depo196

Member

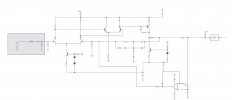

Let me inrtodce transformer free Phonograph Preamplifier for MM and MC cartridges based on the most modern component and design. Just admire please

6 main advantages:

1. Constant loop gain for no THD both @ LF and HF,

2. No coupling capacitors at all, MC-like sound with MM cartridge thanks to

3. aperiodic non-resonant HF correction with lowest input capacitance.

Thanks fo that, the unwanted resonance of the input circuit is shifted far into the ultrasound region and does not manifest itself in the audio range, and the input resistor R1 can be increased to 150 kOhm, thus forming a "passive cooling", which reduces the input noise current in SQRT (150 kOhm / 47 kOhm) = 1.78 times compared to typical Rin = 47 kOhm.

4. At the front end uses a matched pair of Dual, ultra-low noise, low-gate-current audio N-channel JFET - the latest JFE2140 from Texas Instrument. It's allow to achieve a record IEC-A weighted signal-to-noise ratio of 85 dBA relative to a standard 5 mV@1 kHz input level with an attached 0.5 H+ MM head equivalent. 1 kOhm

5. and THD less, then 0.00006% with fantastic overload capacity (64 mV@1 kHz < 0.0007%).

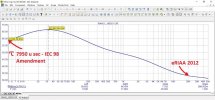

6. The frequency response exactly corresponds to the Enahanced RIAA not with three, as usual, but with five time constants, in addition to 75 + 318 + 3180 µs, a Neumann pole compensator and a rumble-reducing 7950 µs - IEC 98 Amendment are also implemented.

MM

Frequency range: 1 Hz - 45 kHz

Ku at 1 kHz: 49 dB

rated output voltage: 1.4V

signal to noise ratio: >85 dBA

THD for input signal: 5mV@1kHz: <0.00006%

MC

Frequency range: 1 Hz - 45 kHz

Ku at 1 kHz: 68 dB

rated output voltage: 1.4V

signal to noise ratio: >73.9 dBA

THD for input signal: 0.4 mV@1 kHz: <0.0004%

6 main advantages:

1. Constant loop gain for no THD both @ LF and HF,

2. No coupling capacitors at all, MC-like sound with MM cartridge thanks to

3. aperiodic non-resonant HF correction with lowest input capacitance.

Thanks fo that, the unwanted resonance of the input circuit is shifted far into the ultrasound region and does not manifest itself in the audio range, and the input resistor R1 can be increased to 150 kOhm, thus forming a "passive cooling", which reduces the input noise current in SQRT (150 kOhm / 47 kOhm) = 1.78 times compared to typical Rin = 47 kOhm.

4. At the front end uses a matched pair of Dual, ultra-low noise, low-gate-current audio N-channel JFET - the latest JFE2140 from Texas Instrument. It's allow to achieve a record IEC-A weighted signal-to-noise ratio of 85 dBA relative to a standard 5 mV@1 kHz input level with an attached 0.5 H+ MM head equivalent. 1 kOhm

5. and THD less, then 0.00006% with fantastic overload capacity (64 mV@1 kHz < 0.0007%).

6. The frequency response exactly corresponds to the Enahanced RIAA not with three, as usual, but with five time constants, in addition to 75 + 318 + 3180 µs, a Neumann pole compensator and a rumble-reducing 7950 µs - IEC 98 Amendment are also implemented.

MM

Frequency range: 1 Hz - 45 kHz

Ku at 1 kHz: 49 dB

rated output voltage: 1.4V

signal to noise ratio: >85 dBA

THD for input signal: 5mV@1kHz: <0.00006%

MC

Frequency range: 1 Hz - 45 kHz

Ku at 1 kHz: 68 dB

rated output voltage: 1.4V

signal to noise ratio: >73.9 dBA

THD for input signal: 0.4 mV@1 kHz: <0.0004%