kemmler3D

Master Contributor

We were promised flying cars!!

Hang on, wrong thread. OK.

There have been a few papers describing acoustic treatments that are very thin by current standards that can work well into the bass region.

pubs.aip.org

pubs.aip.org

www.nature.com

etc etc.

www.nature.com

etc etc.

Apparently the manufacture of most of these is pretty straightforward with a consumer-grade 3D printer. Looking at the pictures of the panels in the papers, I could certainly whip some of these up if I had a design to use.

The problem is - I don't have the designs. And I don't have the math to design one myself. And there's no calculators out there for these things, as far as I can tell. I understand that serious FEM/BEM modeling is required to validate these designs, but that just means it would take maybe a day per design instead of 5 minutes.

Meanwhile we're still in threads wondering and arguing about 1970s diffusion tech (BADs and QRDs) and how much fiberglass to screw to our walls. What gives??

1) Why aren't the commercial acoustics outfits manufacturing these?

2) If they're not selling them, why isn't there any way for me to make them myself?

I think QRDs look cool which is why I'm making one. But for god's sake, why can't I make something invented this century? Does anyone know?

If my understanding of these papers is correct, the metamaterial panels would blow the doors off everything on the market and can be manufactured using whatever 3D printer you happen to have at hand. So...? Is it a patent problem, are the papers bogus, or what?

Hang on, wrong thread. OK.

There have been a few papers describing acoustic treatments that are very thin by current standards that can work well into the bass region.

Metadiffusers for quasi-perfect and broadband sound diffusion

Sound diffusion refers to the ability of a surface to evenly scatter sound energy in both time and space. However, omni-directional radiation of sound, or perfe

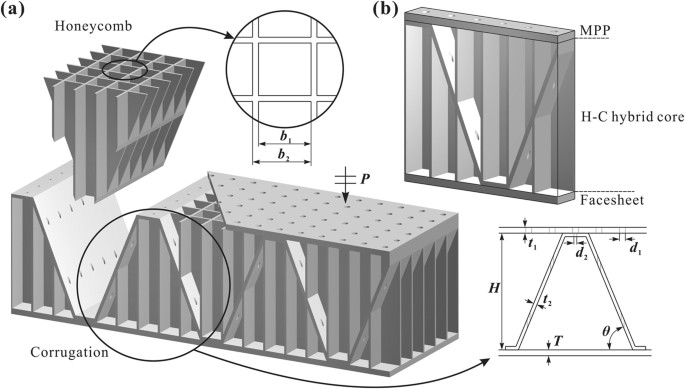

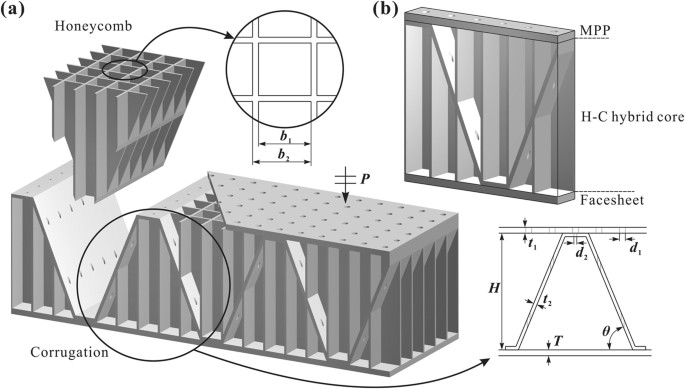

Hybrid acoustic metamaterial as super absorber for broadband low-frequency sound - Scientific Reports

A hybrid acoustic metamaterial is proposed as a new class of sound absorber, which exhibits superior broadband low-frequency sound absorption as well as excellent mechanical stiffness/strength. Based on the honeycomb-corrugation hybrid core (H-C hybrid core), we introduce perforations on both...

Apparently the manufacture of most of these is pretty straightforward with a consumer-grade 3D printer. Looking at the pictures of the panels in the papers, I could certainly whip some of these up if I had a design to use.

The problem is - I don't have the designs. And I don't have the math to design one myself. And there's no calculators out there for these things, as far as I can tell. I understand that serious FEM/BEM modeling is required to validate these designs, but that just means it would take maybe a day per design instead of 5 minutes.

Meanwhile we're still in threads wondering and arguing about 1970s diffusion tech (BADs and QRDs) and how much fiberglass to screw to our walls. What gives??

1) Why aren't the commercial acoustics outfits manufacturing these?

2) If they're not selling them, why isn't there any way for me to make them myself?

I think QRDs look cool which is why I'm making one. But for god's sake, why can't I make something invented this century? Does anyone know?

If my understanding of these papers is correct, the metamaterial panels would blow the doors off everything on the market and can be manufactured using whatever 3D printer you happen to have at hand. So...? Is it a patent problem, are the papers bogus, or what?