- Thread Starter

- #181

Is the team still using the 5” ceramic SB Acoustics woofer?

No, we are using the SB15NBAC30-4.

Is the team still using the 5” ceramic SB Acoustics woofer?

So is this a firm commitment to this SBA mid/woofer model?No, we are using the SB15NBAC30-4.

Confirmed. Stick to the 4 ohm. SIG180 is too large to be a substitute.So is this a firm commitment to this SBA mid/woofer model?

I noticed in the other thread that other mid/woofer drivers (like SiG180) seemed to be the front-runner as recently as late March. I realize this is all volunteer work and there are no guarantees; I'm just trying to confirm my perception of the current plan, to the extent there is one.

I'm placing a large-ish order for drivers for a different project and it would be a convenient (and well priced) opportunity to get the SB15NBAC30-4 and the DXT tweeters. I will patiently wait for the crossover design to settle out, and realize it may be weeks/months/seasons before its "done", but it would be great if you could let me know your confidence the SB15NBAC30-4 will not change.

Thanks for all your effort on these designs, they have been great learning.

EDIT: or am I wrong in perceiving "budget Directiva" and "Directiva R2" to be the same project??

Your work on this is appreciated! Is the SIG180 too large because of cabinet size constraints, or the cardioid effect cannot be achieved over the needed band, or something else?Confirmed. Stick to the 4 ohm. SIG180 is too large to be a substitute.

Separate projects, the budget one is closer to r1 than r2.

Your work on this is appreciated! Is the SIG180 too large because of cabinet size constraints, or the cardioid effect cannot be achieved over the needed band, or something else?

(I'm hoping to follow along on how this is designed, and then take a shot at something similar but with higher output. I guess I'll see if that will be possible. The Lavoce DF10.144LK, not out yet…

IF you were wondering .... we are struggling to precisely define the type and quantity of damping material needed.[\QUOTE]

Thanks for the update Rick. That aspect of the desigh is the "raison d' être" of the whole project and its distinctive feature, so we appreciate that getting it right and precisely reproductible for anyone that tries to build one is key.

In that vein, I think that if you could make that work with globe wide available brand products, like for example example 3M stuff, it would help a lot. It might increase cost, but that way, even if you are starting in DIY and dont have a proper measurement rig or knowledge to verify compliance, you could be sure to get the same results, and would make sourcing and applying it easier, wherever you are located.

Fiberglass insulation works pretty well (remove the backing). It performs about as well as rockwool according to the video for which I posted the link below. I used it and I am happy with the results.As it turns out, mineral wool and some of the alternative materials are pricey and need to buy way more than is need for a small speaker.

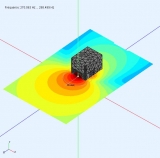

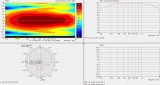

Would love to see those displayed, since I'm tinkering with a similar project (2-way mid-high frequencies speaker w/resistance enclosure mid box for controlled directivity)...The above is the original slot configuration and this is the new one...

As mentioned, I plan to add a small bass module to make it a small 3-way. Before that will be doing some spins to optimize the damping material.

Fiberglass insulation works pretty well (remove the backing). It performs about as well as rockwool according to the video for which I posted the link below. I used it and I am happy with the results.

See the video starting about 4:20.

Fiberglass insulation works pretty well (remove the backing). It performs about as well as rockwool according to the video for which I posted the link below. I used it and I am happy with the results.

See the video starting about 4:20.

Thank you for the advice!HI, Rick has answered this already, but as a doctor, let me emphasize this : Do NOT use fiberglass on speaker filling, other than closed boxes, but even then, I would never do it , (if you do, used approtiate prote ction, minimum N95 mask, goggles, gloves, gown when opening it ) With manipulation, vibration and degradation over time, it continuously breaks in microscopic shard that is a huge health hazard, particularily for skin and lung, an also eye. Its not as bad as asbestos wich is a direct carcinogenic, but it will still provoque asthma, bronchitis and chronic obstrutive lung disesase, and skin allergy.

Leave this stuff alone, it is only acceptable for professional handling with protective gear and specific applications, like hull manufacturing, bodyshop/fairing or surfboard production but Not including speaker filling.

Thank you for the advice!

I have fiberglass insulation all over my attic, and I do need to go up there from time-to-time.

I had an extra roll sitting up there, which is where I grabbed it for my speakers. I modified the speakers so that they are sealed, though.