Hi,

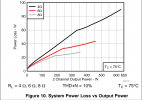

Computer CPUs dissipate a lot of heat and from what I understand (very little) their cooling systems are very much developed and performant. I never see heat pipes assemblies in power amps (I am not interested in water cooling). Is there a reason for that or is it just that is not usually necessary?

Thank you for your comments.

PS: the reason I am asking is that I am thinking on, maybe, building (that is, PCB included, not premade module) a multichannel TPA3xxx amp, but the condition is that it is possible to make it very small. What worries me most is of course the cooling, and before even starting I want to know if it would be possible to clamp the amp chips to a laptop CPU like cooling system (heat pipes - radiator - fan) with no additional heat sink other than the enclosure. The amp would be hidden and the fan noise is not expected to be an issue. I am not interested in any commercially available amps.

Computer CPUs dissipate a lot of heat and from what I understand (very little) their cooling systems are very much developed and performant. I never see heat pipes assemblies in power amps (I am not interested in water cooling). Is there a reason for that or is it just that is not usually necessary?

Thank you for your comments.

PS: the reason I am asking is that I am thinking on, maybe, building (that is, PCB included, not premade module) a multichannel TPA3xxx amp, but the condition is that it is possible to make it very small. What worries me most is of course the cooling, and before even starting I want to know if it would be possible to clamp the amp chips to a laptop CPU like cooling system (heat pipes - radiator - fan) with no additional heat sink other than the enclosure. The amp would be hidden and the fan noise is not expected to be an issue. I am not interested in any commercially available amps.