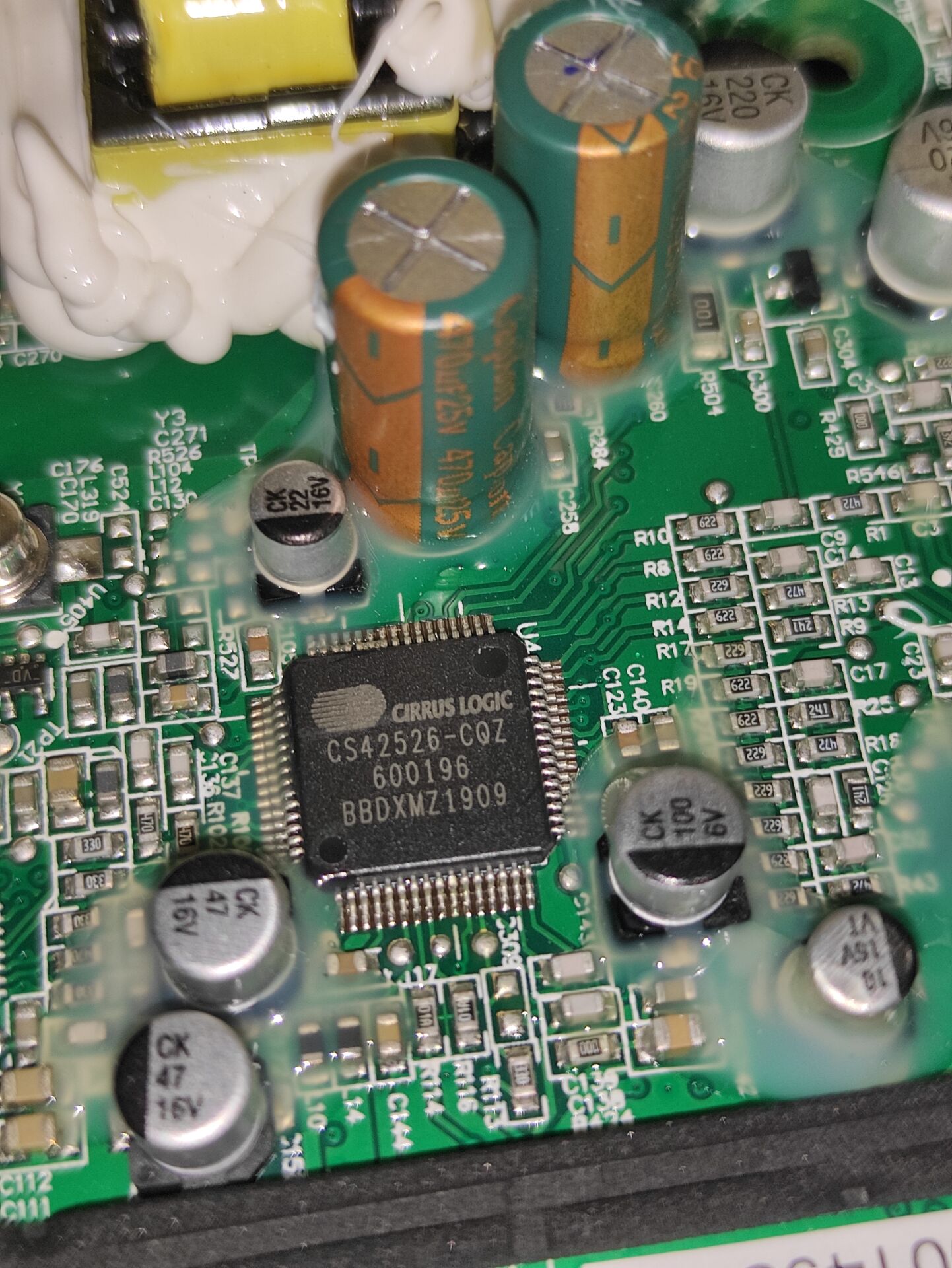

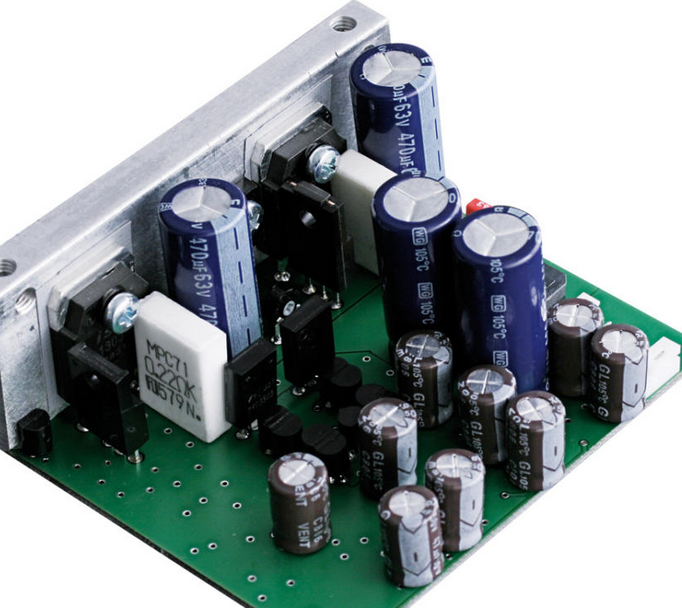

They are using one of the absolute worst tier of capacitors in the world for catastrophic failure. CapXon. I can see 11 of them on the one board.

All to save a few cents. Neuman are taking their customers for fools. Shame.

They are using one of the absolute worst tier of capacitors in the world for catastrophic failure. CapXon. I can see 11 of them on the one board.

All to save a few cents. Neuman are taking their customers for fools. Shame.

Last edited:

Mario Sanchez

Active Member

- Joined

- Jan 11, 2021

- Messages

- 161

- Likes

- 288

While I try to clean up the cabinet, a few more images:

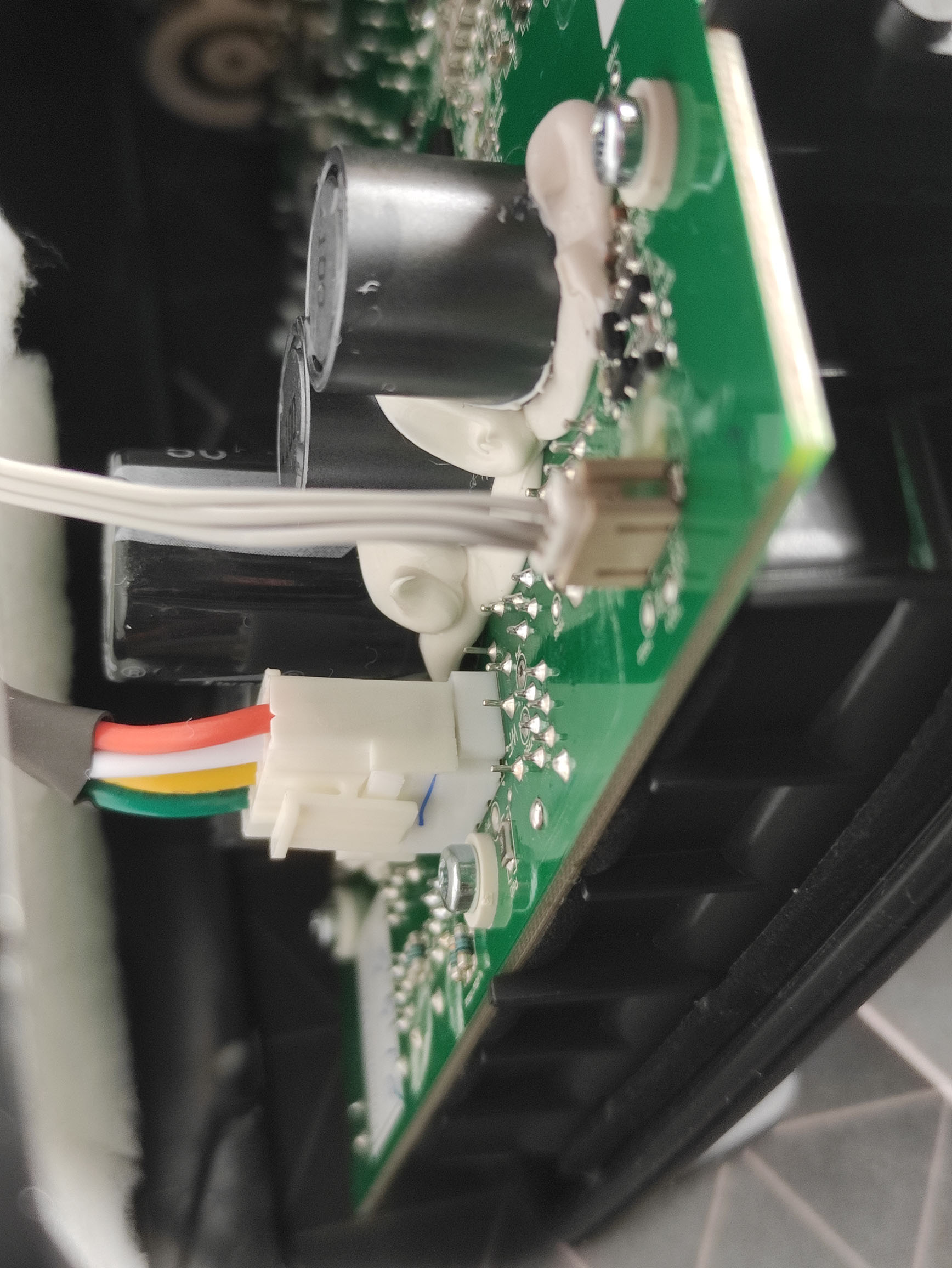

The cabinet's rear portion comes off easily after unscrewing the two Torx 20 (ish) screws at the bottom rear edge of the cabinet and giving the upper edge of the rear portion a push. There are three plastic extrusions on each side that hook onto cutouts on the cabinet wall. The perimeter of the rear shell is lined with rubber. presumably to improve the seal between the rear shell and the rest of the cabinet. You can also see the glued-down screw holding the heat sink on the opposite side of PCB in place.

The cabinet's rear portion comes off easily after unscrewing the two Torx 20 (ish) screws at the bottom rear edge of the cabinet and giving the upper edge of the rear portion a push. There are three plastic extrusions on each side that hook onto cutouts on the cabinet wall. The perimeter of the rear shell is lined with rubber. presumably to improve the seal between the rear shell and the rest of the cabinet. You can also see the glued-down screw holding the heat sink on the opposite side of PCB in place.

Disconnect the larger 4-pin which goes to the driver as well as the smaller 3-pin which goes to the LED, and the rear portion detaches from the rest of the speaker.

There is a big fat foam chunk of sorts behind the tweeter driver which also helps the cables stay in place. The cabinet is, of course, made of PC plastic but they have a nice thickness to them and are fairly rigid. There is a strut in the middle of the speaker presumably to reinforce its structure. There are only two types of screws in the kh80: One is a Torx T20(ish) M4 screw that holds the drivers, the port, the strut in the middle of the cabinet, and the rear shell of the speaker in place. The other is a Torx T10(ish) M3 screw which is used to affix PCBs to the speaker.

The port tube is of a curious design - There is a small hole in the middle of it blocked by the same material which stuffs the upper part of the cabinet! I'll leave it to someone savvier in these things to explain this.

Disconnect the larger 4-pin which goes to the driver as well as the smaller 3-pin which goes to the LED, and the rear portion detaches from the rest of the speaker.

There is a big fat foam chunk of sorts behind the tweeter driver which also helps the cables stay in place. The cabinet is, of course, made of PC plastic but they have a nice thickness to them and are fairly rigid. There is a strut in the middle of the speaker presumably to reinforce its structure. There are only two types of screws in the kh80: One is a Torx T20(ish) M4 screw that holds the drivers, the port, the strut in the middle of the cabinet, and the rear shell of the speaker in place. The other is a Torx T10(ish) M3 screw which is used to affix PCBs to the speaker.

The port tube is of a curious design - There is a small hole in the middle of it blocked by the same material which stuffs the upper part of the cabinet! I'll leave it to someone savvier in these things to explain this.

- Joined

- May 21, 2019

- Messages

- 4,036

- Likes

- 6,880

Wasn't that reputation earned 10+ years ago? A lot water under the bridge since then.They are using one of the absolute worst tier of capacitors in the world for catastrophic failure. CapXon. I can see 11 of them on the one board.

restorer-john

Grand Contributor

Wasn't that reputation earned 10+ years ago? A lot water under the bridge since then.

Nearly 20 years ago they earned that reputation. And a lot of electrolyte vented under that same bridge since.

Just the other day it was 2018 CapXons I pulled out of a dead rackmount gigabit switch onboard SMPS at our call centre. 3 years old.

There's just no reasonable excuse for using sh#t capacitors.

- Joined

- May 21, 2019

- Messages

- 4,036

- Likes

- 6,880

Component science review? We need some of that and some stats.Nearly 20 years ago they earned that reputation. And a lot of electrolyte vented under that same bridge since.

Just the other day it was 2018 CapXons I pulled out of a dead rackmount gigabit switch onboard SMPS at our call centre. 3 years old.

There's just no reasonable excuse for using sh#t capacitors.

restorer-john

Grand Contributor

We need some of that and some stats.

I used to keep dead capacitors in a parts bin, but decided the chemicals seeping out were not a good thing to be breathing. Now I throw them away the same day.

Vented electros smell like fish. Eeww.

Ron Texas

Master Contributor

- Joined

- Jun 10, 2018

- Messages

- 6,654

- Likes

- 10,371

My goodness.

They are using one of the absolute worst tier of capacitors in the world for catastrophic failure. CapXon. I can see 11 of them on the one board.

All to save a few cents. Neuman are taking their customers for fools. Shame.

This is the soft underbelly of active speakers. How well are the electronics built?

Mario Sanchez

Active Member

- Joined

- Jan 11, 2021

- Messages

- 161

- Likes

- 288

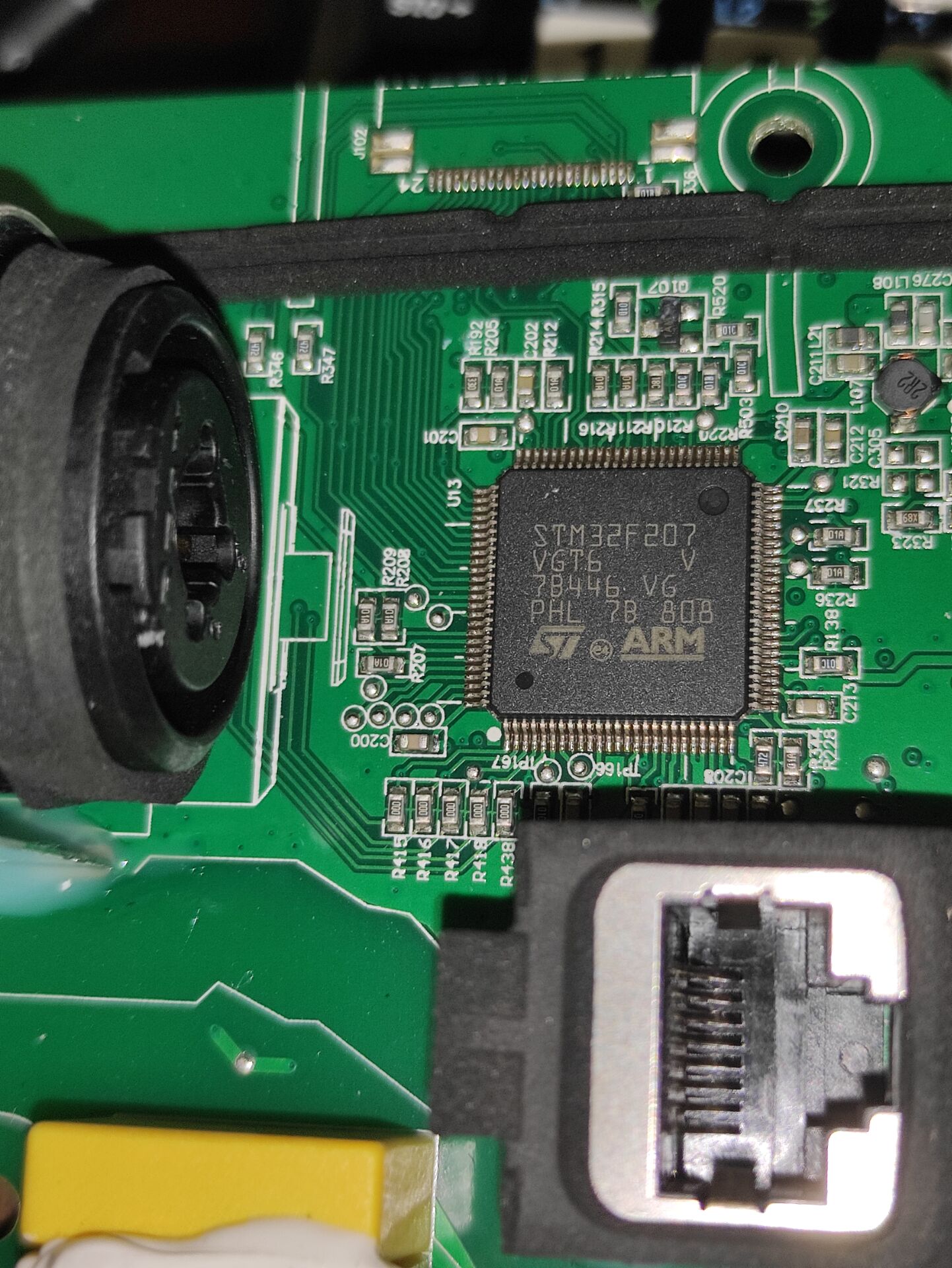

I managed to remove the heatsink. Amp chip is a lonely TAS5613A. This is a stereo chip from Texas Instruments. My uneducated guess is that it is used in a similar fasion to the STA350BW on JBL305p MkII with one channel hooked up to bass and the other linked to the tweeter.

Component science review? We need some of that and some stats.

There kind of is one:

Are capxons really that bad?

Mario Sanchez

Active Member

- Joined

- Jan 11, 2021

- Messages

- 161

- Likes

- 288

My goodness.

They are using one of the absolute worst tier of capacitors in the world for catastrophic failure. CapXon. I can see 11 of them on the one board.

All to save a few cents. Neuman are taking their customers for fools. Shame.

There are also a couple "JWCO" capacitors on the board (The green capacitor with a yellowish trim rather than orangeish, as well as one big capacitor on the driver side of PCB).

Any opinions on these?

restorer-john

Grand Contributor

There are also a couple "JWCO" capacitors on the board (The green capacitor with a yellowish trim rather than orangeish, as well as one big capacitor on the driver side of PCB).

That's a new one to me. Apparently Jiaweicheng Electronic Co.

http://www.jiaweicheng.com/en/about.html

what's a really funny coincidence however is this company: http://www.jwco.com/. They provide blowout response services!

Guess we'll find out in time whether to add them to the badcaps list or not. But Neumann using cheap capacitors is clearly not a good look.

I wouldn't buy anything with crap capacitors in it. Don't care what it is, it doesn't come into my house.

Last edited:

@restorer-john, anything on this board trigger any alarms? It's the AB tweeter amp from an Adam AX series I found on Adam's site (I own A5Xs.):

https://www.adam-audio.com/content/uploads/2016/09/adam-audio-technologies-tweeter-amp-1400x933.jpg

https://www.adam-audio.com/content/uploads/2016/09/adam-audio-technologies-tweeter-amp-1400x933.jpg

Similar threads

- Replies

- 3

- Views

- 964

- Replies

- 50

- Views

- 20K

- Replies

- 8

- Views

- 796