Hello,

I try to insulate kind of a wardrobe, where is heat recovery unit is hidden. That is - to absorb as much sound inside it as possible on tight budget. Heat recovery unit is a mechanical air ventilation device built from steel with rotational heat exchanger, which has 3 electric motors inside: 2 for moving the air and one for rotating the heat exchanger itself. That last motor is connected with gearbox and both of them are VERY noisy. Think as a half of washing machine noise or more. That motor was changed by the seller of the device couple of times during warranty, the new ones were silent just for couple of weeks, then again: weird noises. The type of noise is vibrational-mechanical type, like a small drill or slow washing or drying machine.

I am on-topic, as we can treat wardrobe as a small room

What I did to lessen the sound:

The butyl rubber is glued on inside, foam - on the outside. In front there are double panels, the foam is between them. Can post more photos if necessary.

Photos:

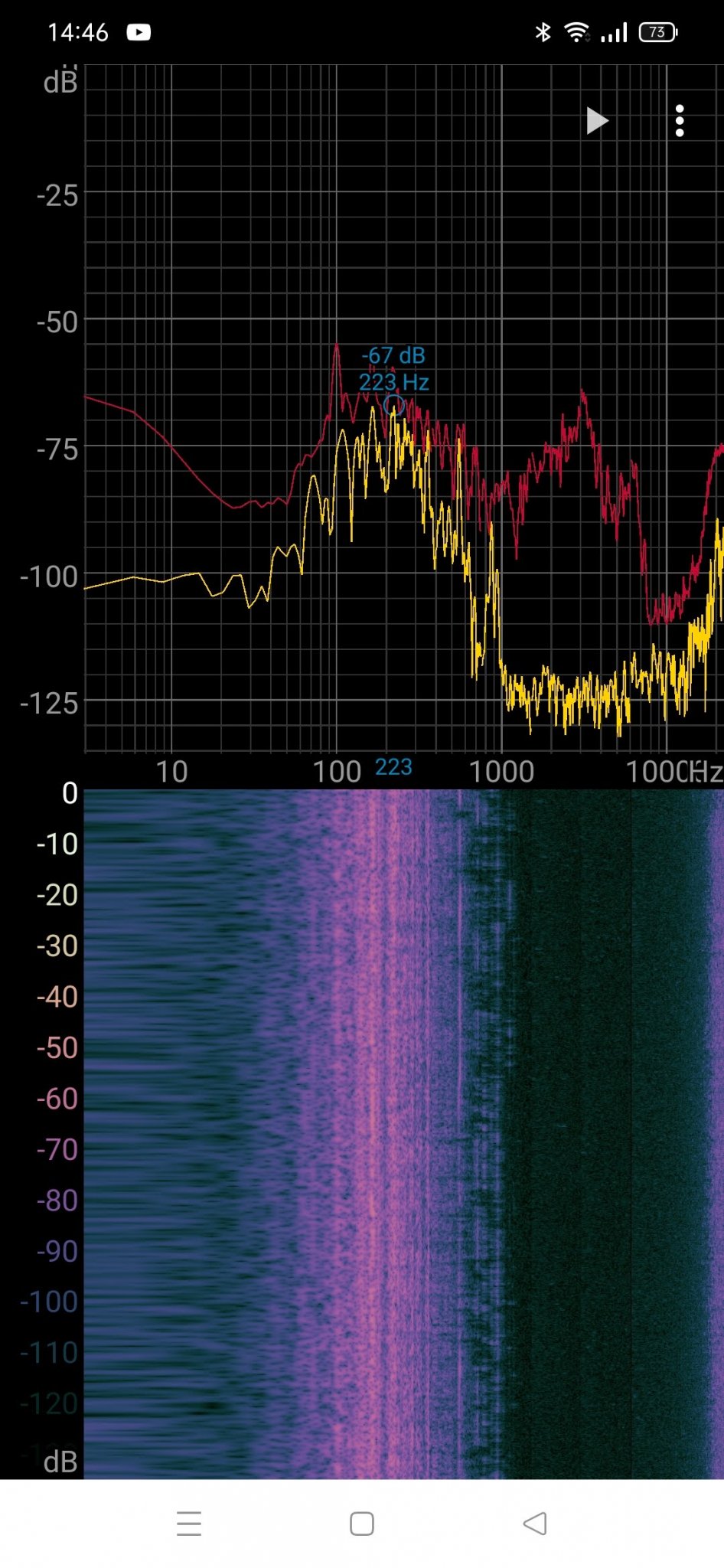

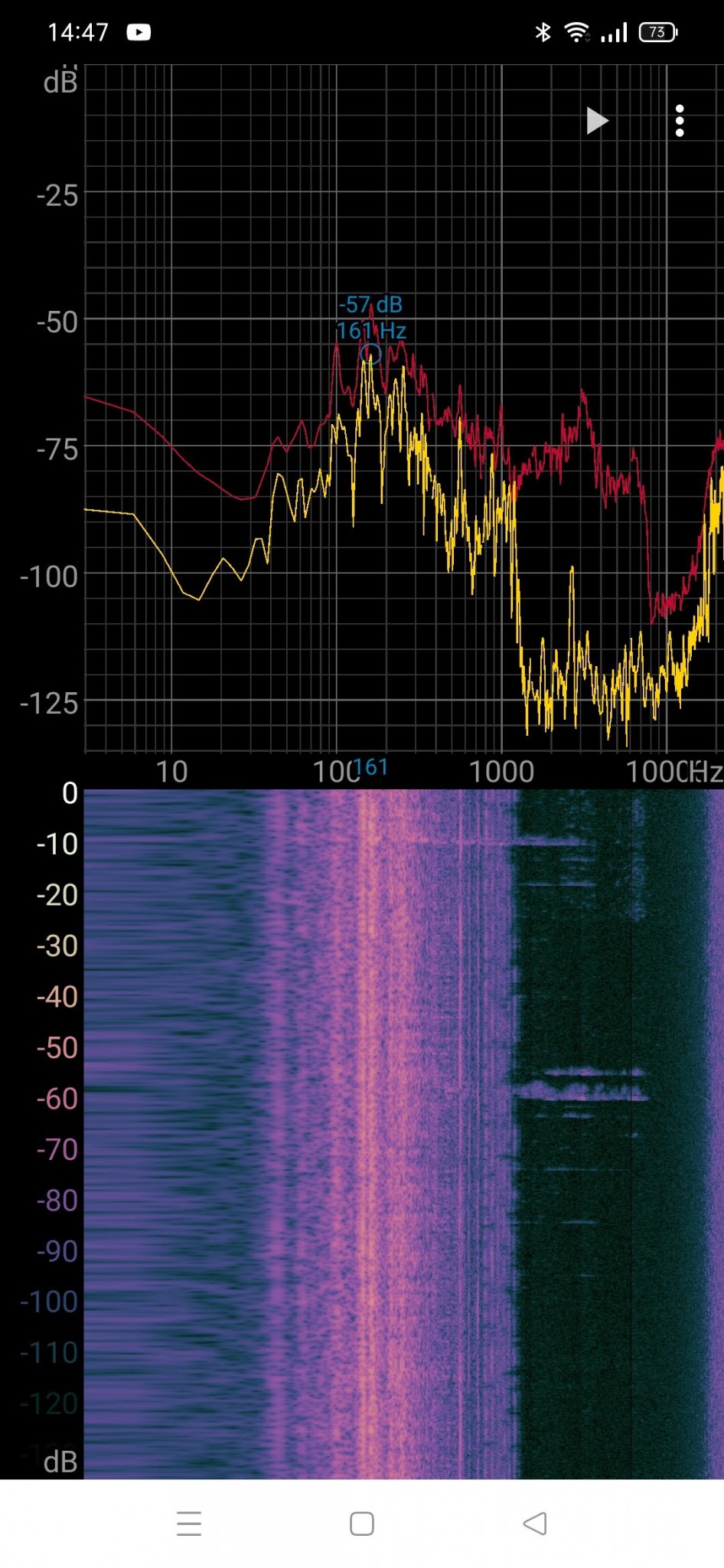

Sound profile 1m in front of wardrobe with doors closed and open:

Wardrobe is not air tight and there is no way I can make it.

There is still too much noise coming out, and if we think machine is a noise source, then we also can think that inside of a wardrobe is like a small room.

What I want to do is to glue some additional automotive soundproofing material, of felt type but... specialized is both expensive and supply chain issues also present.

Plan B is to glue some homemade rockwool acoustic panel on the front of machine as sound blocker and there is also a room for 1 another acoustic panel type absorber on 1 of the inside walls of closet. Around 10-12cm thickness is most space in front for noise blocker and 5-6cm on the side wall absorber. I am using term "rockwool" as a general term, we can say basalt fiber wool to make it more correct

Questions:

My doubts about the rockwool got stronger after seeing this video:

Whyyyy???? How????

Because glassfibers are longer than rockwool? Because of flufyness? Because fibers are thinner? Will dense glassfiber work too?

It is a sound of 1000Hz, and not much science behind it, but... the result is way too good for glassfibers.

Both materials are sold in bulk, and I do not want to waste money and material which will be not used after, so if someone already tried both, please share your findings.

Btw, there are some industrial type sound absorption panels on sale, but... again, there are supply chain issues or/and I have to buy bulk

The most I want to block 160-220Hz spectrum.

Thank you all in advance.

I try to insulate kind of a wardrobe, where is heat recovery unit is hidden. That is - to absorb as much sound inside it as possible on tight budget. Heat recovery unit is a mechanical air ventilation device built from steel with rotational heat exchanger, which has 3 electric motors inside: 2 for moving the air and one for rotating the heat exchanger itself. That last motor is connected with gearbox and both of them are VERY noisy. Think as a half of washing machine noise or more. That motor was changed by the seller of the device couple of times during warranty, the new ones were silent just for couple of weeks, then again: weird noises. The type of noise is vibrational-mechanical type, like a small drill or slow washing or drying machine.

I am on-topic, as we can treat wardrobe as a small room

What I did to lessen the sound:

- I built a wardrobe type box for it. Result: now there is definitely less sound amount, but some resonances are more pronounced. Overall still a positive thing

- 5+% of total surface of machine including near that noisy motor, glued with antivibrational butyl rubber sound and vibration deadening material for automotive soundproofing. Maybe will glue some more, as only small amount had at hand from last project. Possitive impact, but expected more. I have a feeling, that it dampened the lowest freq sounds, or raised main ones

- 50+% of total surface glued with some 6mm rubbery foam, also from automotive industry. Not much impact

- Front panel on the inside glued 2 layers of dense synthetic 2mm felt, so 4mm total. Not much impact.

- Inside panels and doors of the wardrobe near the machine glued with pyramid shaped foam. A lot of impact, did not expected much, but it worked well!

The butyl rubber is glued on inside, foam - on the outside. In front there are double panels, the foam is between them. Can post more photos if necessary.

Photos:

Sound profile 1m in front of wardrobe with doors closed and open:

Wardrobe is not air tight and there is no way I can make it.

There is still too much noise coming out, and if we think machine is a noise source, then we also can think that inside of a wardrobe is like a small room.

What I want to do is to glue some additional automotive soundproofing material, of felt type but... specialized is both expensive and supply chain issues also present.

Plan B is to glue some homemade rockwool acoustic panel on the front of machine as sound blocker and there is also a room for 1 another acoustic panel type absorber on 1 of the inside walls of closet. Around 10-12cm thickness is most space in front for noise blocker and 5-6cm on the side wall absorber. I am using term "rockwool" as a general term, we can say basalt fiber wool to make it more correct

Questions:

- Can they be built the same?

- Is dense stiff rockwool the right material?

My doubts about the rockwool got stronger after seeing this video:

Whyyyy???? How????

Because glassfibers are longer than rockwool? Because of flufyness? Because fibers are thinner? Will dense glassfiber work too?

It is a sound of 1000Hz, and not much science behind it, but... the result is way too good for glassfibers.

Both materials are sold in bulk, and I do not want to waste money and material which will be not used after, so if someone already tried both, please share your findings.

Btw, there are some industrial type sound absorption panels on sale, but... again, there are supply chain issues or/and I have to buy bulk

The most I want to block 160-220Hz spectrum.

Thank you all in advance.