See Amir's review here!

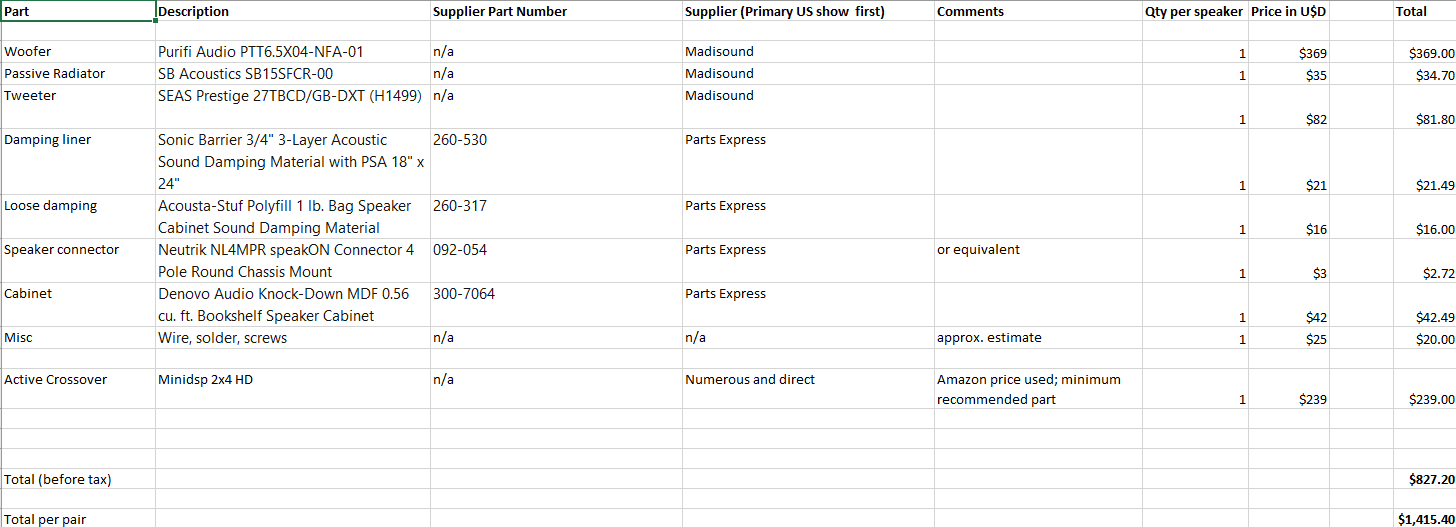

Here is BOM...

So this is a build of the Directiva r1 speaker. I have not give much thought to a good naming scheme, so am calling it r1 for now. It is based on a Denovo cabinet sold by Parts Express (and others). Parts Express has changed suppliers, and the replacement cabinet should be available in March 2024.

https://www.parts-express.com/Knock-Down-MDF-0.56-ft-Bookshelf-Cabinet-300-7064

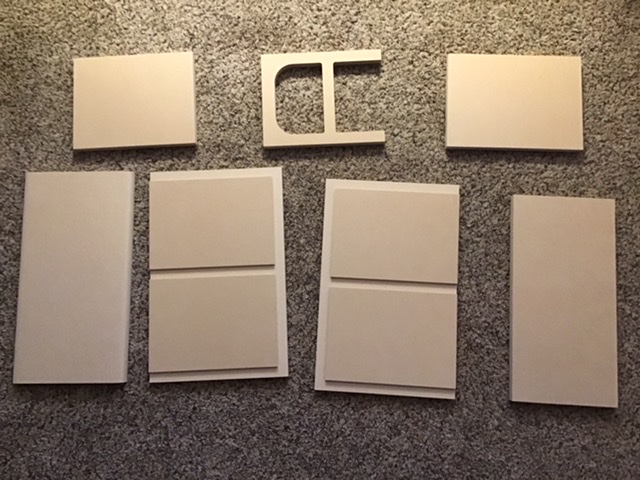

If you have worked with these flat packs before, you might have expected the back the be rabbeted, but in this case it is the sides. While clearly more milling is involved, this approach yields only one joint on each side and so offers a more even paint surface.

The back is in the bottom right and the front baffle is on the bottom left in the pic above. We will start with the front... (see next post)

P.S. (EDIT)

While using wood screws has not been an issue (as far as I know), in any of my earlier DIY speaker build for ASR, my rebuild of the Purifi SPK5s, brought some light to some ugly resonances that were apparently caused by wood scews rather than machine screws and nutserts or equiv. All of my subwoofers have used t-nuts, so given the excursion of the Purufi woofer used in r1, highly recommend using better fasteners to mount the woofer (and likely the tweeter too). As soon as I can do so with my r1 prototype, will retrofit and supply some measurements to illustrate the difference.

Here is BOM...

So this is a build of the Directiva r1 speaker. I have not give much thought to a good naming scheme, so am calling it r1 for now. It is based on a Denovo cabinet sold by Parts Express (and others). Parts Express has changed suppliers, and the replacement cabinet should be available in March 2024.

https://www.parts-express.com/Knock-Down-MDF-0.56-ft-Bookshelf-Cabinet-300-7064

If you have worked with these flat packs before, you might have expected the back the be rabbeted, but in this case it is the sides. While clearly more milling is involved, this approach yields only one joint on each side and so offers a more even paint surface.

The back is in the bottom right and the front baffle is on the bottom left in the pic above. We will start with the front... (see next post)

P.S. (EDIT)

While using wood screws has not been an issue (as far as I know), in any of my earlier DIY speaker build for ASR, my rebuild of the Purifi SPK5s, brought some light to some ugly resonances that were apparently caused by wood scews rather than machine screws and nutserts or equiv. All of my subwoofers have used t-nuts, so given the excursion of the Purufi woofer used in r1, highly recommend using better fasteners to mount the woofer (and likely the tweeter too). As soon as I can do so with my r1 prototype, will retrofit and supply some measurements to illustrate the difference.

Last edited:

). The notch is 2.4 inches wide by 1.75 inches deep and centered on the top sheet.

). The notch is 2.4 inches wide by 1.75 inches deep and centered on the top sheet.