TimW

Major Contributor

This guide will show you how to make a case for the Khadas Tone Board. Actually you don’t need to make a case, you just need to buy a premade case and cut some openings in it so the board can breathe. This guide should provide you with a complete parts list and instructions for how to make this case work with the board. I even provide nifty drawings that can be used to reduce the amount of measuring you have to do. And for those who wish to make their own case or use one other than what I show here, I also include a dimensioned drawing of the Tone Board which you can use to come up with your own openings. With that out of the way let’s get into the nitty gritty of it.

Parts List:

Note that you only need two of these because you can’t fit three with the close spacing of the RCA connectors.

Unfortunately many of you may not have a locally available hardware store with the same kind of selection as mine. So here are some internet sources for these things:

Amazon

JMAC Supply

FASTENAL

Optionally:

After this I tape this cutout to the part. It is a little tricky to get the edges lined up at first but once it is on there the tape provides a little bit of movability. I use this attribute of the tape along with my measuring device to get the paper cutout exactly where it needs to be on the part.

With this project I got very accurate results with this method and it took much less time than measuring and marking the center of each opening would have. You can use whatever method you wish to get your center marks, just make sure it is accurate so that you get a good fit with the Tone Board.

When I cut the opening for the USB-C connector I drilled two holes, one on each end, and used a coping saw to cut out the middle section. I now realize that I could have just drilled a third hole in the middle of the connector opening, so that is what I recommend. A rectangular needle file is required to make a good looking opening with either method.

The standoff holes in the bottom of the case are slightly oversized to provide you with some wiggle room. I used the same cutout method to make the center marks for these holes and the result was them being slightly off center but still useable. These are the trickiest holes to get right because there are multiple assembled parts involved unlike the end plate openings where you are only really dealing with the well-made Tone Board. If you find that you cannot get them to line up it should be fine to drill them out with a 7/64” bit. This is actually the size of hole I drilled but that was on accident.

You will want to deburr the holes you drill in the case. It is difficult to deburr the ones drilled in the bottom of the case for the standoffs. I just used a flat head screw driver to scrape most of the burrs around these holes off. I would not worry too much about how well you deburr the inside of the case because it will not be seen and we want the standoffs that mount here to make electrical contact with the case.

As you may have noticed I used a countersink bit to allow these small screws to reach further into the case. These things are really microscopic so they need all the help you can give them. This countersink can be created with other types of countersink tools or even another drill bit of appropriate size. Just be sure to go slowly and check how deep the countersink is getting often. The only reason I am using these screws rather than purchasing longer ones is because I can’t get anything smaller than an M3 locally and I don’t want to pay for shipping on something so cheap.

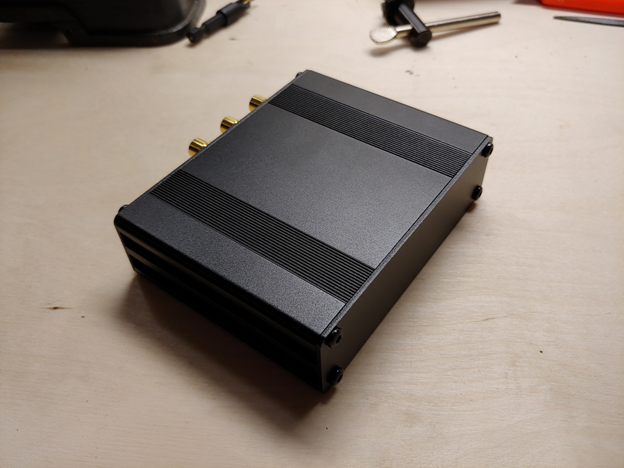

Should end up looking something like this:

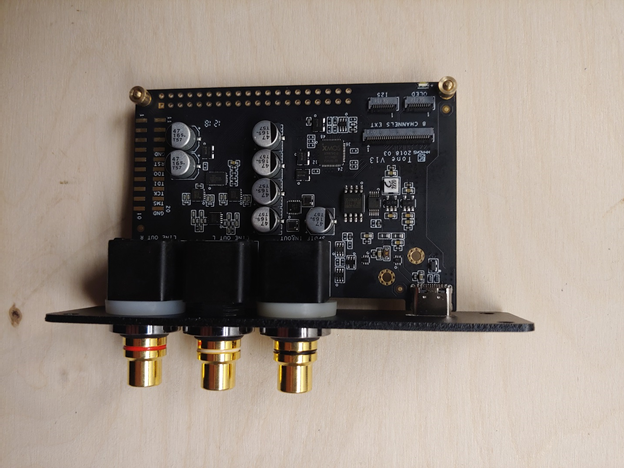

Okay we are going to be using these standoffs in a way they apparently weren’t meant for. I say that because the brass nuts that come with the board are not threaded all the way through. It seems like they are but when the standoff threads get to the narrow end of the nut it starts to bind. Now you can solve this by running an M2 tap through these nuts but like many people I don't have one on hand. So instead I used pliers to force the standoff to thread all the way through the nut and now it works properly. It’s okay if these end up looking a bit marred as they will be hidden within the case.

The threaded portion of the standoffs go through the two holes on the empty end of the board. The nuts then thread onto these connecting them to the board. I placed the nuts with the narrow end toward the board to make sure they have good electrical contact with the plated holes. These standoffs are what ground the board to the case. The holes in the case may be making electrical contact with the standoffs directly but I have found that the little screws are grounded as well.

As you may have noticed I did not use the included lock washers. Unfortunately the use of the nylon washers as spacers has left me with few threads to screw the nuts on with. You could probably still fit the lock washers in there but I don’t see much of a point in using them. My DACs just sit in one place untouched for long periods of time and as such I don’t feel the need for lock washers.

I also don’t have any tools I could use for tightening these strange nuts. I’m not even sure what they’re called. If you know what they’re called and what tool to use for tightening them please let me know. For now I have just tightened them as best I can with my hand and have had no issues with them loosening.

My girlfriend says they are ugly and I tend to agree. In the pictures on BOX Enclosures website the red ones looked more like maroon. IRL they look Ferrari red and pretty bulky. I will not be using them so there’s $7.50 down the drain. If you like them rest assured that they do not interfere with any of the openings and negate the need for rubber feet.

These pads will give you around 5V but it will depend on what the Tone Board is powered from so you may want to assume the circuit could see up to 5.5V or so. A resistor wired in series must be used with ordinary LED’s so that they don’t burn out. You will need to decide what color, shape, and size of LED you want to use so that you can nail down its specs. Namely Forward Voltage and Forward Current which are needed to calculate the resistor value. Here is a useful calculator I use for this. Pay attention to the polarity of the LED when you wire this up.

As you can see I went with a small green led mounted in the center of the front end plate.

Looks pretty good sitting on top of my Stax SRM-252S if I say so myself.

I blacked out the opening for this LED with a sharpie just like I did to the opening for the USB-C connector.

After I created and posted some dimensioned drawings of the Khadas Tone Board on this forum, Amir contacted me and let me know that Khadas had offered to supply sample boards and that I could receive one for the purposes of physical dimensioning. I was happy to except this offer and soon thereafter a Tone Board arrived at my doorstep. After some research and fabrication I was able to put together this mostly coherent DIY guide for putting the board in a case. Hopefully this contribution was worth the cost of the unit they sent me. Good luck to you if you've decided to undertake this project and thanks for reading.

Parts List:

- Khadas Tone Board (of course)

I have the Generic version of the board which is the version you should get if you want to put it in a case this size. The headers on the VIMs version make it too tall for the case.

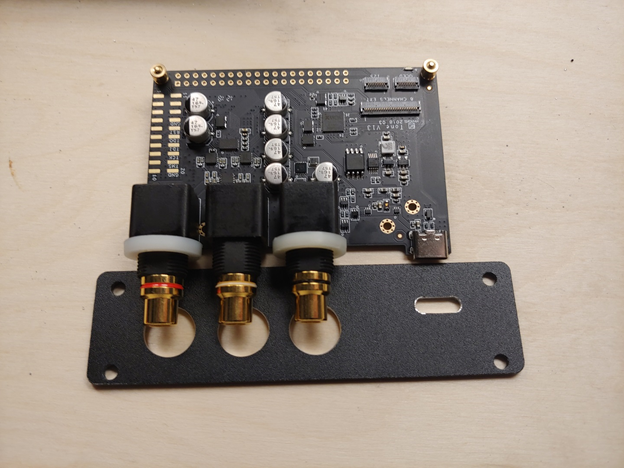

There are some accessories that come with the Tone Board which will be used to mount it in the case. Specifically we need two of the short brass standoffs with long threaded sections, two of the brass nuts, and two of the short black screws. We also need the gunmetal gray nuts that go around the RCA connectors.

Amazon

Khadas

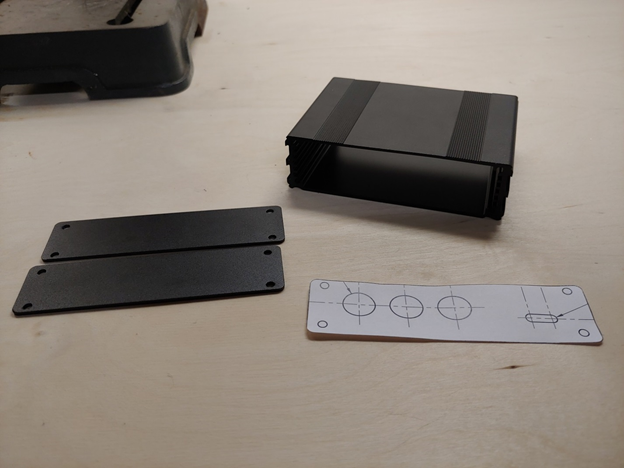

- BOX Enclosures BEX Series 2 B2-080 (the same exact case specified for the O2 headphone amplifier)

Available in Black, Blue, Gold, Green, Red, and Silver. BEX Series 2

Kit includes the main case body, end plates, and two different sets of screws for securing said end plates. Optional accessories include mounting flanges for surface mounting the case and rubber end caps that I thought would look neat…

BOX Enclosures, Inc. (best price I could find)

Newark

Allied Electronics

Farnell

- Hammond Manufacturing 1455L801

Available in Black, Blue, Red, and “Clear” (Aluminum color). 1455 Series

This case has black ABS plastic bezels which go between the main case body and its aluminum endplates. There is also versions with all plastic end plates which are only available in Black and Clear. A benefit of this case is that it has a removable “belly” plate which I would recommend orienting as the top plate. It also includes rubber feet. I own a product which uses one of these cases and it feels like a quality unit. You should know that I have not worked with one of these cases before and I am only including it to provide another option.

Mouser (best price I could find)

Digi-Key

Newark

Allied Electronics

Farnell

- The Hillman Group 59559 0.750 x 0.505 x 0.125-Inch Nylon Fender Washer (or equal) X2

The reason we need washers for this project is to act as spacers. You see the flat surface of the RCA connector body, which acts as the mating surface with the end plate, is only protruding about half a millimeter from the edge of the circuit board. And for some reason Khadas decided to place the USB-C connector out on a 2.75 mm protrusion of the circuit board. This makes it so that if the end plate were flush with the flat surface of the RCA connector body, this circuit board protrusion would have to pass through the end plate. I didn’t like the way this looked on paper and I wanted my USB-C connector to be slightly recessed so that when a cable is plugged in it has a satisfying look to it.

For this reason I sought out and found these washers at my local Ace Hardware in a drawer labeled “Nylon Specialty Washers.”

Note that you only need two of these because you can’t fit three with the close spacing of the RCA connectors.

Unfortunately many of you may not have a locally available hardware store with the same kind of selection as mine. So here are some internet sources for these things:

Amazon

JMAC Supply

FASTENAL

Optionally:

- Self-Adhesive Rubber Feet for the B2-080 case.

You can find these in all sorts of shapes and sizes from many different retailers. But if you don’t feel like searching here are the ones supplied with the Hammond case:

Mouser

Digi-Key

Newark

Allied Electronics

Farnell

And here is a 3M brand product on Amazon:

Amazon

- An accurate measuring device (I used calipers)

- A center punch

- A hammer for the center punch unless it is an automatic type

- Drill bits:

- 3/32” or 2.5 mm

- 5/32” or 4 mm

- 1/2” or 13 mm

- A drill (I used a drill press)

- A rectangular (flat) needle file

- A printer for printing out the Opening_Dims drawing I have provided for the case you’ve chosen

- Scissors for cutting out the case parts from this drawing

- Tape for taping these drawings to the actual case parts

- A sharpie or similar for making the opening around the USB-C connector black

- A vice for holding the case parts while drilling

- A countersink or slightly oversized drill bit for countersinking the 3/32” holes in the bottom of the case

- A deburring tool (can also use an oversized drill bit for this)

- A coping saw

- An M2 tap for fixing the brass nuts

- An M3 tap for using the Torx screws included with the B2-080 case

- A T10 Torx bit for tightening those Torx screws

- A Multimeter for testing grounding

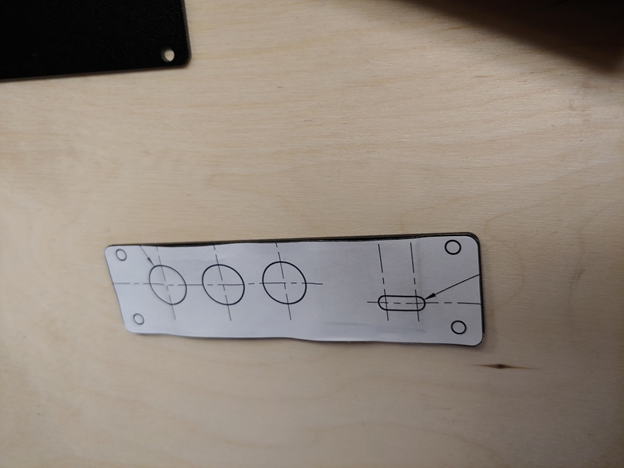

- Print out either B2-080_Opening_Dims or 1455L801_Opening_Dims based on which case you are using.

This step is technically optional but I like to have a hard copy of my drawings when I’m at the workbench. You may also want to print out a second copy for cutting up and using as a guide as I have done. If you do this be sure to print it out Full Size on a letter size sheet and verify that the dimensions are to scale. There are also A4 versions of these drawings available for those of you who print on that size of sheet.

After this I tape this cutout to the part. It is a little tricky to get the edges lined up at first but once it is on there the tape provides a little bit of movability. I use this attribute of the tape along with my measuring device to get the paper cutout exactly where it needs to be on the part.

- Make center marks on the case.

I use my center punch to mark the center of the openings, using the centerlines printed on my cutout. You can use pencil marks on tape or lines etched into the finish of the case or whatever method you’re comfortable with.

- Drill the required holes in your case.

On the Opening_Dims drawings I have provided the diameter of each size of hole. These dimensions say TYP as in Typical because they refer to multiple holes. There are three 1/2” (13 mm) holes for the RCA connectors, three 5/32” (4 mm) holes for the USB-C connector, and two 3/32” (2.5 mm) holes for the standoff screws. I used the 5/32” bit to drill pilot holes for the three 1/2” holes while I had it in the drill chuck.

The standoff holes in the bottom of the case are slightly oversized to provide you with some wiggle room. I used the same cutout method to make the center marks for these holes and the result was them being slightly off center but still useable. These are the trickiest holes to get right because there are multiple assembled parts involved unlike the end plate openings where you are only really dealing with the well-made Tone Board. If you find that you cannot get them to line up it should be fine to drill them out with a 7/64” bit. This is actually the size of hole I drilled but that was on accident.

You will want to deburr the holes you drill in the case. It is difficult to deburr the ones drilled in the bottom of the case for the standoffs. I just used a flat head screw driver to scrape most of the burrs around these holes off. I would not worry too much about how well you deburr the inside of the case because it will not be seen and we want the standoffs that mount here to make electrical contact with the case.

As you may have noticed I used a countersink bit to allow these small screws to reach further into the case. These things are really microscopic so they need all the help you can give them. This countersink can be created with other types of countersink tools or even another drill bit of appropriate size. Just be sure to go slowly and check how deep the countersink is getting often. The only reason I am using these screws rather than purchasing longer ones is because I can’t get anything smaller than an M3 locally and I don’t want to pay for shipping on something so cheap.

- Use a rectangular needle file to finish the USB-C opening.

This should look like it does on the Opening_Dims drawing. Kind of looks like the same shape as a USB-C connector doesn’t it? I guess this is called an obround or stadium.

- Install standoffs on tone board.

The threaded portion of the standoffs go through the two holes on the empty end of the board. The nuts then thread onto these connecting them to the board. I placed the nuts with the narrow end toward the board to make sure they have good electrical contact with the plated holes. These standoffs are what ground the board to the case. The holes in the case may be making electrical contact with the standoffs directly but I have found that the little screws are grounded as well.

- Mount the Tone Board to the end plate using the included nuts. The two nylon fender washers should be placed around the right channel output and coaxial input as shown.

Wait. Before you actually do this step you should consider using something like a sharpie to blacken the inside of the USB-C connector opening. It may not match the color of the case perfectly but in my opinion it looks much better and the color difference isn't noticeable at normal viewing distances. I didn’t have a sharpie on hand at the time but later when I disassembled the case I went back and did this.

As you may have noticed I did not use the included lock washers. Unfortunately the use of the nylon washers as spacers has left me with few threads to screw the nuts on with. You could probably still fit the lock washers in there but I don’t see much of a point in using them. My DACs just sit in one place untouched for long periods of time and as such I don’t feel the need for lock washers.

I also don’t have any tools I could use for tightening these strange nuts. I’m not even sure what they’re called. If you know what they’re called and what tool to use for tightening them please let me know. For now I have just tightened them as best I can with my hand and have had no issues with them loosening.

- Assemble the case.

The B2-080 case I used here comes with two sets of screws. A self-tapping Philips head set that any sane person would use and an M3 Torx head set for us masochists. If you want to use the Torx screws you will need a T10 driver, an M3 tap, and the patience to tap 8 oddly shaped holes. After tapping four of these lop sided holes I was really starting to regret using these screws.

- Install the standoff screws.

Now that you have the case assembled the standoffs attached to the board should align with the holes in the bottom of the case. Screw those little black screws into those brass standoffs through the holes you made in the case and voila! You’re Tone Board is fully mounted in its case.

- Stare in amazement at your beautiful creation.

- Ensure that the USB-C connector lines up with it’s opening properly.

The USB-C connector is almost perfectly centered in its opening in my case. If yours is not then try loosening the nuts and standoff screws and nudging the board into its proper position, there should be just a little play. If things still aren’t looking hunky dory then you may need to modify your openings with some light metal work.

The USB-C connector on the board should not be touching any surfaces of the end plate.

- Ensure the case is grounded.

This step is mostly optional. What I gather from my conversation with Amir is that grounding the case is really unnecessary. Case in point, the Tone Board measurements he took were very good even without a case. He said that with the standoff holes on the board being grounded, it would probably be best if the case is grounded to them. He also said that the USB-C connector is not an ideal location for grounding to the case.

When assembling the case I didn’t really pay attention to anything concerning grounding. Later when I tested the ground connection I found that luckily the case is fully grounded anyway. To test this you’ll want to set your Multimeter to continuity test mode and touch one lead to the outer shell of an RCA connector. Touch the other lead to the various parts of the case (main body and both end caps). The anodized finish of the case will not be grounded but any place where this finish is removed should be. I found that the screws connecting the end plates to the main body of the case were grounded. The screws and countersinks connecting the standoffs to the case were grounded. The USB-C connector opening was grounded. And if I stabbed my test lead into the bottom of the front end panel, it was grounded too.

If you find that your case is not fully grounded you may want to disassemble it and remove anodization in places where the case parts contact each other. If you don’t feel like doing this testing or you don’t have a Multimeter… well it’s probably not the end of the world if you don’t test this. The assembly of the case will probably lead to proper grounding and even if it doesn’t, as Amir has shown, a grounded case isn’t necessary for getting good performance out of the Tone Board.

- Take a look at these (beautiful?) rubber end caps I got for my case:

My girlfriend says they are ugly and I tend to agree. In the pictures on BOX Enclosures website the red ones looked more like maroon. IRL they look Ferrari red and pretty bulky. I will not be using them so there’s $7.50 down the drain. If you like them rest assured that they do not interfere with any of the openings and negate the need for rubber feet.

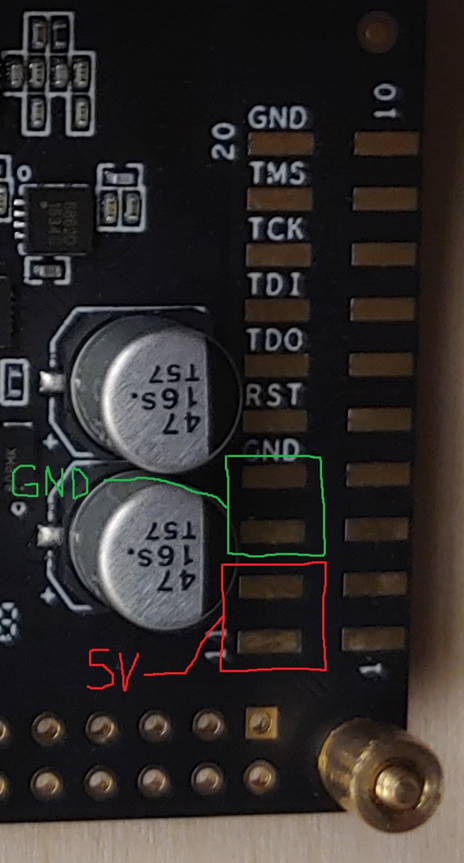

- If you want your finished Tone Board in case to still have a power indicator light like every other audio product, then you’ll need to wire one up and mount it. The empty pads on the Generic version of the board include a few places to get GND and +5V. Take a look at the 20 Pin Header Pinout on the Tone Board Spec Page if you don’t believe me. I’ve even created a crudely labeled sketch to show which pads to use:

These pads will give you around 5V but it will depend on what the Tone Board is powered from so you may want to assume the circuit could see up to 5.5V or so. A resistor wired in series must be used with ordinary LED’s so that they don’t burn out. You will need to decide what color, shape, and size of LED you want to use so that you can nail down its specs. Namely Forward Voltage and Forward Current which are needed to calculate the resistor value. Here is a useful calculator I use for this. Pay attention to the polarity of the LED when you wire this up.

As you can see I went with a small green led mounted in the center of the front end plate.

Looks pretty good sitting on top of my Stax SRM-252S if I say so myself.

Attachments

-

Khadas_Tone_Board_Dims(4).pdf39.9 KB · Views: 1,680

-

1455L801_Opening_Dims(1).pdf21.5 KB · Views: 1,136

-

B2-080-MASTER-DRAWING_PDF.pdf338.1 KB · Views: 951

-

1455L801BK.pdf163.5 KB · Views: 733

-

B2-080_Opening_Dims(3).pdf21.3 KB · Views: 847

-

A4_Khadas_Tone_Board_Dims(1).pdf39.4 KB · Views: 778

-

A4_B2-080_Opening_Dims(1).pdf21.5 KB · Views: 770

-

A4_1455L801_Opening_Dims(1).pdf21.3 KB · Views: 796

Last edited: