KSTR

Major Contributor

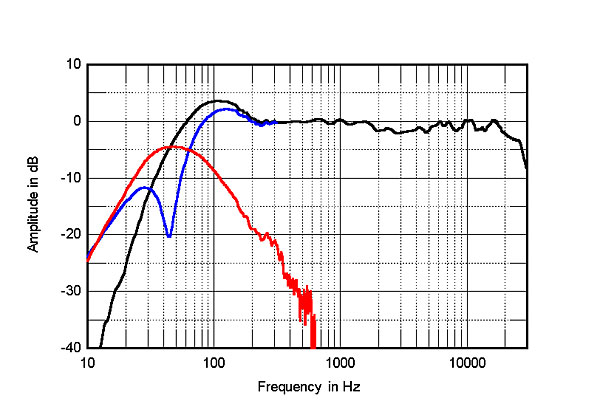

Measuring port output to sufficient precision (lower than -20dB) usually requires that the front output of the mid-woofer must be fully diverted away (isolated acoustic space) from the mic in/at the port, otherwise you mix the true leakage (be it resonant or not) with the bleed from the front output (woofer or midrange) where any amount of addition or cancelling may take place.All of the above and/or something entirely different?

For this speaker, the port is quite far away from the woofer so the measured output is cleaner by just that alone (same for rear ports). When the port is directly adjacent to the woofer it is impossible to really see the port's true contribution. Whenever you see a port plot with a notch at some frequency then rising again (as in #27), you can be almost certain this is cancelling and bleed. A way to check this is varying the mic placement, when this results in a different position of the notch/dip the measurement is not covering the real situation.

Last edited: