Mains related hum and noise in power amplifiers

We have had some discussion in another thread

https://www.audiosciencereview.com/...they-really-sound-different.18415/post-910720

about the reason of higher residual mains related components hum in the measurement of JC5 amplifier posted by @SIY in post #271

https://www.audiosciencereview.com/...they-really-sound-different.18415/post-910157

Most of the contributors would address the hum to the radiated electromagnetic fields, however I do not think so. Based on decades of years of designing and measuring amplifier circuits and on measurements of electromagnetic interference, I would vote for mistakes in amplifier PCB design and probably insufficient PSRR (power supply ripple rejection) which is related to circuit design. This all is perfectly explained in book [1] by Douglas Self, so I will concentrate to measured plots rather than explaining basics. The study applies to stand-alone class A and class AB amplifiers with unregulated linear power supplies and does not cover ground loops constituted by link cables to DAC or preamp.

Measurements were performed on a functional sample of the Class A power amplifier with idle current of 1.4A, supplied from +/-24Vdc power supply with 230V/2x18V/270VA EI core transformer, center tapped diode rectifier and 2 x 14100uF capacitor bank.

1. Measurements of radiated electromagnetic field near the transformer

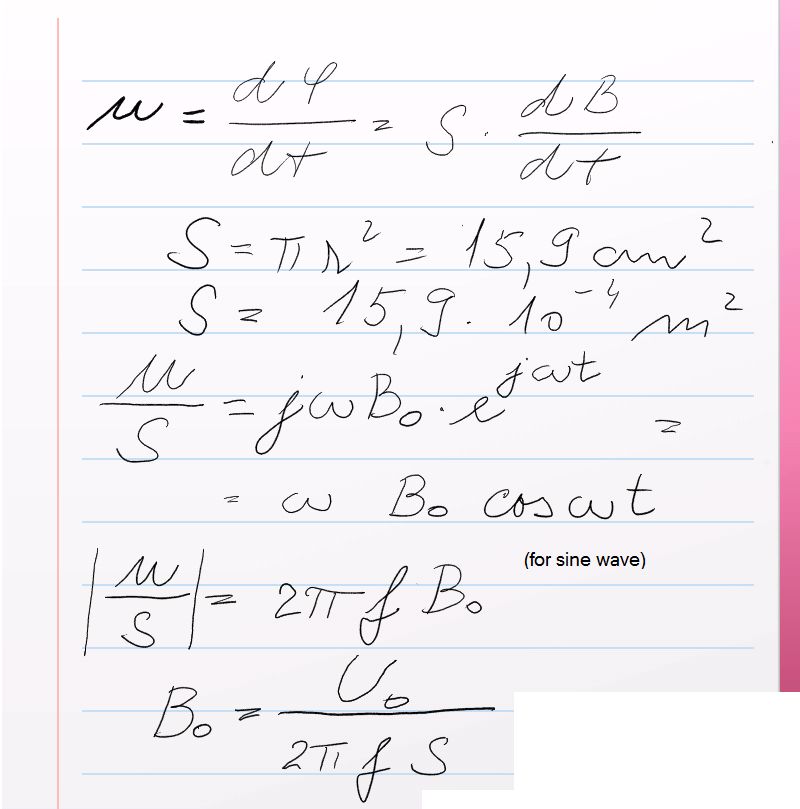

Loop sensor probe is used for this measurement which gives output voltage proportional to derivative of magnetic flux according to equations in the image below

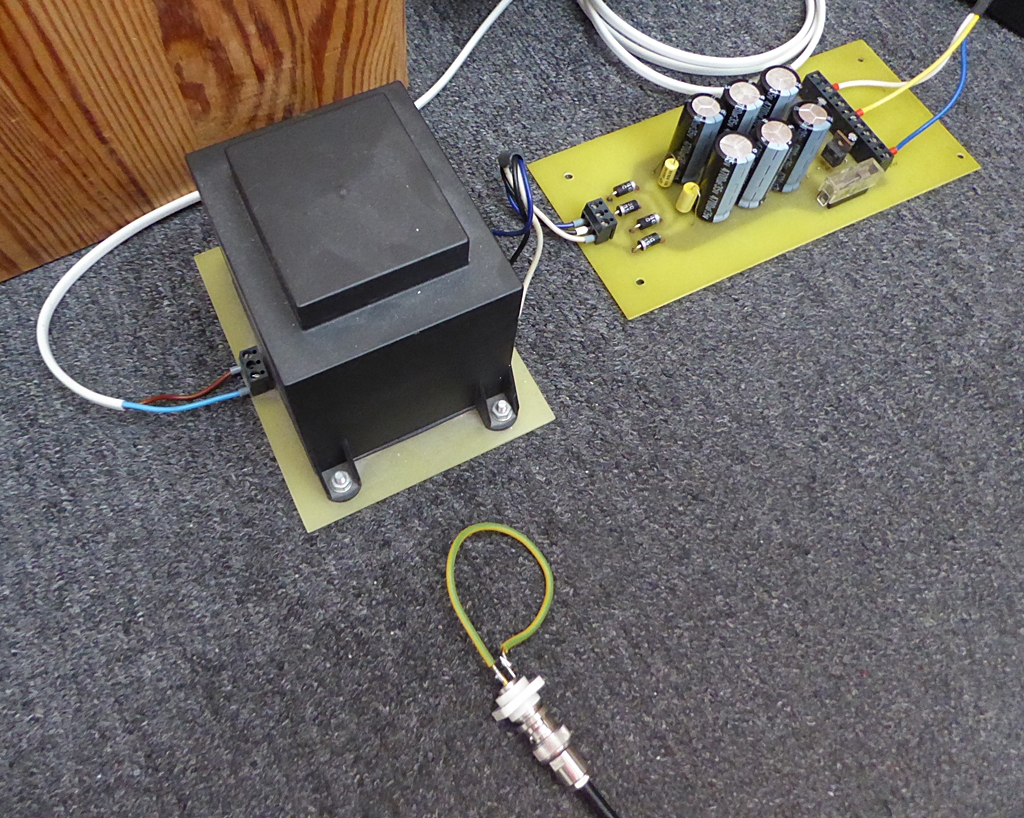

The output voltage of the loop sensor is directly proportional to the derivative of intensity of electromagnetic induction dB/dt. The loop sensor was placed side by the transformer as shown in the next image.

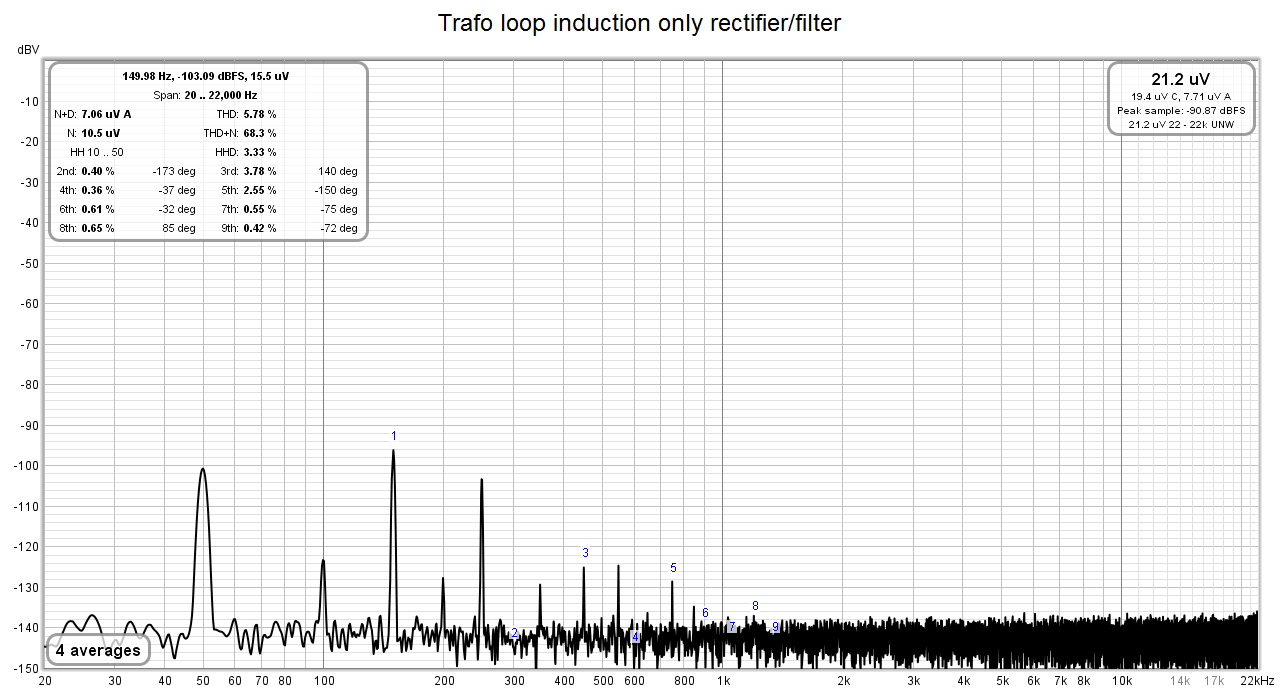

When the transformer is connected only to bridge rectifier with capacitor bank, the loop sensor output voltage looks like this and is dominated by 50Hz, 150Hz and 250Hz spectral lines:

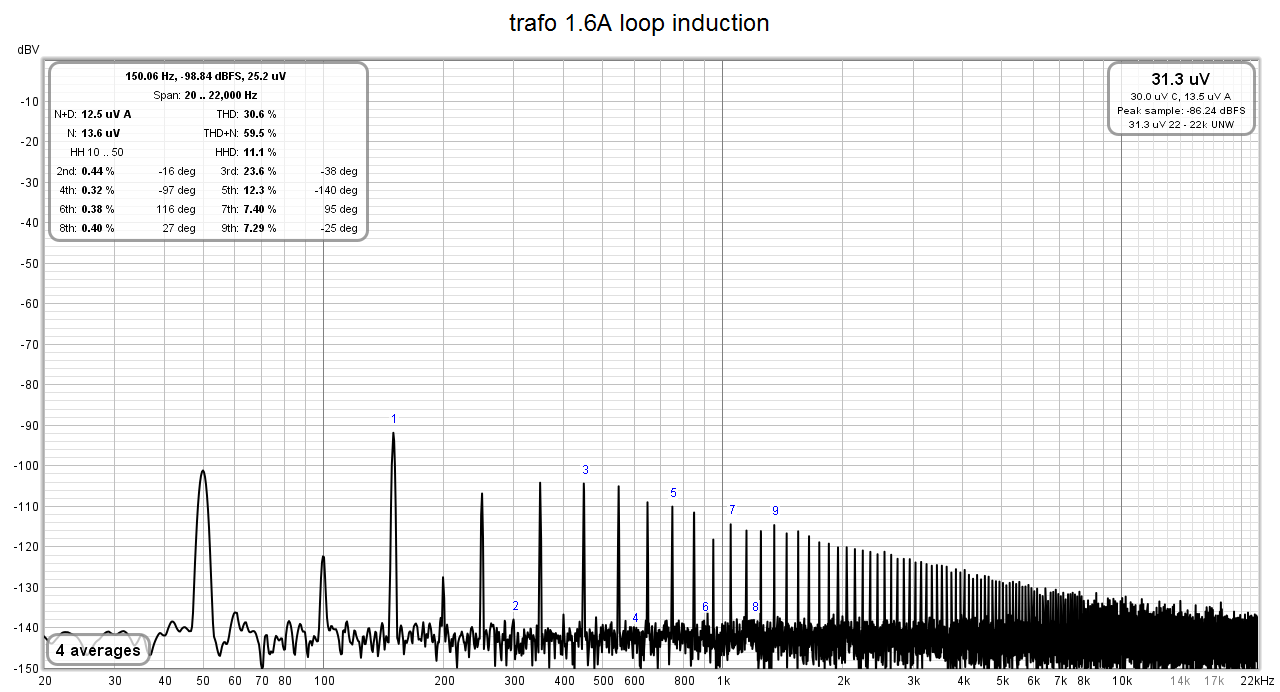

When the amplifier with 1.4A idle current is connect to the output of the capacitor bank, the sensor spectrum shows a lot of high order harmonics due to current impulses that are needed to charge the capacitor bank.

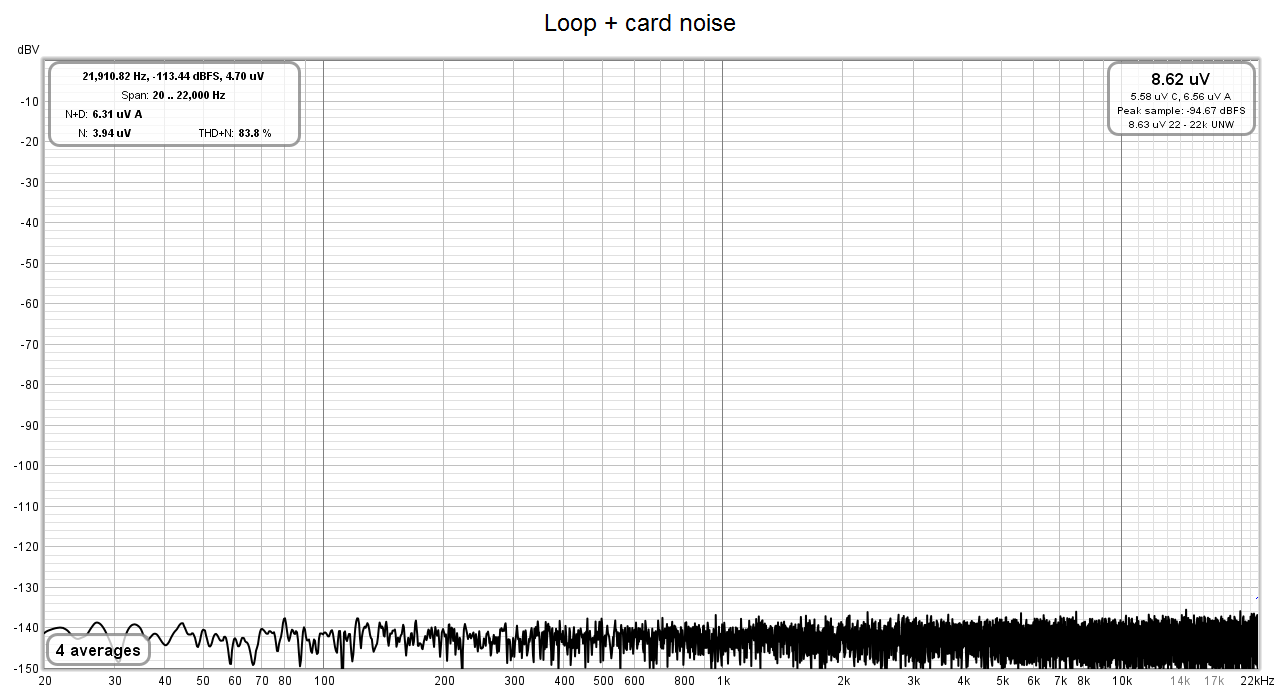

Last, measurement with transformer turned off, showing residual measuring noise

This loop sensor is very useful to check the radiated field inside the power amplifier and to try to minimize its possible effect to input circuitry and induction into PCB circuits track loops. We may or not improve the hum components at the power amplifier output by transformer re-positioning and turning, but not always. Often we come to conclusion that output hum components do not depend much on transformer placement or the improvement is not satisfactory. To check if the hum components are a result of transformer and rectifier radiated fields or not we place the transformer and rectifier with capacitor bank outside the amplifier in a distance when intensity of electromagnetic field from the transformer is negligible. 1 – 2m is enough. And we measure mains related components at the amplifier output again. We often find that the difference with power supply inside or outside the amplifier is insignificant so we have to find another sources of hum than the transformer radiated field. Again for further study there is a literature [1]. In my experience the biggest issues regarding hum/buzz components are ground returns, especially ground return of audio signal shared with bypass capacitor returns or dividers connected to supply rails. Several centimeters of shared PCB ground may completely destroy the effort of getting good S/N.

2. Measurements with two grounding schemes

Two grounding schemes were chosen, #1 has about 5cm of shared ground for signal and 47uF bypass capacitors, #2 tries to keep star ground concept as much as possible. Amplifier module under test is class A with idle current of 1.4A, as already stated. Spectrum of 1KHz 5W THD/THD+N is measured and also the spectrum with no input signal. The noise measurement and noise component in THD+N (noise floor) is unfortunately affected by the soundcard used - we are loosing about 6dB in noise.

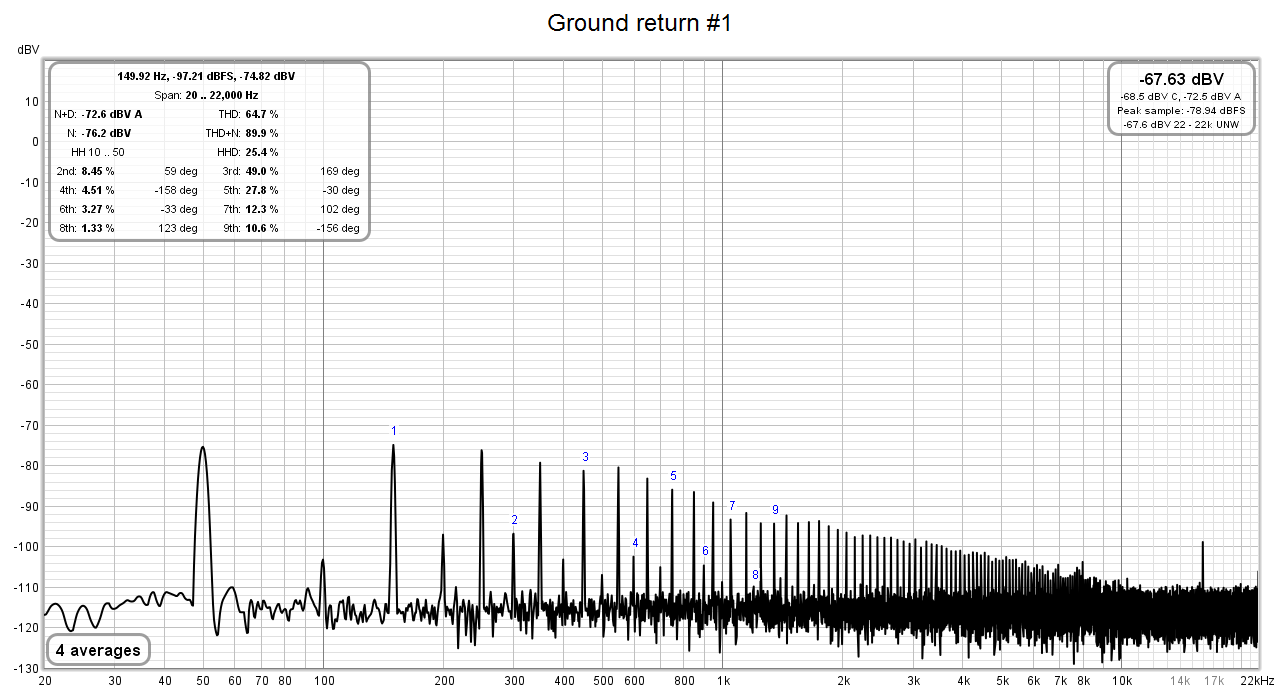

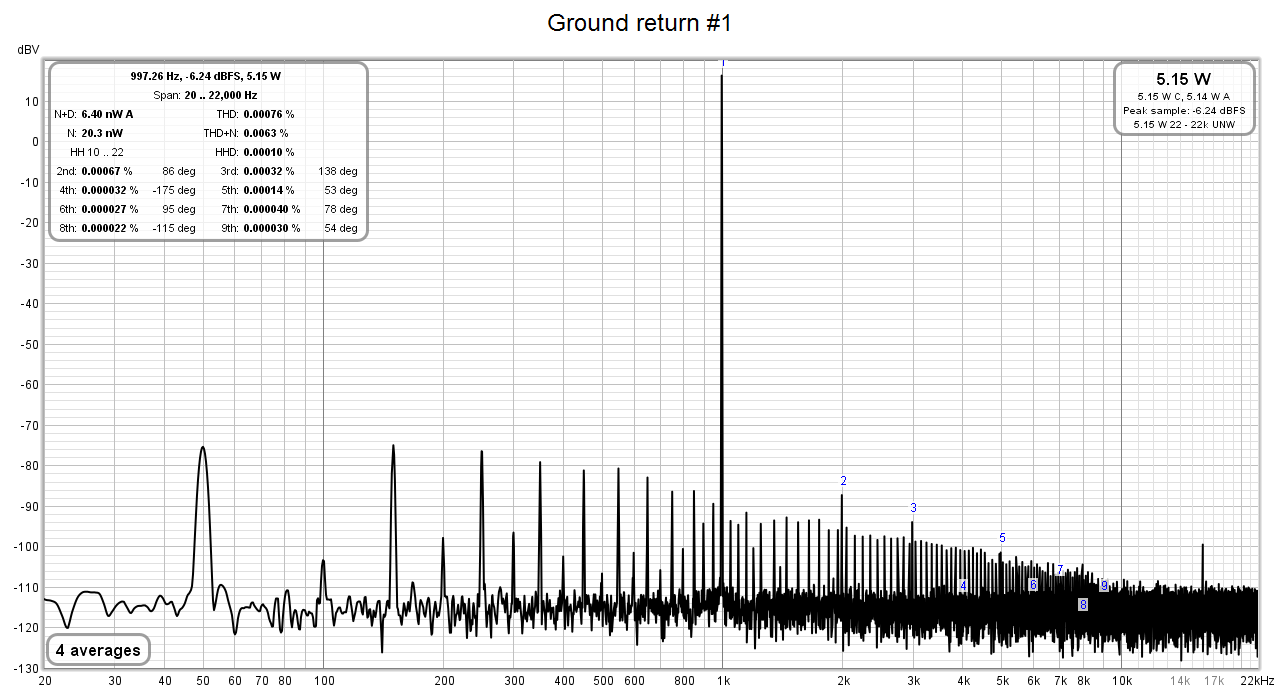

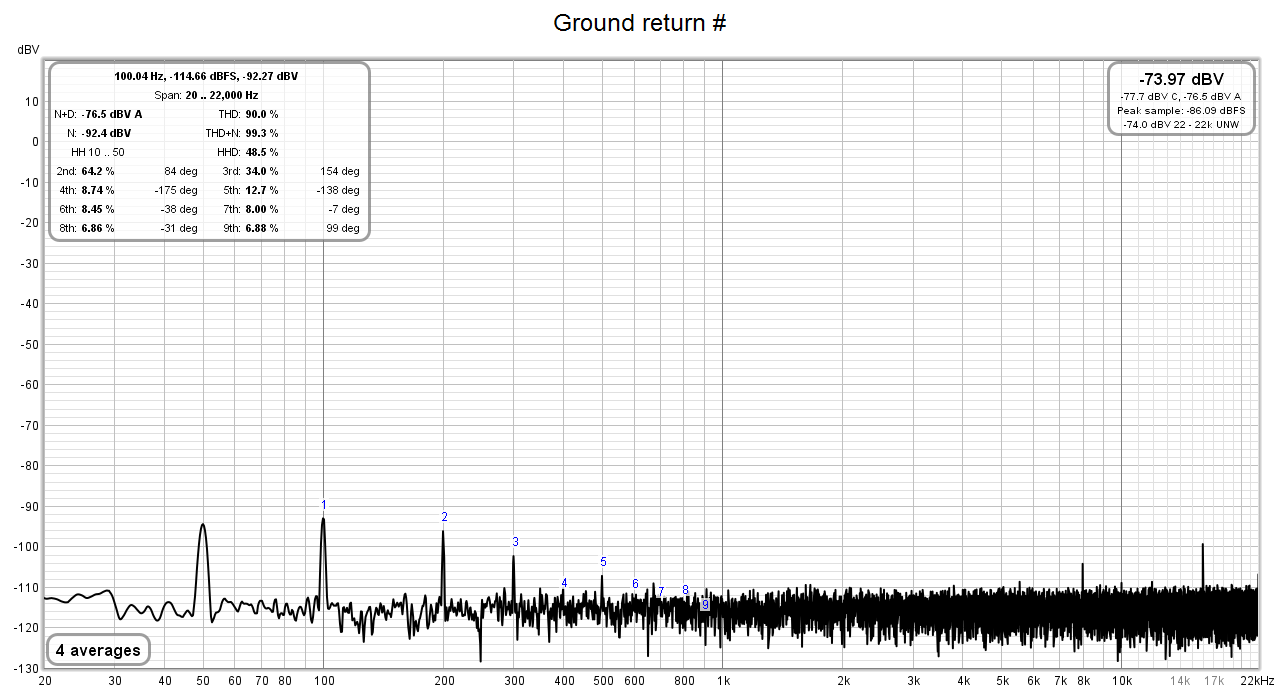

Grounding scheme #1

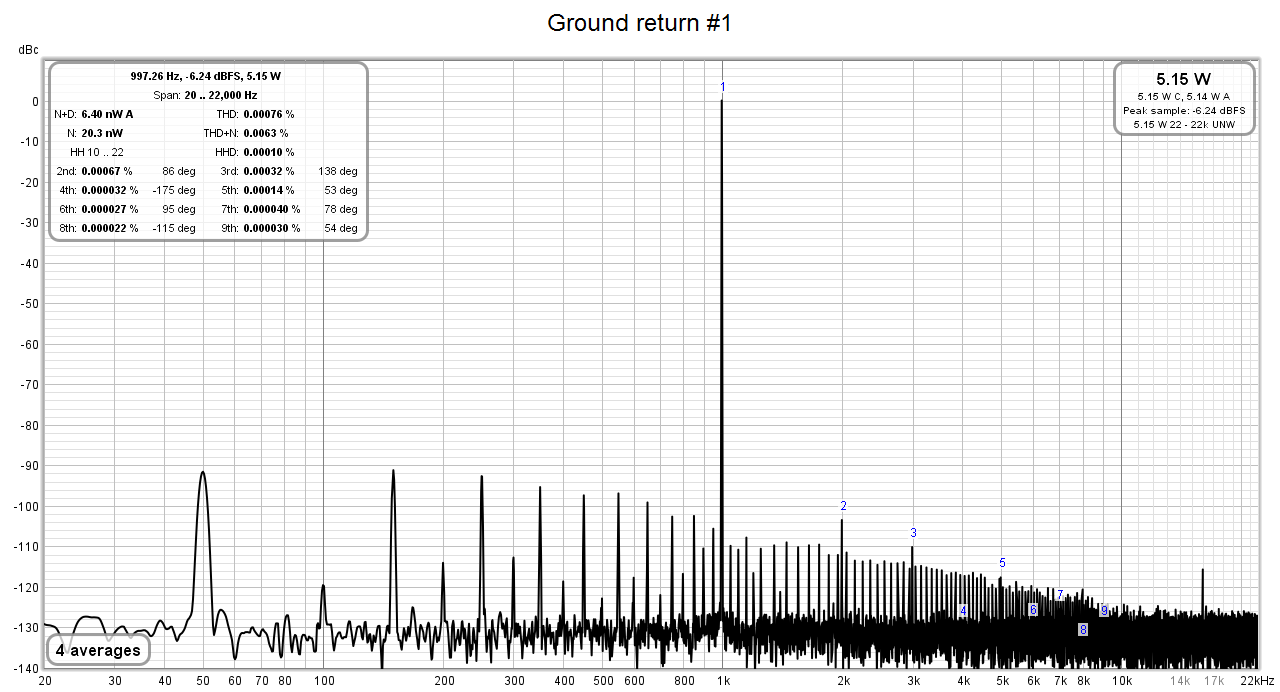

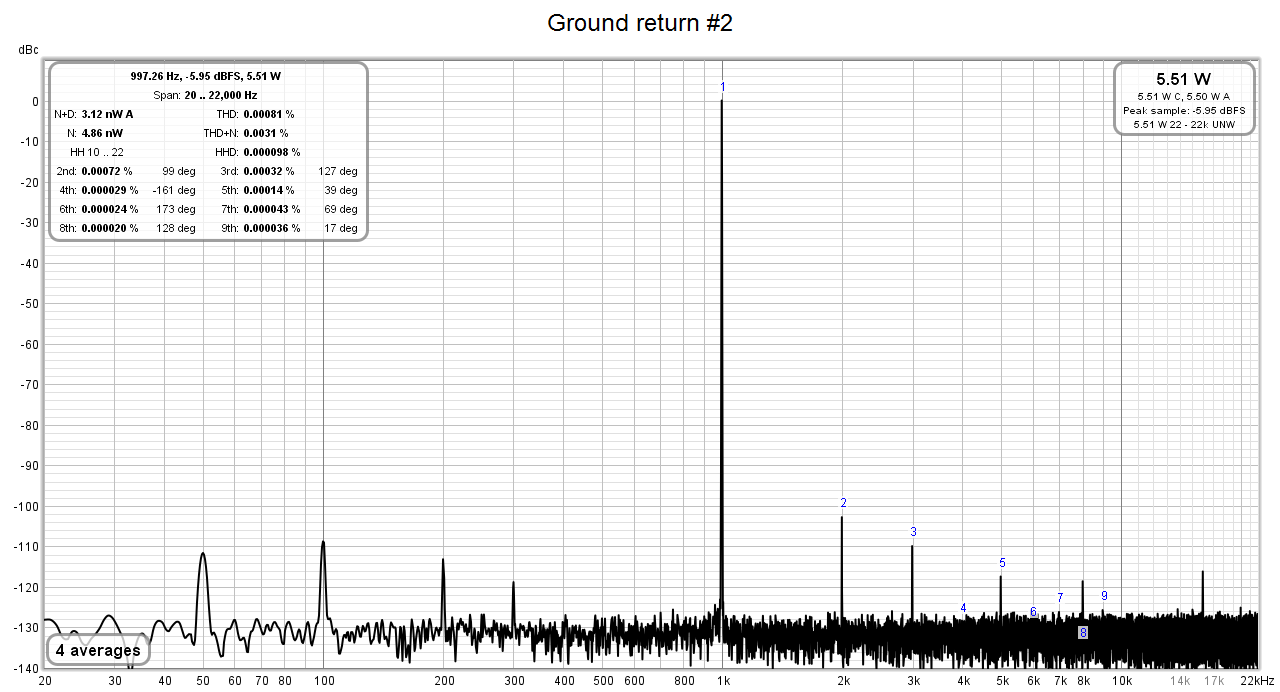

The same in dBr related to 0dBr, which is more usual at ASR, though it is the same thing

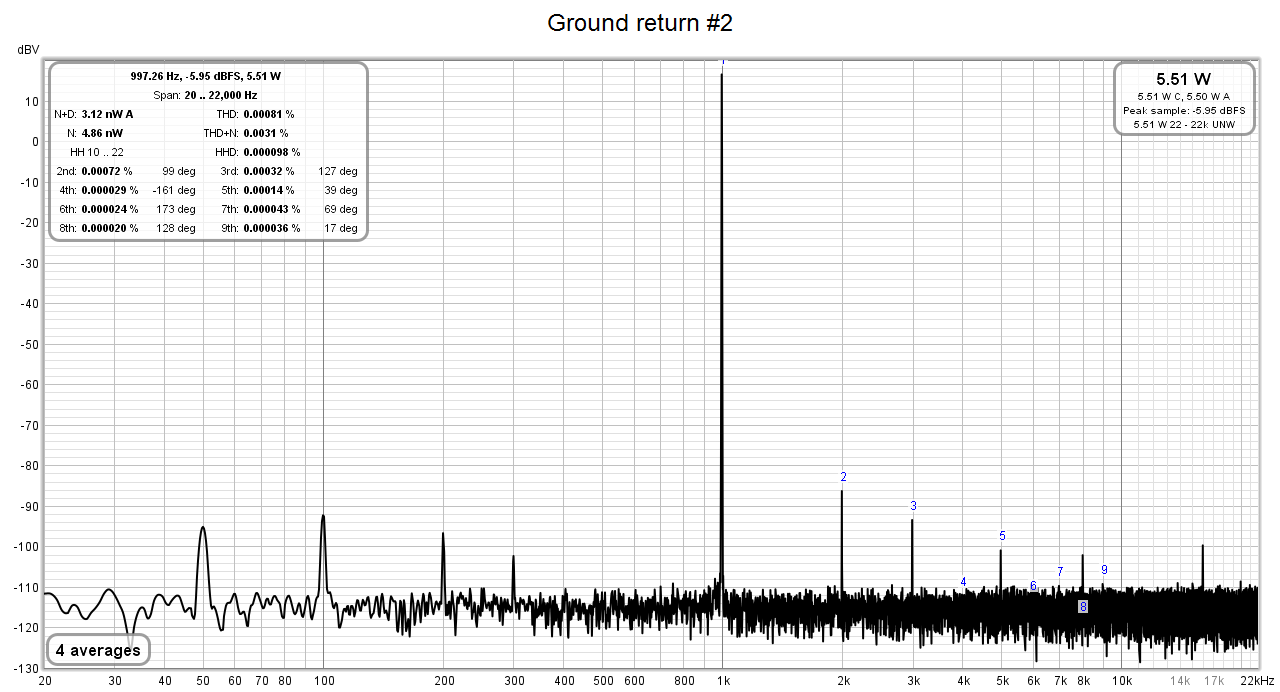

Grounding scheme #2

The same in dBr related to 0dBr, which is usual at ASR though it is the same thing

We can see that even if the transformer radiated field is kept negligible simply by the distance of the power supply from the amplifier, it is the PCB design, namely ground returns, that are responsible for resulting output mains related hum components, together with PSRR of the circuit design. Scheme #2 is much better than #1, but still there is a space for improvements. However it is time consuming and sadly we often see quite unacceptable results in the mass produced amplifiers.

Literature:

[1] Self, D.: Audio Amplifier Power Design Handbook, third edition, Newnes, 2002.

We have had some discussion in another thread

https://www.audiosciencereview.com/...they-really-sound-different.18415/post-910720

about the reason of higher residual mains related components hum in the measurement of JC5 amplifier posted by @SIY in post #271

https://www.audiosciencereview.com/...they-really-sound-different.18415/post-910157

Most of the contributors would address the hum to the radiated electromagnetic fields, however I do not think so. Based on decades of years of designing and measuring amplifier circuits and on measurements of electromagnetic interference, I would vote for mistakes in amplifier PCB design and probably insufficient PSRR (power supply ripple rejection) which is related to circuit design. This all is perfectly explained in book [1] by Douglas Self, so I will concentrate to measured plots rather than explaining basics. The study applies to stand-alone class A and class AB amplifiers with unregulated linear power supplies and does not cover ground loops constituted by link cables to DAC or preamp.

Measurements were performed on a functional sample of the Class A power amplifier with idle current of 1.4A, supplied from +/-24Vdc power supply with 230V/2x18V/270VA EI core transformer, center tapped diode rectifier and 2 x 14100uF capacitor bank.

1. Measurements of radiated electromagnetic field near the transformer

Loop sensor probe is used for this measurement which gives output voltage proportional to derivative of magnetic flux according to equations in the image below

The output voltage of the loop sensor is directly proportional to the derivative of intensity of electromagnetic induction dB/dt. The loop sensor was placed side by the transformer as shown in the next image.

When the transformer is connected only to bridge rectifier with capacitor bank, the loop sensor output voltage looks like this and is dominated by 50Hz, 150Hz and 250Hz spectral lines:

When the amplifier with 1.4A idle current is connect to the output of the capacitor bank, the sensor spectrum shows a lot of high order harmonics due to current impulses that are needed to charge the capacitor bank.

Last, measurement with transformer turned off, showing residual measuring noise

This loop sensor is very useful to check the radiated field inside the power amplifier and to try to minimize its possible effect to input circuitry and induction into PCB circuits track loops. We may or not improve the hum components at the power amplifier output by transformer re-positioning and turning, but not always. Often we come to conclusion that output hum components do not depend much on transformer placement or the improvement is not satisfactory. To check if the hum components are a result of transformer and rectifier radiated fields or not we place the transformer and rectifier with capacitor bank outside the amplifier in a distance when intensity of electromagnetic field from the transformer is negligible. 1 – 2m is enough. And we measure mains related components at the amplifier output again. We often find that the difference with power supply inside or outside the amplifier is insignificant so we have to find another sources of hum than the transformer radiated field. Again for further study there is a literature [1]. In my experience the biggest issues regarding hum/buzz components are ground returns, especially ground return of audio signal shared with bypass capacitor returns or dividers connected to supply rails. Several centimeters of shared PCB ground may completely destroy the effort of getting good S/N.

2. Measurements with two grounding schemes

Two grounding schemes were chosen, #1 has about 5cm of shared ground for signal and 47uF bypass capacitors, #2 tries to keep star ground concept as much as possible. Amplifier module under test is class A with idle current of 1.4A, as already stated. Spectrum of 1KHz 5W THD/THD+N is measured and also the spectrum with no input signal. The noise measurement and noise component in THD+N (noise floor) is unfortunately affected by the soundcard used - we are loosing about 6dB in noise.

Grounding scheme #1

The same in dBr related to 0dBr, which is more usual at ASR, though it is the same thing

Grounding scheme #2

The same in dBr related to 0dBr, which is usual at ASR though it is the same thing

We can see that even if the transformer radiated field is kept negligible simply by the distance of the power supply from the amplifier, it is the PCB design, namely ground returns, that are responsible for resulting output mains related hum components, together with PSRR of the circuit design. Scheme #2 is much better than #1, but still there is a space for improvements. However it is time consuming and sadly we often see quite unacceptable results in the mass produced amplifiers.

Literature:

[1] Self, D.: Audio Amplifier Power Design Handbook, third edition, Newnes, 2002.

Last edited: