hyperplanar

Senior Member

Hi all, it seems pretty hard to find any pictures of the KH120's internals online, so I thought I would post these here. Maybe they can be of use to someone!

These pictures aren't of my own KH120s. I found them several years ago with great difficulty thru Google Translate on a registration-only Chinese hi-fi forum. I'll also try to include my interpretation of the original poster's comments on each picture.

The enclosure and main screws holding it all together.

There's a gasket between the two halves of the enclosure, which is covered in an oily sealant substance.

The bass reflex port is well designed, with flared endings, multiple openings to reduce resonances, and plenty of damping material.

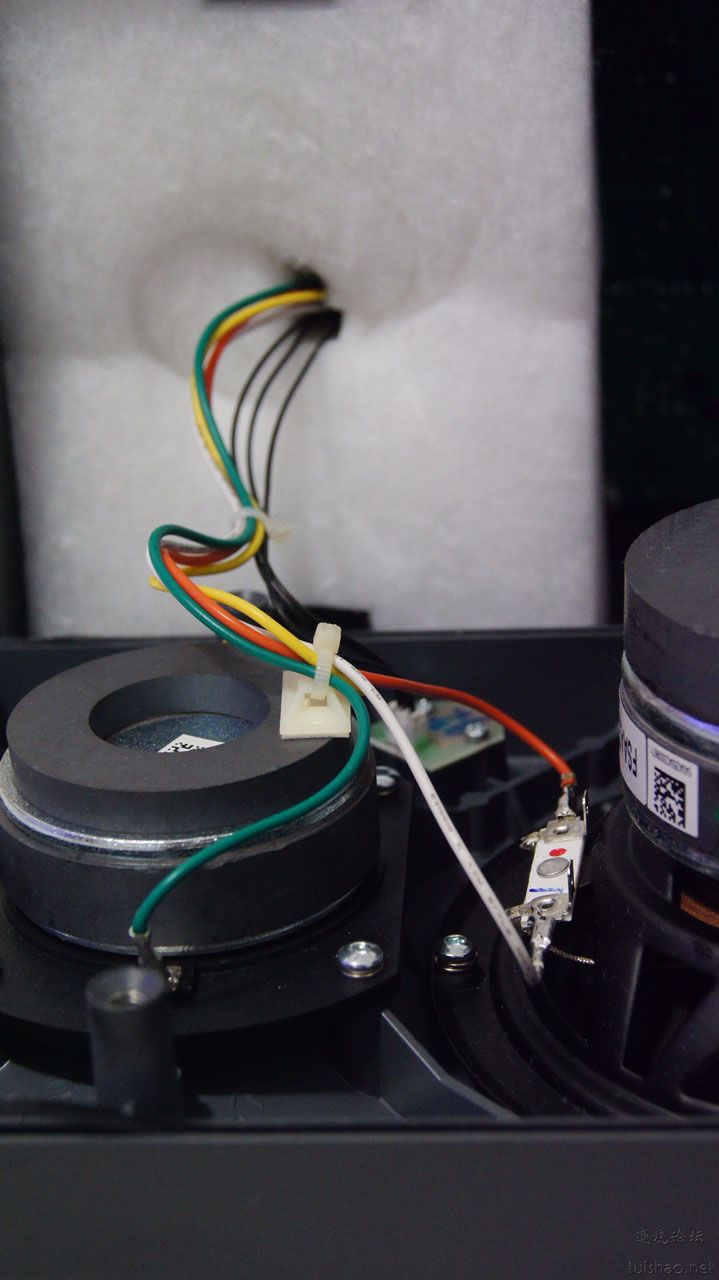

Seems like a good amount of care was taken to secure the speaker wires so they don't rattle around.

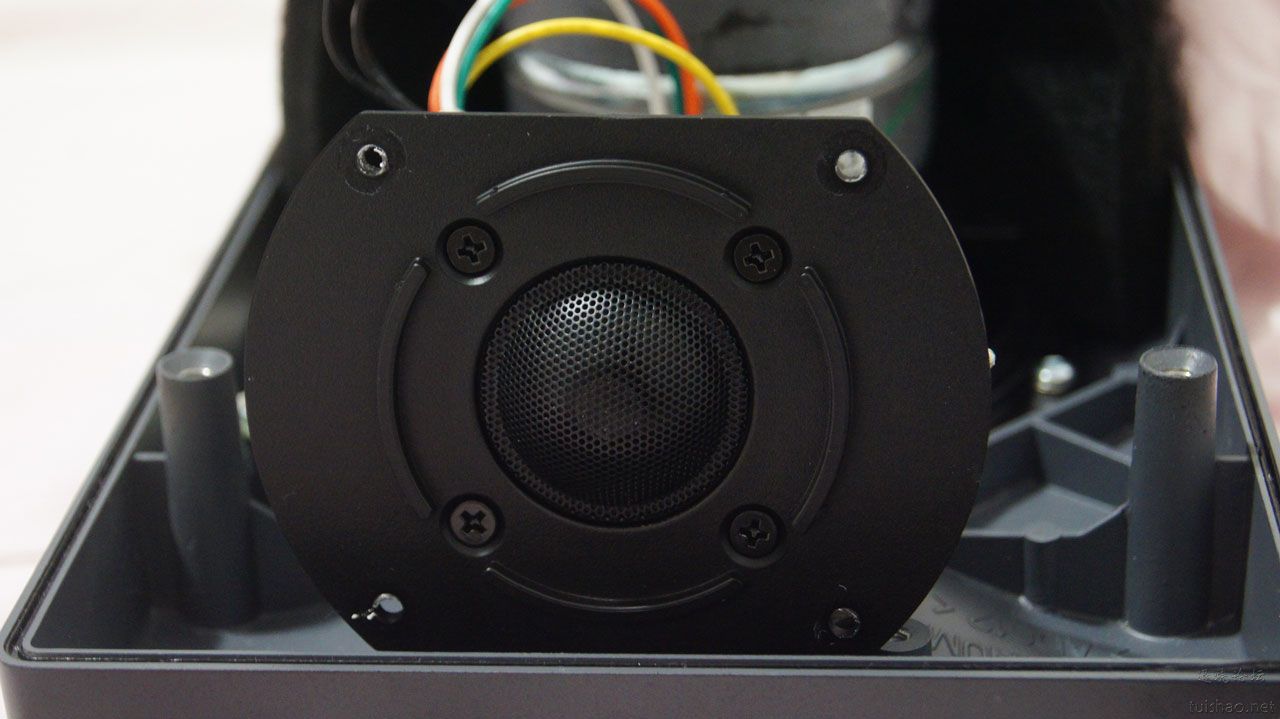

The tweeter. The magnet is very strong. Titanium diaphragm with fabric (silk?) dampening.

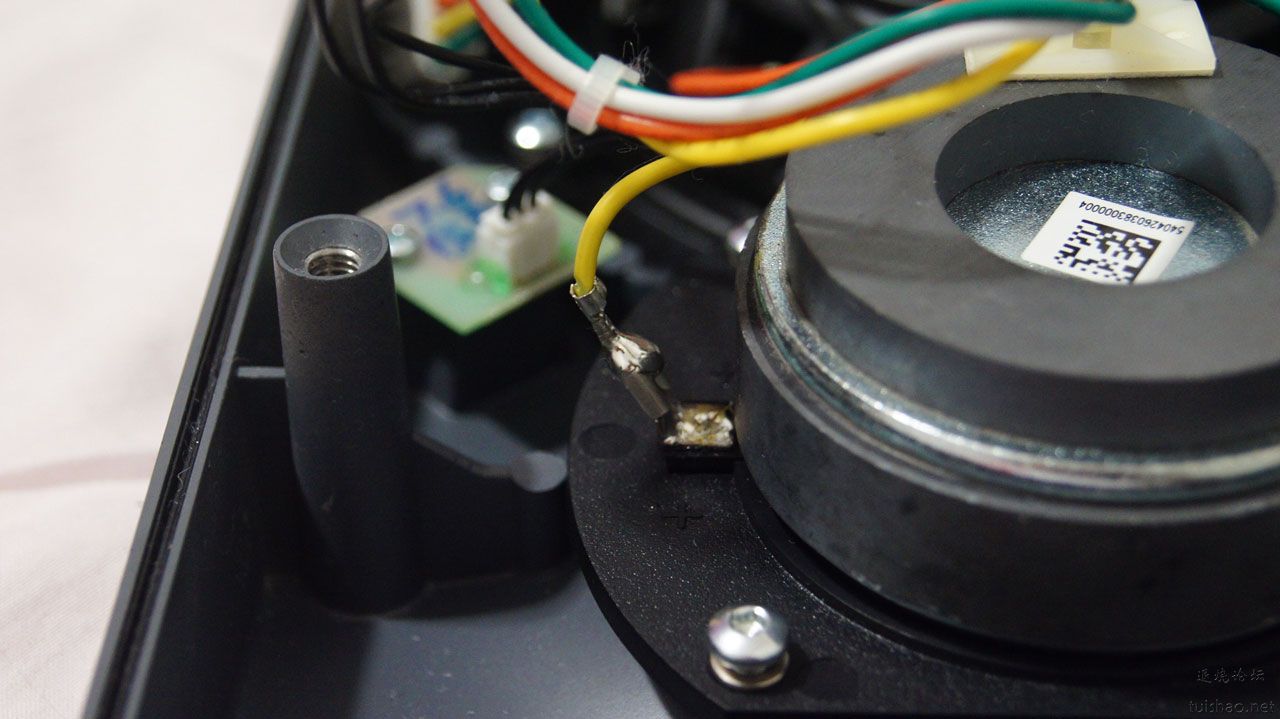

Speaker connections are soldered, so no worries about them coming loose.

Spring washers on the screws.

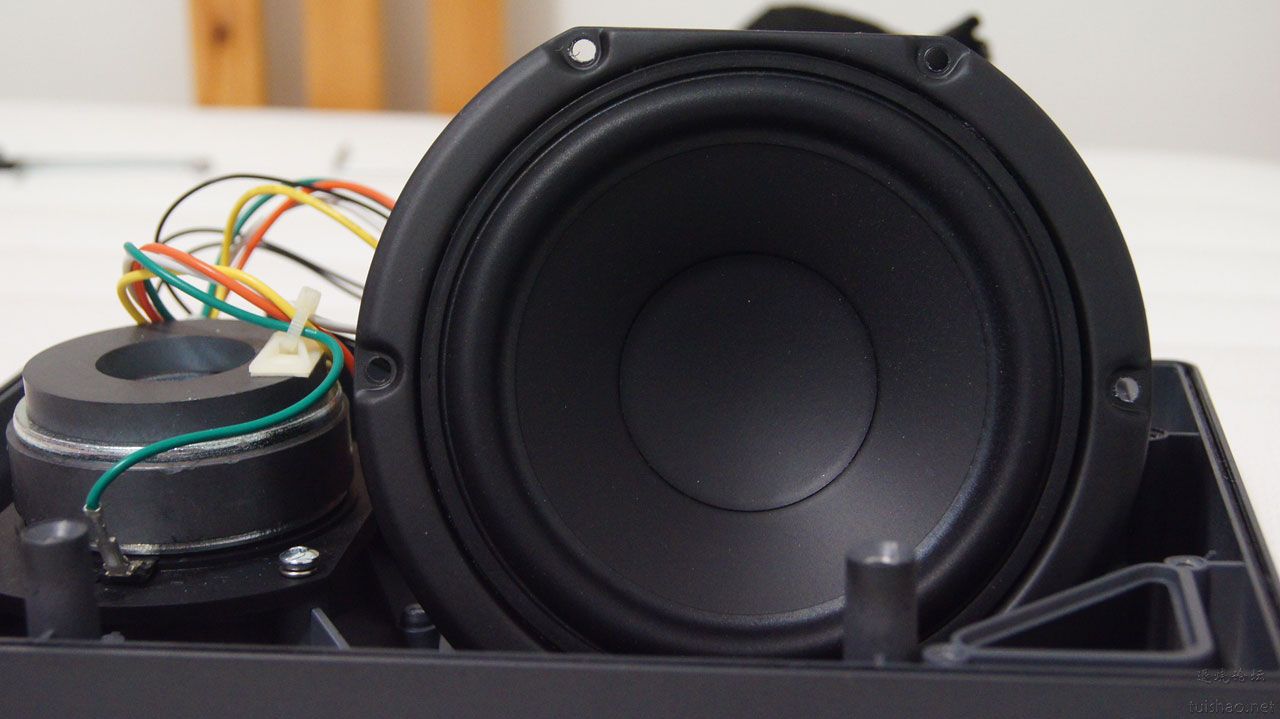

Woofer. The basket looks like the one on the Peerless SDS series, but (according to the original poster) this woofer'simpedance inductance is even lower than the Peerless HDS series.

Woofer side view. According to the OP, it handles +-5mm excursion at 50 Hz without noise.

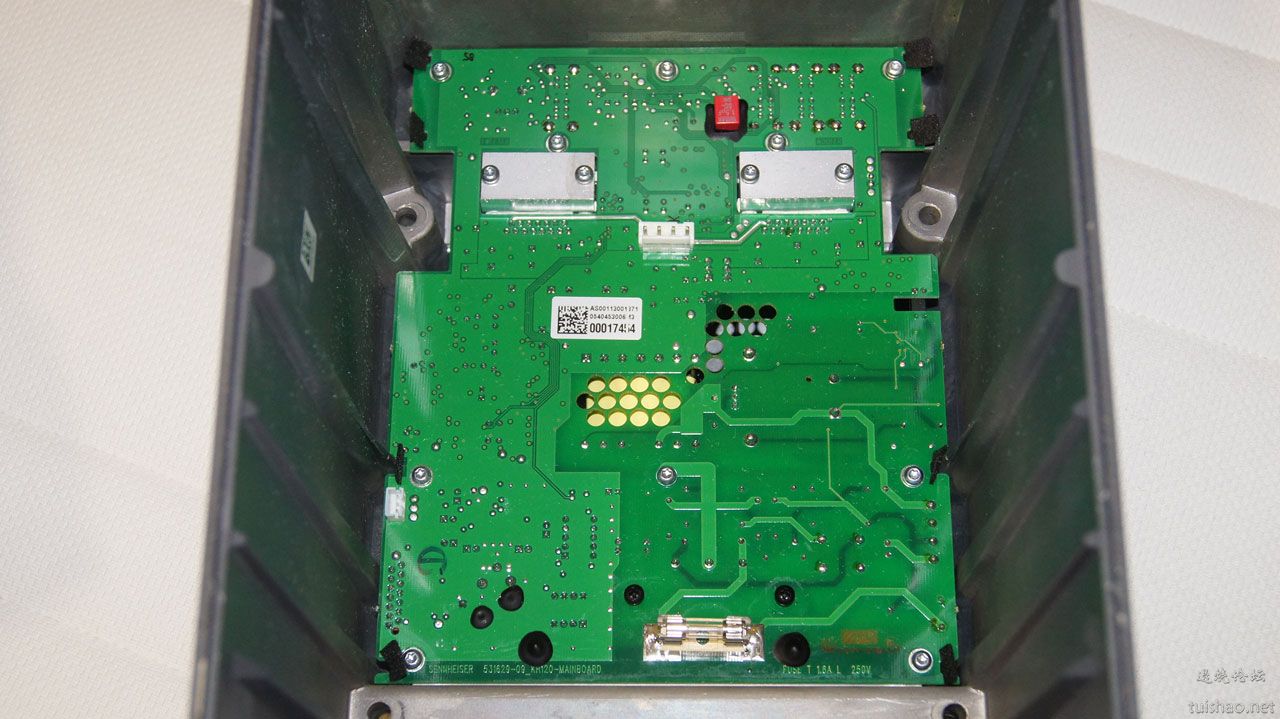

Rear of PCB. Marked "Sennheiser" on the bottom left corner.

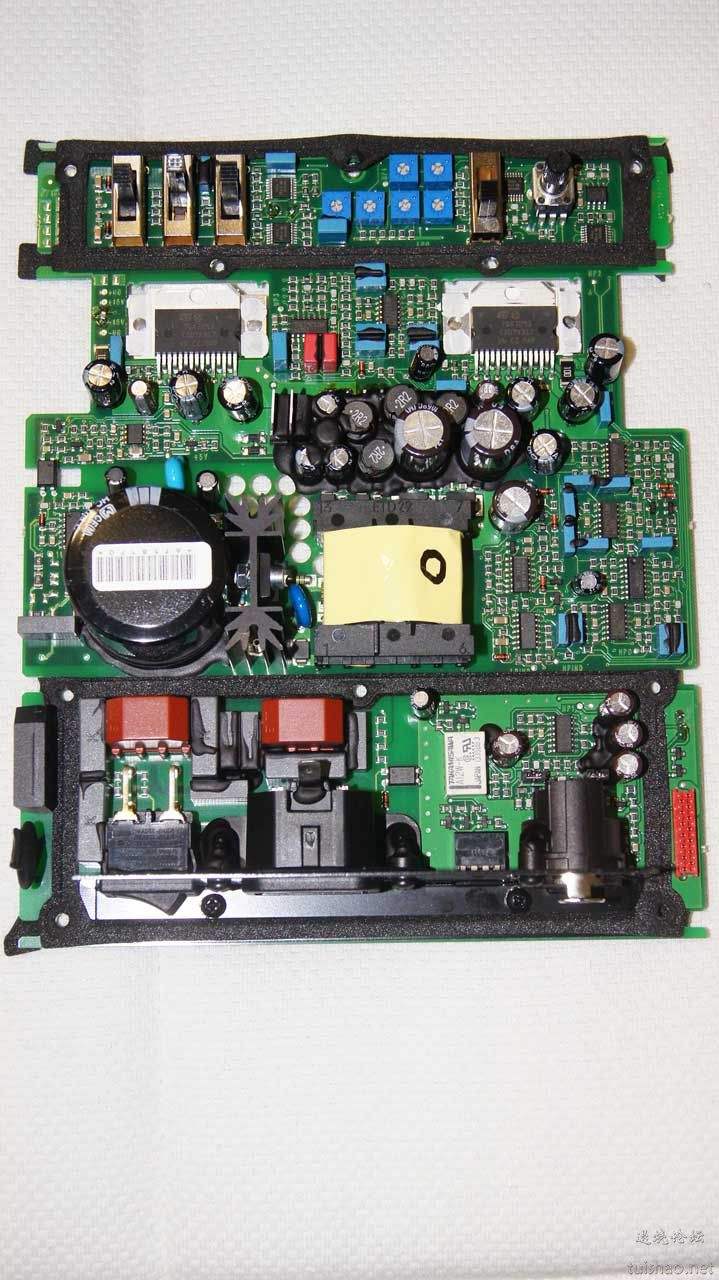

Front of PCB. Lots of dampening and sealant material. Two TDA7293 Class AB chip amps, one for the woofer and one for the tweeter. ST33079 and TL074 op-amps.

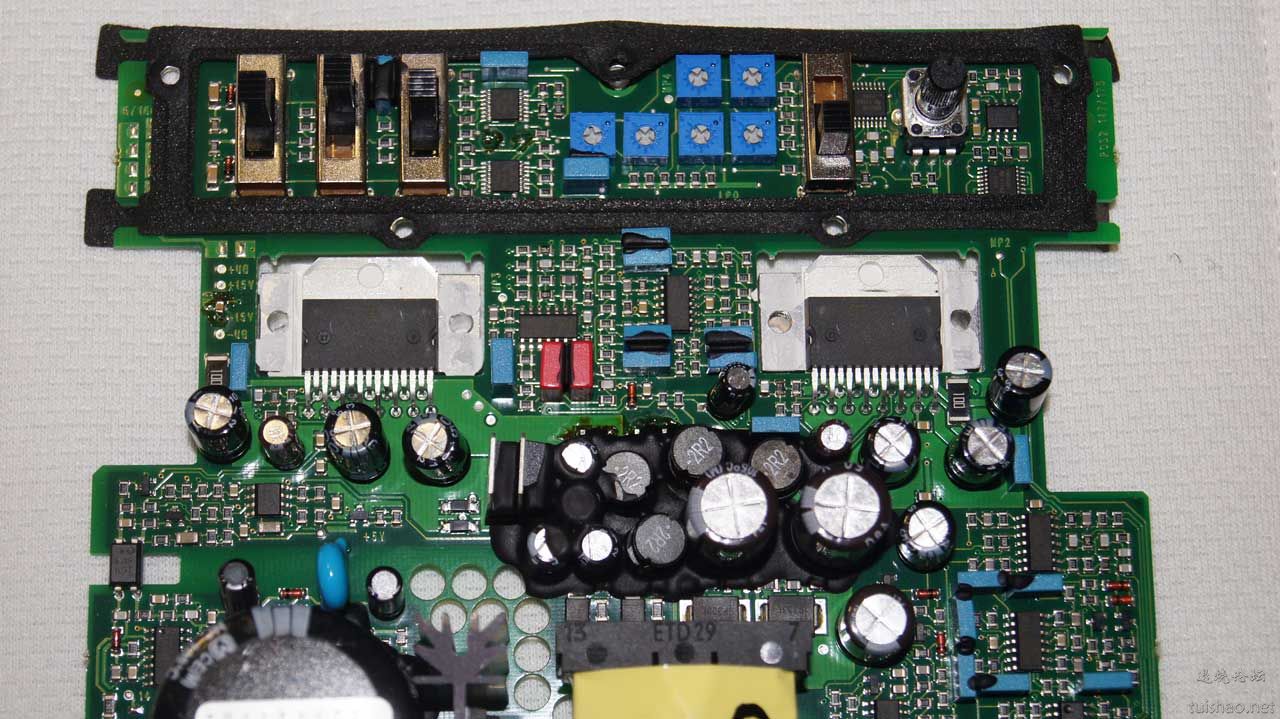

Closeup of upper half of PCB. The six blue trim pots on the top are used for the factory calibration of each unit.

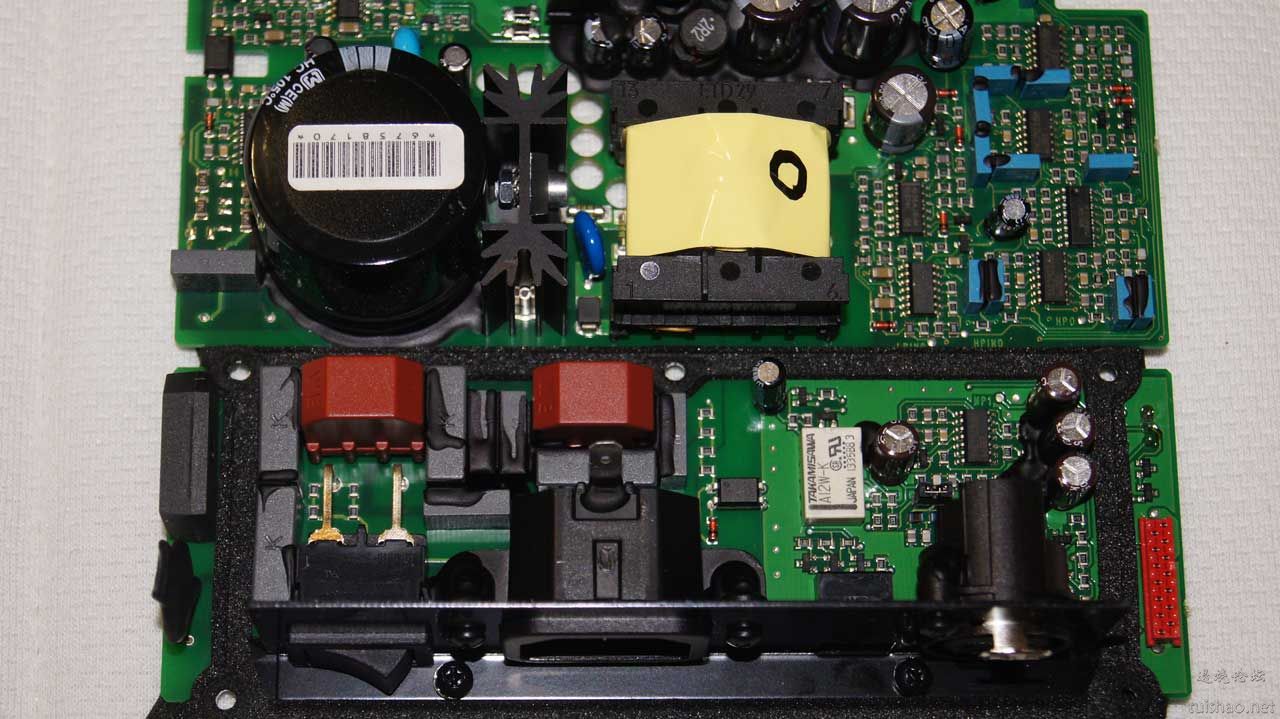

Bottom half of PCB. This studio monitor uses an internal SMPS.

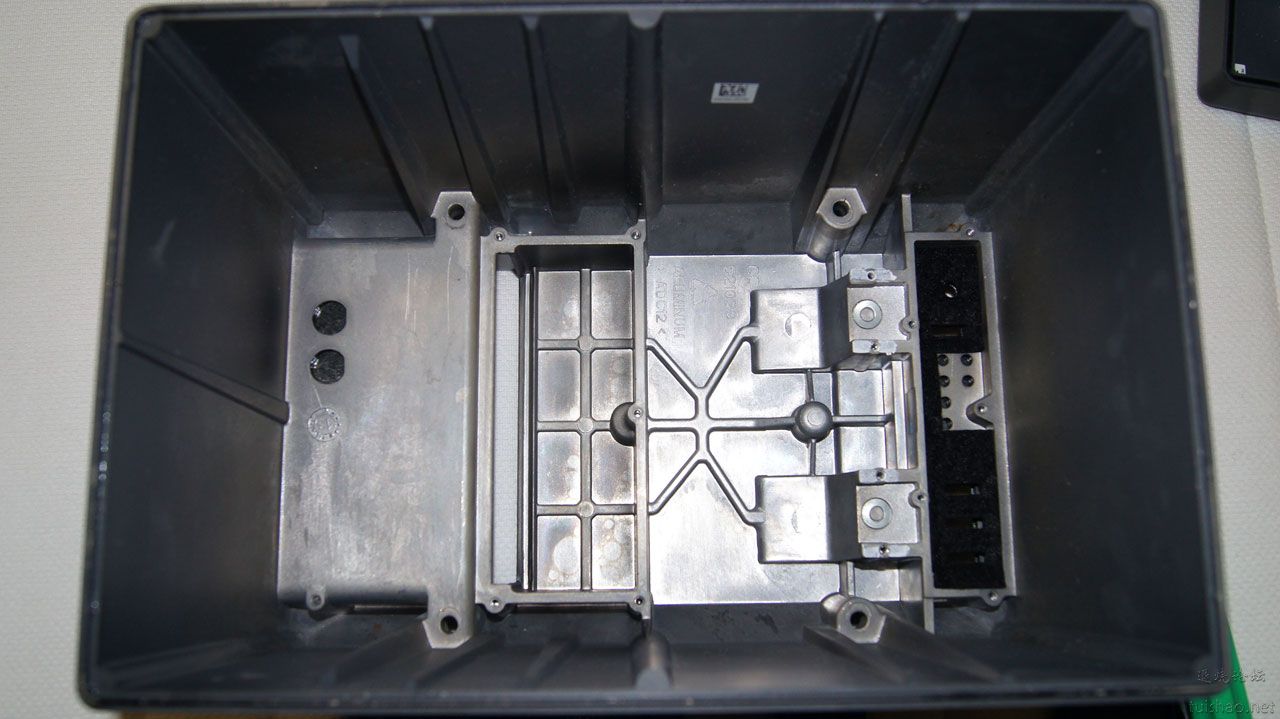

Rear half of enclosure, which the TDA7293s are heatsinked to.

These pictures aren't of my own KH120s. I found them several years ago with great difficulty thru Google Translate on a registration-only Chinese hi-fi forum. I'll also try to include my interpretation of the original poster's comments on each picture.

The enclosure and main screws holding it all together.

There's a gasket between the two halves of the enclosure, which is covered in an oily sealant substance.

The bass reflex port is well designed, with flared endings, multiple openings to reduce resonances, and plenty of damping material.

Seems like a good amount of care was taken to secure the speaker wires so they don't rattle around.

The tweeter. The magnet is very strong. Titanium diaphragm with fabric (silk?) dampening.

Speaker connections are soldered, so no worries about them coming loose.

Spring washers on the screws.

Woofer. The basket looks like the one on the Peerless SDS series, but (according to the original poster) this woofer's

Woofer side view. According to the OP, it handles +-5mm excursion at 50 Hz without noise.

Rear of PCB. Marked "Sennheiser" on the bottom left corner.

Front of PCB. Lots of dampening and sealant material. Two TDA7293 Class AB chip amps, one for the woofer and one for the tweeter. ST33079 and TL074 op-amps.

Closeup of upper half of PCB. The six blue trim pots on the top are used for the factory calibration of each unit.

Bottom half of PCB. This studio monitor uses an internal SMPS.

Rear half of enclosure, which the TDA7293s are heatsinked to.

Last edited: