Fitzcaraldo215

Major Contributor

- Joined

- Mar 4, 2016

- Messages

- 1,440

- Likes

- 634

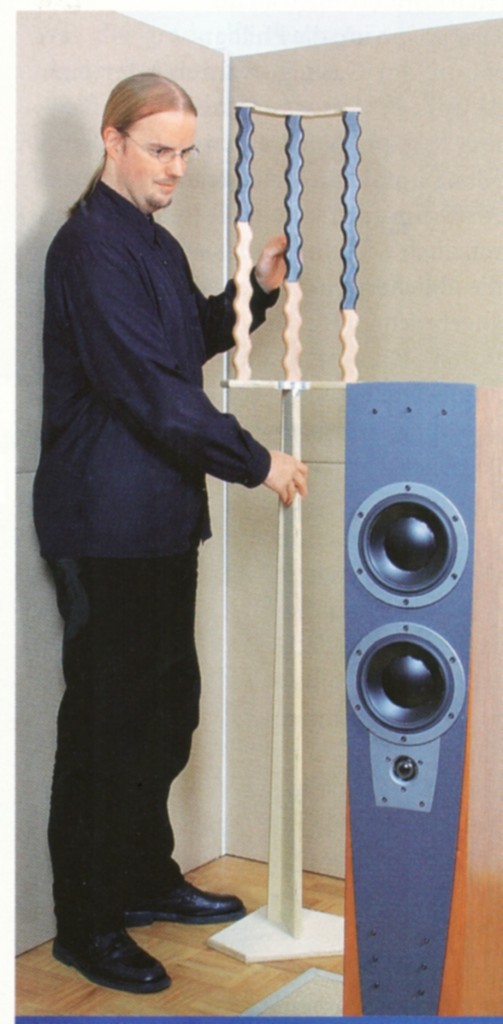

No collection of wood diffusers would be complete without a Shakti Hallograph.

Why is the speaker upside down?No collection of wood diffusers would be complete without a Shakti Hallograph.View attachment 242045

View attachment 242045

Maybe it sounds “better”.Why is the speaker upside down?

Indeed it is. Never heard of it before. Thank you posting.

I like it especially because it uses my favourite acoustic tool Helmholtz resonator

A big Bravo to the inventors?It's been 3D printed and tested it as well... https://pub.dega-akustik.de/ICA2019/data/articles/001008.pdf

What would be ace is to make a fiberglass mould and then use vacuum to press a sheet of heated plastic over the mould and make them in quantity and economically. Make diffusers that is. Not helmholtz resonators.A big Bravo to the inventors?

I think 3D printing like they did will be more economical. Not to mention allowing more sizes.What would be ace is to make a fiberglass mould and then use vacuum to press a sheet of heated plastic over the mould and make them in quantity and economically.

For a helmholtz resonator 3D printing is the solution but I think for a 1m x 2m or larger diffuser panel a vacuum indented lightweight thin plastic material is easily shipped at the weight of maybe 5 pounds.I think 3D printing like they did will be more economical. Not to mention allowing more sizes.

Molds can be very very expensive thoughFor a helmholtz resonator 3D printing is the solution but I think for a 1m x 2m or larger diffuser panel a vacuum indented lightweight thin plastic material is easily shipped at the weight of maybe 5 pounds.

For a helmholtz resonator 3D printing is the solution but I think for a 1m x 2m or larger diffuser panel a vacuum indented lightweight thin plastic material is easily shipped at the weight of maybe 5 pounds.

I saw the error in my statement and I clarified it in this post.I didn't think you could vacuum form something this shape (you could extrude it)...

View attachment 242050

www.audiosciencereview.com

www.audiosciencereview.com

It is a composite of Helmholtz resonator and diffuser. It was designed to be customise for each job. A single model that will be stocked is not what the device is designed for.For a helmholtz resonator 3D printing is the solution but I think for a 1m x 2m or larger diffuser panel a vacuum indented lightweight thin plastic material is easily shipped at the weight of maybe 5 pounds.

After making several or more diffusers a mould would be economical and could be used to resale more diffusers which apparently have a lack of packaged product availability in the world's market.Molds can be very very expensive though.

:max_bytes(150000):strip_icc()/diffusers_on_wall-56a900383df78cf772a2af97.jpg)

Could a end user buy various sizes of packaged and ready for use lightweight panels made from ~2.5+mm thick plastic and then assemble them into larger sizes as is required for a environment's special needs. That would get close to the goal parameters?It is a composite of Helmholtz resonator and diffuser. It was designed to be customise for each job. A single model that will be stocked is not what the device is designed for.

Can you share guidelines on how to approximate the frequencies a diffusor will scatter, based on the size or shape of its protuberences?... As an acoustician I am tired to tell people not to think room treatment only as absorption. In most small rooms absorption often creates more issues than it solves. Diffusion is a better solution. ...

Diffusers on the other hand stops reflections by scattering the sound so that reflections occur at very high frequencies and hence at less amplitude.

yep, that's the kind of guideline I was looking for.If you look at various charts you will see that the effectiveness curve is not steep. As there’s only one element at work the curve is 6dB/octave I.E. it is 50% effective at half the frequency you calculated and 30% at a third.

...

However, 5cm is very small for a diffuser. There are picture frames deeper than that!if you use 10cm at least you should expect effectiveness at half of the audible range. Go another 5cm and you cover 2/3rd.