infinitesymphony

Major Contributor

- Joined

- Nov 21, 2018

- Messages

- 1,072

- Likes

- 1,809

Pretty cool. I'm holding out for a North American distributor due to shipping costs.Posted by @pos in the tone board thread:

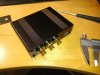

@Audiophonics just released a 15€ aluminium case for the tone board: https://www.audiophonics.fr/en/alum...num-casing-for-khadas-tone-board-p-13626.html