restorer-john

Grand Contributor

We've been discussing conductive adhesive issues in another thread.

Here's some pictures of what happens. All these items were either dead or dying and brown glue was the cause. Do not underestimate the mess this stuff can do. Your gear, regardless of brand can be a time-bomb.

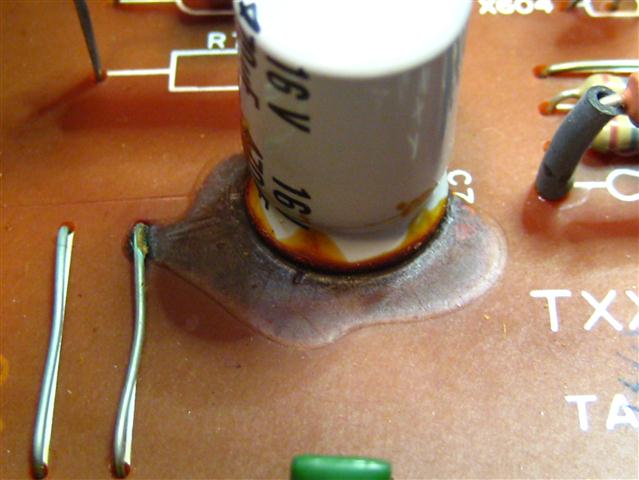

The poor capacitor is essentially hermetically sealed to the phenolic PCB by the bond glue. It cannot vent even a tiny bit. The glue ages and corrodes the legs, the cap leaks electrolyte because of the corrosion going up the legs and into the cap itself. Cap loses an entire leg or it eats down the pcb hole and reacts with the PbSn and Cu and makes a big mess. Sometimes caps can shoot off like a bullet from this reaction. These days, more caps have a one-time vent on the top, but all smaller electros still have the vent on the rubber base.

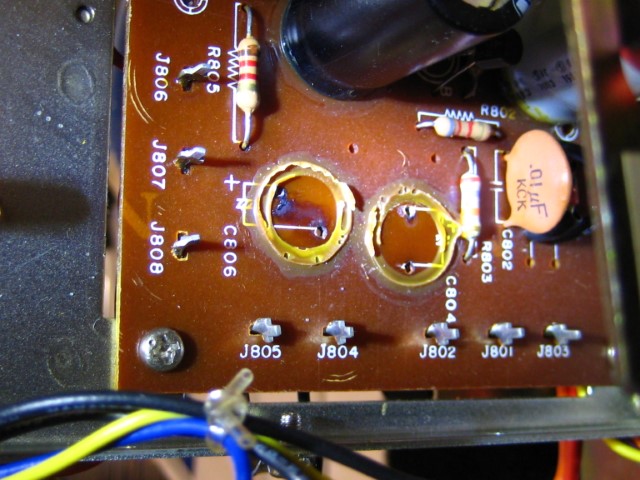

Capacitor's legs eaten away from under the glue, completely invisible from either side. This is a small PSU in a vintage amp.

Get rid of those ancient caps and clean up the mess!

New Nichicon UFGs!

This is caused by the glue at the base, reacting with the tinned copper legs, not allowing venting at the cap base and the reaction travels up the inside of the sleeve to the top.

Same cap at base

That wretched glue loves to eat transistors too

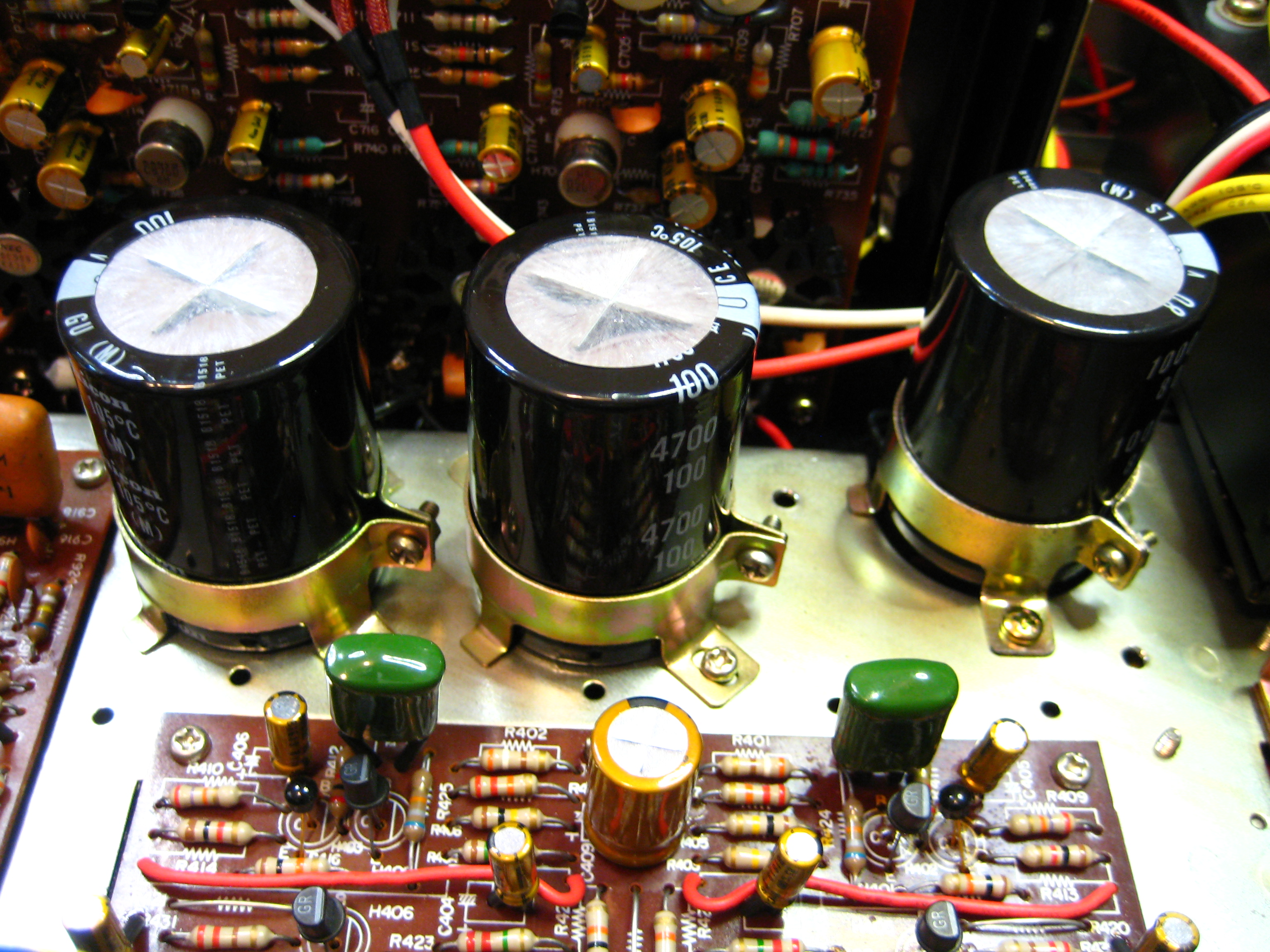

Rebuilt. Even used an original perfectly matching Elna cap bracket from my NOS stock. Previous PSU filter cap on right was larger diameter. Holes were predrilled in the factory for the two sizes in 1974.

Here's some pictures of what happens. All these items were either dead or dying and brown glue was the cause. Do not underestimate the mess this stuff can do. Your gear, regardless of brand can be a time-bomb.

The poor capacitor is essentially hermetically sealed to the phenolic PCB by the bond glue. It cannot vent even a tiny bit. The glue ages and corrodes the legs, the cap leaks electrolyte because of the corrosion going up the legs and into the cap itself. Cap loses an entire leg or it eats down the pcb hole and reacts with the PbSn and Cu and makes a big mess. Sometimes caps can shoot off like a bullet from this reaction. These days, more caps have a one-time vent on the top, but all smaller electros still have the vent on the rubber base.

Capacitor's legs eaten away from under the glue, completely invisible from either side. This is a small PSU in a vintage amp.

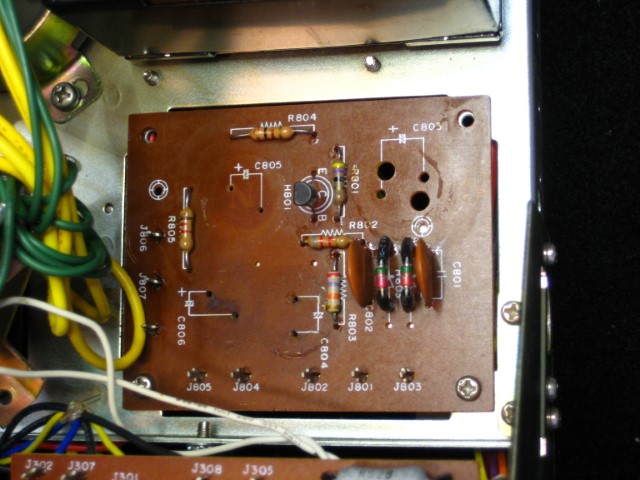

Get rid of those ancient caps and clean up the mess!

New Nichicon UFGs!

This is caused by the glue at the base, reacting with the tinned copper legs, not allowing venting at the cap base and the reaction travels up the inside of the sleeve to the top.

Same cap at base

That wretched glue loves to eat transistors too

Rebuilt. Even used an original perfectly matching Elna cap bracket from my NOS stock. Previous PSU filter cap on right was larger diameter. Holes were predrilled in the factory for the two sizes in 1974.

Last edited: