MRC01

Major Contributor

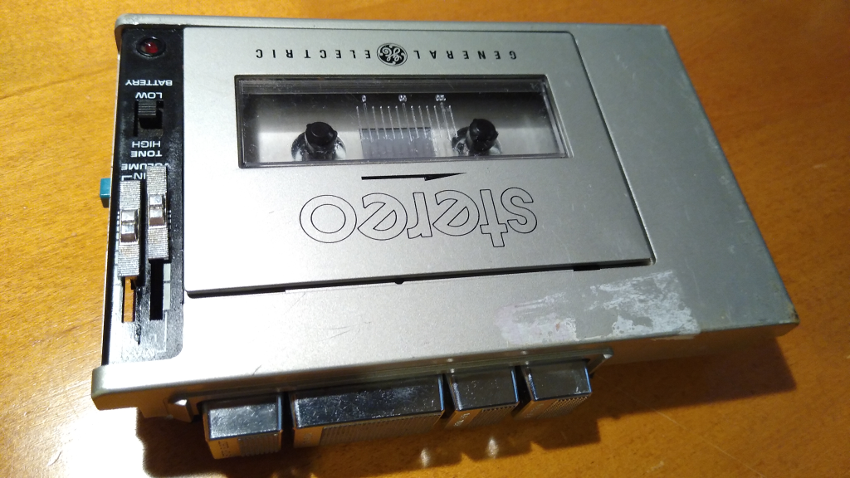

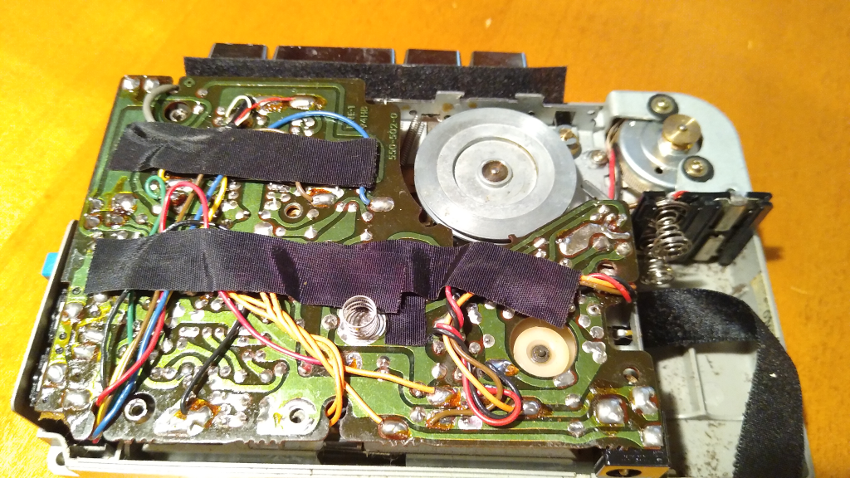

I've decided to restore my brother's old tape player from the early 1980s. When I put in batteries, the motor spins. So it looks like all it needs is a new set of belts. While I'm at it I'll clean up stuff in side. I still have my old tape head demagnetizer wand. Anything else I should do? Lubricate anything?