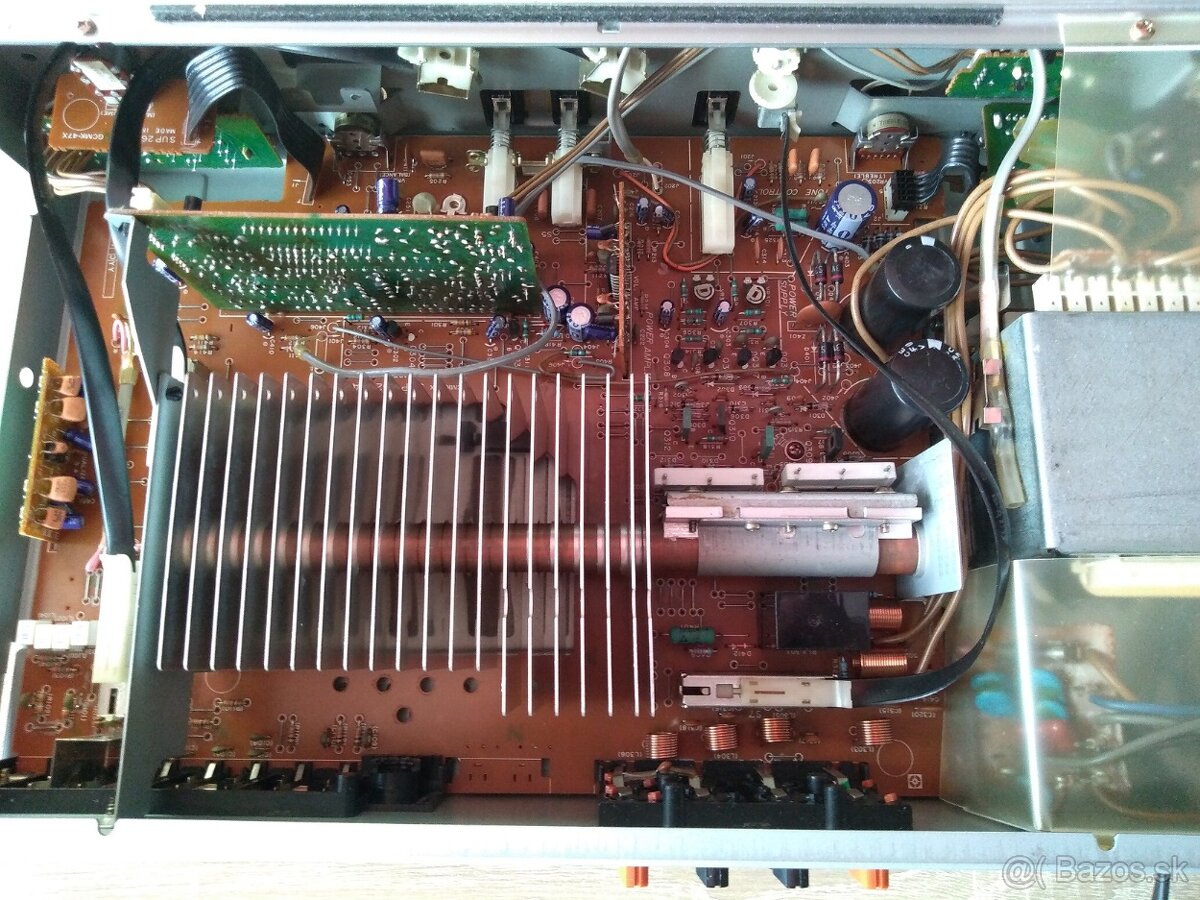

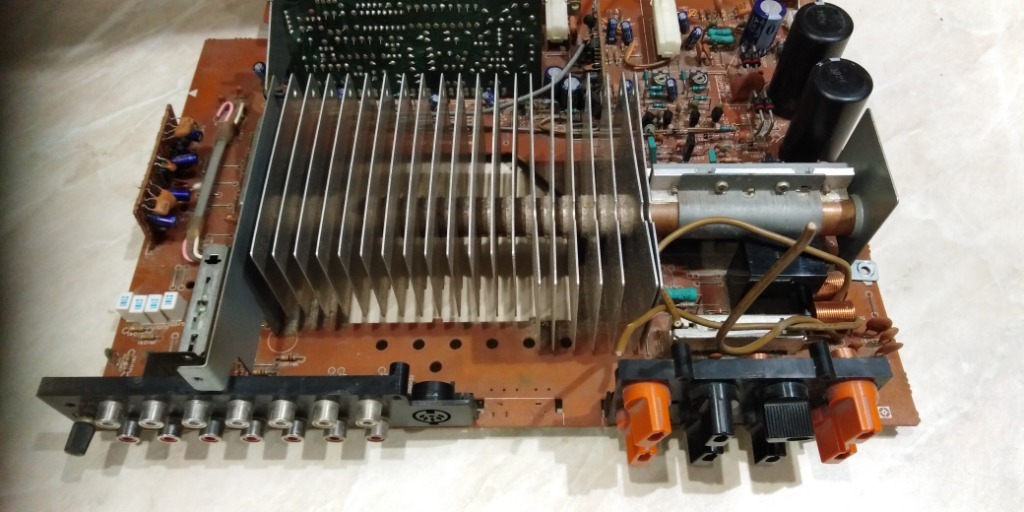

Here are images of a heat pipe assembly used on 1980s, 35w/ch Technics SU-V303 integrated amplifier. The orientation of the heat pipe clamping surface is not as you will require but I think this might give you some ideas about how to design the clamping assembly so that you have a flat, machined with tight clamping force surface that will mate with the power devices that you need to cool. If you can fabricate a soft malleable sheet metal that can go around the heat pipe, use that to clamp to a easily available thin flat metal stock like aluminum and then have that flat stock mate with the power devices using thermal paste at the PCB by using screws and locking nuts that you will have a effective clamping assembly that can conduct a lot of thermal energy.

You could even find a old Technics SU-V303 and use the heat pipe and assembly and adapt it to fit your PCB layout assembly technique.

NOTE: There are other brands that used heat pipes and they may have a heat pipe cooler assembly that is better than the Technics.

You could even find a old Technics SU-V303 and use the heat pipe and assembly and adapt it to fit your PCB layout assembly technique.

NOTE: There are other brands that used heat pipes and they may have a heat pipe cooler assembly that is better than the Technics.