Hello,

After some look around the forum, I could find few posts around 3D printing but I could not find a particular thread related to 3D Printed speakers as a method of building D.I.Y speakers.

I have not tried myself yet but I will list the different projects I could find to start the discussions:

I propose that we only had projects that have been "evaluated" or at least with advanced designs to avoid all the quick and cheap speakers.

Bookshelf / Fullrange:

Subwoofers:

Satellite / Surrounds / Mini:

5.1:

Please share if you have tried to build any of the models above, others or design your own !

For my 5.1 (or more), I am planning to do 2 active Dozer + 4 P-cubes + 1 (or 2) Hexibox subwoofer, will update with my trial later on.

After some look around the forum, I could find few posts around 3D printing but I could not find a particular thread related to 3D Printed speakers as a method of building D.I.Y speakers.

I have not tried myself yet but I will list the different projects I could find to start the discussions:

I propose that we only had projects that have been "evaluated" or at least with advanced designs to avoid all the quick and cheap speakers.

Bookshelf / Fullrange:

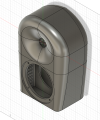

- Hexibase - Dozer

- Hexibase - Full Range Speaker Project, Longer LK4, Plus DEMO!

- DIYPerks - Building EXCEPTIONAL speakers using MODERN TECHNIQUES

- To avoid consuming too much plastic, he only print a shell / thin wall and then use an mix of Plaster of Paris+PVA Glue as absorption material

- Loudifier - D notes (based on C Notes) - Printables

- Ringoton - Bookshelf Speakers Powered by Daytone Audio with a Custom 3D Printed Enclosure - Reddit

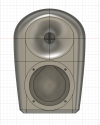

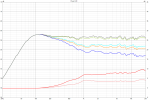

- zx82net - LCM Monitor Speaker - 40Hz waveguide - Bluetooth - DSP - Thingiverse --> Review by Erin Audio Corner

- zx82net - Bookshelf Speaker (Hexibase remix) v2

- Guppyk - Back Horn Speaker V2.0 BL2

- Waveguided Bookshelf Speakers using SB15 woofer and SB26 tweeter

- Scorg project

Subwoofers:

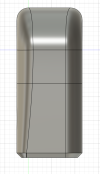

- Hexibase - Hexibox series- A few version & remakes exists for this design:

- First version: Can a 3D printed enclosure get low?

- Last version to date: ELEGOO Neptune 3 Plus Review & Feature Build - Printables

- Guppyk - Isobaric subwoofer

Satellite / Surrounds / Mini:

5.1:

- Made with Layers (Thomas Sanladerer) - DIY 5.1 Surround speakers - a learning opportunity!

- Building a 5.1 Surround Home Theater System 3D PRINTED - by SoundBlab

Please share if you have tried to build any of the models above, others or design your own !

For my 5.1 (or more), I am planning to do 2 active Dozer + 4 P-cubes + 1 (or 2) Hexibox subwoofer, will update with my trial later on.

Last edited: