- Joined

- Dec 17, 2021

- Messages

- 649

- Likes

- 1,423

- Thread Starter

- #21

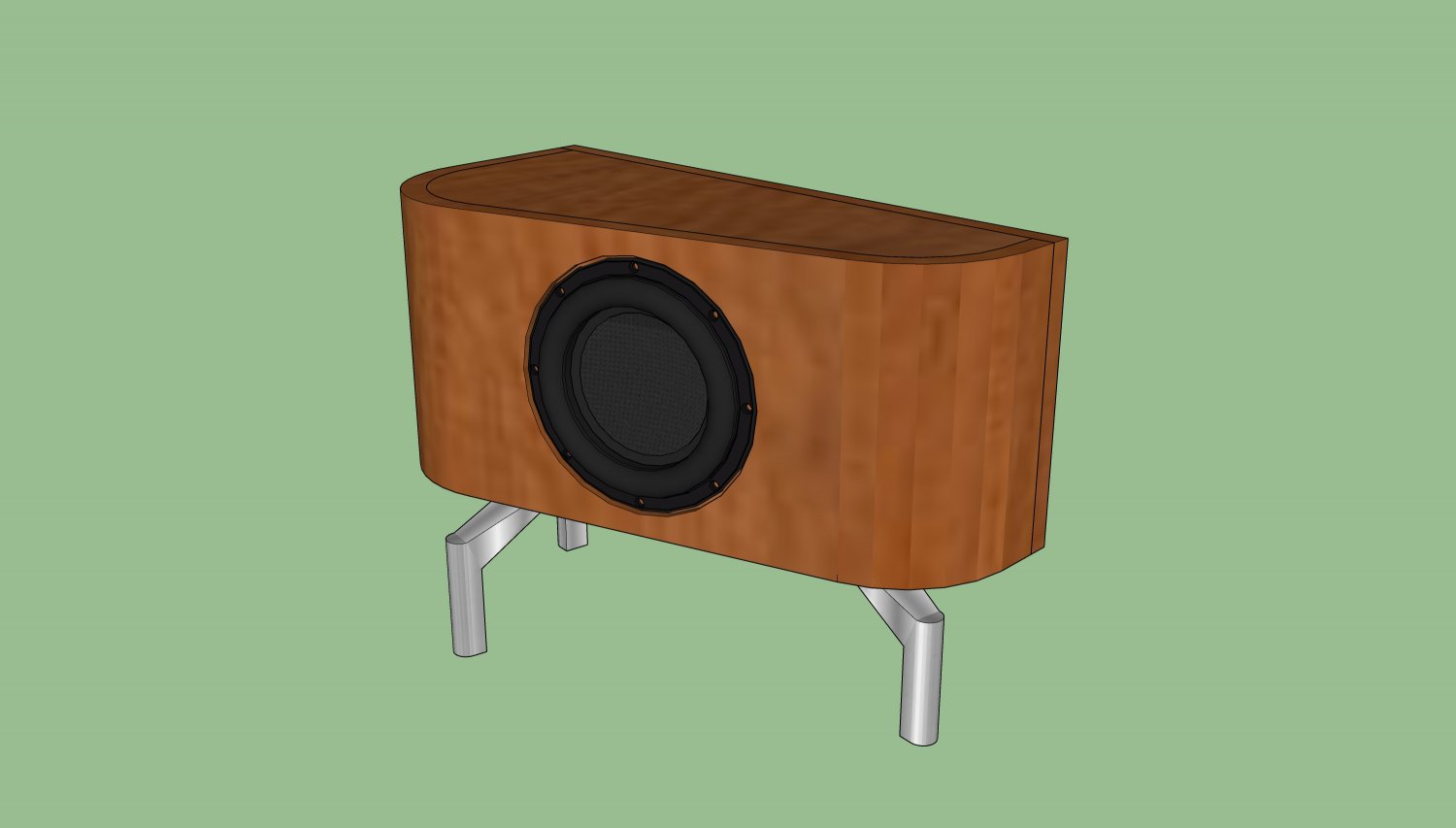

I started building these this weekend! I'll post a few progress pics in the next post. I ended changing the design to something that was less corner specific, and instead I am building a pair of these, angled opposite each other:

The internal bracing is complicated with 75° angles and other stuff — it would not have been worth the effort to design these without CAD. The build is a bit more complicated then my last two, but I'm doing this for fun so I don't care. The rounded outsides of the sub will not be pressurized and are only for looks. The will be filled densely with polyfill, and the final sealed internal volume will be identical to the other two I built.

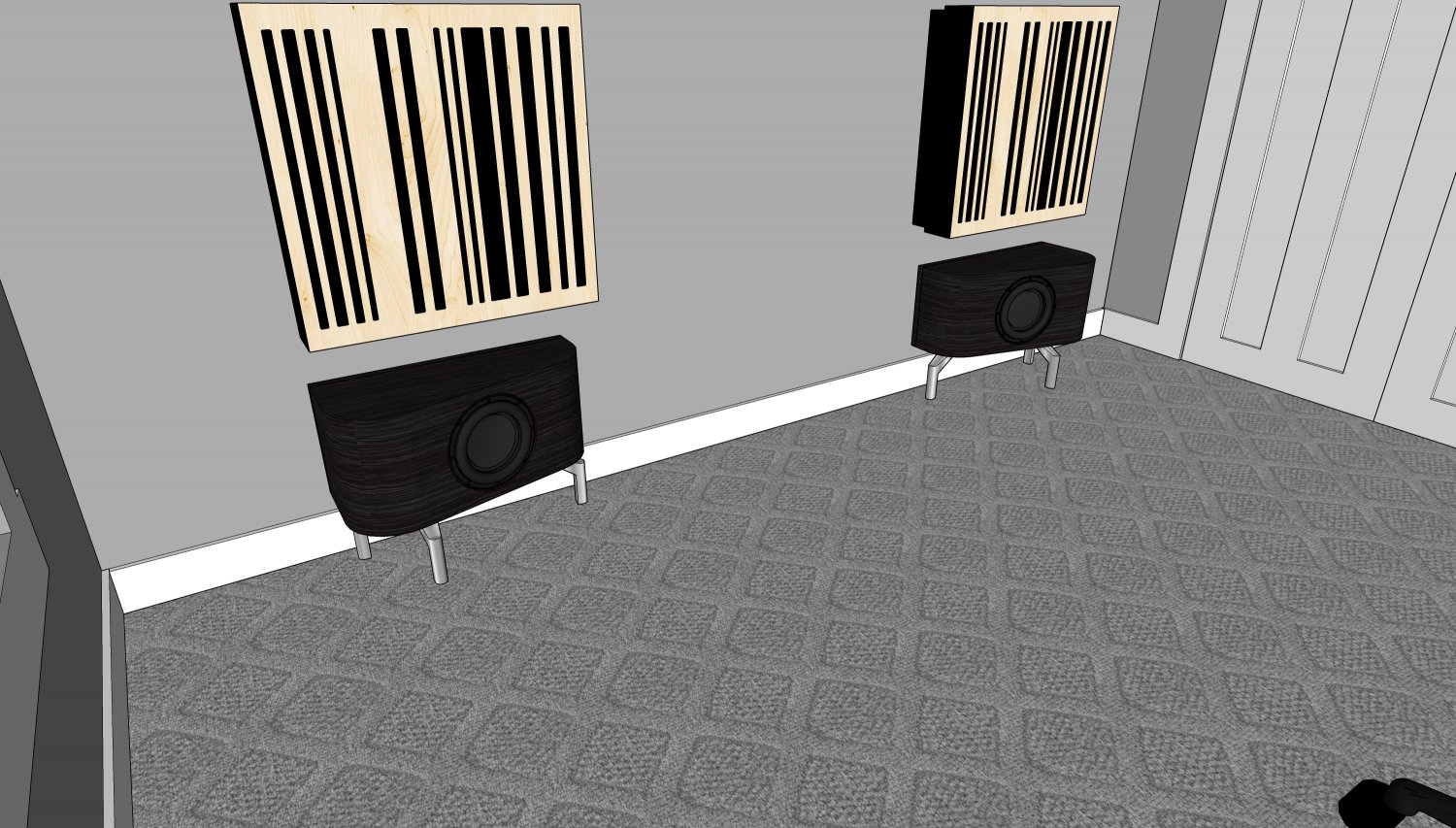

They will be placed along the back wall of my office so the drivers are angled directly at me:

The internal bracing is complicated with 75° angles and other stuff — it would not have been worth the effort to design these without CAD. The build is a bit more complicated then my last two, but I'm doing this for fun so I don't care. The rounded outsides of the sub will not be pressurized and are only for looks. The will be filled densely with polyfill, and the final sealed internal volume will be identical to the other two I built.

They will be placed along the back wall of my office so the drivers are angled directly at me: