Hi Guys,

Driver suspension break-in is a well known effect. For example, please see this paper from Klippel on the topic. https://www.aes.org/e-lib/browse.cfm?elib=16000

You can also find some slides from the paper here: https://www.klippel.de/fileadmin/kl...tigue_and_Aging_of_suspension_AES_NY_2011.pdf

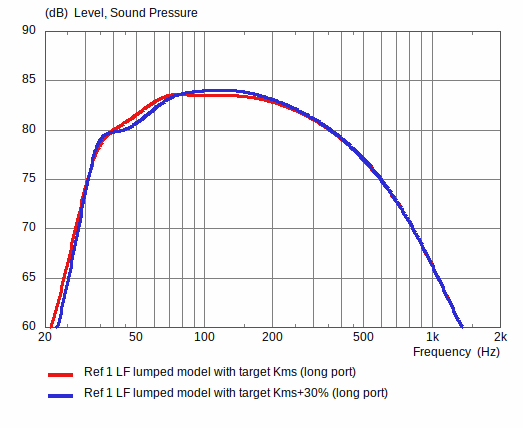

Very typically our driver suspension stiffness directly from the production line is around 20-30% higher than the final target stiffness value. You can see from the Klippel paper that it typically requires a several hours of running at moderate levels to get to the final target value*. A good suspension will settle to a consistent final value and won't continue to fatigue. The frequency response variation depends on the exact loudspeaker but it can often be as much as 1dB, plus the pre-run-in response often tends to peak up around port tuning.

I'm travelling currently but here's some data from a lumped model using the Reference 1 for demonstration.

Kind regards,

Jack.

*as you can see from the Klippel paper, you can run speakers in very fast using high level signals but I'd never recommend that customers do it that way as there's significant potential to damage the drivers.

Driver suspension break-in is a well known effect. For example, please see this paper from Klippel on the topic. https://www.aes.org/e-lib/browse.cfm?elib=16000

You can also find some slides from the paper here: https://www.klippel.de/fileadmin/kl...tigue_and_Aging_of_suspension_AES_NY_2011.pdf

Very typically our driver suspension stiffness directly from the production line is around 20-30% higher than the final target stiffness value. You can see from the Klippel paper that it typically requires a several hours of running at moderate levels to get to the final target value*. A good suspension will settle to a consistent final value and won't continue to fatigue. The frequency response variation depends on the exact loudspeaker but it can often be as much as 1dB, plus the pre-run-in response often tends to peak up around port tuning.

I'm travelling currently but here's some data from a lumped model using the Reference 1 for demonstration.

Kind regards,

Jack.

*as you can see from the Klippel paper, you can run speakers in very fast using high level signals but I'd never recommend that customers do it that way as there's significant potential to damage the drivers.