Do you owe it to yourself to check out the latest electrostatic speaker designs?

Ahh; YES.

No speaker is perfect but I wish everyone could hear the latest commercial and DIY ESL designs.

I'm sure many would find their sound addictive.

I will discuss both, but first I must confess my bias favoring ESLs, which I've championed for years, and in particular my own DIY design.

In my experience, it's far easier for a DIY'er to build a world-class ESL than a world-class conventional speaker. I don't mean that it's less work (the labor is horrendous)-- just that a good result is more certain because you start with less baggage.

I can list as many cons as pros for ESLs but the pros are really good and the cons are not terribly hard to remedy in a good design. Some manufacturers mitigate the cons quite well and the latest offerings are better than ever.

Pros:

1. The ultra-low moving mass diaphragm is so effectively dampened by the greater air mass it's coupled to, that it simply doesn't *ring.

2. Line-source configuration gives really good imaging.

3. Contrary to popular belief and the commercial offerings, DIY designs can tailor dispersion patterns as desired or even provide switch-selectable wide & narrow dispersion modes (costly but do-able).

4. No crossover-- or a hybrid can use a single crossover down low where it's less audible.

5. Typically excellent/superior coherence, resolution & transient response.

*An ESL diaphragm is remarkably resonance-free across the audio bandwidth except for its single fundamental "drum-head" resonance peak which typically occurs in the bass region at a frequency determined by its tension. This resonance is analogous to a woofer's free-air resonance (f/s) and is likewise undesirable.

Cons:

1. The diaphragm's drum-head resonance is a nasty-loud distortion that's difficult to mask.

2. Anemic bass unless the panel is huge, and drum-head resonance can render it boomy & sluggish.

3. Hybrids add the bass but few achieve a seamless blending of the woofer & stat panel.

4. Narrow dispersion which some listeners find objectionable (i.e. "head-in-a-vise" effect).

5. Capacitive load & impedance as low 1 Ohm in treble band requires a strong, stable amp.

6. Long-term reliability is historically iffy, especially in DIY versions.

Mitigating the drum head resonance:

Acoustat and some other full range designs apply a felt strip or mesh fabric on the rear stator which partially absorbs the resonance energy.

Soundlab uses the drum-head resonance to boost bass output by dividing the diaphragm into multiple different-width sections which break up the single/loud/narrow resonance peak into multiple softer resonances spread over a wider bandwidth (i.e. "distributed resonance"). It's an innovative solution that mitigates the booming effect and boosts bass output, but it's not a perfect solution because the the drum head resonance is by definition a distortion, so using it must include its distortion.

Martin Logan tensions the diaphragm quite high, and likewise uses distributed resonance to enhance the upper bass/lower midrange, so that less EQ'ing is required to offset the panel's dipole roll off and flatten its response curve. Here again, distributed resonance spreads out the drum-head resonance, which necessarily includes its distortion.

Mitigating the narrow dispersion:

Narrow dispersion is not necessarily a flaw. In fact, the Sanders/InnerSound speakers are purposely designed or narrow dispersion because it gives the most precise imaging at their tightly focused sweet spot. Some prefer the narrow sweet spot but it's not so good for entertaining guests, and most speaker designers opt for wider dispersion.

Some designs (ML, Soundlab) curve the stat panel to about 30 degrees of arc, which curves its projected wave-front and widens the sweet spot. The small curvature is still a bit beamy but retains much of the magical imaging.

Some designs use a separate, narrow treble panel to spread the highs.

The Quad 63 and similar designs use separate bass panels and a center mid/treble panel with concentric ring conductors sequentially driven thru an LC delay line to function as a point source projecting a spherical wave front.

Mitigating the load capcitance:

Most designs add low value resistors in front of the transformers which renders the load partially-resistive (although still mostly capacitive).

Reliability:

Most manufactures now produce reliable speakers, although 20 years seems to be the best-case limit (except for Acoustats which are seemingly immortal). I would not advise purchasing a DIY ESL unless you do your homework on the specific design, and you and trust the builder to stand behind it.

The weakest link in any ESL is the diaphragm coating degrading over time. So; a good design goal would make the panel easy to disassemble without damaging the stators, and preferably also leaving the diaphragm intact. If thus accessible; the diaphragm could be easily re-coated or replaced.

The most robust designs use insulated wire stators because of their higher resistance to arcing.

Perf metal stators can be reliable if made by a manufacturer like ML who has mastered the specialized processes required to prevent arcing.

I would no longer build or purchase a DIY ESL with perf metal stators because it's so difficult to perfectly smooth-over the cut metal edges and apply the insulating coatings as required to prevent arcing.

The old Acoustat ESLs are practically bullet proof because they used superbly insulated wire stators and a simple carbon black diaphragm coating that remained stable over time-- these continue to play happily for decades!

So; if you want a reliable ESL; buy or build one similar to the Acoustat design. Or at least with stators than can be easily disassembled to access the diaphragms.

*********************************************************************************************************************

My latest DIY design (Jazzman MkIII):

The drum head resonance: Is simply avoided (not excited) by tensioning the diaphragm to resonate <100Hz, and then crossing the panel out to the woofer at least one octave above the resonance using a steep-sloped digital crossover (250Hz @48db/oct). Hence; the panel is not being energized/excited near the diaphragm's resonance frequency.

Dispersion: Tailoring the dispersion requires choosing either a narrow sweet spot with very precise imaging or a wide sweet spot with less precise imaging or something in-between (physics forces this choice-- you can't have it all).

I chose the latter option and tailored the segmentation scheme accordingly.

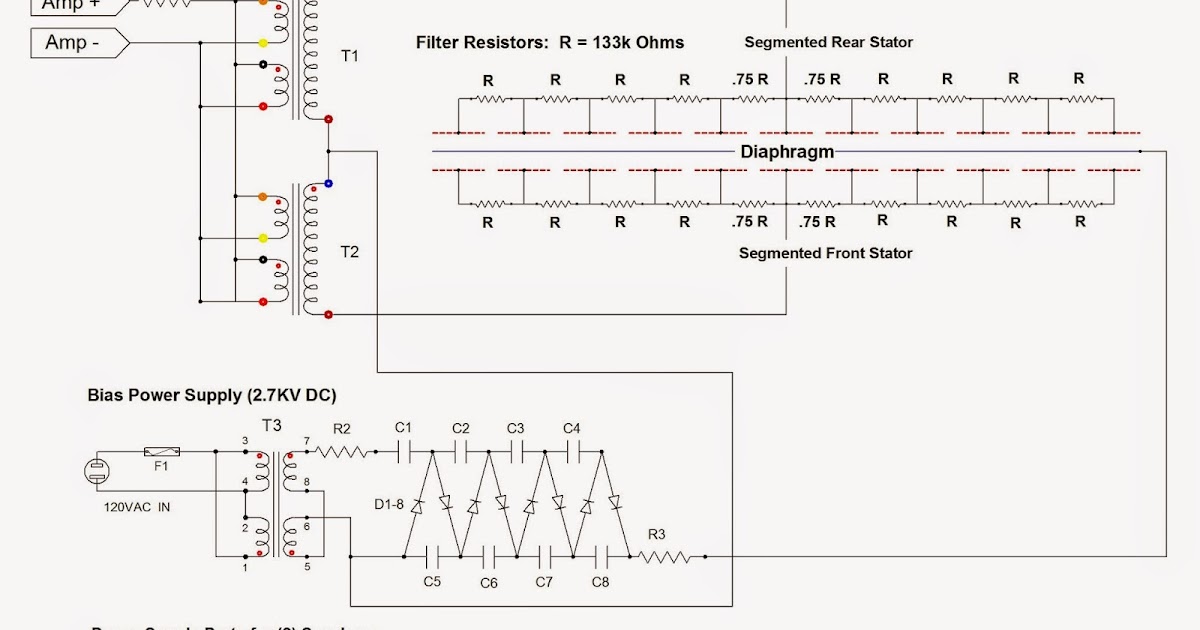

The stat panel employs symmetrical multi-segmented wire stators driven sequentially from the panel centerline outward to function as a line source projecting a cylindrical wave-front. This works amazingly well; giving wide, smooth-trending dispersion.

Load/Impedance: The RC line used to curve the wave front effectively linearizes the impedance and renders it predominantly resistive, as only the smaller capacitance of the first two wire groups is reflected back to the amp. This also reduces the degrees of phase rotation for the impedance reflecting back to the amp (very desirable).

Woofer/Panel Integration:

The matching dipole radiation patterns of the excellent OB mounted Eminence KappaLite 3012LF woofer and the stat panel merge seamlessly to sound like a single, coherent driver-- the best integration I've heard in a hybrid ESL.

Reliability:

The wood lattice supported wire stators are less impact-tolerant than perf metal stators and must be handled accordingly. Otherwise; they are highly arc resistant resistant and therefore unlikely to be harmed by even crazy-loud volume levels. Even with no protection circuitry, the electronics interface has also proven to be reliable. Over the past five years I've built seven pairs for myself and audio pals, and none have failed.

The stators can be either bond bonded together or mechanically mated in this design. If mechanically mated; the stators can be easily separated to access the diaphragms, should servicing them ever be needed.

How long will the diaphragm coating last? I can vouch for 5 years so far-- but I'll get back to you on that in about 10 years if I'm blessed to still be here.

Website with build photos & write-ups: http://jazzman-esl-page.blogspot.com/?m=0

Photo of the Jazzman MkIII ESL:

Ahh; YES.

No speaker is perfect but I wish everyone could hear the latest commercial and DIY ESL designs.

I'm sure many would find their sound addictive.

I will discuss both, but first I must confess my bias favoring ESLs, which I've championed for years, and in particular my own DIY design.

In my experience, it's far easier for a DIY'er to build a world-class ESL than a world-class conventional speaker. I don't mean that it's less work (the labor is horrendous)-- just that a good result is more certain because you start with less baggage.

I can list as many cons as pros for ESLs but the pros are really good and the cons are not terribly hard to remedy in a good design. Some manufacturers mitigate the cons quite well and the latest offerings are better than ever.

Pros:

1. The ultra-low moving mass diaphragm is so effectively dampened by the greater air mass it's coupled to, that it simply doesn't *ring.

2. Line-source configuration gives really good imaging.

3. Contrary to popular belief and the commercial offerings, DIY designs can tailor dispersion patterns as desired or even provide switch-selectable wide & narrow dispersion modes (costly but do-able).

4. No crossover-- or a hybrid can use a single crossover down low where it's less audible.

5. Typically excellent/superior coherence, resolution & transient response.

*An ESL diaphragm is remarkably resonance-free across the audio bandwidth except for its single fundamental "drum-head" resonance peak which typically occurs in the bass region at a frequency determined by its tension. This resonance is analogous to a woofer's free-air resonance (f/s) and is likewise undesirable.

Cons:

1. The diaphragm's drum-head resonance is a nasty-loud distortion that's difficult to mask.

2. Anemic bass unless the panel is huge, and drum-head resonance can render it boomy & sluggish.

3. Hybrids add the bass but few achieve a seamless blending of the woofer & stat panel.

4. Narrow dispersion which some listeners find objectionable (i.e. "head-in-a-vise" effect).

5. Capacitive load & impedance as low 1 Ohm in treble band requires a strong, stable amp.

6. Long-term reliability is historically iffy, especially in DIY versions.

Mitigating the drum head resonance:

Acoustat and some other full range designs apply a felt strip or mesh fabric on the rear stator which partially absorbs the resonance energy.

Soundlab uses the drum-head resonance to boost bass output by dividing the diaphragm into multiple different-width sections which break up the single/loud/narrow resonance peak into multiple softer resonances spread over a wider bandwidth (i.e. "distributed resonance"). It's an innovative solution that mitigates the booming effect and boosts bass output, but it's not a perfect solution because the the drum head resonance is by definition a distortion, so using it must include its distortion.

Martin Logan tensions the diaphragm quite high, and likewise uses distributed resonance to enhance the upper bass/lower midrange, so that less EQ'ing is required to offset the panel's dipole roll off and flatten its response curve. Here again, distributed resonance spreads out the drum-head resonance, which necessarily includes its distortion.

Mitigating the narrow dispersion:

Narrow dispersion is not necessarily a flaw. In fact, the Sanders/InnerSound speakers are purposely designed or narrow dispersion because it gives the most precise imaging at their tightly focused sweet spot. Some prefer the narrow sweet spot but it's not so good for entertaining guests, and most speaker designers opt for wider dispersion.

Some designs (ML, Soundlab) curve the stat panel to about 30 degrees of arc, which curves its projected wave-front and widens the sweet spot. The small curvature is still a bit beamy but retains much of the magical imaging.

Some designs use a separate, narrow treble panel to spread the highs.

The Quad 63 and similar designs use separate bass panels and a center mid/treble panel with concentric ring conductors sequentially driven thru an LC delay line to function as a point source projecting a spherical wave front.

Mitigating the load capcitance:

Most designs add low value resistors in front of the transformers which renders the load partially-resistive (although still mostly capacitive).

Reliability:

Most manufactures now produce reliable speakers, although 20 years seems to be the best-case limit (except for Acoustats which are seemingly immortal). I would not advise purchasing a DIY ESL unless you do your homework on the specific design, and you and trust the builder to stand behind it.

The weakest link in any ESL is the diaphragm coating degrading over time. So; a good design goal would make the panel easy to disassemble without damaging the stators, and preferably also leaving the diaphragm intact. If thus accessible; the diaphragm could be easily re-coated or replaced.

The most robust designs use insulated wire stators because of their higher resistance to arcing.

Perf metal stators can be reliable if made by a manufacturer like ML who has mastered the specialized processes required to prevent arcing.

I would no longer build or purchase a DIY ESL with perf metal stators because it's so difficult to perfectly smooth-over the cut metal edges and apply the insulating coatings as required to prevent arcing.

The old Acoustat ESLs are practically bullet proof because they used superbly insulated wire stators and a simple carbon black diaphragm coating that remained stable over time-- these continue to play happily for decades!

So; if you want a reliable ESL; buy or build one similar to the Acoustat design. Or at least with stators than can be easily disassembled to access the diaphragms.

*********************************************************************************************************************

My latest DIY design (Jazzman MkIII):

The drum head resonance: Is simply avoided (not excited) by tensioning the diaphragm to resonate <100Hz, and then crossing the panel out to the woofer at least one octave above the resonance using a steep-sloped digital crossover (250Hz @48db/oct). Hence; the panel is not being energized/excited near the diaphragm's resonance frequency.

Dispersion: Tailoring the dispersion requires choosing either a narrow sweet spot with very precise imaging or a wide sweet spot with less precise imaging or something in-between (physics forces this choice-- you can't have it all).

I chose the latter option and tailored the segmentation scheme accordingly.

The stat panel employs symmetrical multi-segmented wire stators driven sequentially from the panel centerline outward to function as a line source projecting a cylindrical wave-front. This works amazingly well; giving wide, smooth-trending dispersion.

Load/Impedance: The RC line used to curve the wave front effectively linearizes the impedance and renders it predominantly resistive, as only the smaller capacitance of the first two wire groups is reflected back to the amp. This also reduces the degrees of phase rotation for the impedance reflecting back to the amp (very desirable).

Woofer/Panel Integration:

The matching dipole radiation patterns of the excellent OB mounted Eminence KappaLite 3012LF woofer and the stat panel merge seamlessly to sound like a single, coherent driver-- the best integration I've heard in a hybrid ESL.

Reliability:

The wood lattice supported wire stators are less impact-tolerant than perf metal stators and must be handled accordingly. Otherwise; they are highly arc resistant resistant and therefore unlikely to be harmed by even crazy-loud volume levels. Even with no protection circuitry, the electronics interface has also proven to be reliable. Over the past five years I've built seven pairs for myself and audio pals, and none have failed.

The stators can be either bond bonded together or mechanically mated in this design. If mechanically mated; the stators can be easily separated to access the diaphragms, should servicing them ever be needed.

How long will the diaphragm coating last? I can vouch for 5 years so far-- but I'll get back to you on that in about 10 years if I'm blessed to still be here.

Website with build photos & write-ups: http://jazzman-esl-page.blogspot.com/?m=0

Photo of the Jazzman MkIII ESL:

Last edited: