-

WANTED: Happy members who like to discuss audio and other topics related to our interest. Desire to learn and share knowledge of science required. There are many reviews of audio hardware and expert members to help answer your questions. Click here to have your audio equipment measured for free!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Pads to reduce vibration

- Thread starter nikkon

- Start date

Maybe sorbothane?

Just get some Mason Super Ws (3/4-inch version) off of Amazon. If you're running the typical bookshelves with limited low frequency response, you won't get into amplification and they will be strongly effective by 60 to 70 Hz. Size them using the chart on the cutsheet, although you'll probably need to use 4 2"x2" squares per stand for stability so a mass plate might be needed to fully load the pads.

The question is what are you trying to accomplish by isolating the stand from the floor?

EDIT: I see, you meant that you have floorstanding tower speakers (ATC SMC40?). I don't know why you want to isolate them but the Super Ws will do the job for very low cost -- as mentioned above, you will probably need a mass plate to fully load down to pads to the optimum weight PSI.

The question is what are you trying to accomplish by isolating the stand from the floor?

EDIT: I see, you meant that you have floorstanding tower speakers (ATC SMC40?). I don't know why you want to isolate them but the Super Ws will do the job for very low cost -- as mentioned above, you will probably need a mass plate to fully load down to pads to the optimum weight PSI.

Unless the speakers are on carpet and stability was an issue or something, don't see the benefit for spikes. Is the floor vibrating sympathetically? What kind of floor is it? Perhaps rubber feet would be better.

nikkon

Member

- Joined

- Sep 4, 2020

- Messages

- 63

- Likes

- 28

- Thread Starter

- #5

I have a wooden floorUnless the speakers are on carpet and stability was an issue or something, don't see the benefit for spikes. Is the floor vibrating sympathetically? What kind of floor is it? Perhaps rubber feet would be better.

JSmith

Master Contributor

ZolaIII

Major Contributor

- Joined

- Jul 28, 2019

- Messages

- 4,199

- Likes

- 2,477

And bigger thicker one's, this is just to point you in a right direction so you can search for ones adopted to go on spike's ISO packs and so on but no need to pay much and you can also make your own. Key word is silicone.

Edit: cuple bucks DIY cast idea. Candles in melt cups and tube of quality silicone. Remove candle, fill cup with silicone over the top use isolation tape wrapped around it to give it extension of about 1 cm. When dried remove isolation tape, turn it around and punch it at center a bit with straight awl just a bit so it gets a hosting for spike. Put it underneath and you are done.

Edit: cuple bucks DIY cast idea. Candles in melt cups and tube of quality silicone. Remove candle, fill cup with silicone over the top use isolation tape wrapped around it to give it extension of about 1 cm. When dried remove isolation tape, turn it around and punch it at center a bit with straight awl just a bit so it gets a hosting for spike. Put it underneath and you are done.

Last edited:

Basic Channel

Member

- Joined

- Mar 22, 2024

- Messages

- 83

- Likes

- 68

I use the thick mats you buy for putting under washing machines. I break them into smaller bits and put under speakers and sub.

But I’m cheap like that.

But I’m cheap like that.

nikkon

Member

- Joined

- Sep 4, 2020

- Messages

- 63

- Likes

- 28

- Thread Starter

- #10

looking for some rubber components, yesUnless the speakers are on carpet and stability was an issue or something, don't see the benefit for spikes. Is the floor vibrating sympathetically? What kind of floor is it? Perhaps rubber feet would be better.

Basic Channel

Member

- Joined

- Mar 22, 2024

- Messages

- 83

- Likes

- 68

the things I use are rubber btw. And I suppose about 8cm thick once doubled up.

If the speakers have threaded inserts you can perhaps simply replace the spikes with some rubber cabinet feet.looking for some rubber components, yes

Somewhere here a member posted the formula for calculating the size / thickness / durometer you'll need based on the weight of the speakers.

Hopefully the search function is up to the task.

Hopefully the search function is up to the task.

Here is a link to Sorbothane's vibration calculator.

www.sorbothane.com

www.sorbothane.com

Sorbothane® Design Guide Vibration Calculator

Our online Sorbothane Design Guide Vibration Calculator helps you determine the proper shape, geometry and material for your desired Sorbothane® application.

www.sorbothane.com

www.sorbothane.com

ZolaIII

Major Contributor

- Joined

- Jul 28, 2019

- Messages

- 4,199

- Likes

- 2,477

In short why is Silicone better especially thermal one then Sorbothane.

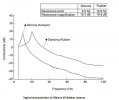

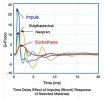

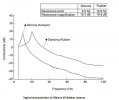

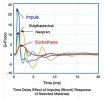

For one Silicone propagation frequency is considerably lower 9.5 Hz vs 19 Hz Sorbothane and 19.8 rubber. Magnitude is lower then rubber but bigger than Sorbothane but on the other hand harmonic propagation is both higher and uper compared to Silicone. This changing with introduction of slim 1mm metal casing around Silicone and now it's best by all metrics. They all lose properties and propagation moves higher with pressure applied so a tin metal casing reinforcement is more than advisable in any case, again Silicone is best. Energy doesn't disappear or can be dispersed entirely so cheneling it to under hearing threshold is the most important property in sound related use cases which is not the case with either rubber or Sorbothane and with Silicone it remains to be even with large amount of mounted pressure.

Long story short make your own acoustic isolators as described not only they will be cheap and nice looking but also most efficient. Don't expect industry to do it for you, there is no money for them in doing that.

For one Silicone propagation frequency is considerably lower 9.5 Hz vs 19 Hz Sorbothane and 19.8 rubber. Magnitude is lower then rubber but bigger than Sorbothane but on the other hand harmonic propagation is both higher and uper compared to Silicone. This changing with introduction of slim 1mm metal casing around Silicone and now it's best by all metrics. They all lose properties and propagation moves higher with pressure applied so a tin metal casing reinforcement is more than advisable in any case, again Silicone is best. Energy doesn't disappear or can be dispersed entirely so cheneling it to under hearing threshold is the most important property in sound related use cases which is not the case with either rubber or Sorbothane and with Silicone it remains to be even with large amount of mounted pressure.

Long story short make your own acoustic isolators as described not only they will be cheap and nice looking but also most efficient. Don't expect industry to do it for you, there is no money for them in doing that.

Sorry. The information in your post was wrong.In short why is Silicone better especially thermal one then Sorbothane.

For one Silicone propagation frequency is considerably lower 9.5 Hz vs 19 Hz Sorbothane and 19.8 rubber. Magnitude is lower then rubber but bigger than Sorbothane but on the other hand harmonic propagation is both higher and uper compared to Silicone. This changing with introduction of slim 1mm metal casing around Silicone and now it's best by all metrics. They all lose properties and propagation moves higher with pressure applied so a tin metal casing reinforcement is more than advisable in any case, again Silicone is best. Energy doesn't disappear or can be dispersed entirely so cheneling it to under hearing threshold is the most important property in sound related use cases which is not the case with either rubber or Sorbothane and with Silicone it remains to be even with large amount of mounted pressure.

View attachment 361358

View attachment 361359View attachment 361362

Long story short make your own acoustic isolators as described not only they will be cheap and nice looking but also most efficient. Don't expect industry to do it for you, there is no money for them in doing that.

First, the natural frequency of a spring-mass system (as shown in the top attached picture in your post) depends on the mass and spring stiffness. The mass obviously depends on the mass of the speaker, and the stiffness depends on the durometer rating of the type of Sorbothane and the geometry of the pads (thickness, cross-sectional area, number of pads used in the support, etc.). You can alter the geometry of the pad using either material to replicate the frequency response curve of the other material.

The bottom right pic in your post actually showed Sorbothane to have the best vibration damping/dissipation characteristics. It should be no surprise since the pic came from Sorbothane's standard product guide (page 4).

Then, there are 2171 listings on MatWeb for silicone rubbers. Which is the right one for OP?

Last edited:

Similar threads

- Replies

- 8

- Views

- 817

- Replies

- 26

- Views

- 1K

- Replies

- 7

- Views

- 599

- Replies

- 6

- Views

- 586