Do not use WD40 on electronics. It's not meant for that, and can cause damage to contacts.What is your thought on WD40 vs Deoxit?

-

WANTED: Happy members who like to discuss audio and other topics related to our interest. Desire to learn and share knowledge of science required. There are many reviews of audio hardware and expert members to help answer your questions. Click here to have your audio equipment measured for free!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Technics SU-C01 beautiful circuit board - how to fix input selector

- Thread starter BadAudioAdvice

- Start date

restorer-john

Grand Contributor

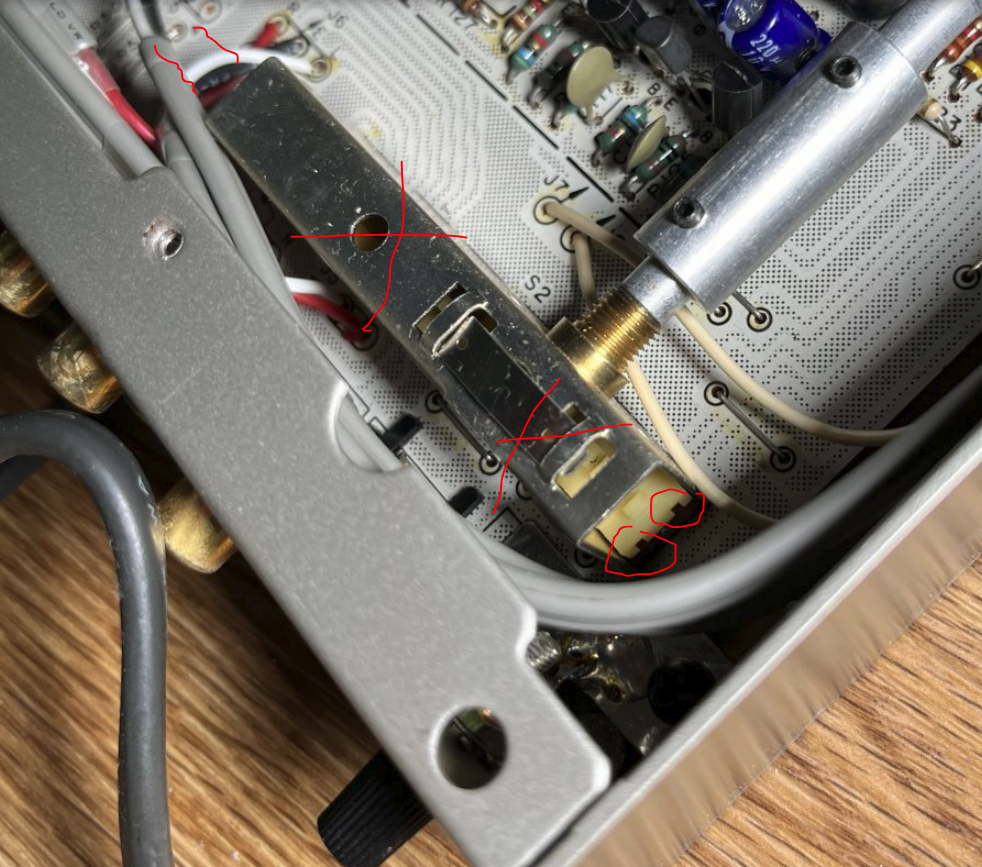

Inside the switch there will be 8 sets of slide contacts. You cannot see them, but they slide on rails like my linked pictures above.

Rotate the switch to each extreme point and you will see the ends of the twin rails. squirt a little De-oxit in the rail/slider gap. Do the same for the opposite end. That will get you contact cleaner on 50% of the contacts. The other four are deep in the centre of the switch. Do not squirt De-Oxit into the top of the switch or into the gear/rack assembly through top holes. It will do nothing and just make a mess, or worse, make the nylon brittle.

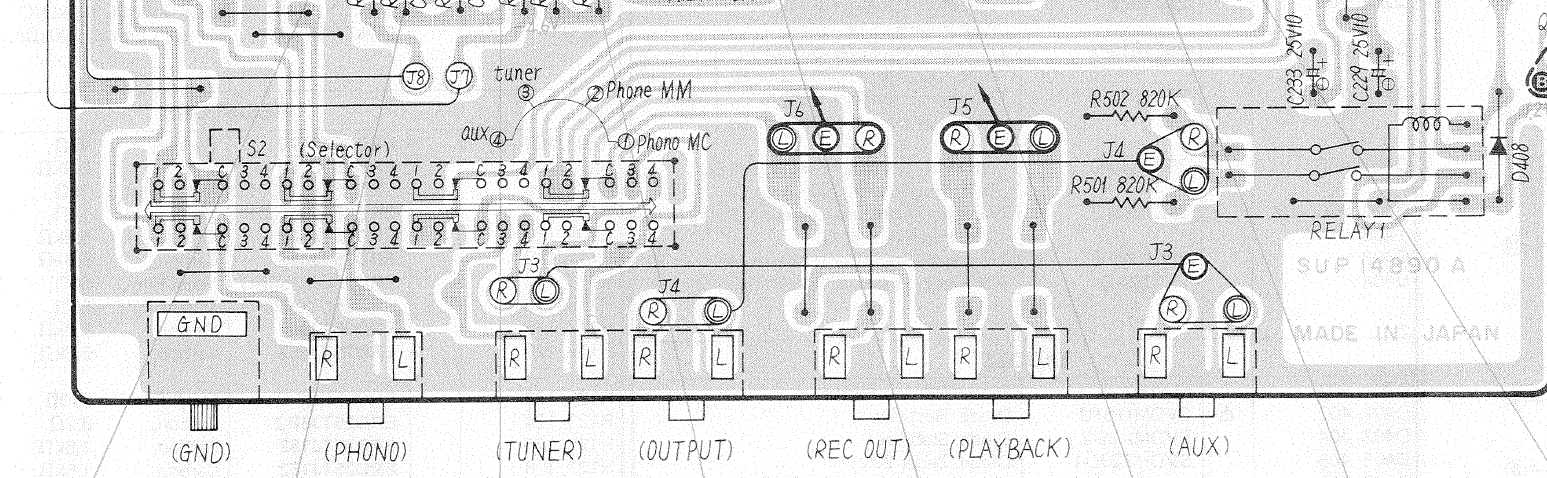

Imagine all these contacts (x8) all moving at once along 2 sets of 4 keyed contact rails- that's how it works. The "C" means common, and that is the top of the contact rails (look at that link I posted), the numbers (1,2,3,4) represent the contacts at the bottom of the switch and the selector position. You can even ascertain which contacts are giving you the trouble from the outside by decoding the PCB layout picture below.

If it's the left channel aux input for example, follow L-aux input to J3 (wire link), you can see it's the very top right contact at the end of the switch, position 4.

Rotate the switch to each extreme point and you will see the ends of the twin rails. squirt a little De-oxit in the rail/slider gap. Do the same for the opposite end. That will get you contact cleaner on 50% of the contacts. The other four are deep in the centre of the switch. Do not squirt De-Oxit into the top of the switch or into the gear/rack assembly through top holes. It will do nothing and just make a mess, or worse, make the nylon brittle.

Imagine all these contacts (x8) all moving at once along 2 sets of 4 keyed contact rails- that's how it works. The "C" means common, and that is the top of the contact rails (look at that link I posted), the numbers (1,2,3,4) represent the contacts at the bottom of the switch and the selector position. You can even ascertain which contacts are giving you the trouble from the outside by decoding the PCB layout picture below.

If it's the left channel aux input for example, follow L-aux input to J3 (wire link), you can see it's the very top right contact at the end of the switch, position 4.

Last edited:

OP

BadAudioAdvice

Active Member

- Thread Starter

- #23

And in the 1982 stack

I've got that whole stack

Interestingly the amplifier came in two versions, one with a separate component that turned AC into DC (as shown in that stack), and another version that had the amplifier power supply built-in. I'm not sure which one is more common.

I noticed the missing screw as soon as I opened it up - however no rattle, and couldn't seem to locate it. No vents in the case either, so a bit of a mystery where it could have gone...look for a loose grub screw rattling around in the case

OP

BadAudioAdvice

Active Member

- Thread Starter

- #24

If it's the left channel aux input for example

How did you know?? It is the left aux channel that is giving me trouble.

I'll do as you suggested and report back. Thank you!

restorer-john

Grand Contributor

How did you know?? It is the left aux channel that is giving me trouble.

I'll do as you suggested and report back. Thank you!

Special magical powers.

Logic actually. Aux is the most likely input you use (DAC/line source in 2024) and the left set of contacts are near the exposed end of the switch and would have oxidised more than the right set of Aux contacts, which are deep in the switch.

OP

BadAudioAdvice

Active Member

- Thread Starter

- #26

I decided to delay the "repair" by a day, so that I could order a small vial of the brush-style DeoxIT D100L, as the DeoxIT that I had on hand was the spray kind, and I was concerned about 1. making a mess by spraying too much and 2. access to the left side of the switch near the case would be difficult without removing the board.

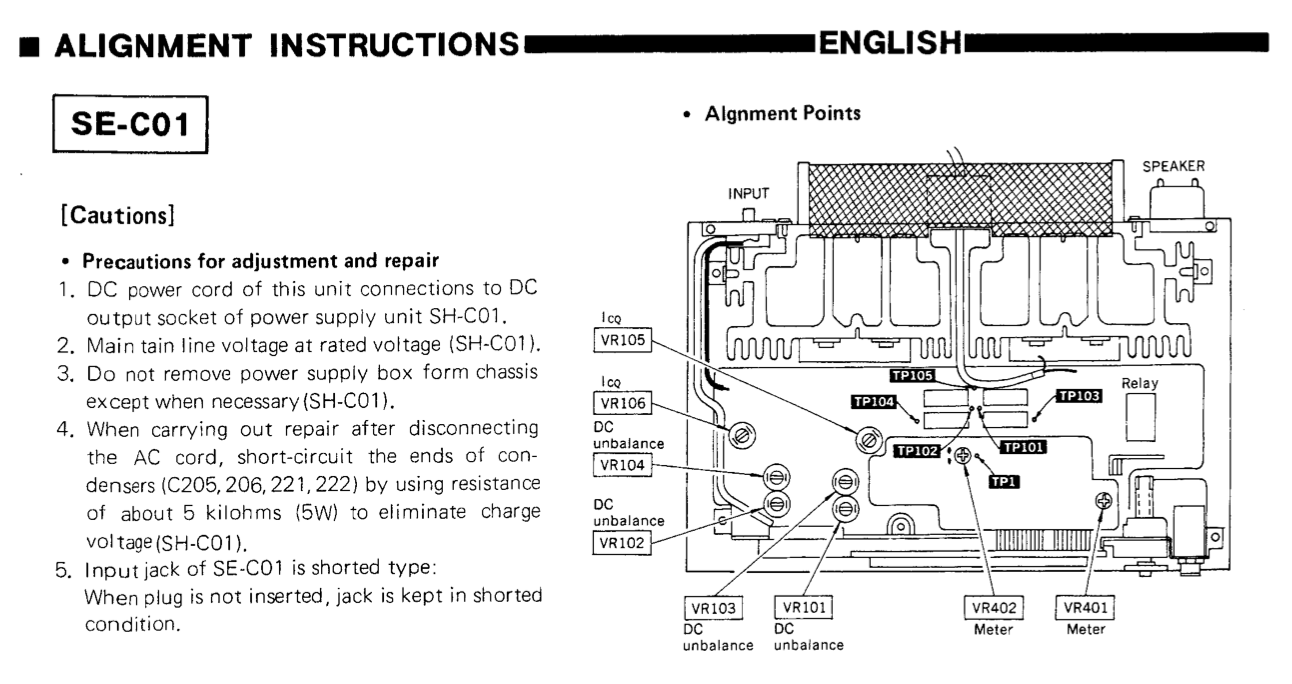

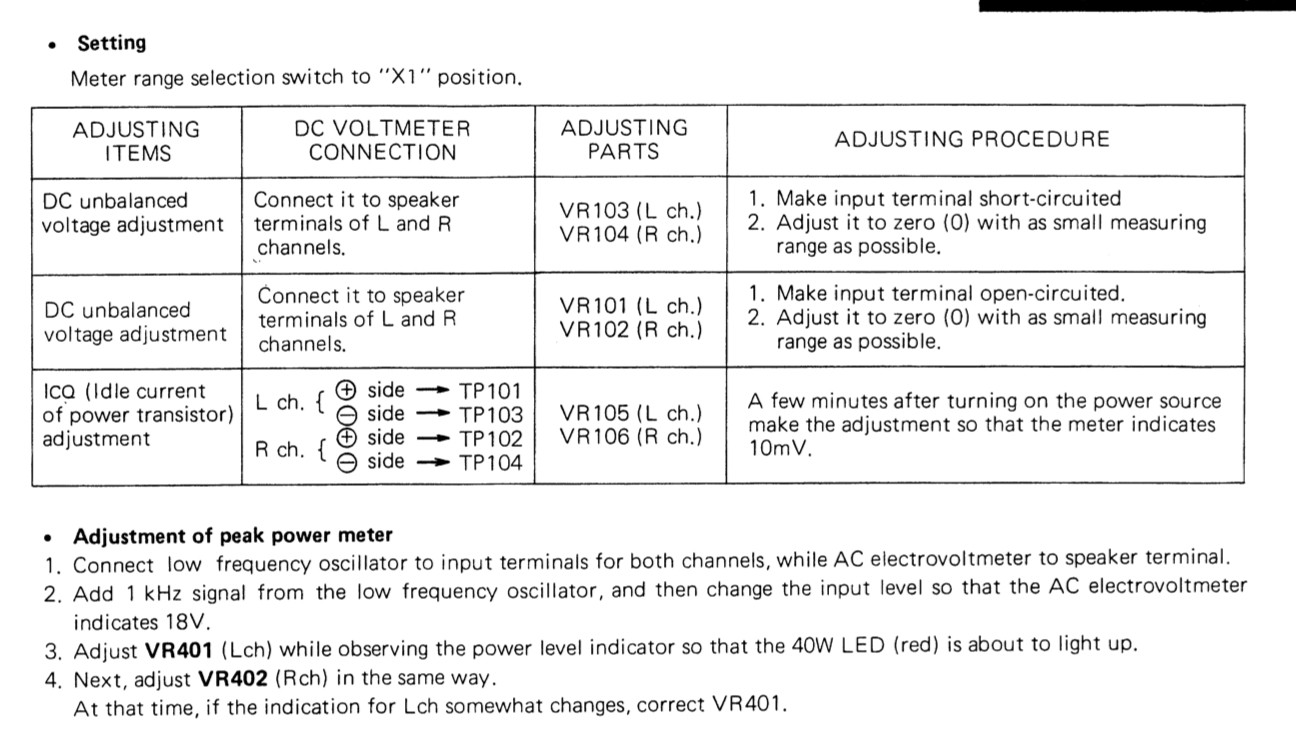

In the meantime, I am looking at fixing the DC voltage on the output of the amplifier. (One channel has about 60mV, the other 40mV).

In the service manual I found the following section, and I had a couple of questions that I'm hoping you might be able to shed some light on.

Is Step 5 asking me to short the inputs? Would that just be connecting the shield to the inner signal pin?

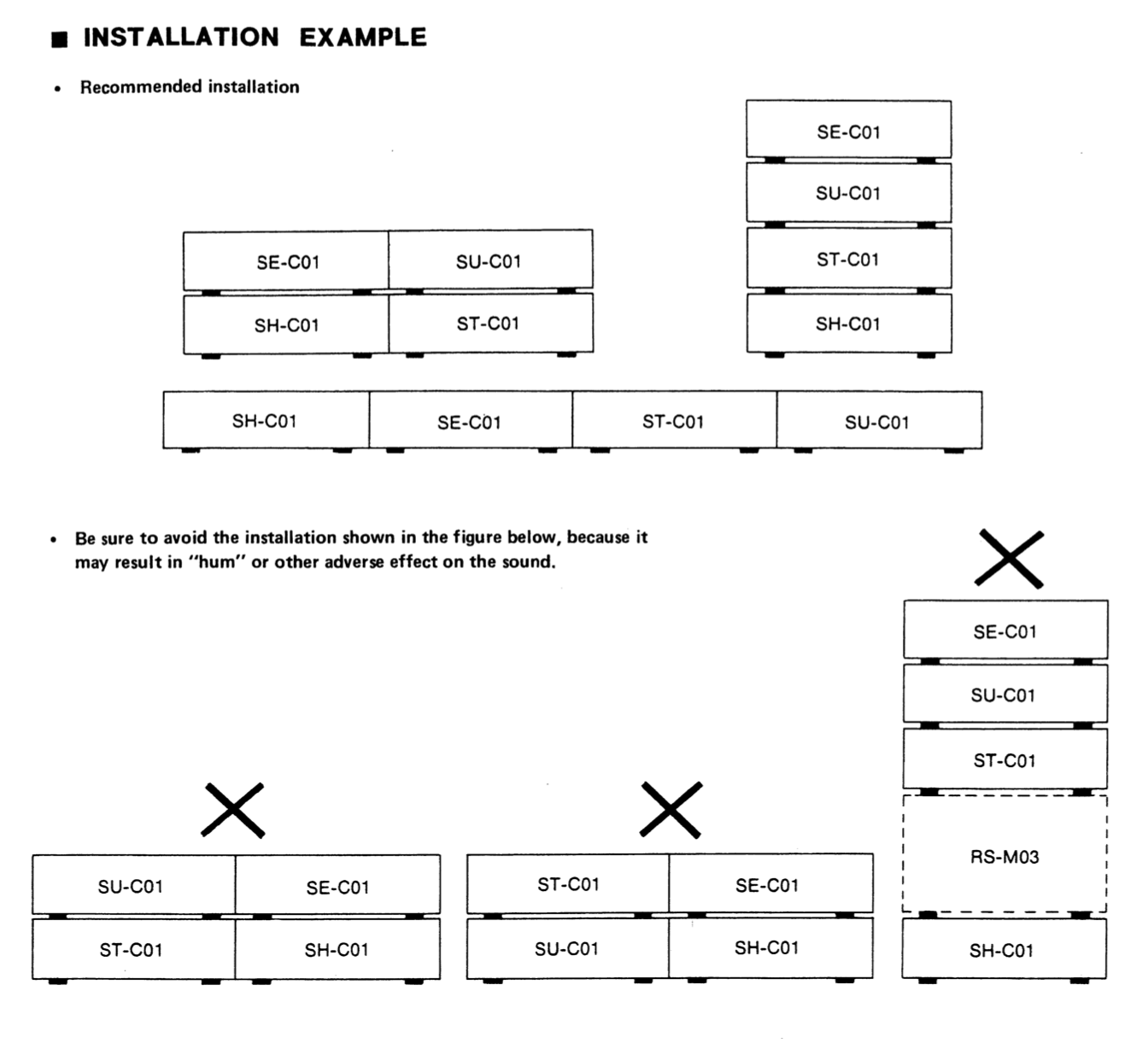

Also neat that there is a graphic at the end that shows recommended stacking of the whole system, and what to avoid.

In the meantime, I am looking at fixing the DC voltage on the output of the amplifier. (One channel has about 60mV, the other 40mV).

In the service manual I found the following section, and I had a couple of questions that I'm hoping you might be able to shed some light on.

Is Step 5 asking me to short the inputs? Would that just be connecting the shield to the inner signal pin?

Also neat that there is a graphic at the end that shows recommended stacking of the whole system, and what to avoid.

audio_tony

Addicted to Fun and Learning

Yes on both counts.Is Step 5 asking me to short the inputs? Would that just be connecting the shield to the inner signal pin?

However the DC offsets you have (60mV and 40mV) are tiny, and I wouldn't worry about them at all.

Roland68

Major Contributor

WD40, Ballistol, Carramba, contact sprays, etc. are completely unsuitable for such work. A sudden improvement is followed by a worsening of the problem over time. The solvents and oils contained can attack not only the switch, but also surrounding surfaces and components.Based on the measurements printed on the case, seems like this offers SOTA performance

The only problem is that the input select isn't behaving nicely. I need to position it in-between inputs, otherwise the Left channel is very distorted (sometimes it works OK in the actual position, but usually not).

I was thinking that it would be a quick fix with some Deoxit, but I'm not at all familiar with how they implemented the selector switch.

Also, when taking off the bottom, I was struck by how beautiful IMO the circuit board is, the tidy wiring, layout, and the labelling on the circuit board.

Any advice appreciated, and enjoy the pics!

If you do not want to open such switches, use a syringe/cannula or atomizer to soak the inside of the switch with pure isopropanol and then rinse thoroughly. To do this, perhaps remove the circuit board or move the device into the appropriate position. After the isopropanol has evaporated completely and without leaving any residue, add some Cramolin protection (lubricant and corrosion protection for contacts), less is more.

If you want to disassemble the switch, someone here shows how similar switches are reprocessed.

https://ftbw.de/sale/amplifiers/cyrus1-new-nextel-01.html

You could also replace the switch with a rotary switch in the same place. Screw it to the housing using an angle bracket and wire freely.

Isopropanol which I tried several times does not really work either on oxidized or corroded contacts. It can just only clean. To get reduction process the oxide there must be some more agressive chemicals. I agree that some contact spray like Contact 60 or similar does not help over time. Anyway, I use WD40 and Ballistol and it works, but need proper cleaning/removing.WD40, Ballistol, Carramba, contact sprays, etc. are completely unsuitable for such work. A sudden improvement is followed by a worsening of the problem over time. The solvents and oils contained can attack not only the switch, but also surrounding surfaces and components.

If you do not want to open such switches, use a syringe/cannula or atomizer to soak the inside of the switch with pure isopropanol and then rinse thoroughly. To do this, perhaps remove the circuit board or move the device into the appropriate position. After the isopropanol has evaporated completely and without leaving any residue, add some Cramolin protection (lubricant and corrosion protection for contacts), less is more.

If you want to disassemble the switch, someone here shows how similar switches are reprocessed.

https://ftbw.de/sale/amplifiers/cyrus1-new-nextel-01.html

You could also replace the switch with a rotary switch in the same place. Screw it to the housing using an angle bracket and wire freely.

OP

BadAudioAdvice

Active Member

- Thread Starter

- #30

A little bit of DeoxIT did the trick - we will see how long it remains static free.

Great that you got it fixed without removing the switch.View attachment 353021

A little bit of DeoxIT did the trick - we will see how long it remains static free.

Similar threads

- Replies

- 47

- Views

- 8K

- Replies

- 136

- Views

- 28K