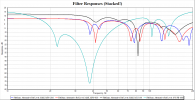

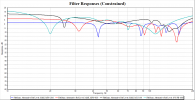

- I did see PEQ stacking happen occasionally, with what I thought was reasonable choice of Reference Level, which is why I found that graphing the filters was so useful, just to monitor what was happening.

I'd like to clarify that there is a difference between the "reference level" that you choose to figure out by eyeballing what the maximum boost and cut of the PEQ filters should be, and the reference level that you enter into the optimization options dialog. Once you figure out the maximum PEQ boost and cut by eyeballing, the reference level number you enter into the optimization options dialog is irrelevant to the final result.

I read somewhere that the Reference Level is set at the Max frequency of the "Criteria: Frequency Range to Optimize" (160Hz in my case) and mapped to the Target Curve.

This is true.

So I try to "best fit" my target curve to the (Baseline) measured response by eye, and then check that my choice of Reference Level does not result in any PEQ filters hitting their limits of attenuation (if possible). It would be nice if the software could select the optimum Reference Level in a Sub-Only configuration.

Regarding the reference level that you enter into the optimization options dialog, there is no optimum value. Regarding the "eyeball" reference level for picking the maximum boost and cut of the PEQs, the optimum level depends on how much PEQ boost or cut you're willing to have. Different users have different needs determined by their situation. "Stacking" is prevented by using the Constraints page of the optimization options dialog to set the maximum total PEQ boost and cut to be just a hair larger than the maximum individual PEQ boost and cut respectively.

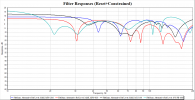

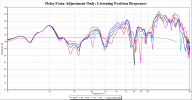

Speaking of this, your data indicate that your modal problems are pretty minimal, but that low-frequency boost (or high-frequency cut) is needed. In your case, this is best done not with PEQs, but with either a shared LF shelving filter with LF boost, or a shared HF shelving filter with HF cut. Just one shared shelving filter would do a lot to reach your target curve, with PEQs used only for cleanup of modal issues.

I'd suggest either:

- A shared LF shelving filter of type "LF Shelf Variable Q Second-Order (Alt)", or

- A shared HF shelving filter of type "HF Shelf Variable Q Second-Order (Alt)"

These would have a center frequency of about 40 Hz (the "half boost/half cut frequency"). If you use an LF shelf, it would have an LF boost of about 8 dB, while an HF shelf would have an HF cut of about 8 dB. Q should be between 0.5 and 0.707. If you have boatloads of additional adjustable sub amp gain available, the HF shelf with HF attenuation is the way to go, as this would minimize the required voltage swing of the miniDSP to reach a given SPL. The miniDSP must never be allowed to clip before the power amp does.

You can get a good idea of what the final shelving parameters should be (to limit the parameter ranges for the optimizer) by using the tuning feature, as described in the docs about the

target curve example. You should be able to do a lot with just this one shelving filter. The tuning function will show the effects of the shelving filter in real time. Try tuning using the target curve example first.

To reiterate, a claim that the reference level number you enter into the optimization options dialog is critically important is not a lesson to be learned, but a myth. Prior to 1.1.6, exceeding gain block limits could be a problem, but with 1.1.6 and later, this is no longer a concern.