Hello,

I have a JBL SCS 125 which is 5 satelite speakers and 1 subwoofer connected to a Harman Kardon AVR 300RDS.

Recently, the subwoofer kept turning on and off rapidly for 1 to 2 minutes before staying on.

It's only after that clicking on and off for 1 to 2 minutes that I could start using the subwoofer.

I'm new to repair and willing to learn so this is going to be my learning project.

On a youtube video you can find the problem I had:

In the comments section, someone suggested that the problem could be the 2 big capacitors 6800uF 50V 85°C that might have leaked.

When I opened up my subwoofer, there was some corrosion on the components that were near these 2 capacitors.

One of the capacitors leaked. So I removed both of them and installed 2 new ones 6800uF 50V 105°C .

And cleaned with isopropanol alcohol all I could clean and removed as much corrosion from near by resistors.

As well as removed as much brown glue as possible.

I tried the turn on the subwoofer, it turned on right away which felt like a victory but the speaker from the subwoofer wasn't reacting.

I thought almost there then.

After opening the subwoofer a second time, I tested with my digital multimeter surrounding components new the capacitors.

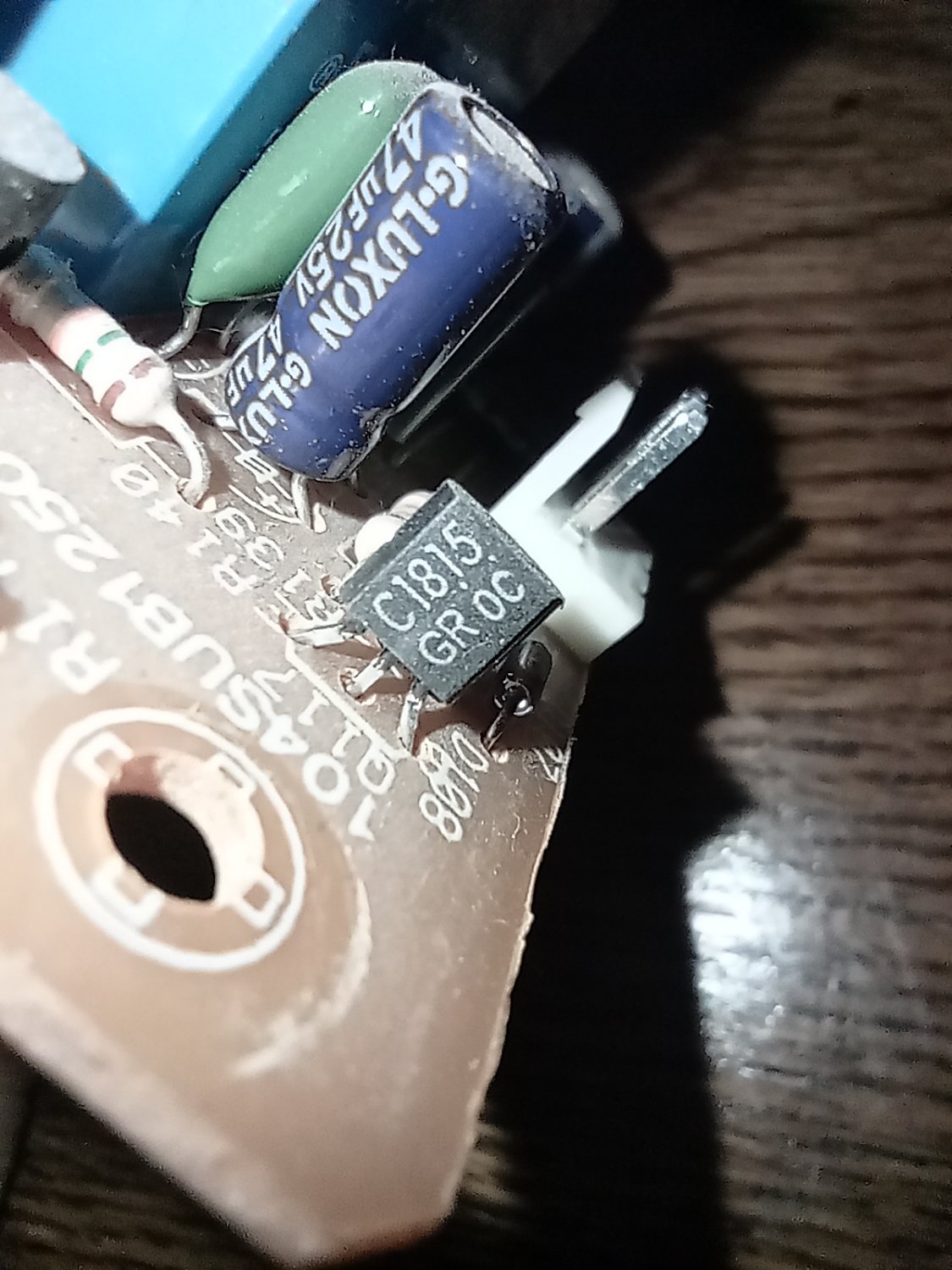

Resistors were giving almost the right values, the transistors C1815 and A1015 seemed to work well as well.

But I decided to change these 2 transistors with new ones which were for some reason smaller.

I swapped C1815 GR 0C with C1815 GR 331 and A1015 GR 0A with A1015 GR 331.

Now the subwoofer turns on and off repeatedly every seconds and make the subwoofer's speaker bump at the same pace.

The nob to increase and decrease bass has no effect on the speaker.

Now I'm stuck, not sure what to do next.

I could replace all caps and transistors but it would be better to be able to identify all the components posing problem first and replace those first.

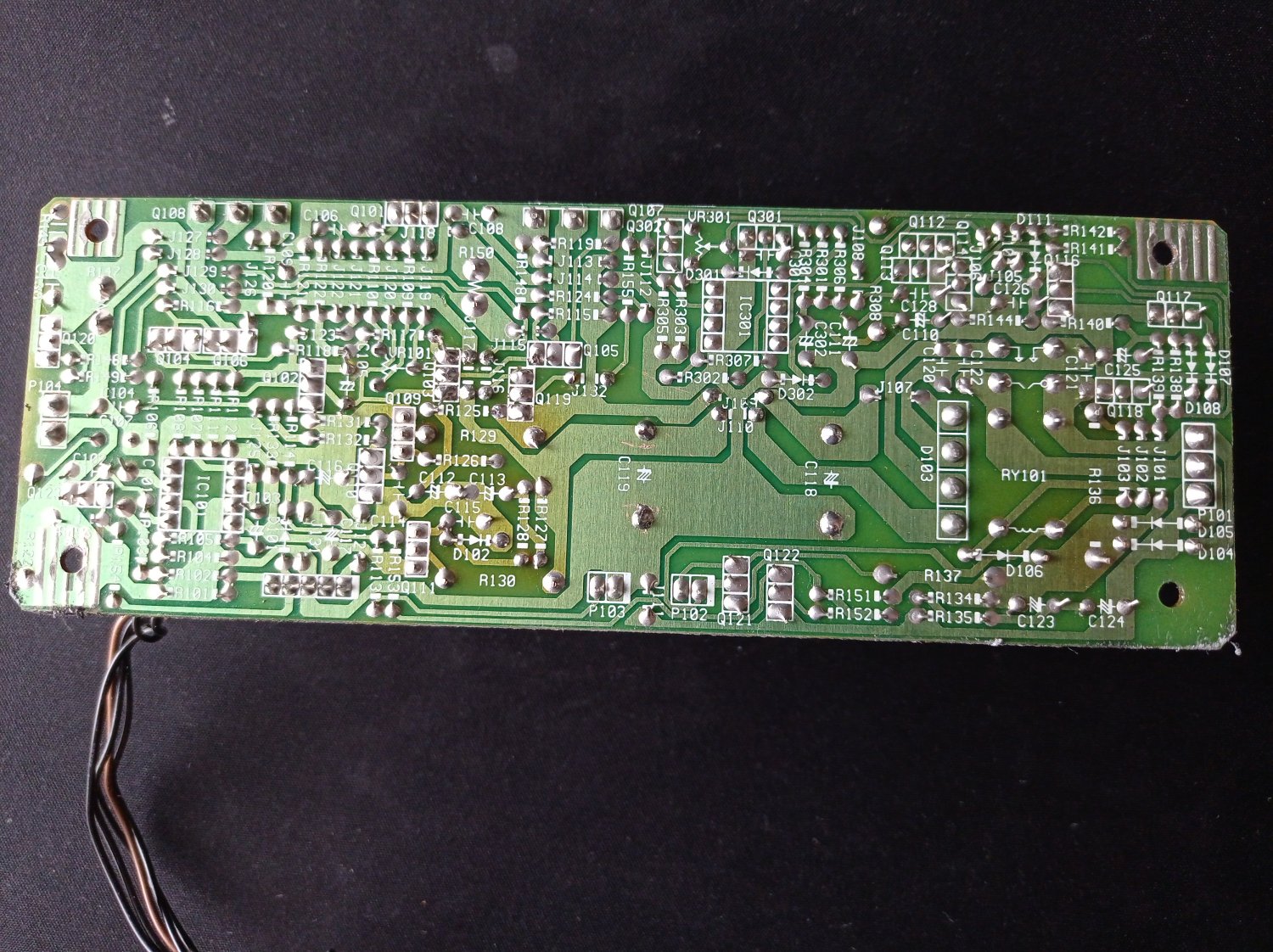

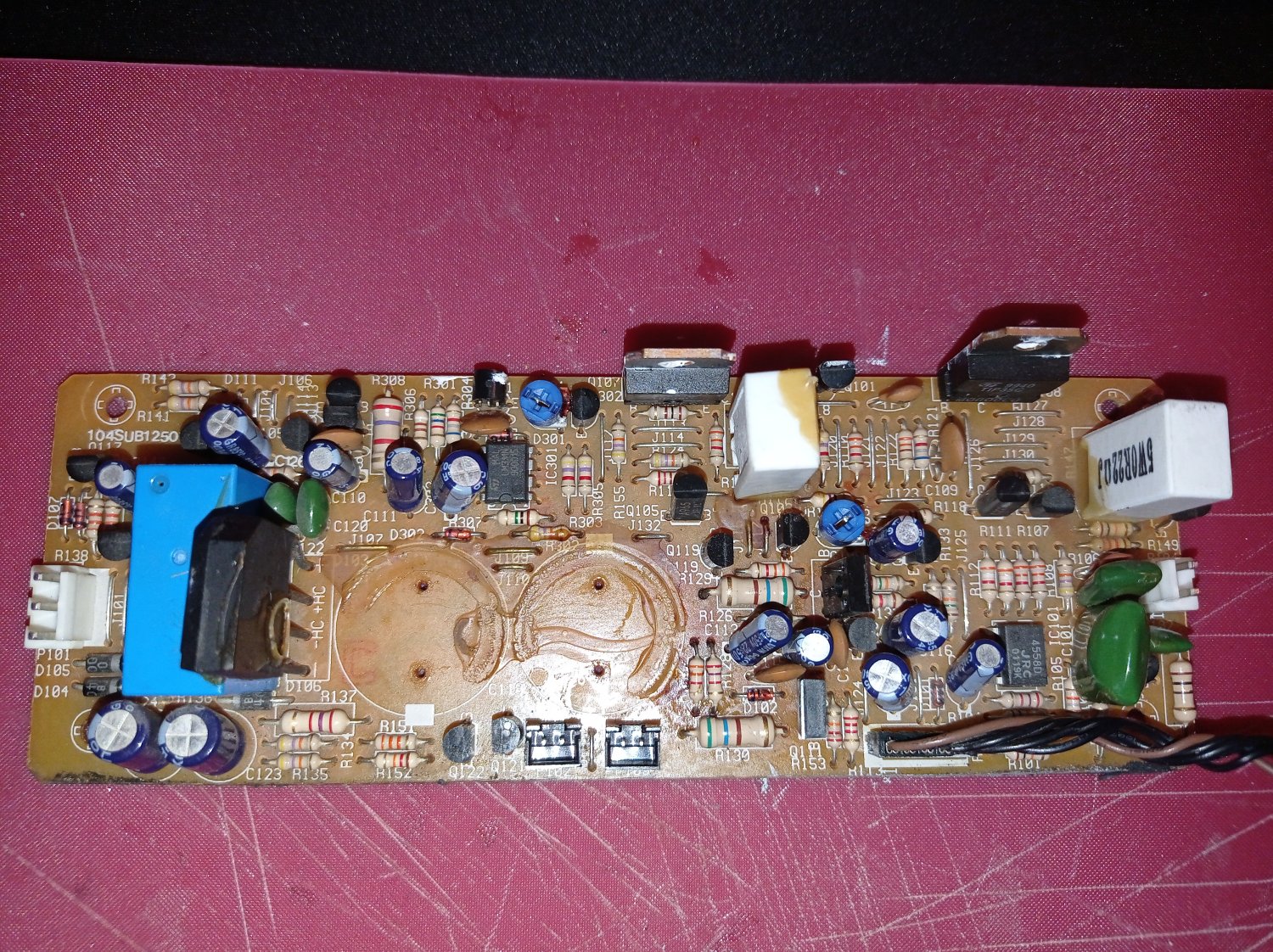

There are only 2 boards in the subwoofer. One is the small amp I guess, the other one is the psu.

On the back of the PSU board, there are 2 yellow marks, one near the big capacitor C119, in the area around the big resistor R129.

And the other one near the blue relay around the resistor R136.

I cleaned all the links in the area as well as the resistors in the area.

For the resistors, I wasn't sure if I should have replaced them with new ones since they tested ok on the multimeters outside of the board.

And I'm not sure with what I should replace them, in terms of size, I wasn't sure what to buy.

R302: yellow, violet, orange, Gold – looks oxi - 47kOhms 5% - 1/4w? or 1/2w? or? (5mm)

R129: green, blue, brown, gold – looks oxi - 560Ohms 5% - 1w or 2W or 3w? (11mm)

R127: orange, orange, red, gold – looks oxi - 3,3kOhms 5% - 1/4w? or 1/2w? or? (5mm)

R128: red, violet, red, gold – looks oxi - 2,7kOms 5% - 1/4w? or 1/2w? or? (5mm)

Let me know if you need any additional info.

Do you have any suggestion as to what I could be testing in order to troubleshoot the problem and find a fix?

Thank you in advance

I have a JBL SCS 125 which is 5 satelite speakers and 1 subwoofer connected to a Harman Kardon AVR 300RDS.

Recently, the subwoofer kept turning on and off rapidly for 1 to 2 minutes before staying on.

It's only after that clicking on and off for 1 to 2 minutes that I could start using the subwoofer.

I'm new to repair and willing to learn so this is going to be my learning project.

On a youtube video you can find the problem I had:

In the comments section, someone suggested that the problem could be the 2 big capacitors 6800uF 50V 85°C that might have leaked.

When I opened up my subwoofer, there was some corrosion on the components that were near these 2 capacitors.

One of the capacitors leaked. So I removed both of them and installed 2 new ones 6800uF 50V 105°C .

And cleaned with isopropanol alcohol all I could clean and removed as much corrosion from near by resistors.

As well as removed as much brown glue as possible.

I tried the turn on the subwoofer, it turned on right away which felt like a victory but the speaker from the subwoofer wasn't reacting.

I thought almost there then.

After opening the subwoofer a second time, I tested with my digital multimeter surrounding components new the capacitors.

Resistors were giving almost the right values, the transistors C1815 and A1015 seemed to work well as well.

But I decided to change these 2 transistors with new ones which were for some reason smaller.

I swapped C1815 GR 0C with C1815 GR 331 and A1015 GR 0A with A1015 GR 331.

Now the subwoofer turns on and off repeatedly every seconds and make the subwoofer's speaker bump at the same pace.

The nob to increase and decrease bass has no effect on the speaker.

Now I'm stuck, not sure what to do next.

I could replace all caps and transistors but it would be better to be able to identify all the components posing problem first and replace those first.

There are only 2 boards in the subwoofer. One is the small amp I guess, the other one is the psu.

On the back of the PSU board, there are 2 yellow marks, one near the big capacitor C119, in the area around the big resistor R129.

And the other one near the blue relay around the resistor R136.

I cleaned all the links in the area as well as the resistors in the area.

For the resistors, I wasn't sure if I should have replaced them with new ones since they tested ok on the multimeters outside of the board.

And I'm not sure with what I should replace them, in terms of size, I wasn't sure what to buy.

R302: yellow, violet, orange, Gold – looks oxi - 47kOhms 5% - 1/4w? or 1/2w? or? (5mm)

R129: green, blue, brown, gold – looks oxi - 560Ohms 5% - 1w or 2W or 3w? (11mm)

R127: orange, orange, red, gold – looks oxi - 3,3kOhms 5% - 1/4w? or 1/2w? or? (5mm)

R128: red, violet, red, gold – looks oxi - 2,7kOms 5% - 1/4w? or 1/2w? or? (5mm)

Let me know if you need any additional info.

Do you have any suggestion as to what I could be testing in order to troubleshoot the problem and find a fix?

Thank you in advance