This is a teardown of the Anthem MRX 520 Home Theater Receiver (AVR). I already reviewed the MRX 520. With kind permission of the owner, I took the lid off it and took some shots. Alas, the boards are tightly stacked on top of each other and I don't want to remove them in the odd chance that something happens to them. So this is not a very detailed teardown.

Here is a shot of the unit (click on the image for larger size):

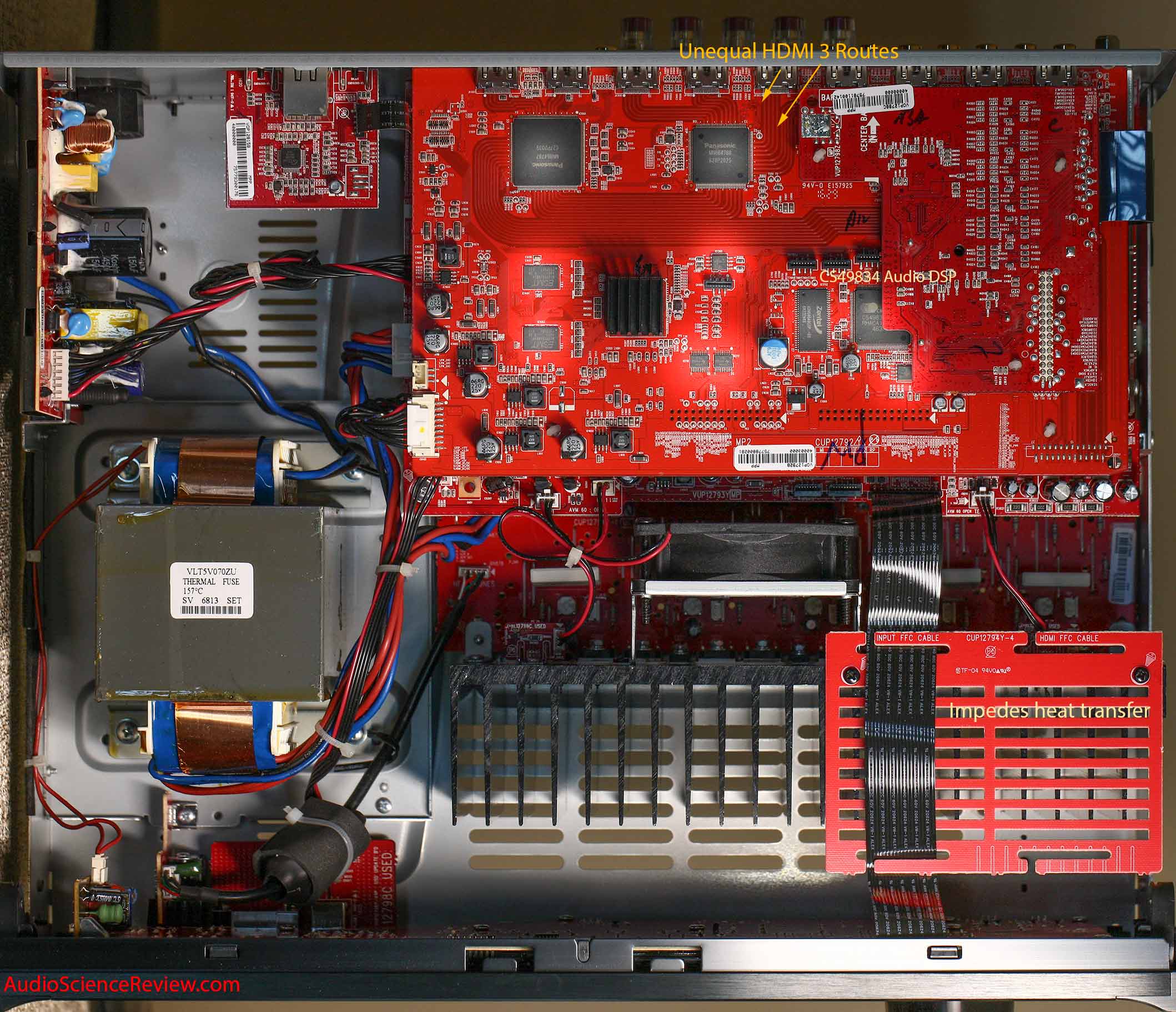

Overall, it is a very clean assembly. There is EMI filtering and such on the AC terminals, etc. A few issues though:

1. HDMI uses a parallel set of differential lines and a clock. The standard assumes that the timing and hence lengths of each of these parallel connections are identical. Otherwise the clock can "skew" relative to them causing data recovery issue. What this means is that when you look at the HDMI transceiver chip, all traces from it to the connector must be equal length. They are that for HDMI 1 and 2 inputs. But if you look at the traces for HDMI 3 input, the inner traces that make the 90 degree bend are by definition shorter than the outer ones. Given the speed of HDMI these days with 4K, high frame rate and color depth, this becomes doubly important.

This is a common problem with AVRs. But doesn't excuse the fact that it can cause compatibility issues with other devices. So if you are using HDMI 3 and having trouble, switch to the other inputs and see if the problem goes away.

Someone was clever with using a PCB as a bracket to hold that ribbon cable that communicates with the front panel. PCB can be cheap to build so may have been cheaper than using a clip of sorts. Problem is, even with all the slots in it, it will impede convection flow.

There is forced fan cooling as you see. The fan however should be placed on top or below the fins as they have much more surface area to cool them. Still, once that fan kicks in, it will provide far more cooling than you would get with convection alone.

I also like to see the fan farther away from interference point of view. And putting it on top like Pioneer does will do that.

The fan by the way is a brushless 12 volt DC unit by Xfan (used for computers and such). So you have options to change it to something else.

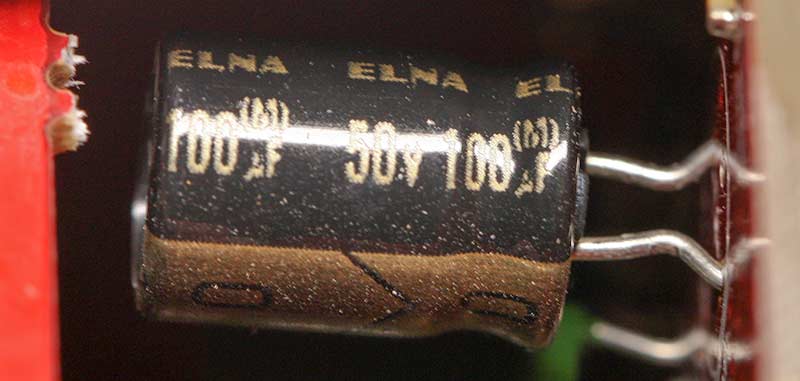

The analog board seems to use high-quality Elna capacitors:

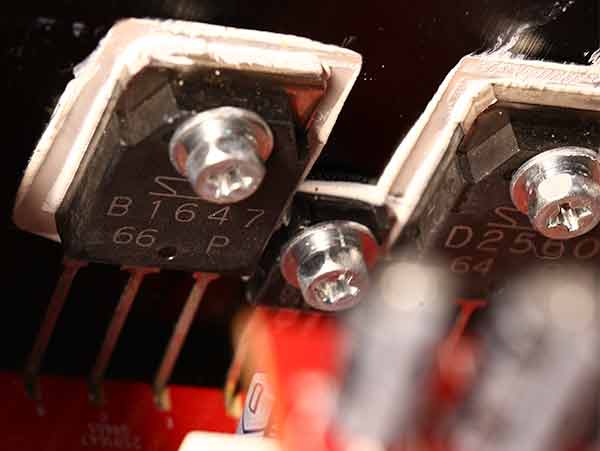

Here are the beefy output transistors:

They are the Sanken 2SB1647 and 2SD2560 darlington transistor pairs. Darlington configuration is a quick way to get high gain.

That's it really. I still have the unit open so shout if you want to see something else in the next couple of hours.

Here is a shot of the unit (click on the image for larger size):

Overall, it is a very clean assembly. There is EMI filtering and such on the AC terminals, etc. A few issues though:

1. HDMI uses a parallel set of differential lines and a clock. The standard assumes that the timing and hence lengths of each of these parallel connections are identical. Otherwise the clock can "skew" relative to them causing data recovery issue. What this means is that when you look at the HDMI transceiver chip, all traces from it to the connector must be equal length. They are that for HDMI 1 and 2 inputs. But if you look at the traces for HDMI 3 input, the inner traces that make the 90 degree bend are by definition shorter than the outer ones. Given the speed of HDMI these days with 4K, high frame rate and color depth, this becomes doubly important.

This is a common problem with AVRs. But doesn't excuse the fact that it can cause compatibility issues with other devices. So if you are using HDMI 3 and having trouble, switch to the other inputs and see if the problem goes away.

Someone was clever with using a PCB as a bracket to hold that ribbon cable that communicates with the front panel. PCB can be cheap to build so may have been cheaper than using a clip of sorts. Problem is, even with all the slots in it, it will impede convection flow.

There is forced fan cooling as you see. The fan however should be placed on top or below the fins as they have much more surface area to cool them. Still, once that fan kicks in, it will provide far more cooling than you would get with convection alone.

I also like to see the fan farther away from interference point of view. And putting it on top like Pioneer does will do that.

The fan by the way is a brushless 12 volt DC unit by Xfan (used for computers and such). So you have options to change it to something else.

The analog board seems to use high-quality Elna capacitors:

Here are the beefy output transistors:

They are the Sanken 2SB1647 and 2SD2560 darlington transistor pairs. Darlington configuration is a quick way to get high gain.

That's it really. I still have the unit open so shout if you want to see something else in the next couple of hours.