So apparently SAT has released a DD turntable (which is actually just an SL-1000R).

EDITED: because I am stupid.

EDITED: because I am stupid.

Last edited:

It wouldn't be the first time a boutique 3rd party audiophile vendor performed useless, suspect, performance-degrading, and/or overpriced modifications to a stock mass-market product.

It's

At $18k, I wouldn't call the SL-1000R "mass market".

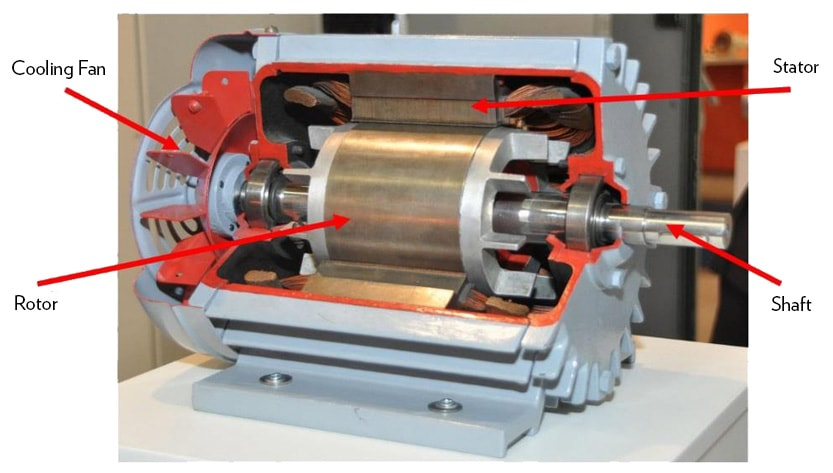

When I think "platter on top of a motor" I am thinking something like this

Only rotated 90º with a plate stuck on top.

The motor you pictured is a high speed induction motor, usually to run at one speed although variable frequency drive can offer a range of speeds.

Direct drive turntables are obviously very low speed motors which need to be driven with dedicated electronics to give uniform rotational characteristics. The Technics motors in the new turntables are not remarkable to me, other than they can be individually trimmed in the factory and use a sophisticated shaped drive to each coil that can be individually set in the firmware on the production line. They also use an additional set of offset coils and magnets in the top models. Are they really any better than the motors of yesteryear? I'm not convinced and have yet to see any tests which show they are superior.

Most belt drives use DC servo motors, synchronous AC motors driven by either the line frequency or dedicated frequency generators (can be Quartz Xtal derived) or even a few implementations I've seen with BSL quartz locked motors driving a belt.

Everything "high-end" (or that aspires to be) is AC synchronous (Linn, Pro-ject, Rega, et cetera).

MeWell, still much cheaper and objectively better than a lot of turntables out there. But yeah it is pretty expensive. I actually don't know to whom the SL-1000R is supposed to marketed toward. The people who have that much cash to spend on a turntable are generally buying something with a belt-drive or a Shindo which uses an idler wheel and has a drive that was designed in 1956 (or thereabouts—I can't remember).