Hello Everyone!

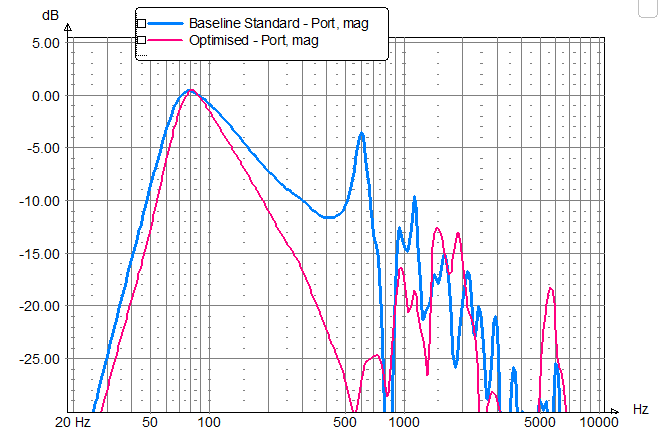

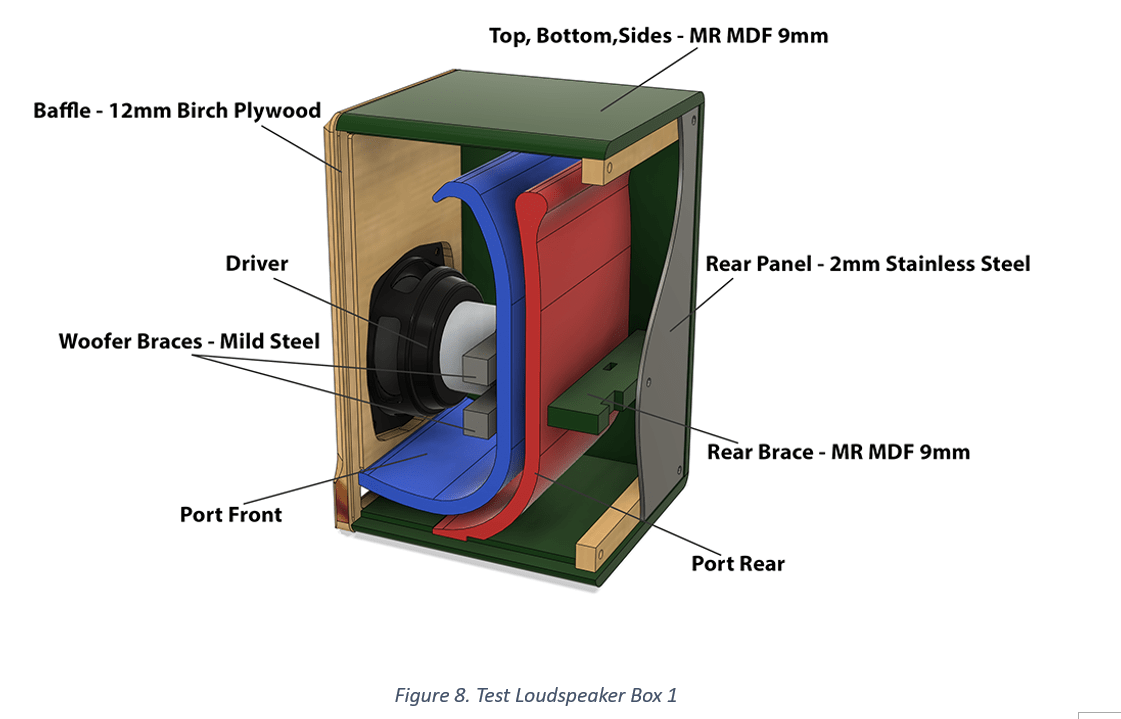

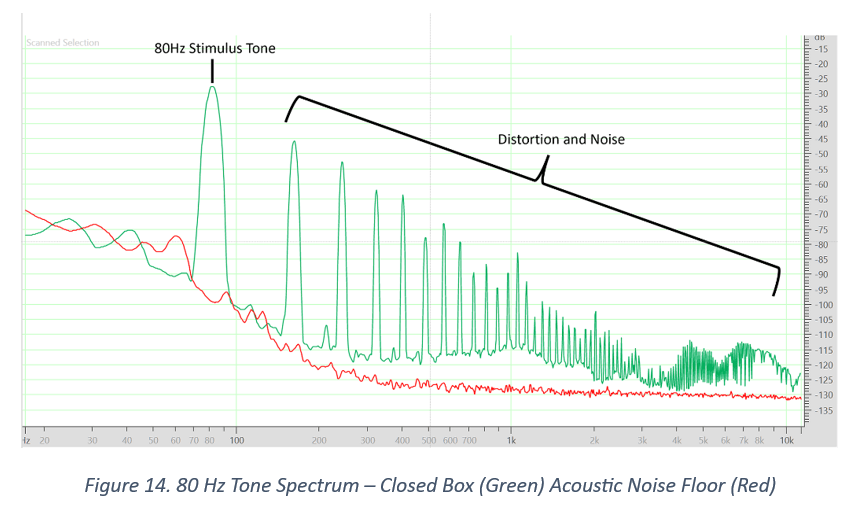

I would like to share with you the conclusions of a study I have been working on over the past months to design an optimised 3D printed port for a desktop loudspeaker. I tested various methods to reduce unwanted resonances, while keeping an eye on port turbulence.

3D Printed Loudspeaker Port Design Study < Clicky Click

Here are a few snap-shots:

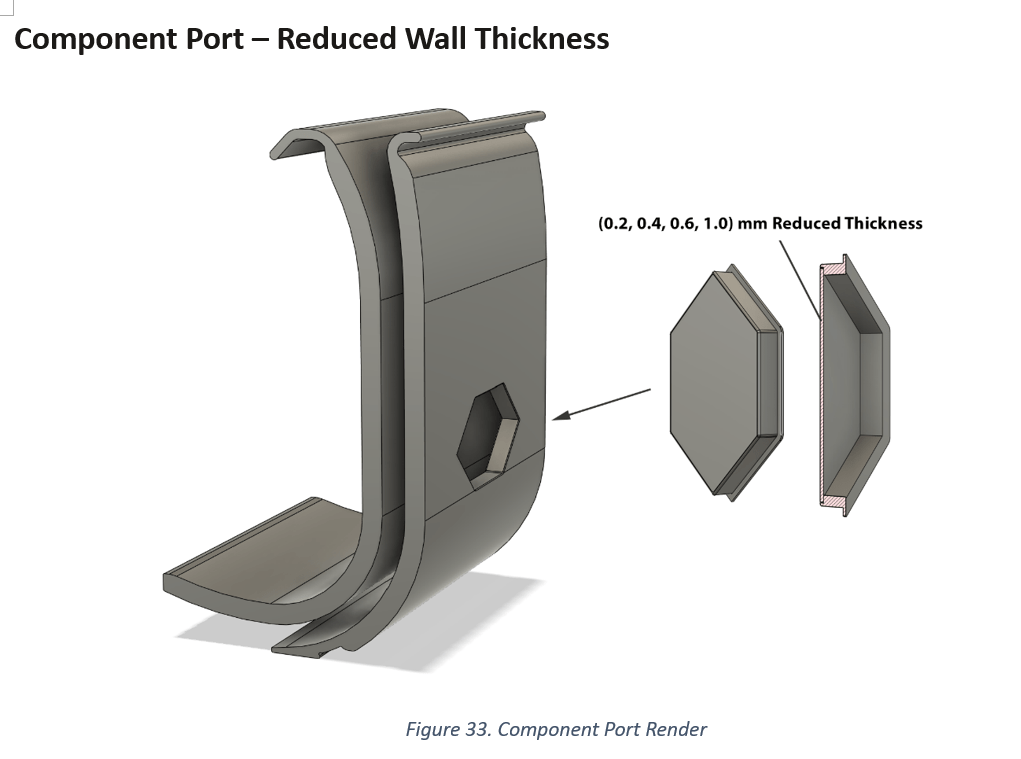

There is a whole lot of info in the paper beyond this including the effect of holes in ports, reduced wall thickness, constrained layer damping and what bending ports does to the response. I encourage you to check it out, since it took me a lot of work

While I unveil the fruits of the efforts, I must confess I have the intention of eventually offering a DIY kit and a finished product for sale based on the methods revealed in this study. I hope this doesn't detract from my wish as a fellow enthusiast to share what I discovered.

Simon

I would like to share with you the conclusions of a study I have been working on over the past months to design an optimised 3D printed port for a desktop loudspeaker. I tested various methods to reduce unwanted resonances, while keeping an eye on port turbulence.

3D Printed Loudspeaker Port Design Study < Clicky Click

Here are a few snap-shots:

There is a whole lot of info in the paper beyond this including the effect of holes in ports, reduced wall thickness, constrained layer damping and what bending ports does to the response. I encourage you to check it out, since it took me a lot of work

While I unveil the fruits of the efforts, I must confess I have the intention of eventually offering a DIY kit and a finished product for sale based on the methods revealed in this study. I hope this doesn't detract from my wish as a fellow enthusiast to share what I discovered.

Simon

Last edited: