TLDR: the speaker uses a laser cut baffle to hold the tweeter/mid on the smallest denovo box. The box uses edge moulding to form the 44mm radius. All of that sits on the top of a sub that is on a stand. …It is a stacked 3way will sit on each side of my desk.

I wanted a nice set of speakers for my desk and decided on gambling on myself rather than dropping coin on something that did not suit my needs. If I listen to loud music my ears will ring the rest of the day so I wanted to see what it was like to build something that was to my specs.

No speaker is perfect. I don’t expect my first speaker to be without major flaws . I am ok with bumps and warts just to go A-Z with the process. This speaker is not going to look like a slim-n-shiny commercial speaker. I do hope to outperform most commercial designs in some ways- just not max spls.

Project aims: Be domes, lots of bass, clean 2khz-5khz at many angles, small size, easy to breakdown (I move lots), minimal tools, neodymium magnets, keep it simple-no waveguides or complex cabinets, and around $3000usd with tools. Now these were my initial aims. I had to bend things around a little to get there. I also wanted to use drivers that were not 1st gen and that had 3rd party measurements. One last aim was to have the ability to mix and match parts in the future. I like the idea of making a coaxial next and having the ability to just swap things out. I used 4 wire SpeakON for EZ swaps.

I would not have attempted this at all if not for the help from users on this site and on diyaudio. Thanks to you all! I hope I can get more advice/guidance to wrap it all up.

Also, a big thanks to the creator of VirtuixCAD. I was able to learn lots by simulating different drivers, baffles, and XO’s using 3rd party measurements. He also answered my questions via email. Thanks, Kimmo.

And a huge thanks to a diy loudspeaker builder I found in town- hifijim on diyaudio. You are the best! Thanks again for all of the help (and the future help measuring).

Project features:

The last mile is the hardest and I hope to get this wrapped up soon.

Photos:

I wanted a nice set of speakers for my desk and decided on gambling on myself rather than dropping coin on something that did not suit my needs. If I listen to loud music my ears will ring the rest of the day so I wanted to see what it was like to build something that was to my specs.

No speaker is perfect. I don’t expect my first speaker to be without major flaws . I am ok with bumps and warts just to go A-Z with the process. This speaker is not going to look like a slim-n-shiny commercial speaker. I do hope to outperform most commercial designs in some ways- just not max spls.

Project aims: Be domes, lots of bass, clean 2khz-5khz at many angles, small size, easy to breakdown (I move lots), minimal tools, neodymium magnets, keep it simple-no waveguides or complex cabinets, and around $3000usd with tools. Now these were my initial aims. I had to bend things around a little to get there. I also wanted to use drivers that were not 1st gen and that had 3rd party measurements. One last aim was to have the ability to mix and match parts in the future. I like the idea of making a coaxial next and having the ability to just swap things out. I used 4 wire SpeakON for EZ swaps.

I would not have attempted this at all if not for the help from users on this site and on diyaudio. Thanks to you all! I hope I can get more advice/guidance to wrap it all up.

Also, a big thanks to the creator of VirtuixCAD. I was able to learn lots by simulating different drivers, baffles, and XO’s using 3rd party measurements. He also answered my questions via email. Thanks, Kimmo.

And a huge thanks to a diy loudspeaker builder I found in town- hifijim on diyaudio. You are the best! Thanks again for all of the help (and the future help measuring).

Project features:

- Less than ½ the wavelength of the XO c-to-c distance for the tweeter and mid

- ¼ the wavelength of the XO c-to-c distance for the mid and woofer

- 44mm edge radius - https://fypon.com/products/mld605-12?variant=30373559697501

- Uses Denovo boxes – the box for the l26roy is good to go! The tweeter /mid box needs a custom baffle.

- 4mm space between the mid and the tweeter – Lasers make is so I don’t have to become a wood worker.

- Minimal tools required. Just clamps, a drill, sandpaper, miter saw, allen wrench, and a soldering iron. (I might be missing some things but the point is an apt/condo dweller build) The baffle for the tweeter/mid is laser cut using an online service. The sub does not require anything custom.

- Dual sealed subs

The last mile is the hardest and I hope to get this wrapped up soon.

Photos:

- The layers of the baffle. The top baffle layer is hardboard and walnut. Based on https://www.witpress.com/elibrary/wit-transactions-on-the-built-environment/59/18 I decided to toss some in since bamboo should help for mids. The bamboo material that is made up from layers of bamboo veneer. The small rings are for adjust of the height as needed. They are .5mm tall and also bamboo veneer.

- Bamboo graph from paper

- Dry stacked baffle with unfinished walnut veneer.

- VCAD sim that is made from 3rd party measurements- NOT REAL. This is just my guide made from traced measurements run through the baffle sim.

- Early temporary baffle made from pink foam sheets (an idea from hifijim). Jim made a whole speaker out of the foam and it sounded awesome. A person could cut a baffle with just a razor blade. I wanted to test of the speaker was loud enough before committing to the laser cut baffle.

- Temp baffle with 44mm edge radius. The TM box is about 9” tall and 8” wide.

- “”

- L26roy in its temporary position. I don't have it sealed up yet because I still want to compare measurements with diff. amounts of stuffing.

- Distortion at 1 meter and around 83db.

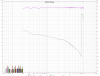

- My latest measurement at 24”. I've been trying to clean up the XO at 1700hz and 320hz. I did a partial sweep to cover this.

- XO timing measurements.

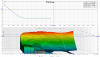

- rt60 decay

- A very rough and close polar.

- Unsmoothed gated 24" measurement.

Attachments

-

baffle_cuts.jpg546.1 KB · Views: 482

baffle_cuts.jpg546.1 KB · Views: 482 -

babmboo_vs_ply.jpg259.8 KB · Views: 638

babmboo_vs_ply.jpg259.8 KB · Views: 638 -

baffle_dryfit.jpg597 KB · Views: 722

baffle_dryfit.jpg597 KB · Views: 722 -

eton3__t25b plus seas plus REALfix Six-pack.png140.8 KB · Views: 688

eton3__t25b plus seas plus REALfix Six-pack.png140.8 KB · Views: 688 -

tempbaff.jpg766.7 KB · Views: 678

tempbaff.jpg766.7 KB · Views: 678 -

tempbaff_front.jpg714.8 KB · Views: 680

tempbaff_front.jpg714.8 KB · Views: 680 -

seasl26roy.jpg683.4 KB · Views: 640

seasl26roy.jpg683.4 KB · Views: 640 -

dist_1m_tapebaffle_223.png131.3 KB · Views: 574

dist_1m_tapebaffle_223.png131.3 KB · Views: 574 -

gated_24in_tapedbaff_xofreq.png37.9 KB · Views: 494

gated_24in_tapedbaff_xofreq.png37.9 KB · Views: 494 -

inverted tweeter delay.png98.9 KB · Views: 481

inverted tweeter delay.png98.9 KB · Views: 481 -

rt60decay_1m_tapebaffle_223.png385.2 KB · Views: 467

rt60decay_1m_tapebaffle_223.png385.2 KB · Views: 467 -

gated_polar_tapedbaff2__0_45_90.png65.7 KB · Views: 432

gated_polar_tapedbaff2__0_45_90.png65.7 KB · Views: 432 -

gated_24in_tapedbaff_xofreq_nosm.png75.7 KB · Views: 459

gated_24in_tapedbaff_xofreq_nosm.png75.7 KB · Views: 459

Last edited: