I already found these thanks to your first post. They are just not what I thought to be affordableFor 300W continuous my heatsink would be small.

Check this

https://uk.rs-online.com/web/c/hvac-fans-thermal-management/electronics-heating-cooling-components/heatsinks/?sort-by=Thermal Resistance&sort-order=asc&pn=1

-

Welcome to ASR. There are many reviews of audio hardware and expert members to help answer your questions. Click here to have your audio equipment measured for free!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

ASR dummy load configuration

- Thread starter Armand

- Start date

- Thread Starter

- #42

What about stack of three of these:

https://www.alibaba.com/product-det...offerlist.normal_offer.d_image.6ddd421e6633Un

5 USD a piece is a lot of cooling per the money. About 0.3K/W per piece and with three units you should have enough space for your resistors and reach about 0.1K/W. Add three 120mm computer fans and make the fan speed automatic using this:

https://www.alibaba.com/product-det...offerlist.normal_offer.d_title.63be11e4hNeFpC

https://www.alibaba.com/product-det...offerlist.normal_offer.d_image.6ddd421e6633Un

5 USD a piece is a lot of cooling per the money. About 0.3K/W per piece and with three units you should have enough space for your resistors and reach about 0.1K/W. Add three 120mm computer fans and make the fan speed automatic using this:

https://www.alibaba.com/product-det...offerlist.normal_offer.d_title.63be11e4hNeFpC

drfous

Member

The Dale 250W 8 ohm non-inductives pop up on eBay from time to time.

Great, great thread - thank you @amirm !

I too found increased distortion at very low voltage levels with generic load resistors on my AHB2 vs. different generics. I couldn't figure out why, but the non-ohmic behavior is perfectly described by VCR (voltage coefficient of resistance).

Just for fun:

I ran a concert production company for a couple of decades and tested high powered amplifiers using ohmic behaving 12Ω 4,500 watt water cooled resistors, (3) in parallel for a 4Ω load capable of dissipating 13,500 watts long-term - like hours.

The resistors are about $10 each at Home Depot. You have to take a multimeter with sharp probes and test them until you find 12Ω units because their nominal rating is 12.8Ω. You will get some strange looks. : )

Resistor

Dual 13,500 watt 4Ω water cooled amp load

God bless you and your precious family - Langston

I too found increased distortion at very low voltage levels with generic load resistors on my AHB2 vs. different generics. I couldn't figure out why, but the non-ohmic behavior is perfectly described by VCR (voltage coefficient of resistance).

Just for fun:

I ran a concert production company for a couple of decades and tested high powered amplifiers using ohmic behaving 12Ω 4,500 watt water cooled resistors, (3) in parallel for a 4Ω load capable of dissipating 13,500 watts long-term - like hours.

The resistors are about $10 each at Home Depot. You have to take a multimeter with sharp probes and test them until you find 12Ω units because their nominal rating is 12.8Ω. You will get some strange looks. : )

Resistor

Dual 13,500 watt 4Ω water cooled amp load

God bless you and your precious family - Langston

Last edited:

- Thread Starter

- #46

A few years ago I made a 8 ohm load from several panel house heaters in parallel. The internal heating wires vibrated slightly with the music so I played Metallica on panel heaters with 1200W power. World record in low efficiency

- Thread Starter

- #47

A few years ago I made a 8 ohm load from several panel house heaters in parallel. The internal heating wires vibrated slightly with the music so I played Metallica on panel heaters with 1200W power. World record in low efficiency

I'm new around here, so apologies on these 3-year late observations re: Amir's extremely helpful post.

1. The quote from the 1966 paper on VCR includes a funny grammar error with the statement that "If the resistor contains a nonlinearity, Ohm's law is no longer valid". I think "If the resistor contains a nonlinearity, Ohm's law is no longer applies as a linear relationship" would be more appropriate. Misbehaving resistors have no power to invalidate laws. : )

2. Methinks that the SINAD vs. load resistor measurements on the AHB2 are invalid because the amp was switched to high-gain on the first measurement and low-gain on the second. I'm sure the conclusion stands, but the measurement should be redone if the old load resistors are available and there's an interest.

God bless you and your precious family - Langston

1. The quote from the 1966 paper on VCR includes a funny grammar error with the statement that "If the resistor contains a nonlinearity, Ohm's law is no longer valid". I think "If the resistor contains a nonlinearity, Ohm's law is no longer applies as a linear relationship" would be more appropriate. Misbehaving resistors have no power to invalidate laws. : )

2. Methinks that the SINAD vs. load resistor measurements on the AHB2 are invalid because the amp was switched to high-gain on the first measurement and low-gain on the second. I'm sure the conclusion stands, but the measurement should be redone if the old load resistors are available and there's an interest.

God bless you and your precious family - Langston

Last edited:

DualTriode

Addicted to Fun and Learning

- Joined

- Oct 24, 2019

- Messages

- 963

- Likes

- 627

Yes, E=IR

At 20 amps a small amount of resistance can show up as several volts across a bad connection.

Whether the mechanism of distortion is a function of delta V or delta V^2 or both. There can be measurable distortion generated across a bad joint.

How do you all connect the load resistor to the speaker cables.

Solder looks good, but not fast.

Crimp?

wire nuts?

split bolt lugs?

Thanks DT

At 20 amps a small amount of resistance can show up as several volts across a bad connection.

Whether the mechanism of distortion is a function of delta V or delta V^2 or both. There can be measurable distortion generated across a bad joint.

How do you all connect the load resistor to the speaker cables.

Solder looks good, but not fast.

Crimp?

wire nuts?

split bolt lugs?

Thanks DT

How do you all connect the load resistor to the speaker cables.

For the "small" amps measured around here (sub 1kW 4Ω), any connection that maintains constant impedance over the span of the measurement will do nicely, as you alluded to above. Of course this assumes your voltage reading is taken at the amp output terminals and not after some length of cabling leading to the test load. Minimizing the current in the measurement path like this makes fancy connections/connectors unnecessary.

High quality banana plugs (Pamona, old stock GenRad, etc.) are is still the standard of the realm, though I prefer high current versions of Neutrik's NL4. I prefer the high current versions due to their lower impedance mating surfaces, not their current capacity. Use a little DeOxit on the connectors and reseat them a few times. Always "test the tester" before executing important measurements (full loopback of the analyzer, cables, amp, etc., used to measure the DUT). The folks that declared they delivered neutrinos from CERN to Italy 60ns quicker than light a few years ago forgot to do that before claiming Einstein's theory of relativity invalid. In their case they had a sync error with the satellite that supplied the clock used to measure elapsed time. Oops.

God bless you and your precious family - Langston

dc655321

Major Contributor

- Joined

- Mar 4, 2018

- Messages

- 1,600

- Likes

- 2,269

The folks that declared they delivered neutrinos from CERN to Italy 60ns quicker than light a few years ago forgot to do that before claiming Einstein's theory of relativity invalid. In their case they had a sync error with the satellite that supplied the clock used to measure elapsed time.

Not quite a satellite sync error - https://profmattstrassler.com/artic...inos-faster-than-light/opera-what-went-wrong/

Make sure your connectors are well seated before declaring Einstein wrong!

DualTriode

Addicted to Fun and Learning

- Joined

- Oct 24, 2019

- Messages

- 963

- Likes

- 627

Hello,

Why would you assume the voltage reading is taken at the amp output terminals and not after some length of cabling leading to the test load.

The question was exactly the opposite;

How do you all connect the load resistor to the speaker cables?

Thanks DT

Why would you assume the voltage reading is taken at the amp output terminals and not after some length of cabling leading to the test load.

The question was exactly the opposite;

How do you all connect the load resistor to the speaker cables?

Thanks DT

audio2design

Major Contributor

- Joined

- Nov 29, 2020

- Messages

- 1,769

- Likes

- 1,859

Almost as a rule non inductive resistors will present less non linearity as the inductance is not fully linear. Thermal non linearities can present but normally not at 1Khz unless the resistor is too small and would depend on composition i.e. tempco. Most power resistors are fairly low tempco but not as a rule.

I suspect those heater elements have quite a tempco but keep them cooled and should not matter much.

I have made test resistors in the past by just putting a ton of low tempco SMT resistors on aluminum PCB with a low thermal coefficient prepreg. Very stable and low resistance but capacitance to the aluminum is a bit high.

I suspect those heater elements have quite a tempco but keep them cooled and should not matter much.

I have made test resistors in the past by just putting a ton of low tempco SMT resistors on aluminum PCB with a low thermal coefficient prepreg. Very stable and low resistance but capacitance to the aluminum is a bit high.

DualTriode

Addicted to Fun and Learning

- Joined

- Oct 24, 2019

- Messages

- 963

- Likes

- 627

Dynamic compression plus overall impedance changes.

I know plenty of my smaller two ways exhibit this phenomenon once I heat up the voice coils a little. Take an impedance sweep on a hot (not burnt out!) speaker vs a cool one.

Here years later, I am still measuring things.

Shure if you are measuring the impedance of a voice coil you should measure it warm under working conditions. Imagine measuring Thiele/Small parameters cold.

APx500 software/procedure measures voltage drop across the driver and across a current sense resistor. The speaker cable conductors are left out of the measurement procedure.

Thanks DT

Last edited:

- Thread Starter

- #55

I have experienced problems with increased THD at high power (above ~200W) when using cheap bananas. I then switched to connect bare wire to the screw terminals which in my book is the safest way. However, -for convenience, I have now switched to more expenside lockable rhodium bananas and have not had any problems yet.

DualTriode

Addicted to Fun and Learning

- Joined

- Oct 24, 2019

- Messages

- 963

- Likes

- 627

Hello All,

I’ve been playing around with resistors and cables for a couple of weeks and sort of reached the point of diminishing returns.

I came to the conclusion that many people do not understand the concept or difference between Voltage Coefficient of Resistance and Thermal Coefficient of Resistance. Much of this does not appear in the cut sheets. What does show up in the cut sheets is DC data. What is important to these audio test loads is a function of frequency.

With an applied DC load the resistor will reach thermal equilibrium.

Beginning with low frequency with an applied AC load the resistance element will heat and cool with the applied AC voltage, there is no equilibrium only changing temperature with the applied AC voltage, the time for heating and cooling decreases with increasing frequency. The distortion caused by the applied AC voltage decreases with increased frequency. As the applied frequency goes high enough there is another sort of equilibrium. This distortion mechanism is all about the thermal modulation that decreases with frequency.

Big heavy resistors have less distortion. Networks of resistors in series and in parallel spread the heat out over multiple resistors. Each resistor has fewer watts to dissipate; there is much reduced distortion as a result.

Switches and relays and the like are another source of resistance and do not belong in the test load test gear.

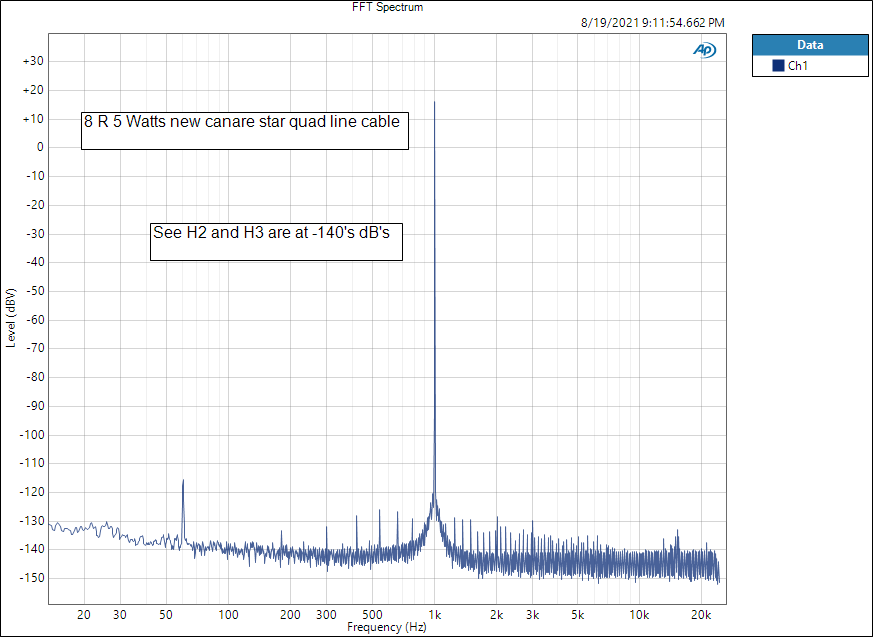

Swapping cords, resistors and stuff I got the 2nd and 3rd Harmonic Distortion peaks to better than -140dB’s.

The SINAD did not change that much, noise is the bigger contributor not distortion

Thanks DT

I’ve been playing around with resistors and cables for a couple of weeks and sort of reached the point of diminishing returns.

I came to the conclusion that many people do not understand the concept or difference between Voltage Coefficient of Resistance and Thermal Coefficient of Resistance. Much of this does not appear in the cut sheets. What does show up in the cut sheets is DC data. What is important to these audio test loads is a function of frequency.

With an applied DC load the resistor will reach thermal equilibrium.

Beginning with low frequency with an applied AC load the resistance element will heat and cool with the applied AC voltage, there is no equilibrium only changing temperature with the applied AC voltage, the time for heating and cooling decreases with increasing frequency. The distortion caused by the applied AC voltage decreases with increased frequency. As the applied frequency goes high enough there is another sort of equilibrium. This distortion mechanism is all about the thermal modulation that decreases with frequency.

Big heavy resistors have less distortion. Networks of resistors in series and in parallel spread the heat out over multiple resistors. Each resistor has fewer watts to dissipate; there is much reduced distortion as a result.

Switches and relays and the like are another source of resistance and do not belong in the test load test gear.

Swapping cords, resistors and stuff I got the 2nd and 3rd Harmonic Distortion peaks to better than -140dB’s.

The SINAD did not change that much, noise is the bigger contributor not distortion

Thanks DT

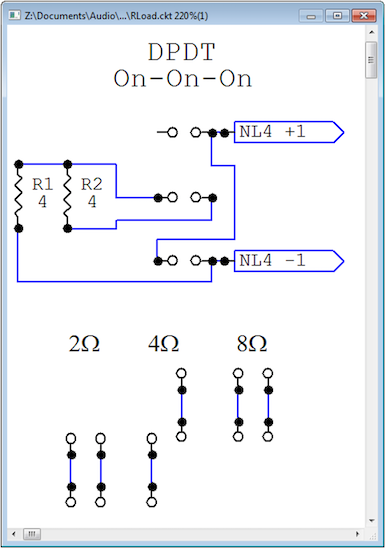

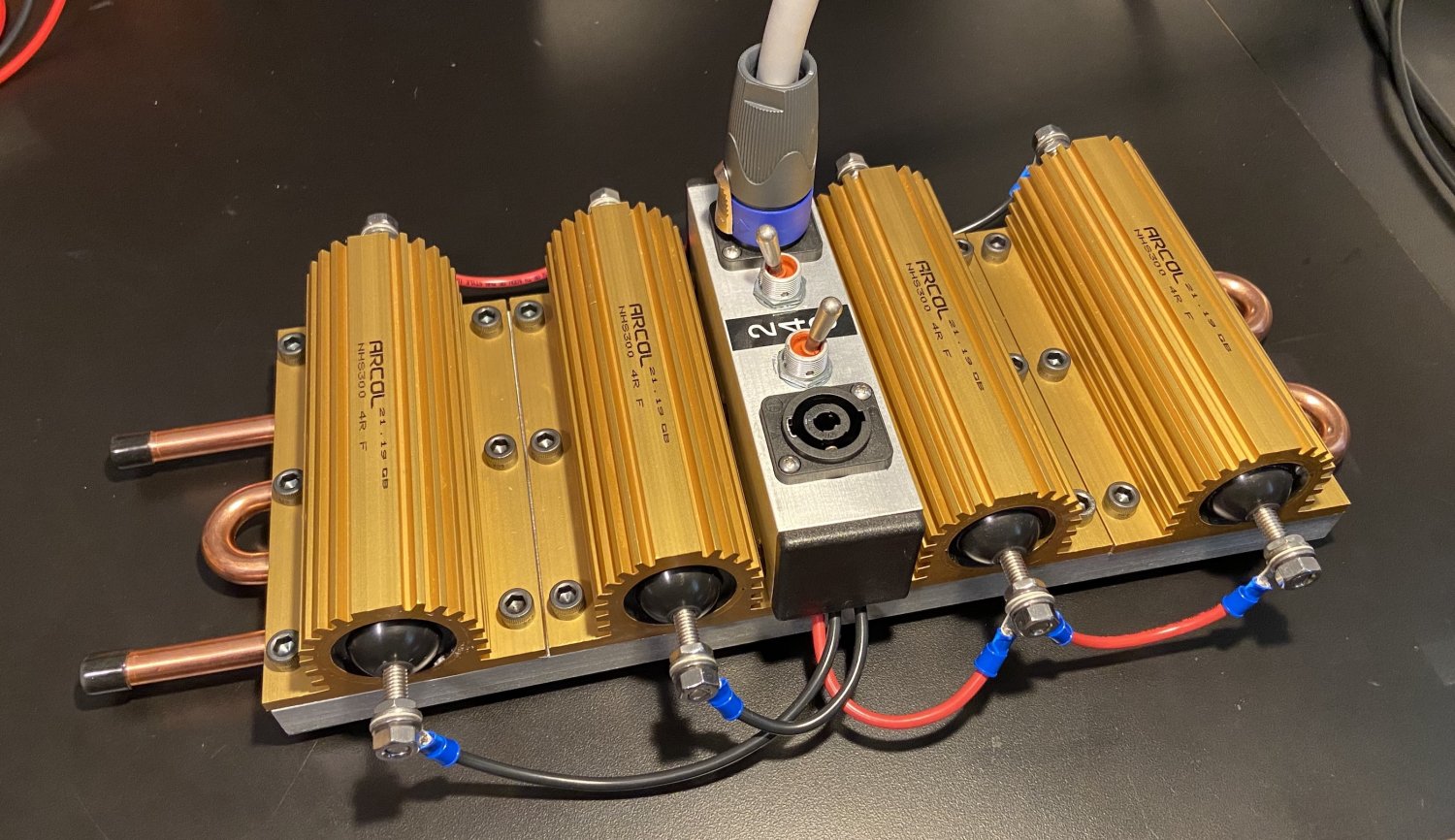

Finally got around to building a resistive amp load that will cover most of my needs.

Features

Picture

God bless you and your precious family - Langston

Features

- (4) 4Ω resistors used in lieu of (8) 8Ω.

- Switches between 2/4/8Ω without cable changes.

- 15A mil-spec On-On-On switch used on each channel.

- Outer resistors are used during two channel 4Ω testing.

- ARCOL NHS 300W 1% resistors avoid non-ohmic VCR within the audio spectrum.

- 15mm aluminum base does not require water-cooling with amps under 500W.

- Thermal paste used between resistors and base.

- All resistors and base heat evenly even during single channel measurements.

- Paralleling both channels at 8Ω allows very high power 4Ω bridged mode tests.

- Parts total $450.

Picture

God bless you and your precious family - Langston

DualTriode

Addicted to Fun and Learning

- Joined

- Oct 24, 2019

- Messages

- 963

- Likes

- 627

Hello All,

Just for grins today I went over to Mouser to look around at wire wound power resistors.

A single 8 Ohm 250 watt RH-250 resistor is ~ $170.00 and has a Thermal Coefficient of Resistance of 50 PPM / C.

8, 50 watt RH-20 resistors at ~$6.00 each, with a TCR of 20 PPM /C, is $48.00 for all 8 resistors for a 400 Watt 8 Ohm test load.

Spreading the heat over 8 resistors decreases the temperature increase under load by a factor of 8. A PPM / C of 20 compared to 50 PPM / C reduces the thermally caused load distortion by and additional factor of 2 ½.

The 300 Watt Arcol resistors appear to have a TCR of 100 PPM / C.

Multiple Vishay RH-50 resistors in Series and Parallel appear to have several SINAD dB’s advantage over the 300 Watt Arcol resistors. Cheaper too.

Thanks DT

Just for grins today I went over to Mouser to look around at wire wound power resistors.

A single 8 Ohm 250 watt RH-250 resistor is ~ $170.00 and has a Thermal Coefficient of Resistance of 50 PPM / C.

8, 50 watt RH-20 resistors at ~$6.00 each, with a TCR of 20 PPM /C, is $48.00 for all 8 resistors for a 400 Watt 8 Ohm test load.

Spreading the heat over 8 resistors decreases the temperature increase under load by a factor of 8. A PPM / C of 20 compared to 50 PPM / C reduces the thermally caused load distortion by and additional factor of 2 ½.

The 300 Watt Arcol resistors appear to have a TCR of 100 PPM / C.

Multiple Vishay RH-50 resistors in Series and Parallel appear to have several SINAD dB’s advantage over the 300 Watt Arcol resistors. Cheaper too.

Thanks DT

...several SINAD dB’s advantage...

SINAD of course being noise and distortion relative to signal level, how are you calculating the reduced noise and/or distortion between resistors?

---

Edit: I repeated Amir's AHB2 "Benchmode" 4Ω measurement with my APx515 (purchased in 2012 for my concert production company). It's in spec even though it hasn't been calibrated since the digital section was repaired in 2017. I'm retired now and finally building a home audio system.

Among other things, my APx515 doesn't offer the high performance analog I/O that comes on the APx555 and this is why my month old AHB2 and the load resistor jig show a SINAD that's about 6dB lower. I think it's fair to conclude that the load resistor jig is innocent of non-ohmic (VCR) behavior beyond the capability of my analyzer.

APx515 Residual THD+N I/O 20kHz BW Specs: ≤ (–102 dB + 1.4 μV).

APx555 Residual THD+N I/O 22kHz BW Specs: ≤ (–117 dB + 1.0 μV), V ≤ 9.3 Vrms; ≤ –115 dB, V > 9.3 Vrms.

Typical of Audio Precision, both Amir's and my analyzers comfortably exceed their specs and mine is 9 years old. : )

Setup

Measurement (the FFT noise and distortion spikes disappear when the stimulus is turned off)

God bless you and your precious family - Langston

Last edited:

DualTriode

Addicted to Fun and Learning

- Joined

- Oct 24, 2019

- Messages

- 963

- Likes

- 627

SINAD of course being noise and distortion relative to signal level, how are you calculating the reduced noise and/or distortion between resistors?

---

Edit: I repeated Amir's AHB2 "Benchmode" 4Ω measurement with my APx515 (purchased in 2012 for my concert production company). It's in spec even though it hasn't been calibrated since the digital section was repaired in 2017. I'm retired now and finally building a home audio system.

Among other things, my APx515 doesn't offer the high performance analog I/O that comes on the APx555 and this is why my month old AHB2 and the load resistor jig show a SINAD that's about 6dB lower. I think it's fair to conclude that the load resistor jig is innocent of non-ohmic (VCR) behavior beyond the capability of my analyzer.

APx515 Residual THD+N I/O 20kHz BW Specs: ≤ (–102 dB + 1.4 μV).

APx555 Residual THD+N I/O 22kHz BW Specs: ≤ (–117 dB + 1.0 μV), V ≤ 9.3 Vrms; ≤ –115 dB, V > 9.3 Vrms.

Typical of Audio Precision, both Amir's and my analyzers comfortably exceed their specs and mine is 9 years old. : )

Setup

View attachment 153430

Measurement (the FFT noise and distortion spikes disappear when the stimulus is turned off)

View attachment 153431

God bless you and your precious family - Langston

Hello,

You have AP equipment on your bench. Login at AP.com and download Bruce Hofer’s article on ultra low distortion design.

https://www.ap.com/download/designing-for-ultra-low-thdn-2/?wpdmdl=5937

You will see that VCR for wire wound resistors is tiny and is perhaps the least responsible for wire wound resistor caused distortion. Thermal Coefficient of Distortion, TCR, is by far the worst offender for causing wire wound resistor distortion.

Other things being equal, a resistor with a TCR of 100 PPM / C will generate 5 times more distortion than a resistor with a TCR of 20 PPM / C. 100/20=5, 20*Log(5) = +14dB’s greater distortion generated by the 100 PPM / C resistor.

Granted a less than perfect generator driving a less than perfect amplifier measured by a less than perfect analyzer may not be able to detect the difference between the 100 PPM / C and 20 PPM / C load resistors.

You have some nice equipment on your bench; the AP analyzer and AHB2 reference amplifier.

Here is an experiment if you are willing. Go to Mouser.com and purchase 4 Vishay 16 Ohm 50 Watt wire wound resistors and connect them in parallel for a test load of 4 Ohms and a TCR of 20 PPM / C. (That is maybe $30.00 in parts) 71-RH50-16

I suspect that you will see an improvement over your current measured 4 ohm 100 PPM / C load resistor.

Thanks DT

Last edited:

Similar threads

- Replies

- 9

- Views

- 1K

- Replies

- 12

- Views

- 1K

- Replies

- 0

- Views

- 323