I recently reviewed the Buckeye Hypex hypex Nc502mp based multichannel amplifier. This is a quick teardown review of the same.

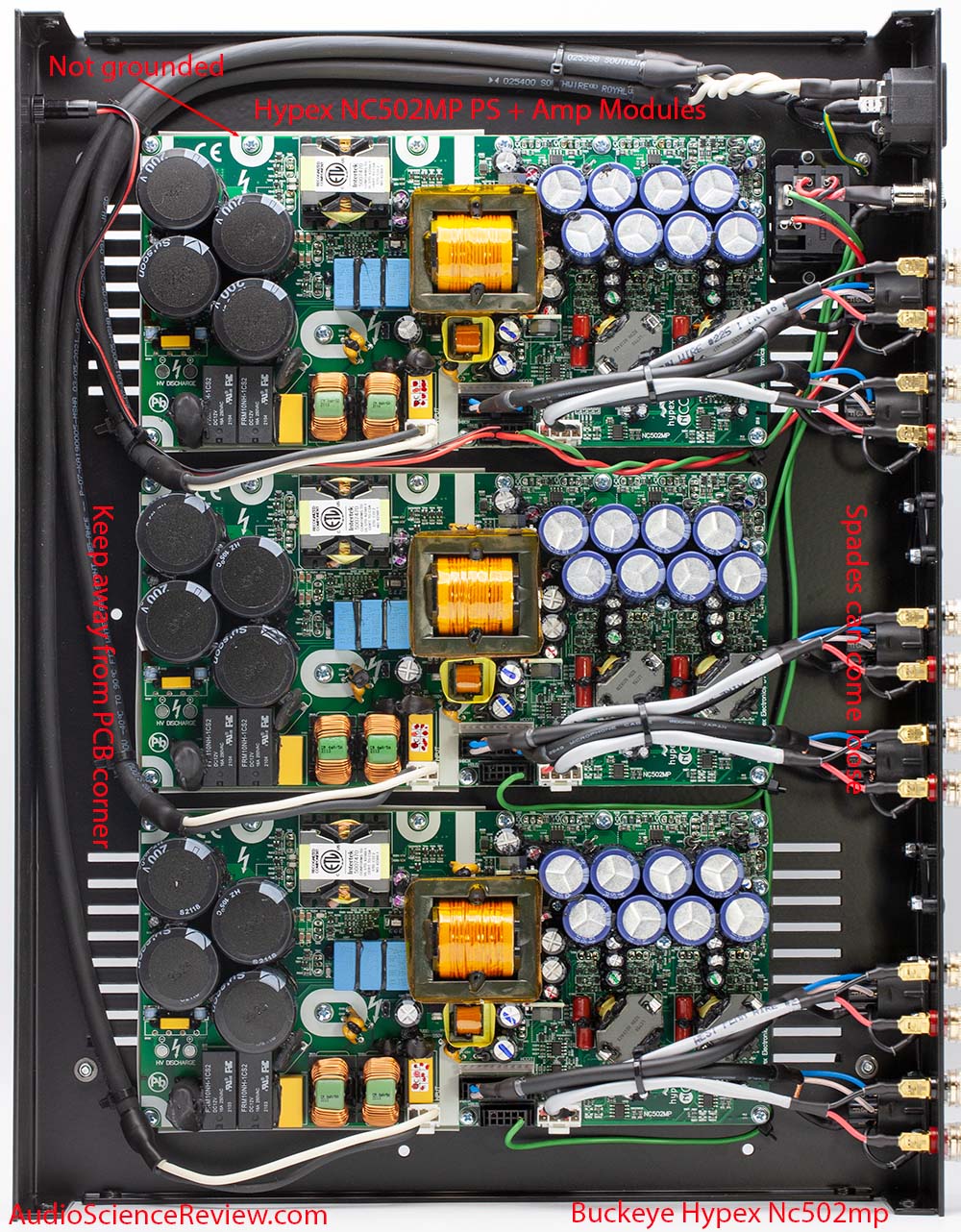

The case is easy to open after which, you see the implementation based on three Hypex stereo NC502MP class D amplifiers with integrated switching power supplies:

Overall this is a clean build and I only have a couple of minor issues:

1. I checked the grounding screw on the Hypex amplifiers and two get routed to the safety ground of the IEC outlet but the top module does not. The resistance was under 1 ohm for the two modules but a few hundred ohms for the top module. Assuming this is recommended practice from Hypex, the case anodization needs to be sanded off underneath.

2. The AC cables are nicely routed away from signal lines. But they bend right at the edge of the amplifier PCB which could nick them. Move the tiedown a hair over and it should be fine.

Speaking of #1, I also like to see the anodization sanded off until bare metal shows. Here they are just scuffed:

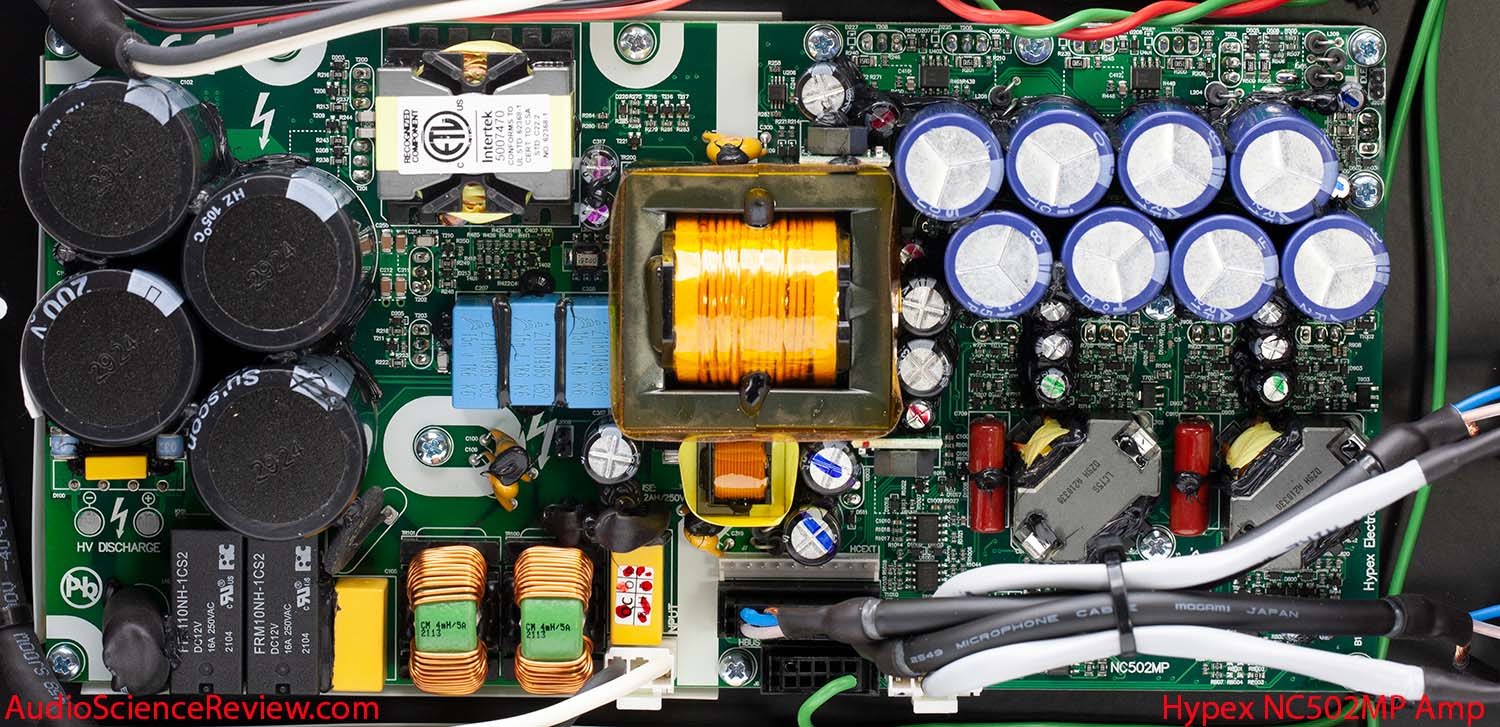

Here is a zoomed image of the Hypex modules:

Examining the branding of the capacitors we find that the ones in the amplifier are from Aishi and those in the power supply, Sus'con:

Both are second or third tier capacitors. Fortunately they are rated at 105 degree C instead of 85 which should give them longer life.

BTW, I am always surprised by the amount of goop hypex puts on their amps. They are good to keep vibrations down and keep failure during shipping low. But I must confess I had not seen them put on transformer in that manner. I wonder if it is there to keep transformer whining down as a post measure. The goop makes repair more of a pain by the way as you can't just desolder and pull the part out.

Conclusions

As small company builds go, Buckeye's amp here is very well assembled. Per above, I only found a couple of things I would improve. I let others opine as to what else they see.

------------

As always, questions, comments, recommendations, etc. are welcome.

Any donations are much appreciated using: https://www.audiosciencereview.com/forum/index.php?threads/how-to-support-audio-science-review.8150/

The case is easy to open after which, you see the implementation based on three Hypex stereo NC502MP class D amplifiers with integrated switching power supplies:

Overall this is a clean build and I only have a couple of minor issues:

1. I checked the grounding screw on the Hypex amplifiers and two get routed to the safety ground of the IEC outlet but the top module does not. The resistance was under 1 ohm for the two modules but a few hundred ohms for the top module. Assuming this is recommended practice from Hypex, the case anodization needs to be sanded off underneath.

2. The AC cables are nicely routed away from signal lines. But they bend right at the edge of the amplifier PCB which could nick them. Move the tiedown a hair over and it should be fine.

Speaking of #1, I also like to see the anodization sanded off until bare metal shows. Here they are just scuffed:

Here is a zoomed image of the Hypex modules:

Examining the branding of the capacitors we find that the ones in the amplifier are from Aishi and those in the power supply, Sus'con:

Both are second or third tier capacitors. Fortunately they are rated at 105 degree C instead of 85 which should give them longer life.

BTW, I am always surprised by the amount of goop hypex puts on their amps. They are good to keep vibrations down and keep failure during shipping low. But I must confess I had not seen them put on transformer in that manner. I wonder if it is there to keep transformer whining down as a post measure. The goop makes repair more of a pain by the way as you can't just desolder and pull the part out.

Conclusions

As small company builds go, Buckeye's amp here is very well assembled. Per above, I only found a couple of things I would improve. I let others opine as to what else they see.

------------

As always, questions, comments, recommendations, etc. are welcome.

Any donations are much appreciated using: https://www.audiosciencereview.com/forum/index.php?threads/how-to-support-audio-science-review.8150/