Vineeth Kumar V

Member

- Joined

- Feb 23, 2021

- Messages

- 46

- Likes

- 252

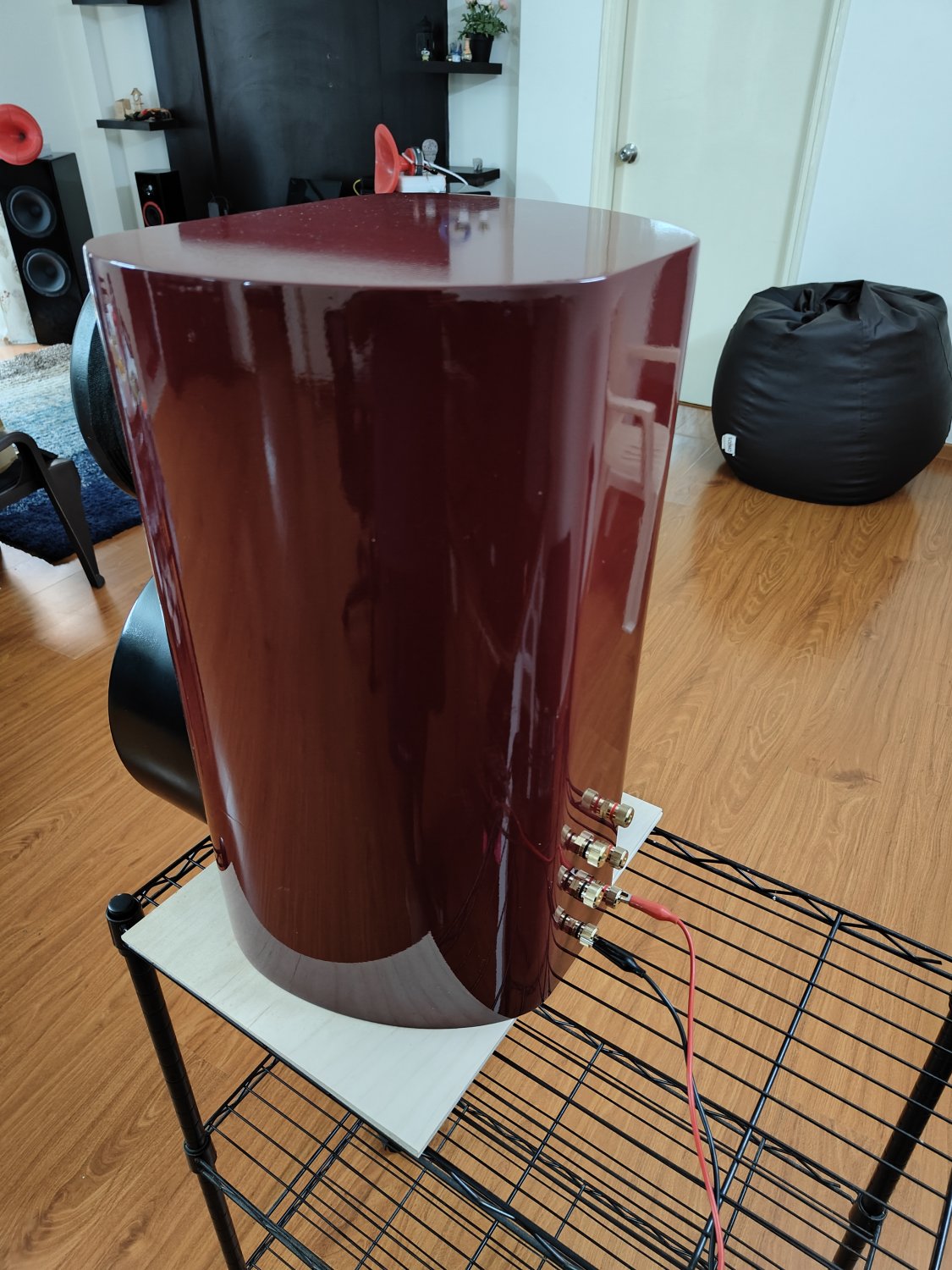

I built a 3 way speaker using a Sica 5.5C1.5CP coaxial driver in a passive cardioid configuration helped in the lows by a Wavecor SW 215 subwoofer in sealed box configuration. This will use a DSP crossover although there is potential for a passive crossover version as well. Here are some pics and other details

Initial prototype for testing cardioid mid. The space behind the Sica coax driver is filled with 50mm thick melamine foam sheets cut to shape

Final CAD design:

Build progress

Driver assembly (The space behind the coax is filled with melamine foam sheets and covered with a sock cloth for now)

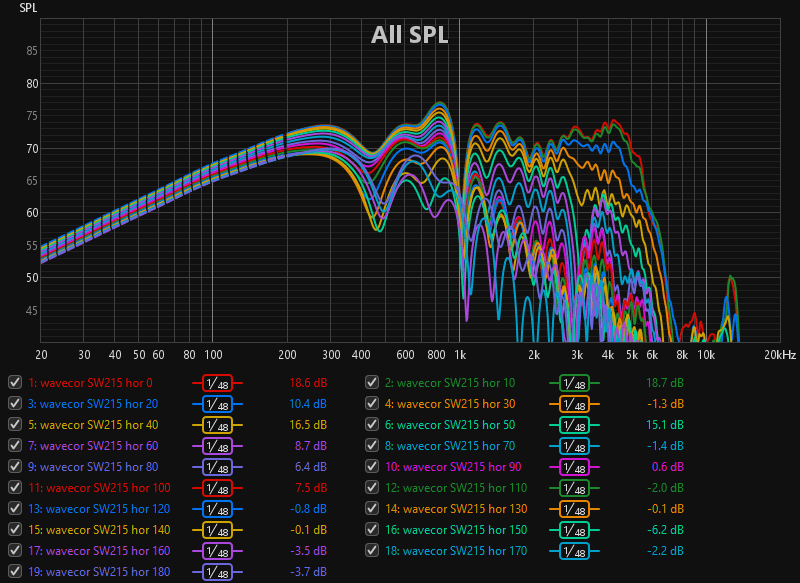

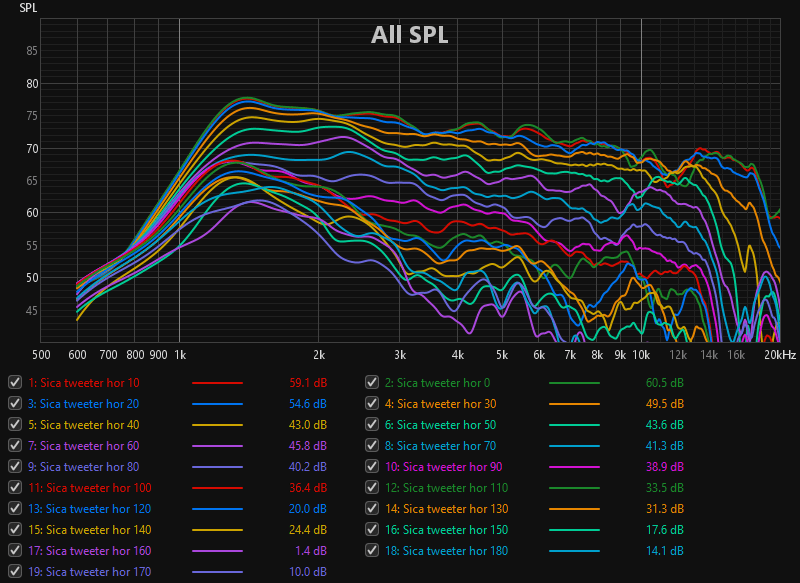

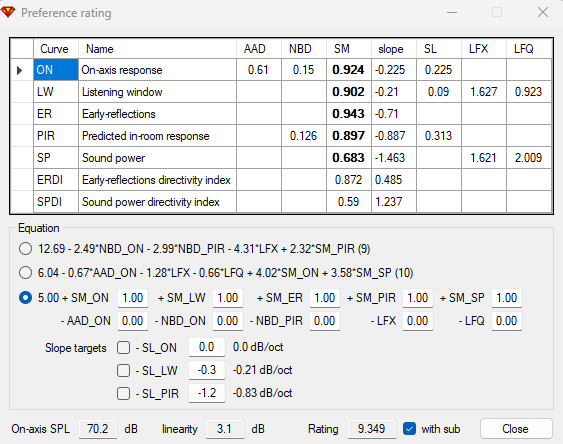

Measurements

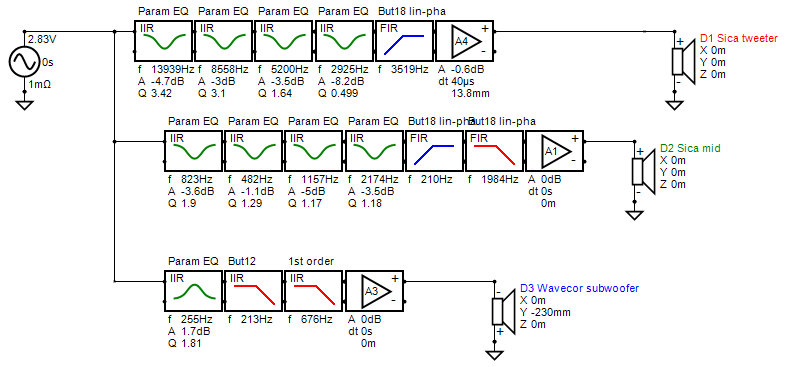

A linear phase crossover: V1 (Reference axis is 20 degrees off axis)

Initial prototype for testing cardioid mid. The space behind the Sica coax driver is filled with 50mm thick melamine foam sheets cut to shape

Final CAD design:

Build progress

Driver assembly (The space behind the coax is filled with melamine foam sheets and covered with a sock cloth for now)

Measurements

A linear phase crossover: V1 (Reference axis is 20 degrees off axis)