bothu

Member

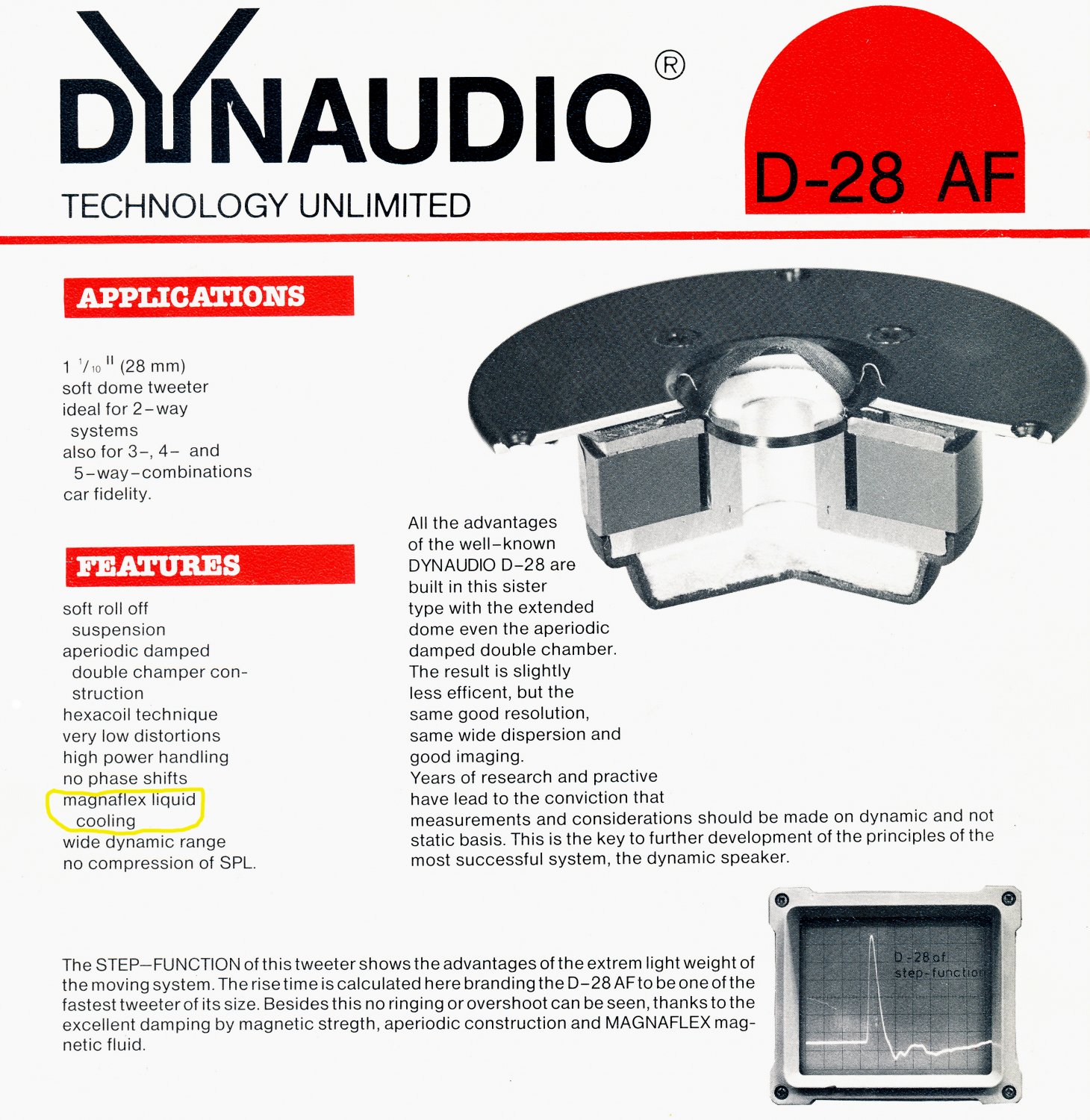

Many years back magnetic oil was often used in tweeters, did it make any improvement or was it "snake oil" ?

Bo Thunér, Linköping, Sweden

Bo Thunér, Linköping, Sweden

if the cutoff is rather low...and rather necessaryI think Kef uses ferrofluid in their coaxes. I’m not particularly a fan of the stuff.

Apparently the tweeters used in Harbeths with ferro-fluod DO NOT degrade over time and apparently measurements on twenty odd year old (or even older) tweeters compared to new ones proved it.allows you to increase the admissible power..some believe that it would take away the finesse..but many hdg tweeters use it..but in fact it degrades, becomes viscous, over time and must be cleaned and changed after a while. ..(but it can also be observed quite easily when measured)

2.1 kHz isn’t particularly low (LS50 meta) There are plenty of low fs tweeters that manage lower without it.if the cutoff is rather low...and rather necessary

if in cutoff a 2.1k is precisely low enough...you don't understand... that s not compression..no?2.1 kHz isn’t particularly low (LS50 meta) There are plenty of low fs tweeters that manage lower without it.

But maybe not all ferrofluid is made equally…

Indeed, I don’t understand any of what you just said…if in cutoff a 2.1k is precisely low enough...you don't understand... that s not compression..no?

But maybe not all ferrofluid is made equally…

A fair few highly regarded driver manufacturers (Bliesma, among others) have chosen to not use ferrofluid as they feel it takes away from the dynamic abilities of the tweeter. I am not particularly sure why this is, it could be because they feel it overdamps the driver.

Do you know what age period is equal to current and past ferrofluids?I have talked in the past with few experienced loudspeaker engineers and they said the current ferrofluids cannot be compared with the early ones regarding aging properties, but would be nice to have some objective data for that.

I operate a small Ferrotec brand ferrofluid distribution Co. in Canada - there are literally dozens of viscosities of ferrofluid available, along with several different carrier liquids.2.1 kHz isn’t particularly low (LS50 meta) There are plenty of low fs tweeters that manage lower without it.

But maybe not all ferrofluid is made equally…