Recently I bought some Dayton Audio ND64 and ND65 speakers for a project, and by the time I got them, they measured out of spec. Many of the T/S parameters were off. I contacted Parts Express customer support and they said I should measure them only after 48 hours of "burn-in". I gave them the benefit of the doubt and here is what happened after.

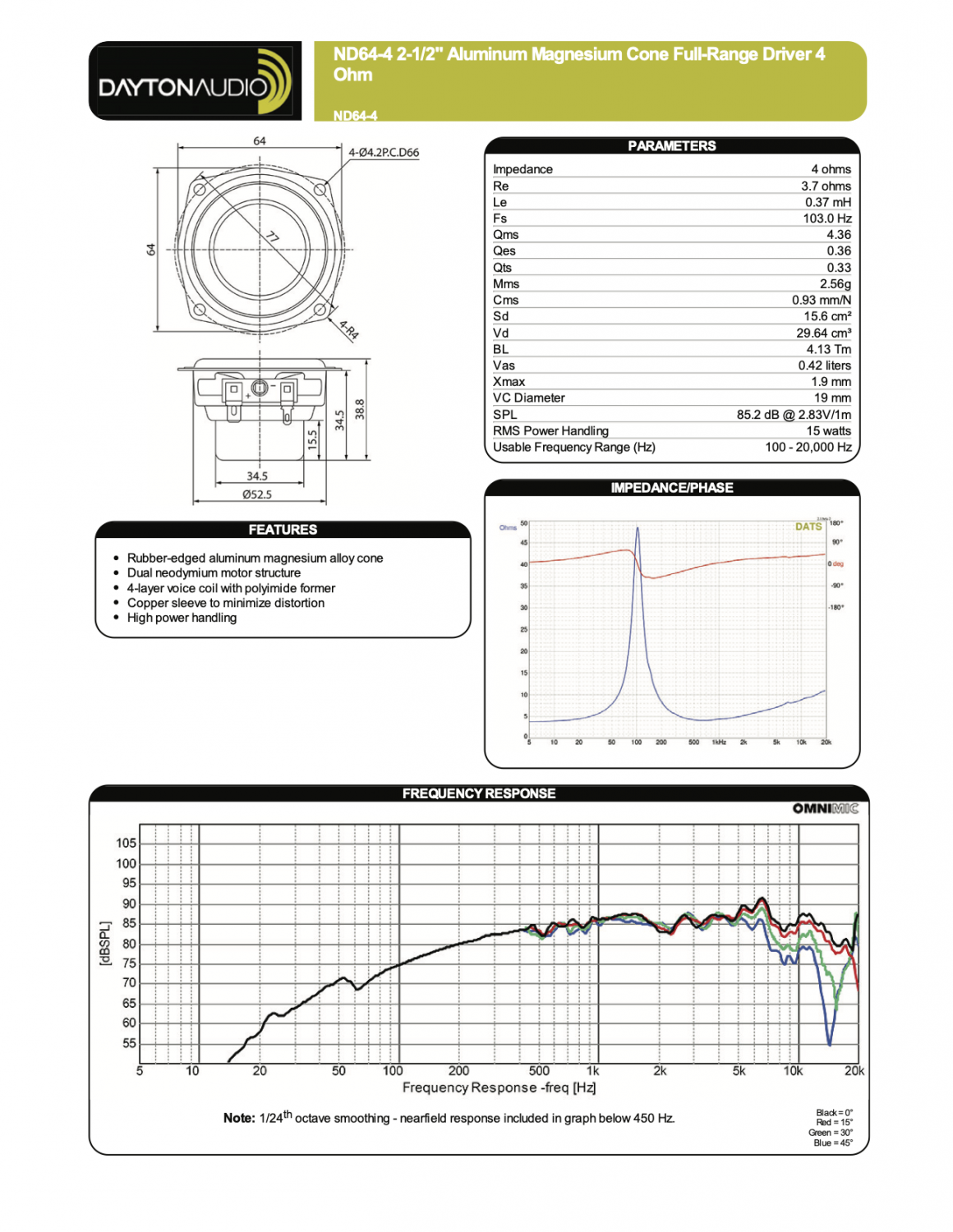

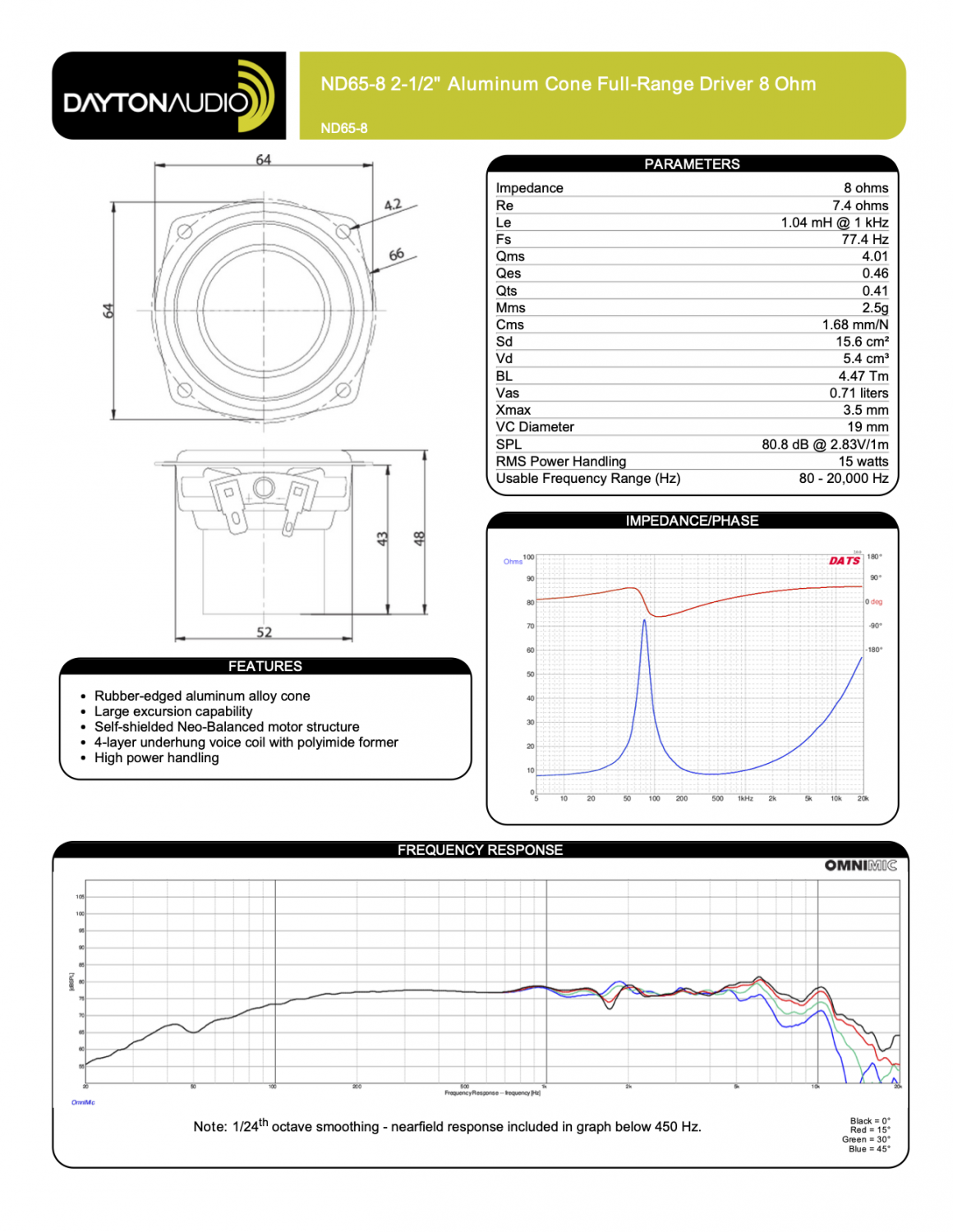

Here are the datasheets of the speakers in question. I bought the ND64-4 and ND65-8 models.

Looks really good, great for a small enclosure with passive radiator design with those low Qts values.

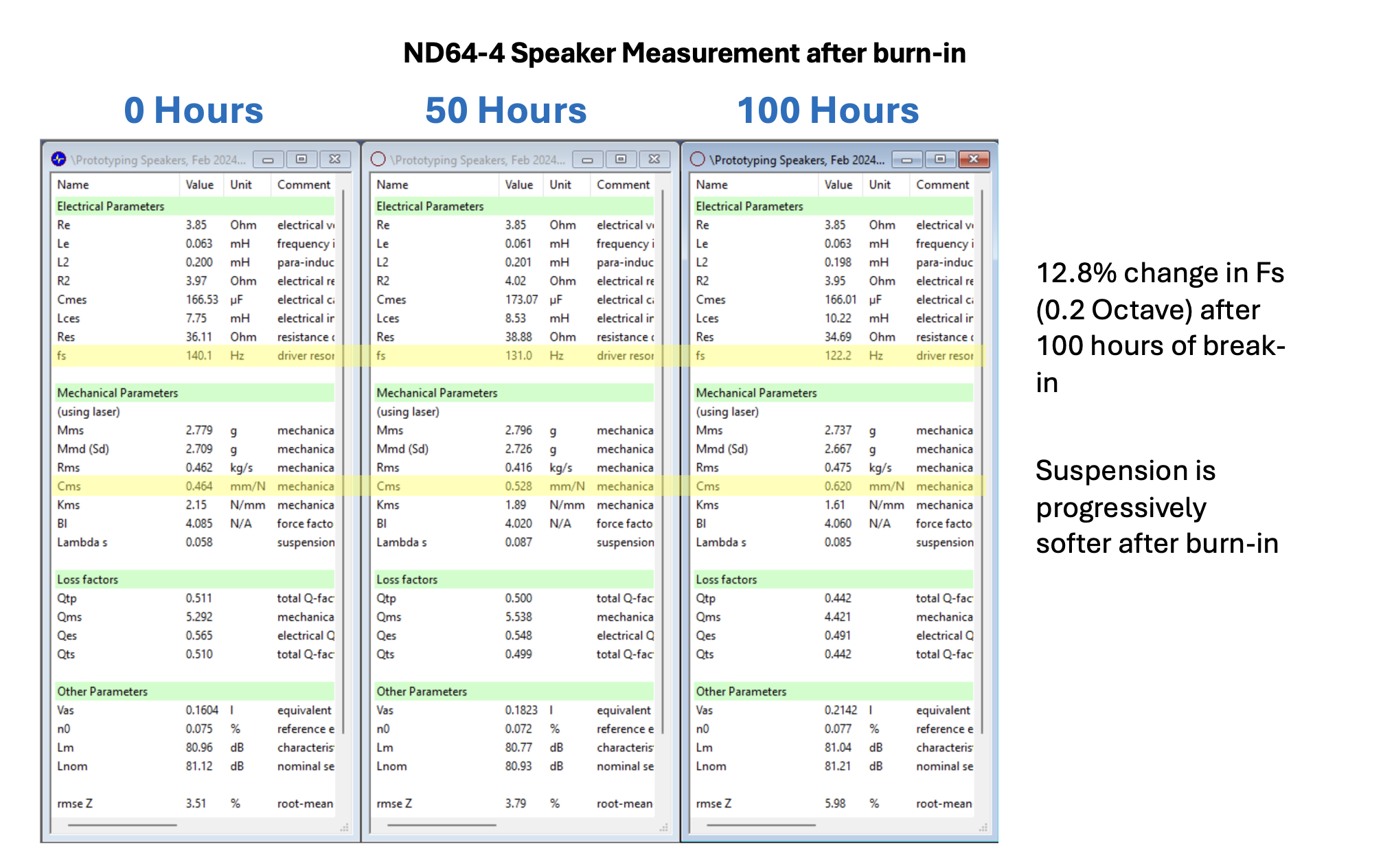

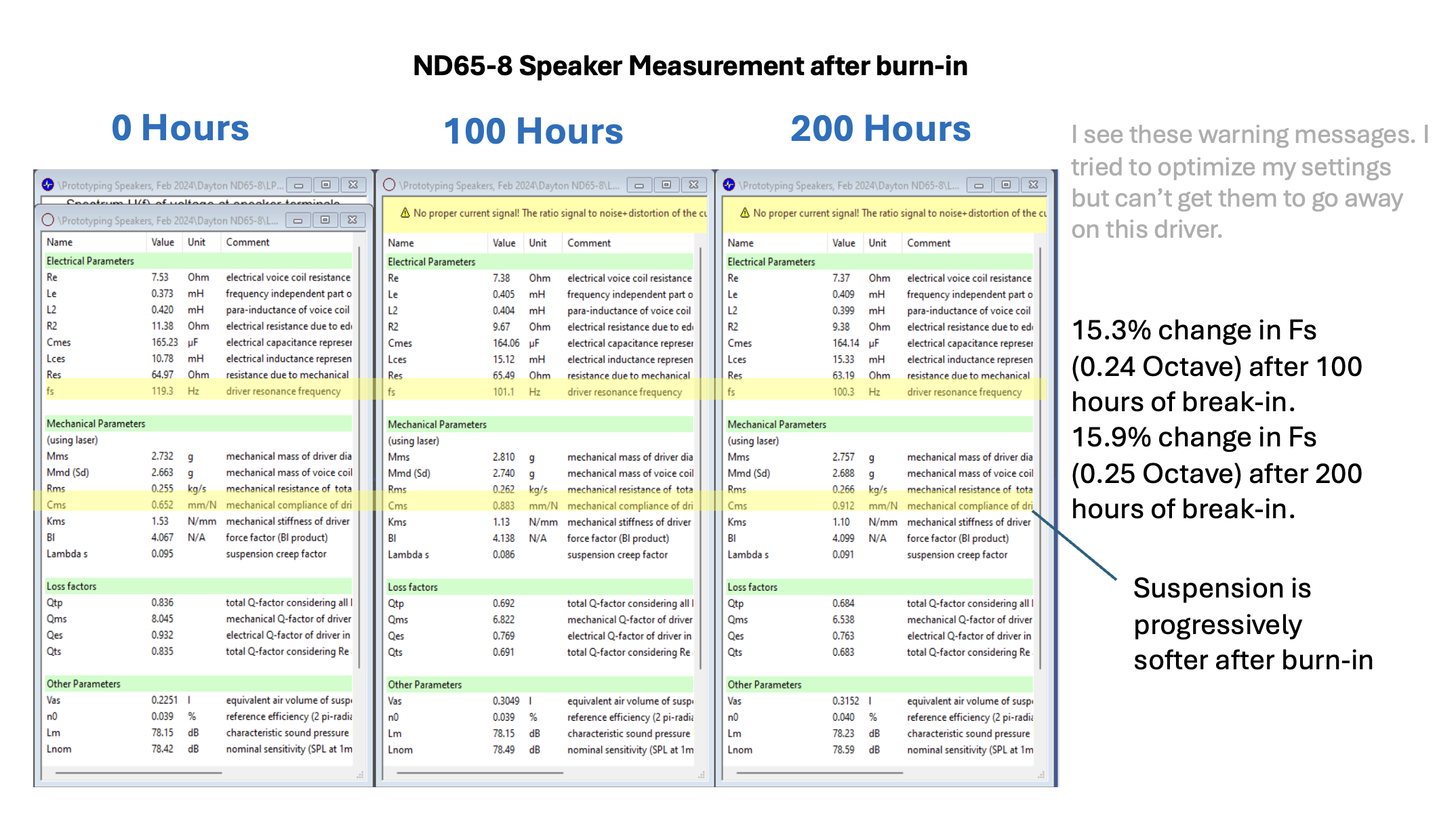

And here is what I got when I measured them, even after a hundred hours of burn-in.

Not exactly the speaker they described. The ND64 was still useable, and the ND65 was no longer suited for the original design plan of a reflex/passive radiator box. What's your experience with burning in speakers? Would you still trust Dayton Audio? They sure have nice datasheets for all of their products, but this time it was a letdown.

Here are the datasheets of the speakers in question. I bought the ND64-4 and ND65-8 models.

Looks really good, great for a small enclosure with passive radiator design with those low Qts values.

And here is what I got when I measured them, even after a hundred hours of burn-in.

Not exactly the speaker they described. The ND64 was still useable, and the ND65 was no longer suited for the original design plan of a reflex/passive radiator box. What's your experience with burning in speakers? Would you still trust Dayton Audio? They sure have nice datasheets for all of their products, but this time it was a letdown.