bothu

Member

How is modern electronic design done ?

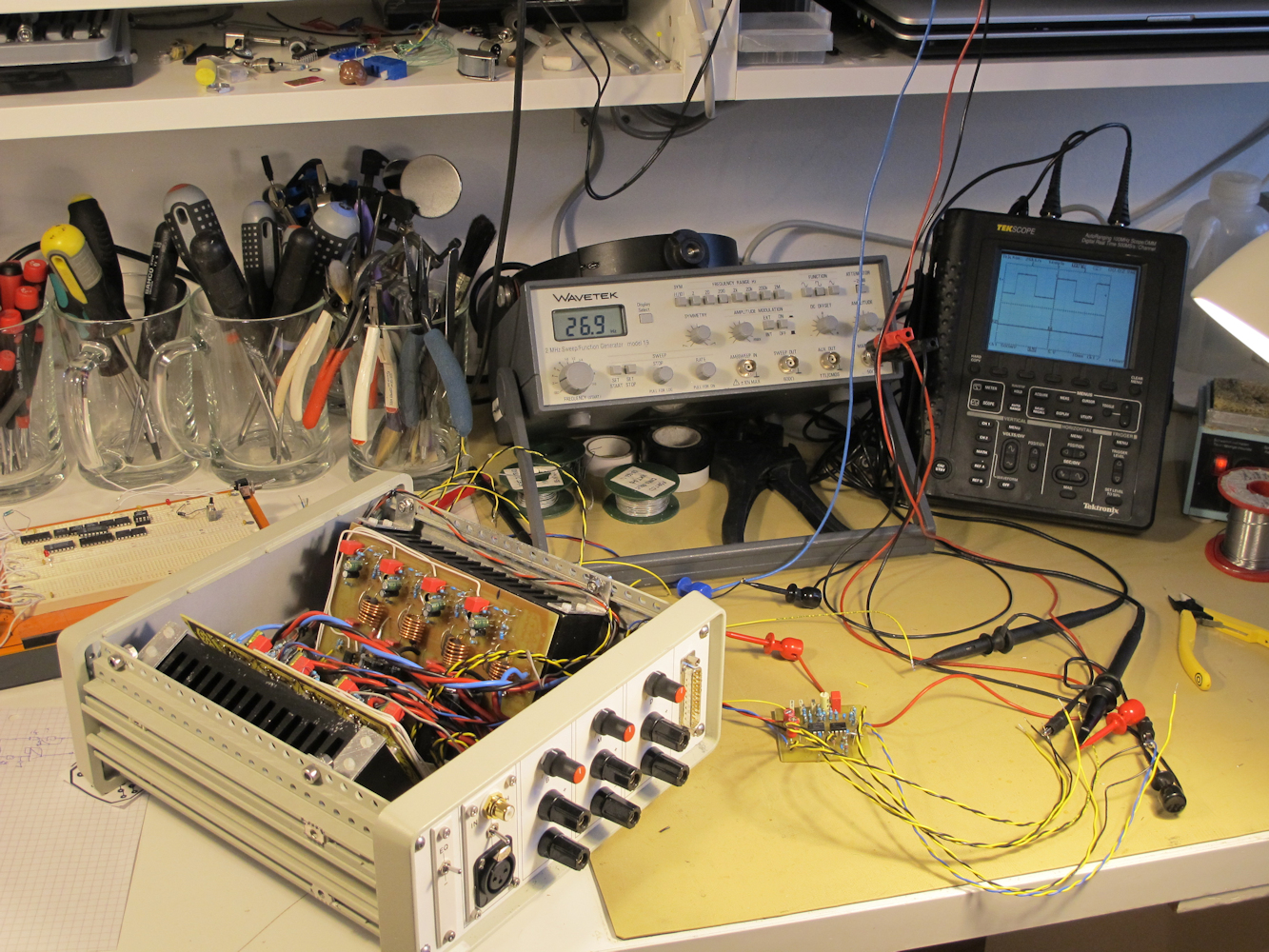

As an hobbyist I am working with old tools. Drawing schematics on a paper, testing the components on a breadboard, adjusting values.

make circuit wiring with a simple CAD program, etching cards, drilling holes, mounting components, testing again and finally mounting it in some case.

That is a lot of physical handling with the electrical components.

I guess that it is not how modern EE nowadays designing/producing products . Advanced circuit simulators, automated layout and routing of cards, robots that place and solder cards and so on. SMD components have got so small so it is impossible to handle them by hand even for professional designers.

My question : Can someone tell me how the workflow from idea to product looks like nowadays.

Sending a picture from my primitive old school desk.

/ Bo Thuné, Linköping, Sweden

As an hobbyist I am working with old tools. Drawing schematics on a paper, testing the components on a breadboard, adjusting values.

make circuit wiring with a simple CAD program, etching cards, drilling holes, mounting components, testing again and finally mounting it in some case.

That is a lot of physical handling with the electrical components.

I guess that it is not how modern EE nowadays designing/producing products . Advanced circuit simulators, automated layout and routing of cards, robots that place and solder cards and so on. SMD components have got so small so it is impossible to handle them by hand even for professional designers.

My question : Can someone tell me how the workflow from idea to product looks like nowadays.

Sending a picture from my primitive old school desk.

/ Bo Thuné, Linköping, Sweden