-

Welcome to ASR. There are many reviews of audio hardware and expert members to help answer your questions. Click here to have your audio equipment measured for free!

- Forums

- Audio, Audio, Audio!

- DACs, Streamers, Servers, Players, Audio Interface

- Combination Audio DAC and Headphone Amplifiers

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

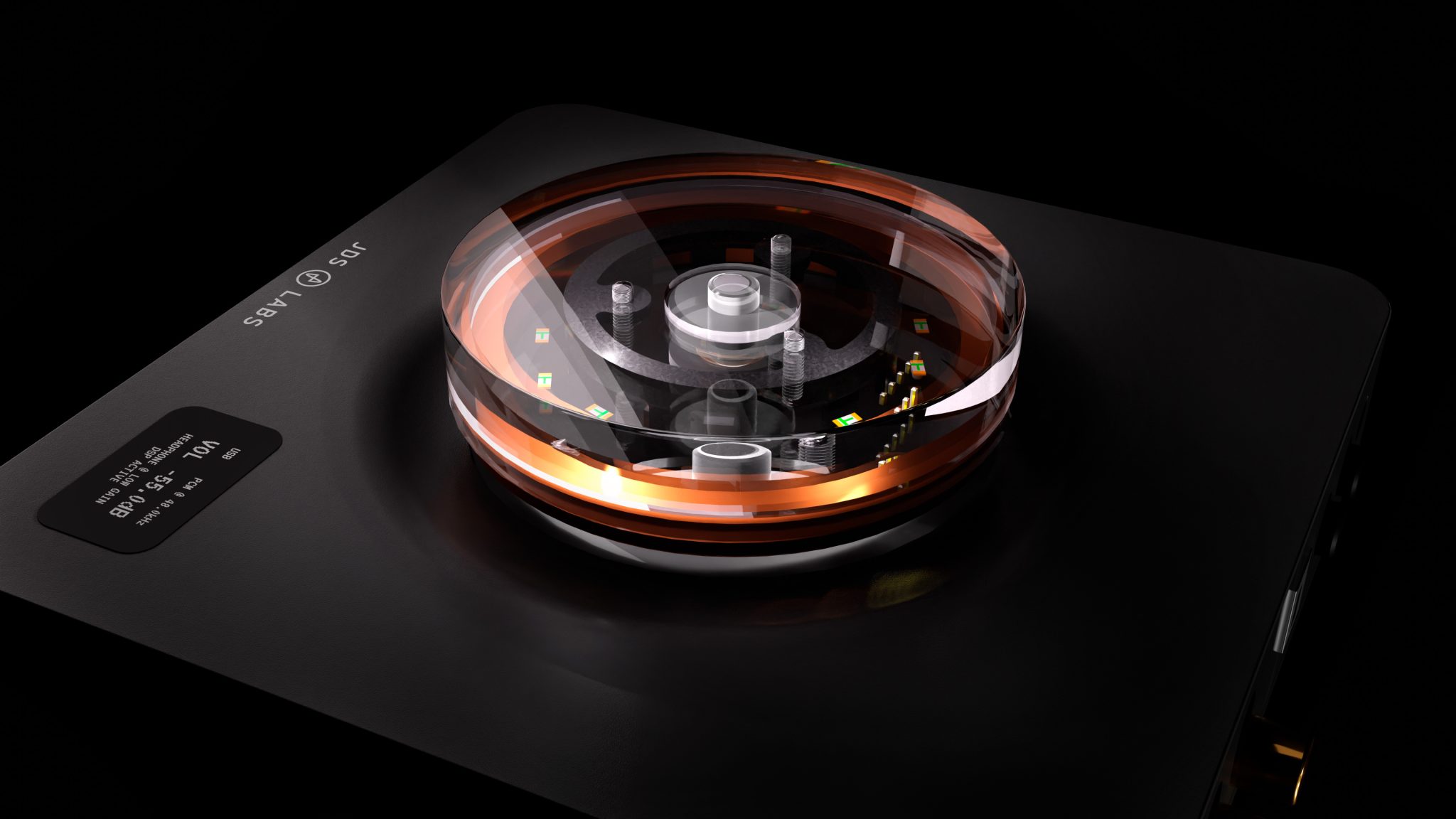

JDS Labs Element IV DAC & HP Amp with EQ Review

- Thread starter amirm

- Start date

Great it is! Very much looking forward to receiving the Element IV in the coming month/year.

Thank you for the review, Amir!

My considerations (in contrast to much negativity in the forum):

+ compact, one device, one power supply

+ two buttons, no switches; buttons that I would actually use or eventually need.

+ good quality volume knob/button (it seems) with perfect channel balance

+ auto gain

+ a small selection of output options; no balanced headphone output that I don't need.

+ no big display(s) showing me info I don't need 99% of the time; e.g. all my music is 44.1 kHz or 48 kHz.

+ no bluetooth; no smart device guy, rarely use bluetooth and wifi.

+ Linux compatible device and app; will install and run the needed Firefox plugin in a separate browser profile for security.

+ made in the USA; voting with my Euros for less dependency on China.

- not state of the art test results but good enough for my ears for sure

- pricy

Thank you for the review, Amir!

My considerations (in contrast to much negativity in the forum):

+ compact, one device, one power supply

+ two buttons, no switches; buttons that I would actually use or eventually need.

+ good quality volume knob/button (it seems) with perfect channel balance

+ auto gain

+ a small selection of output options; no balanced headphone output that I don't need.

+ no big display(s) showing me info I don't need 99% of the time; e.g. all my music is 44.1 kHz or 48 kHz.

+ no bluetooth; no smart device guy, rarely use bluetooth and wifi.

+ Linux compatible device and app; will install and run the needed Firefox plugin in a separate browser profile for security.

+ made in the USA; voting with my Euros for less dependency on China.

- not state of the art test results but good enough for my ears for sure

- pricy

Last edited:

Hey guys, I have a element 4 on order and I have a general question regarding the optical encoder. I live in a dusty city and since most of us leave amps on the desk I'm wondering is to okay to clean the space around the knob using compressed air? Also, in the worst case scenario if something does fall under the knob can it be gently removed like a normal encoder knob and serviced?

Thanks!

Thanks!

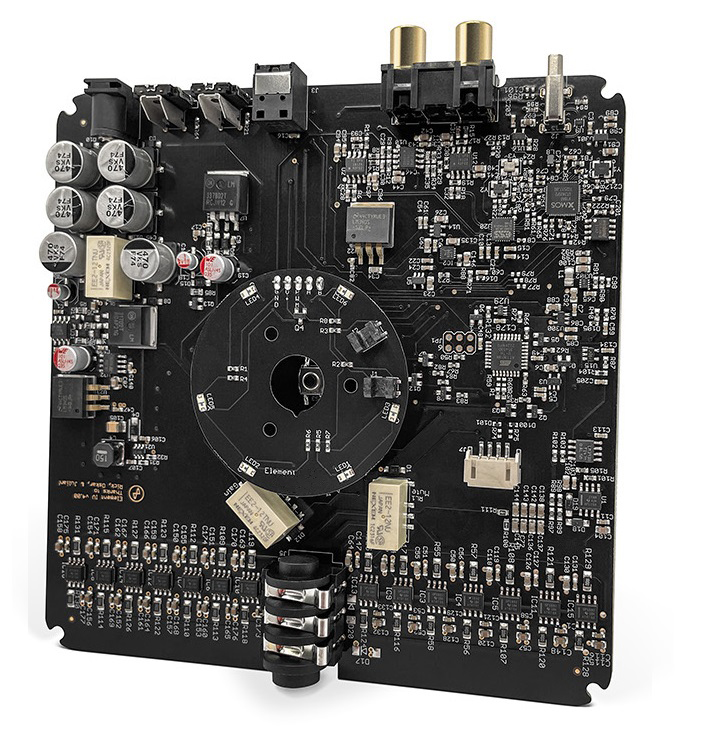

Going off of JDS Labs images it appears that the encoder PCB is directly under the knob. Dropping conductive debris down there would be a bad thing. Compressed/canned air can be hazardous to SMD flat packs etc in that the high pressure gas gets under the flatpacks etc and the force is large enough to lift them right off the PCB. So no aiming it directly at surface mount components and blasting them full strength from a short distance away. I've seen where a tech I worked with used compressed air and lifted a ~120 pin flatpack off a Sony SMD PCB and it went flying. So use caution and common sense and you should be OK.Hey guys, I have a element 4 on order and I have a general question regarding the optical encoder. I live in a dusty city and since most of us leave amps on the desk I'm wondering is to okay to clean the space around the knob using compressed air? Also, in the worst case scenario if something does fall under the knob can it be gently removed like a normal encoder knob and serviced?

Thanks!

Yes, the knob is removable. If you purchase the Element 4 maybe you can pull the knob and snap some images for us to see what JDS Labs did under the knob.Hey guys, I have a element 4 on order and I have a general question regarding the optical encoder. I live in a dusty city and since most of us leave amps on the desk I'm wondering is to okay to clean the space around the knob using compressed air? Also, in the worst case scenario if something does fall under the knob can it be gently removed like a normal encoder knob and serviced?

Thanks!

johny_2000

Addicted to Fun and Learning

The dust cleaner can emit very cold gas, which can condense moisture on the surface, wet and short the conductors on the circuit board. Do this with the power off and let it dry before using.

Extreme_Boky

Active Member

- Joined

- Jun 9, 2020

- Messages

- 134

- Likes

- 87

Element IV is made in the USA. That might be the required/good enough reason to go ahead and buy it.Should i get this or the raw mda-1 for the arya stealth?

However, if you are looking at other things, then for US$500, you can get SMSL DL300 (the flagship AKM DAC chip) or DL400 (the flagship ESS DAC chip). Compare the features and specs... see what suits you better.

I have a condenser mic standing on my desk. When I don't use it I cover it with a cloth to protect it from dust. Perhaps a similiar solution could protect your Element IV when unused.Hey guys, I have a element 4 on order and I have a general question regarding the optical encoder. I live in a dusty city and since most of us leave amps on the desk I'm wondering is to okay to clean the space around the knob using compressed air? Also, in the worst case scenario if something does fall under the knob can it be gently removed like a normal encoder knob and serviced?

Thanks!

Thanks! I'm wondering if it is friction fit? Is there anything to watch out for when disassembling aside from not applying lateral force? Maybe someone from JDS can chime in here.Yes, the knob is removable. If you purchase the Element 4 maybe you can pull the knob and snap some images for us to see what JDS Labs did under the knob.

If I ever take the knob off I'll certainly share pictures and maybe measure the bearing axle for anyone who wants to DIY.

Yes, some preventative measures can be taken, but as I found with my keyboards, dust always seems to find a way.I have a condenser mic standing on my desk. When I don't use it I cover it with a cloth to protect it from dust. Perhaps a similiar solution could protect your Element IV when unused.

Noted, if I can remove the knob then I'll prob resort to a small brush, compressed air always comes with risks and sometimes blows dust onto sensitive components.The dust cleaner can emit very cold gas, which can condense moisture on the surface, wet and short the conductors on the circuit board. Do this with the power off and let it dry before using.

I searched for JDS Labs in the members search field and was unable to track down JDS Labs name for ASR. Can somebody chime in on what name JDS Labs uses. Thanksssss...Thanks! I'm wondering if it is friction fit? Is there anything to watch out for when disassembling aside from not applying lateral force? Maybe someone from JDS can chime in here.

@jseaber (John Seaber). See below link for his posts in this thread.I searched for JDS Labs in the members search field and was unable to track down JDS Labs name for ASR. Can somebody chime in on what name JDS Labs uses. Thanksssss...

Search results

www.audiosciencereview.com

www.audiosciencereview.com

Thank you very much! ...@jseaber (John Seaber). See below link for his posts in this thread.

Search results

www.audiosciencereview.com

Hi @jseaber. Can you please give us a brief rundown on how to remove the Element 4 knob. Does it require much lift pressure etc. What size is the pot shaft?

@wufishy I just requested information from JDS Labs.

- Joined

- Aug 20, 2020

- Messages

- 1,742

- Likes

- 1,844

Don’t fix it unless there is a problem. A nice cloth covering it when not in use should keep it out of trouble. Any time you take something apart for no reason, there is risk of breaking it.Thanks! I'm wondering if it is friction fit? Is there anything to watch out for when disassembling aside from not applying lateral force? Maybe someone from JDS can chime in here.

If I ever take the knob off I'll certainly share pictures and maybe measure the bearing axle for anyone who wants to DIY.

Yes, some preventative measures can be taken, but as I found with my keyboards, dust always seems to find a way.

Noted, if I can remove the knob then I'll prob resort to a small brush, compressed air always comes with risks and sometimes blows dust onto sensitive components.

The last time I had a dust problem was in Arizona with my Canon digital SLR. The super fine dust you kick up while hiking got into the built in flash release mechanism. Some compressed air took care of that - yes the CMOS sensor was sealed while doing this.

Thanks! Very much appreciated!

Yep makes sense, however being repairable is always extra peace of mind.Don’t fix it unless there is a problem. A nice cloth covering it when not in use should keep it out of trouble. Any time you take something apart for no reason, there is risk of breaking it.

The last time I had a dust problem was in Arizona with my Canon digital SLR. The super fine dust you kick up while hiking got into the built in flash release mechanism. Some compressed air took care of that - yes the CMOS sensor was sealed while doing this.

I don't abuse my gear but also try not to baby them too much (a rabbit hole I went through before); I buy them make life better after all.

LoFiAudiophile

Member

- Joined

- Aug 19, 2023

- Messages

- 44

- Likes

- 49

I have an EL-II that I bought when it had just been released - used rough and cleaning is super easy with a microfiber cloth. I think using pressurized air would be easier but I have never tried.

JM Popaleetus

New Member

Whelp, I pulled the trigger. This is my desktop endgame; I couldn't care less about a wall wart. JDS has proven themselves when it comes to long-term customer support.

Finally replacing my antiquated Schiit stack that I purchased used as a "temporary" source until I found something...7 years later.

Finally replacing my antiquated Schiit stack that I purchased used as a "temporary" source until I found something...7 years later.

HaveMeterWillTravel

Senior Member

Going off of JDS Labs images it appears that the encoder PCB is directly under the knob. Dropping conductive debris down there would be a bad thing. Compressed/canned air can be hazardous to SMD flat packs etc in that the high pressure gas gets under the flatpacks etc and the force is large enough to lift them right off the PCB. So no aiming it directly at surface mount components and blasting them full strength from a short distance away. I've seen where a tech I worked with used compressed air and lifted a ~120 pin flatpack off a Sony SMD PCB and it went flying. So use caution and common sense and you should be OK.

Another possible issue is the typical canned-air can create an ESD like event which may damage the circuits electrically.

Thankfully, semiconductors have come along way and they are no where near as sensitive as they used to.

I assume it's just your opinion... Or do you have technical insight, experience, or data to support your statement (that would be interesting...)?I feel like most people could use the EL4 for years and years, and never have problems with dust getting under the knob and causing problems, even without a dust cover.

- Joined

- Jan 12, 2021

- Messages

- 208

- Likes

- 164

The EL3 used the same encoder and knob set up. No issues I have heard of.I assume it's just your opinion... Or do you have technical insight, experience, or data to support your statement (that would be interesting...)?

Similar threads

- Replies

- 16

- Views

- 2K

- Poll

- Replies

- 133

- Views

- 37K

- Replies

- 41

- Views

- 4K

- Replies

- 15

- Views

- 1K

- Poll

- Replies

- 197

- Views

- 51K